Home

Services

About us

Blog

Contacts

Unlocking Precision Earthmoving: How Trimble Earthworks Leads the Way

1.What is Trimble Earthworks – an overview of the platform and its capabilities

2.Market context and opportunity – machine control systems market, trends and why Earthworks matters

3.Core features of Trimble Earthworks today – how the platform delivers value

4.The future of grade-control and earthmoving – next-gen features, AI, autonomy, integration

5.Customisation and deployment – how with A-Bots.com you can build on Earthworks or equivalent, implementation best practices

At A-Bots.com (mobile app development company), we understand that bringing cutting-edge machine-control solutions into the field requires more than off-the-shelf software. Whether you’re running heavy excavators, dozers or graders, you need tailored apps, real-time dashboards, remote monitoring, and integration into mobile workflows. That’s where we step in.

With experience in mobile app development, embedded systems and complex control interfaces, A-Bots.com is uniquely positioned to work with platforms like Trimble Earthworks, or to build custom variants that suit your fleet, terrain and operational workflow. We can develop native Android/iOS apps for operators, back-end cloud services for data sync and analytics, and bespoke integrations with GNSS/RTK hardware or machine-control kits.

Imagine an operator’s tablet showing live grade-control overlays, remote supervisors monitoring site progress from any location, and alerts delivered to your phone when machine performance deviates. A-Bots.com can architect that. We can also assist in testing ground stations, integrating telematics and enabling modular upgrades as your machines evolve.

If your objective is to stay ahead in the machine-control market, boost fleet productivity, reduce rework, and harness data from every pass of the blade — then A-Bots.com is ready to partner with you. Let’s explore how Trimble Earthworks-class solutions can become a custom asset for your business.

1. What Is Trimble Earthworks

The story of Trimble Earthworks is a story of how digital precision reshaped one of the world’s oldest industries — construction and earthmoving. Where once operators relied solely on stakes, string lines, and human intuition, modern contractors now navigate with centimeter-level accuracy using GNSS, sensors, and real-time design overlays. Trimble Earthworks stands at the center of this transformation — a software-driven platform that connects heavy machinery, design models, and on-site operators into one intelligent ecosystem.

From its first introduction in the late 2010s, Trimble Earthworks quickly became the flagship of machine-control innovation. It combined Trimble’s decades of experience in surveying and positioning technology with a new generation of human-centered software design. Instead of cryptic menu trees and monochrome displays, Earthworks brought an Android-based touchscreen interface — colorful, intuitive, and optimized for real-world conditions inside excavator and dozer cabs.

The premise is simple yet revolutionary: turn every machine into a smart, connected instrument capable of interpreting a digital model in real time. The operator no longer guesses how deep to cut or which slope to follow. Instead, Trimble Earthworks fuses GNSS or total-station data with hydraulic-sensor input to calculate exact blade or bucket position relative to the project design. The result: faster cycles, reduced material waste, and the elimination of guesswork that traditionally drove up costs.

From Manual Grading to Smart Earthmoving

Traditional grading relied heavily on survey crews placing stakes that marked the design elevation across the site. Every time a change occurred — a new foundation, a drainage correction, or a layer of aggregate — those stakes needed to be replaced. It was a slow, costly, and error-prone process. Trimble Earthworks digitized this workflow completely.

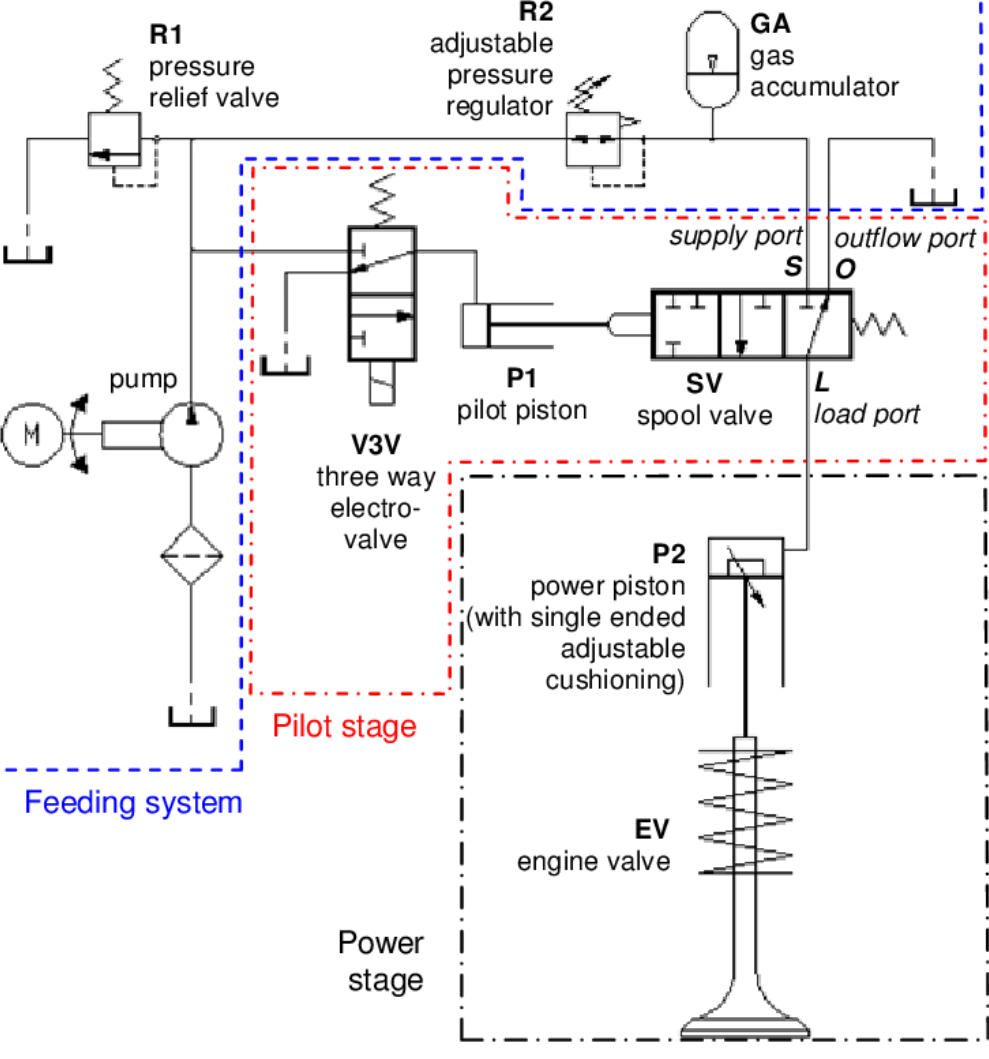

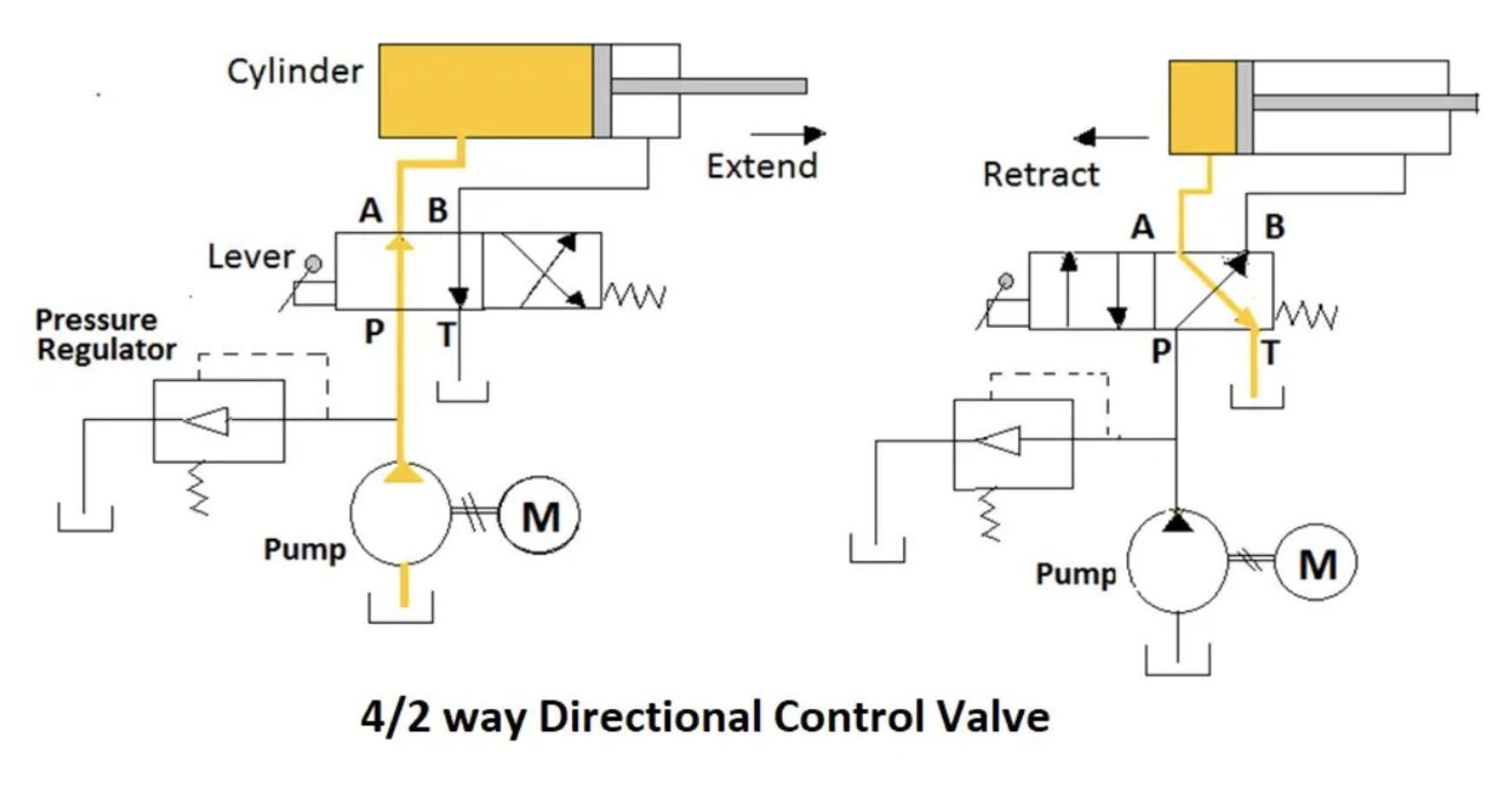

Operators now upload the 3D design model directly into the cab display. GNSS antennas and IMU sensors mounted on the machine provide live positional data, updating several times per second. The software computes the difference between the design and the current surface, displaying intuitive color-coded visuals: red for cut, blue for fill, green for on-grade. When paired with semi-automatic or fully automatic machine-control modules, the system can even adjust the hydraulic valves autonomously to keep the blade or bucket precisely on grade.

It’s not just about convenience — it’s about accuracy and repeatability. In large-scale projects such as highway construction or airport runways, a deviation of 2 cm over a 2 km stretch can mean thousands of cubic meters of material misplaced. Trimble Earthworks reduces those tolerances to sub-centimeter levels, ensuring each pass contributes directly to the final target grade.

Inside the Trimble Earthworks Ecosystem

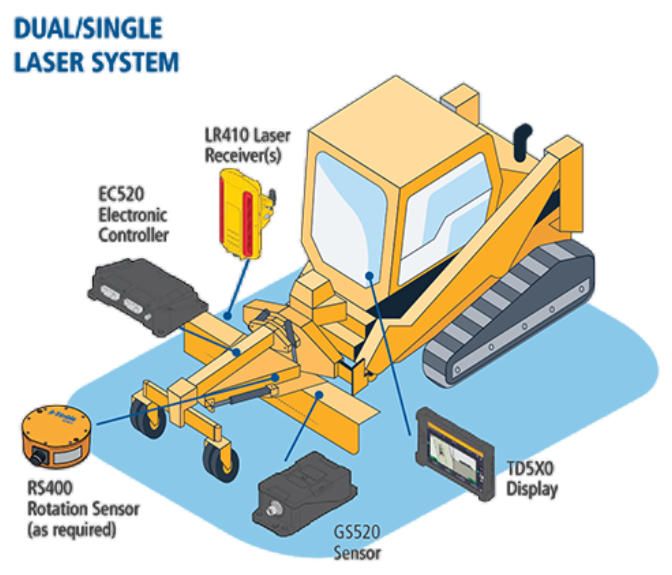

At its core, Trimble Earthworks is modular. Each installation typically consists of:

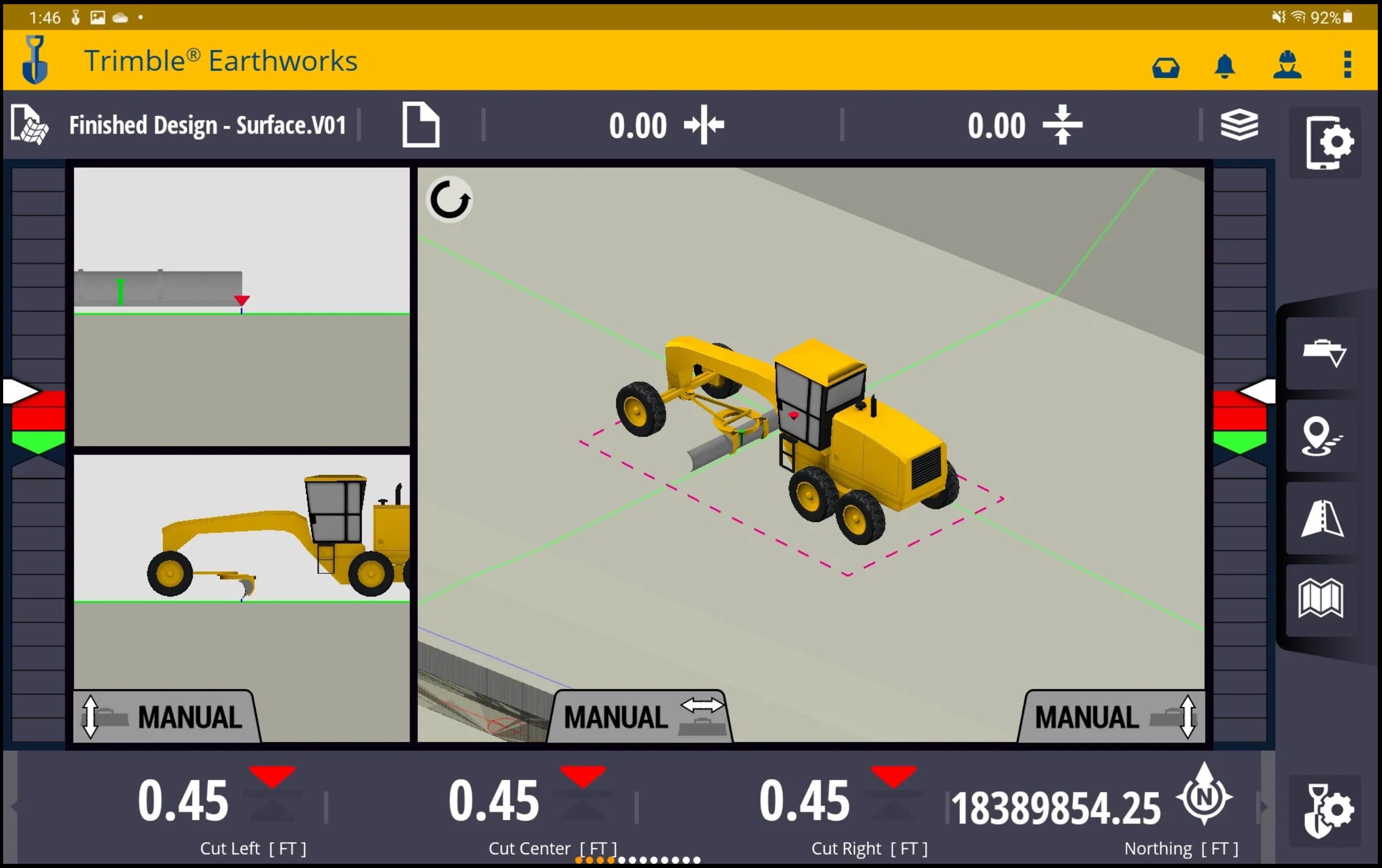

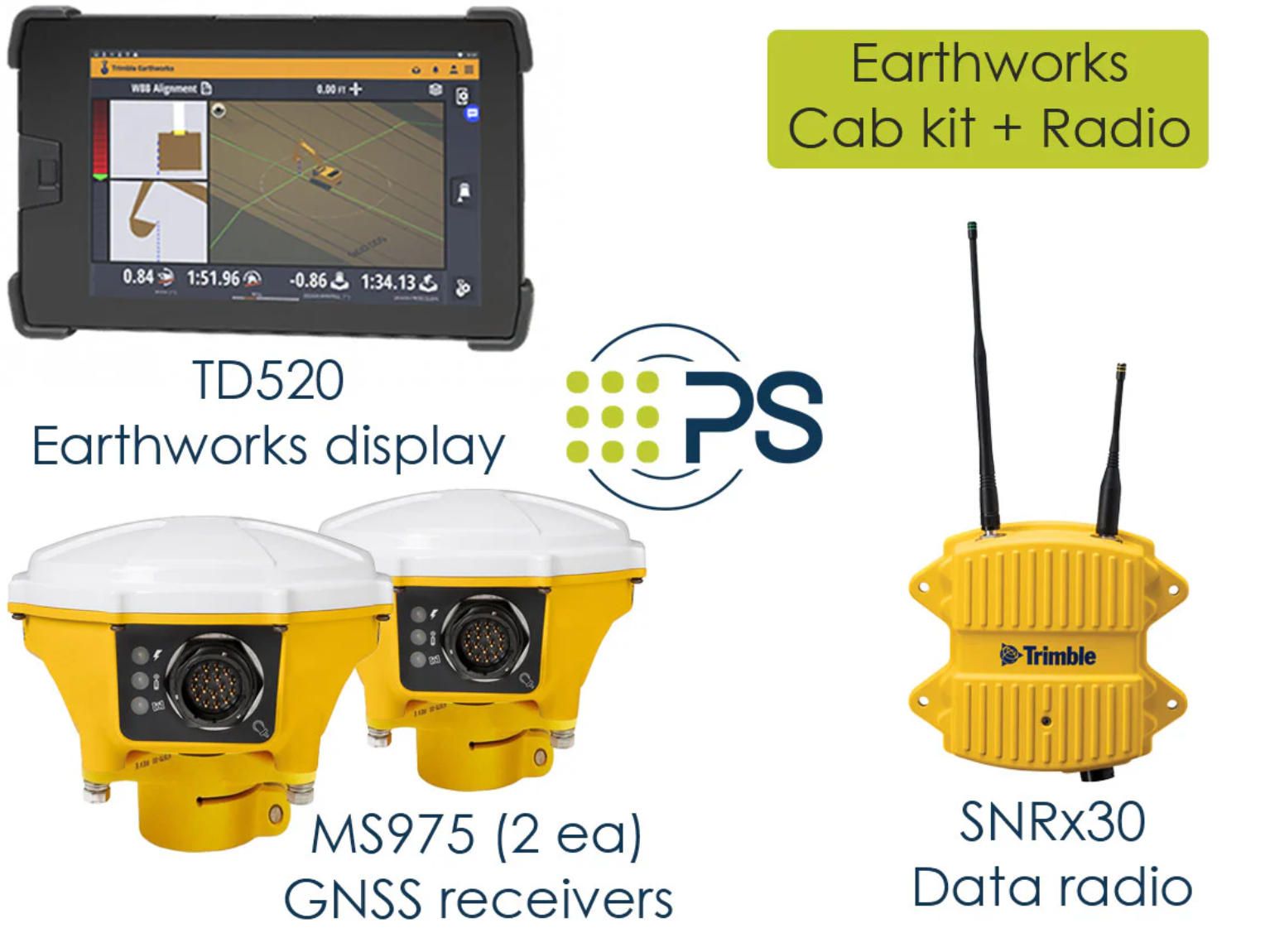

- Display and User Interface: The Android-based control box (for instance, the TD520) that runs the Earthworks app. Its graphical interface allows zooming, rotating 3D models, and viewing cross-sections or plan views in real time.

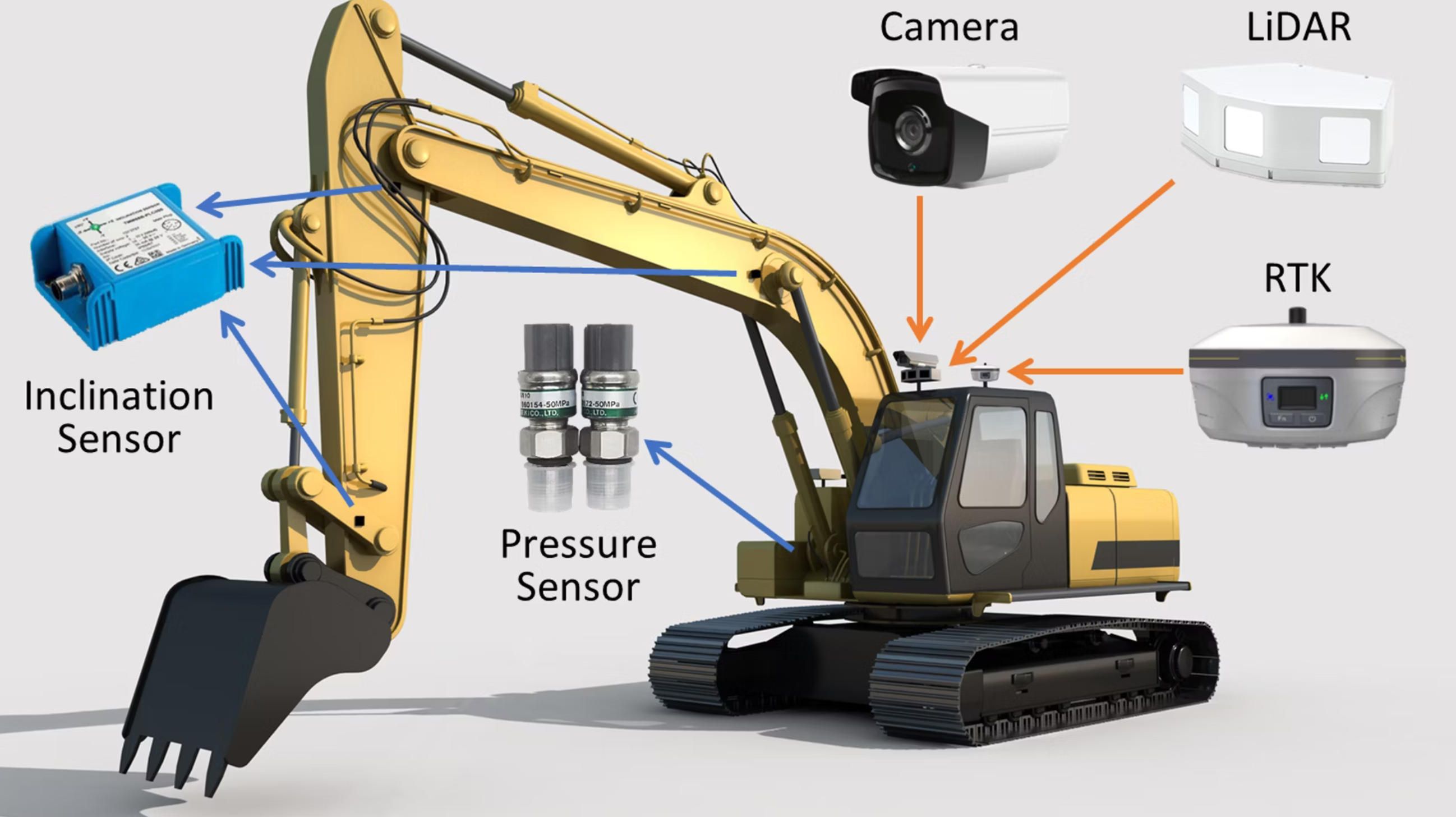

- GNSS & IMU Sensors: Dual-GNSS antennas mounted on the machine provide real-time kinematic (RTK) positioning; IMUs measure tilt, pitch, and roll for dynamic compensation.

- Hydraulic-Control Module: Interfaces directly with the machine’s valves, enabling semi-automatic or full-automatic blade control.

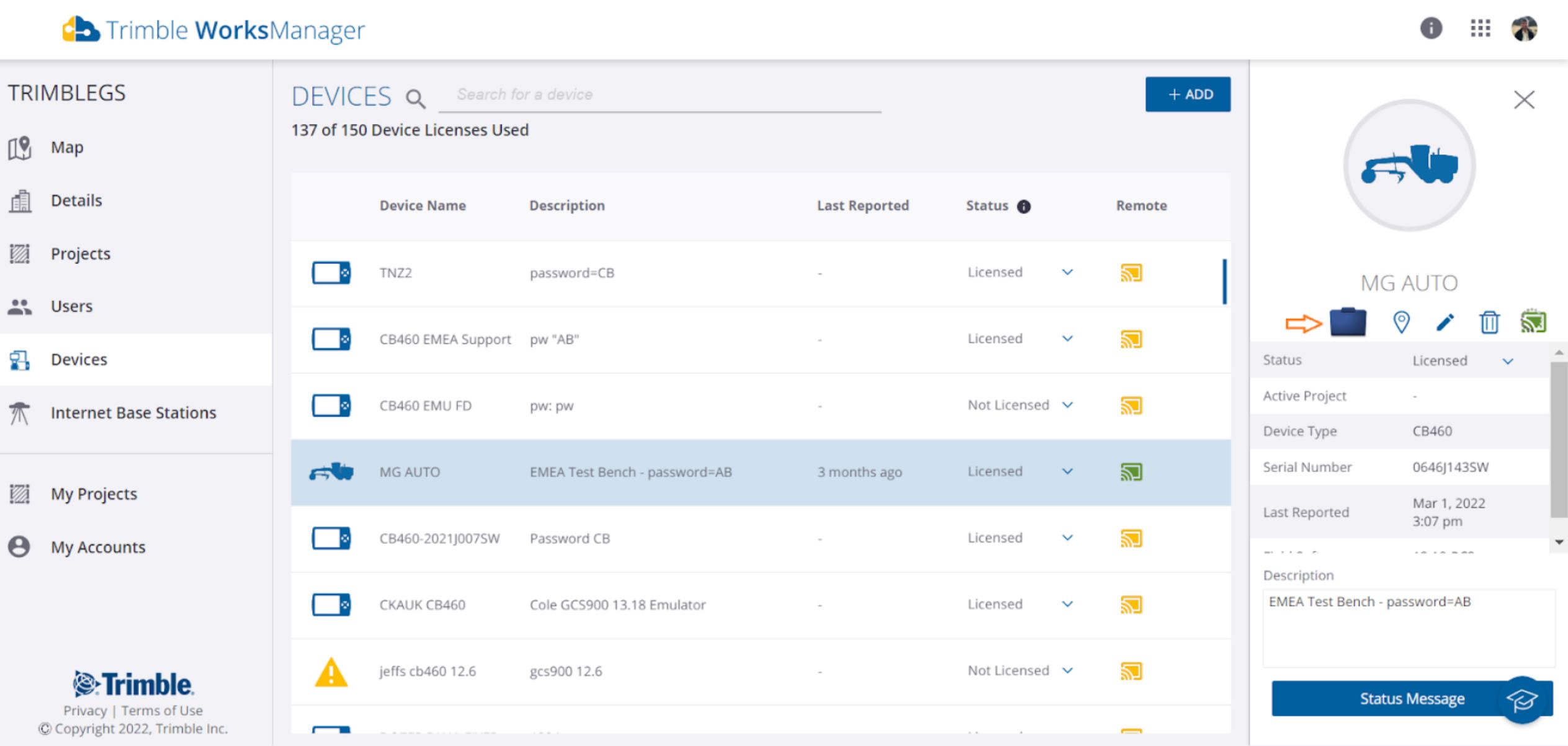

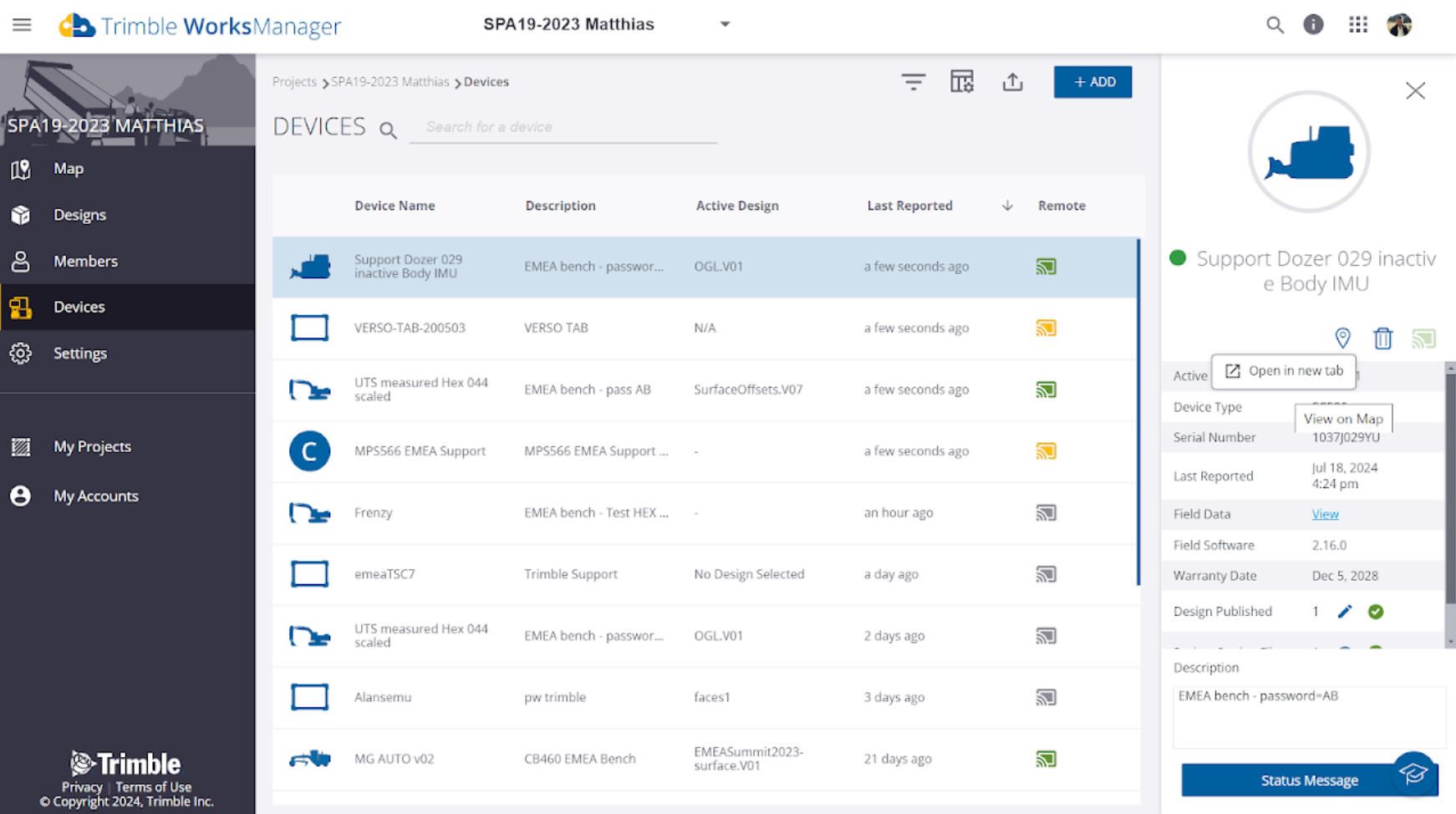

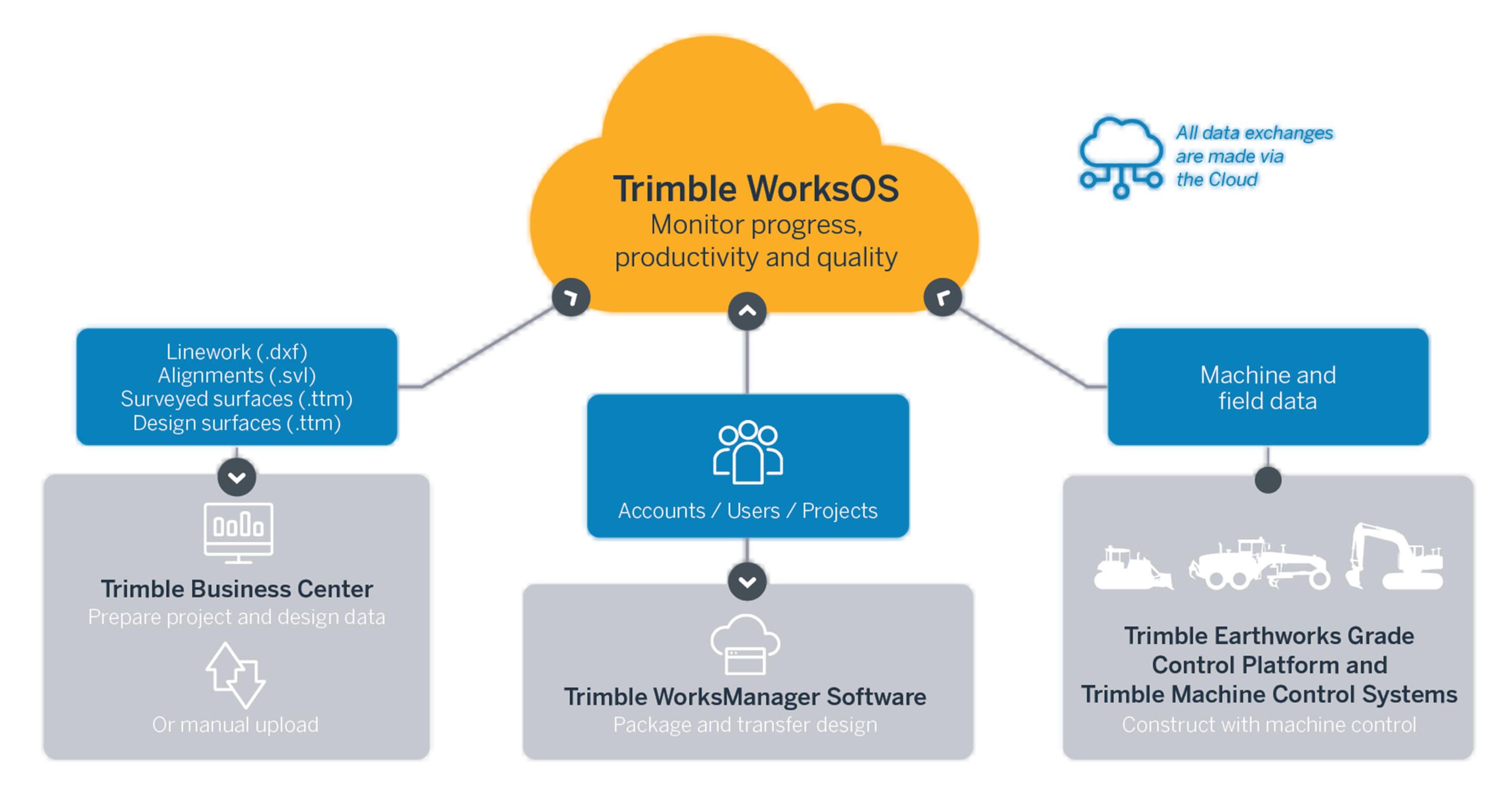

- Connectivity Layer: Wireless sync via Trimble WorksManager or Siteworks to send design updates, manage project data, and monitor performance remotely.

- Cloud Integration: Data aggregation and fleet management via Trimble WorksOS, offering analytics, productivity reports, and digital as-builts.

Through these layers, Earthworks transforms isolated machines into networked participants of a digital jobsite. Supervisors can remotely update designs, track cut/fill progress, or push software updates. Operators can receive changes instantly, without needing surveyors to walk the site.

This integration is what Trimble calls the Connected Construction ecosystem — where data flows seamlessly from the design office to the machine and back again, closing the feedback loop that once took days or weeks.

Beyond 2D Control: The Leap to 3D

Earlier generations of grade-control systems were strictly 2D: they relied on lasers or sonic sensors to maintain a single plane or reference elevation. That approach was sufficient for flat pads but limited for complex surfaces like drainage ditches or compound slopes. Trimble Earthworks expanded this into full 3D modeling.

Now, operators can work directly with BIM or CAD-derived models, visualizing not just a line or level but the entire geometry of the structure — embankments, intersections, retention ponds, and more. The software computes the machine’s position within that 3D context, allowing multi-slope grading and variable design layers.

Trimble’s transition to 3D also aligned with the broader digital construction movement, where every element of a project is represented virtually before being built physically. Earthworks thus became an on-site embodiment of the “digital twin” concept — bridging design and execution.

Human-Centered Design and Operator Experience

One of the understated strengths of Trimble Earthworks is its focus on operator usability. The Android platform not only enabled faster updates and broader compatibility but also lowered the learning curve dramatically. New operators accustomed to smartphones adapt almost instantly.

The interface features large touch targets, vivid colors, and clear numeric feedback. Operators can rotate the 3D model with a swipe, switch between plan and cross-section views, or customize widgets for speed, depth, and slope. The real-time feedback transforms complex grading into a visually intuitive task.

In interviews with site managers, a recurring insight appears: the software helps bridge skill gaps. With intuitive guidance, even less-experienced operators can achieve precision previously reserved for veterans. As one contractor put it:

“Trimble Earthworks doesn’t replace experience — it amplifies it. It gives every operator the eyes of a surveyor and the precision of a laser, all on a single screen.”

This human-centered approach contributed greatly to the platform’s rapid adoption. Trimble effectively turned what was once a purely technical system into a productivity tool that empowers field teams.

Integration with Machine Autonomy

Trimble Earthworks was also a stepping stone toward semi-autonomous and autonomous construction equipment. By controlling hydraulic valves and processing sensor data in real time, it laid the groundwork for machines that can execute grading sequences automatically.

Today, many OEMs integrate Earthworks modules directly into their autonomous development roadmaps. For instance, semi-automatic excavator systems can now adjust boom, stick, and bucket angles automatically to follow design contours, leaving the operator to control only swing and travel. The underlying control algorithms, sensor fusion, and safety redundancies developed for Earthworks inform this next wave of autonomous functionality.

As AI and computer vision merge with GNSS and LiDAR, future iterations of Earthworks-like systems will likely detect soil types, analyze compaction levels, and dynamically optimize excavation paths — tasks that today require human judgment.

Economic Impact and Measurable ROI

The measurable benefits of Trimble Earthworks are consistently documented in independent studies and contractor case reports. Projects report:

- Up to 40 % reduction in material waste, thanks to more accurate cuts and fills.

- 25 – 30 % faster completion times, as rework and staking are minimized.

- Fuel savings of 10 – 15 %, due to fewer machine passes and optimized routes.

These numbers may vary by site and operator, but they underscore one truth: digital precision pays for itself. The software’s combination of accuracy, connectivity, and usability creates compounding efficiencies over the lifecycle of a project.

Furthermore, data collected by Earthworks becomes a valuable asset for post-project analysis. By comparing as-built models with design intent, contractors can validate claims, improve future bids, and comply with increasingly strict reporting standards.

Compatibility Across Machine Classes

One of the most practical strengths of Trimble Earthworks is its flexibility across machine types. The same software platform can power:

- Excavators — with bucket tip position and slope guidance, plus semi-automatic boom/stick control.

- Dozers — for automatic blade control in 2D or 3D modes.

- Motor Graders — for final finishing and high-precision surfaces.

- Compact Equipment — through the Earthworks GO! version, designed for skid steers and compact track loaders using a smartphone interface.

This universality means fleet owners and contractors can standardize on a single ecosystem, simplifying training and maintenance while maximizing interoperability.

Trimble Earthworks in the Digital Jobsite

Trimble Earthworks doesn’t operate in isolation — it’s part of a broader suite of Trimble solutions that includes:

- Trimble WorksManager: cloud-based project management, file transfer, and remote configuration.

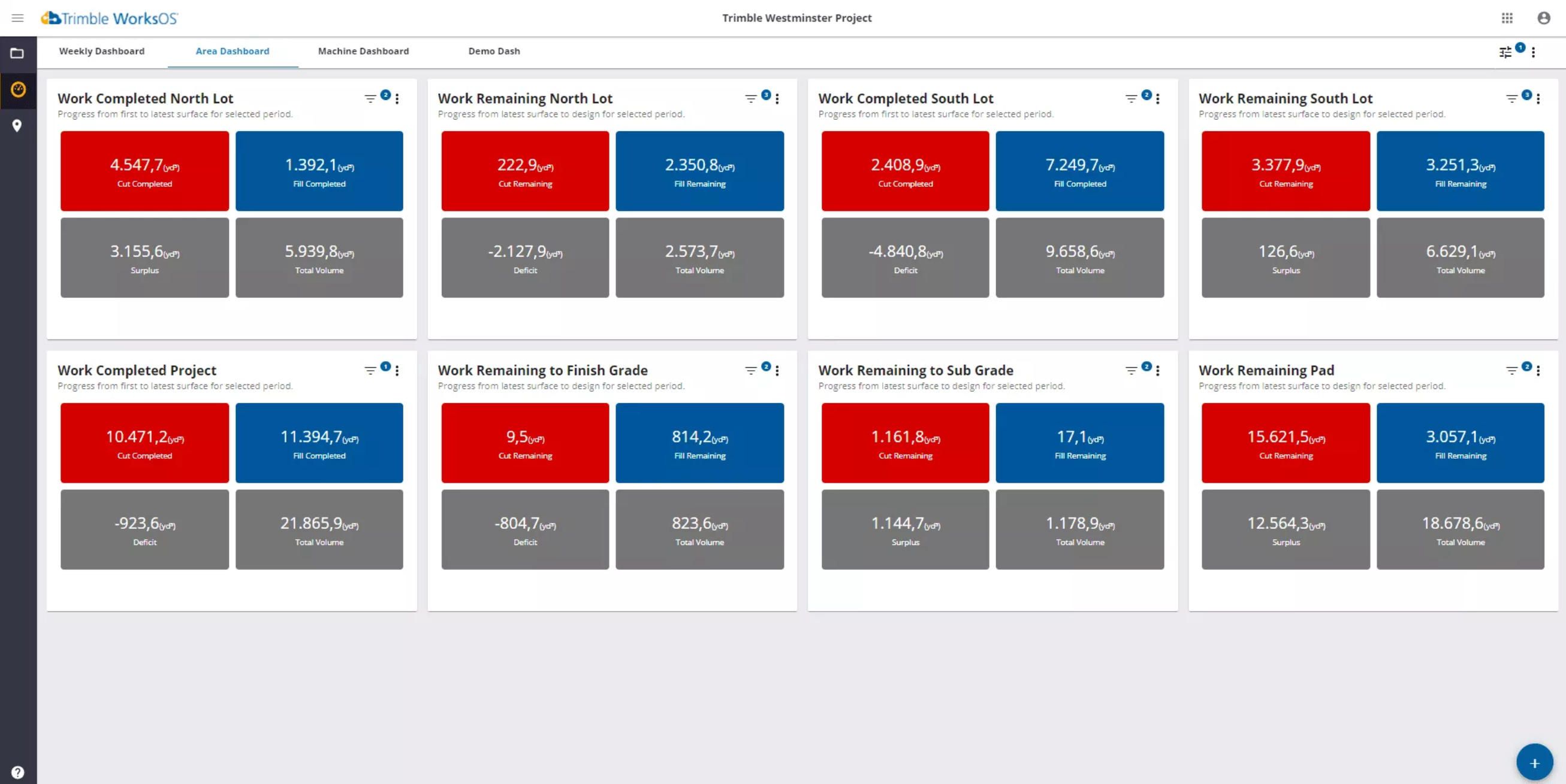

- Trimble WorksOS: productivity analytics and jobsite dashboards for supervisors.

- Trimble Business Center (TBC): design preparation and data exchange with civil-engineering software.

Together, these components form a data continuum — from design creation in the office to execution in the field and back again. The integration reduces human error, ensures version control, and enables real-time collaboration between engineers, surveyors, and operators.

In practical terms, if a design file changes due to new drainage requirements, the update can be pushed instantly to every machine on the site. Within seconds, all operators see the revision reflected in their Earthworks display. This real-time responsiveness eliminates costly delays and miscommunication.

Trimble Earthworks as Industry Benchmark

By now, the name “Trimble Earthworks” has become almost synonymous with machine-control excellence. Competing systems from Leica Geosystems, Topcon, and Hemisphere are often measured against it. Yet Trimble retains a competitive edge through its early adoption of Android, its focus on user experience, and its tight coupling with cloud services.

The platform’s influence extends beyond Trimble’s own ecosystem. Many equipment manufacturers — from Caterpillar to Volvo — offer Trimble-compatible configurations, recognizing the market demand for standardized digital control. Training schools and vocational programs increasingly include Earthworks simulations as part of operator certification, further entrenching its role as an industry standard.

Looking Ahead

Trimble Earthworks exemplifies how software innovation drives physical progress. The future of construction machinery is no longer defined solely by horsepower or steel but by the intelligence embedded in its digital control systems.

In the coming decade, expect platforms inspired by Earthworks to evolve toward predictive automation, mixed-reality visualization, and full integration with digital-twin infrastructures. As 5G networks expand and edge computing becomes commonplace, real-time synchronization between multiple machines, drones, and ground sensors will become the norm.

For developers, OEMs, and contractors, this evolution presents both opportunity and challenge. The opportunity lies in building interoperable, adaptive systems; the challenge is ensuring security, reliability, and human trust in automated decisions. Trimble Earthworks has already shown what’s possible when precision, usability, and connectivity converge — and its legacy will continue to shape the next generation of intelligent jobsite technology.

2. The Market Context and Opportunity of Trimble Earthworks

The construction industry is standing on the brink of a digital transformation that is redefining how earthmoving, grading, and site preparation are performed. Within this transformation, Trimble Earthworks has emerged not just as a tool, but as a benchmark for precision automation and intelligent construction workflows. Understanding its market context means examining the broader evolution of machine-control systems, the economics driving adoption, and the technological forces that make Earthworks indispensable to modern contractors.

From Survey Stakes to Smart Machines

For decades, heavy equipment operation was limited by analog workflows. Surveyors placed stakes; foremen managed cut-and-fill operations by eye; operators relied on intuition and radio communication. These methods were time-consuming, error-prone, and expensive. In large infrastructure projects, even a few centimeters of deviation could mean thousands of cubic meters of incorrect excavation.

Machine-control systems like Trimble Earthworks changed that paradigm. By embedding GNSS/RTK positioning, IMU sensors, and 3D modeling directly into the operator’s cab, they gave machines the ability to “see” the terrain and respond to it autonomously.

This revolution parallels what automation achieved in other sectors: navigation in aviation, precision steering in agriculture, and real-time control in autonomous vehicles. In fact, the construction industry is now experiencing a delayed—but rapid—digital leap that agriculture and manufacturing underwent a decade earlier.

What’s different today is scale: infrastructure spending is rising globally, while the workforce is shrinking. According to McKinsey’s 2024 Global Construction Outlook, the industry faces a projected 25% shortfall in skilled heavy-equipment operators by 2030. As demand for urbanization and infrastructure investment grows, the only scalable answer is intelligent, connected automation — exactly the domain that Trimble Earthworks serves.

Market Growth: Where the Opportunity Lies

The machine-control systems market, encompassing software like Trimble Earthworks, sensors, and telematics integrations, is expanding rapidly. Several authoritative analyses outline this trajectory:

- Grand View Research (2024) valued the market at USD 5.59 billion in 2023, forecasting USD 8.94 billion by 2030, a 7.4% CAGR.

- Fortune Business Insights (2024) projected similar growth, attributing it to increasing automation in civil construction, rising labor costs, and adoption of GNSS-based systems in emerging markets.

- MarketsandMarkets (2025) noted that 3D machine-control systems alone account for over 60% of total revenue, highlighting the growing dominance of advanced modeling and cloud connectivity.

Behind these numbers is a clear narrative: precision and digital workflows are no longer optional—they’re economic imperatives.

Contractors adopting Trimble Earthworks report tangible results:

- Up to 30% improvement in operational efficiency.

- 20–40% reduction in rework and material waste.

- Payback periods averaging less than 12 months, depending on project type.

These gains make a compelling business case. Equipment that costs USD 500,000–800,000 can generate an additional USD 100,000–150,000 in annual savings simply by operating with greater accuracy and fewer corrections.

Regional Dynamics: A Global Race Toward Precision

While Trimble Earthworks has a strong presence in North America and Europe, adoption is accelerating globally.

North America remains the largest market due to established infrastructure programs, high labor costs, and integration of Trimble technology within OEM machines such as Caterpillar, John Deere Construction, and Volvo CE. The U.S. Infrastructure Investment and Jobs Act (IIJA) allocates USD 1.2 trillion for construction projects through 2030, amplifying demand for automation that ensures quality and timeline compliance.

Europe follows closely, driven by sustainability mandates under the EU Green Deal and the Digital Construction 2030 Roadmap. Precision earthmoving helps contractors minimize material use and carbon footprint, two key performance metrics for EU-funded projects.

Asia-Pacific, however, represents the fastest-growing region. Countries like Japan, South Korea, and Australia have aggressively adopted GNSS-guided systems for mining, infrastructure, and coastal engineering. In China, provincial governments encourage digital construction through smart-city initiatives, while in India, Trimble Earthworks-compatible systems are being tested on national highway projects.

This global expansion demonstrates that the technology has transcended regional standards; Earthworks has become a universal language of precision in the construction sector.

Key Drivers of Market Expansion

The rise of Trimble Earthworks coincides with a convergence of global economic, environmental, and technological drivers. Four stand out as particularly transformative:

- Labor Efficiency and Safety

The shrinking workforce demands tools that amplify productivity without overburdening personnel. Earthworks’ semi-automatic controls reduce operator fatigue while improving output. The system’s visual guidance minimizes the need for ground crews near heavy machinery, directly enhancing safety. - Digitalization and BIM Integration

Infrastructure projects increasingly mandate digital-as-built models compliant with Building Information Modeling (BIM) standards. Earthworks’ ability to use, modify, and report 3D models on-site bridges the gap between office design and field execution. - Sustainability and Compliance Pressure

Governments and investors now tie funding to sustainability KPIs. Trimble Earthworks contributes by optimizing material use, cutting fuel consumption, and reducing carbon emissions—creating quantifiable ESG value. - Autonomous Equipment Development

OEMs are integrating Earthworks-style control systems as stepping stones toward autonomy. The same GNSS and hydraulic-control logic that enables automatic grading also forms the basis of self-operating excavators and bulldozers.

These drivers transform Trimble Earthworks from a niche productivity tool into a strategic infrastructure technology, influencing procurement, bidding, and sustainability scoring.

Competitive Landscape and Trimble’s Position

Trimble’s dominance in the intelligent-construction market is not accidental. It stems from decades of geospatial leadership and a vertically integrated ecosystem that connects sensors, software, and cloud services. Competitors such as Leica Geosystems (Hexagon), Topcon Positioning Systems, and Moba Mobile Automation offer capable solutions, yet Trimble’s Earthworks + WorksManager + WorksOS synergy remains unmatched in ecosystem depth.

Several differentiators secure its market position:

- Android-based interface: universal, easy to update, and customizable.

- Cross-machine compatibility: supports excavators, dozers, graders, compact track loaders, and even snowplows.

- Trimble Connect Cloud: ensures live design updates and centralized fleet analytics.

- Extensive OEM partnerships: integration into CAT Grade Control Advanced, Volvo Assist, and John Deere SmartGrade lines.

This broad integration means Earthworks isn’t just a software product — it’s part of an evolving digital-control ecosystem, where field data feeds directly into enterprise resource planning (ERP), safety monitoring, and sustainability dashboards.

Economic Rationale: ROI in Numbers

Let’s quantify why contractors are investing aggressively in Trimble Earthworks.

Suppose a mid-size contractor operates a fleet of 20 dozers and 15 excavators across 3 active sites.

- Each machine costs around USD 600,000.

- Average fuel cost per hour: USD 2.10 per liter × 18 liters = USD 37.8/hour.

- Average operating time: 1,800 hours/year.

With Earthworks, assuming a conservative 12% fuel efficiency gain and 20% rework reduction, the company saves:

- Fuel: 18 × 0.12 × 2.10 × 1,800 ≈ USD 8,162 per machine/year** → roughly USD 285,000 annually for 35 machines.

- Rework/material reduction: estimated USD 200,000/year across projects.

- Downtime reduction: USD 75,000/year in labor savings.

Total ≈ USD 560,000 annual savings, or roughly a 70% ROI in year one.

These figures are not abstract—they reflect averages published by Trimble’s user case studies and industry audits. When paired with the system’s lifespan (5–7 years), the financial argument becomes nearly self-evident.

Sustainability and Environmental Accountability

Modern infrastructure contracts increasingly require sustainability documentation. Trimble Earthworks offers measurable, data-driven reporting on environmental performance. Its precise control of material usage directly correlates with lower fuel consumption and carbon footprint.

For example, the European Green Building Council estimates that every liter of diesel avoided reduces 2.68 kg of CO₂ emissions. Given the earlier example, saving 100,000 liters/year across a fleet equates to 268 metric tons of CO₂ avoided annually — enough to offset the emissions of 60 passenger cars.

Such metrics are more than corporate virtue; they are now bid-winning advantages. Public and private clients increasingly favor contractors capable of documenting sustainable practices through digital systems. Trimble Earthworks turns sustainability from an abstract commitment into a quantifiable outcome.

Technological Convergence: IoT, Cloud, and AI

Another factor fueling the Earthworks opportunity is technological convergence. The platform sits at the intersection of multiple megatrends:

- IoT Telematics: Machines transmit operational metrics — idle time, hydraulic load, grade deviation — to cloud dashboards.

- 5G Connectivity: Enables low-latency data synchronization between multiple machines and remote offices.

- AI Analytics: Predictive algorithms detect inefficiencies, recommend grading patterns, and forecast maintenance needs.

- Edge Computing: Processing occurs locally in the control unit, ensuring sub-second responsiveness even without network coverage.

This convergence transforms Trimble Earthworks from static guidance software into an intelligent orchestration system — the digital nervous system of the jobsite. It’s what allows supervisors to visualize project progress in real time, compare performance across crews, and make informed decisions instantly.

Barriers to Adoption and How They Are Falling

Despite its clear advantages, early adoption faced several obstacles: cost perception, training complexity, and interoperability concerns. Today, each of these is diminishing:

- Cost Efficiency: Subscription models and equipment leasing make entry affordable even for mid-sized firms.

- Ease of Use: The Android interface and intuitive visual cues drastically shorten operator training curves.

- Interoperability: Open data standards (LandXML, IFC) enable integration with most design and fleet-management systems.

Additionally, partnerships between Trimble distributors and training institutions — such as SITECH Academy and Trimble Technology Labs — are creating a new generation of “digital operators.” As a result, adoption rates are accelerating year over year.

The Future Market Trajectory

Looking forward, analysts predict that machine-control systems will become standard equipment, not optional add-ons, by 2030. OEMs are expected to deliver pre-installed or factory-integrated solutions similar to how vehicles now include embedded navigation systems.

Three major trends will shape the next phase:

- AI-Assisted Earthworks: Adaptive algorithms that learn operator behavior and suggest grading optimizations.

- Synchronized Fleets: Cloud coordination among multiple machines working on the same model, adjusting dynamically to maintain optimal workflow.

- Data Commercialization: Contractors monetizing operational data by benchmarking efficiency metrics and offering digital-twin insights to clients.

Trimble Earthworks sits at the nexus of all three trends. Its existing cloud architecture (WorksManager + WorksOS) and open API structure allow it to evolve rapidly without hardware replacement, securing long-term relevance.

A-Bots.com and the Expanding Customization Frontier

For innovative developers like A-Bots.com, this expanding market presents immense collaboration potential. While Trimble delivers the hardware-software foundation, real-world deployments often require custom layers — fleet analytics dashboards, operator-training simulators, mobile companion apps, or integration with proprietary ERP systems.

A-Bots.com specializes in precisely these layers. With deep expertise in mobile development, embedded interfaces, cloud synchronization, and field testing, the company can design modular extensions that transform Trimble-compatible systems into bespoke digital ecosystems.

Imagine:

- A custom app that alerts managers when a machine’s grade deviation exceeds 2 cm.

- A tablet-based visualization tool showing material moved in real time, synchronized with cloud cost data.

- AI modules predicting hydraulic-component wear based on pressure profiles.

Such solutions extend the life and value of the core Trimble Earthworks system while tailoring it to each contractor’s unique workflow. The market is not merely growing; it’s diversifying, creating an entire secondary industry around customization and integration — precisely the domain where A-Bots.com excels.

Perfect Storm of Demand and Capability

The rise of Trimble Earthworks is not an isolated success story; it’s the visible crest of a much larger wave — the automation and digitalization of the global construction sector. As infrastructure programs expand, skilled labor declines, and sustainability pressures mount, intelligent machine-control solutions are no longer a luxury. They are the competitive baseline.

In this context, Trimble Earthworks stands as both a symbol and an opportunity: a symbol of how far construction has come from analog tools, and an opportunity for technology developers, contractors, and OEMs to build the next generation of digital jobsite ecosystems.

Whether it’s developing mobile apps for fleet coordination, cloud systems for data analytics, or AI modules for predictive automation, A-Bots.com can help organizations harness this opportunity. The future belongs to those who integrate precision, intelligence, and adaptability — exactly what Trimble Earthworks embodies, and what A-Bots.com is ready to enhance.

3. Core Features of Trimble Earthworks

If the previous section explained why the construction industry is rapidly embracing digital control systems, this section explains how Trimble Earthworks became the undisputed benchmark. The platform succeeds not because it’s the only machine-control solution available — competitors from Leica, Topcon, and Moba have existed for years — but because Earthworks integrates advanced hardware, intuitive software, and scalable cloud connectivity into a unified system. It doesn’t simply assist the operator; it transforms the very process of excavation and grading into a data-driven, visual, and predictive science.

At its heart, Trimble Earthworks is built around three ideas: precision, usability, and connectivity. Precision ensures centimeter-level accuracy. Usability translates complex geometry into an operator-friendly interface. Connectivity ties every machine, model, and manager into one real-time feedback loop. Together, these principles redefine what it means to move earth efficiently.

Precision Engineering: From the Blade to the Cloud

Trimble Earthworks operates as the digital nervous system of heavy machinery. It continuously fuses data from GNSS satellites, inertial sensors, and hydraulic controllers to determine the exact position and attitude of the blade, bucket, or drum. The system calculates “cut” and “fill” differences against the design surface up to 10 times per second, instantly updating visual feedback for the operator.

The power of this precision lies in how it reduces the chain of uncertainty that once dominated earthmoving. In a traditional setup, an operator depended on survey stakes and intuition to estimate grade depth. Even small misjudgments could lead to cumulative errors — extra passes, wasted material, uneven compaction. Earthworks effectively eliminates that margin of error.

In high-value projects — airport runways, dams, wind-farm foundations — this accuracy is not a luxury but a necessity. For example, in a 2024 case study of a Canadian highway project, a contractor using Trimble Earthworks reduced grade deviation from ±25 mm to under ±8 mm, saving over $180,000 USD in rework.

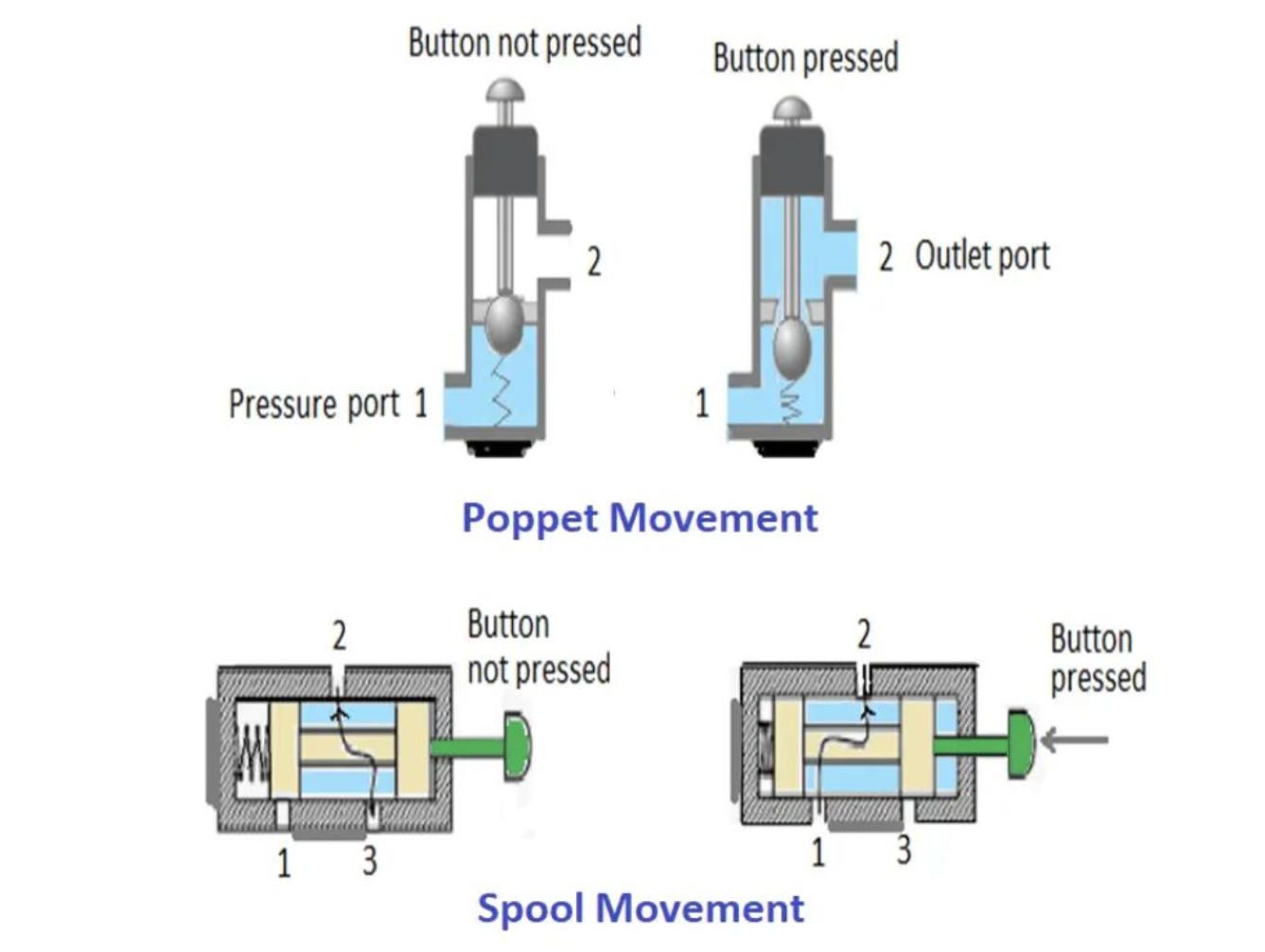

What distinguishes Trimble’s approach is the closed-loop control between sensors and hydraulics. The system doesn’t just measure — it acts. When connected in automatic mode, it adjusts the hydraulic valves in milliseconds, keeping the blade exactly on grade. This is not mere guidance; it’s real-time mechatronic precision.

The Human-Centered Interface

Perhaps the single most revolutionary feature of Trimble Earthworks is its Android-based operator interface. Traditional machine-control displays were functional but intimidating — small black-and-white screens with cryptic menus and numeric codes. Trimble reimagined that entire paradigm with a touch-driven 3D environment.

Operators see a vivid, dynamic representation of their machine moving through the terrain. The screen updates continuously to show:

- Color-coded cut/fill zones: red for excess material (cut), blue for deficit (fill), and green when on-grade.

- Live 3D design model: enabling full rotation, zoom, and cross-section viewing.

- Slope and depth indicators: real-time slope %, elevation differentials, and target line overlays.

The learning curve is minimal. New operators, even those without surveying backgrounds, can become proficient within days. Veteran operators often describe Earthworks as “an extra set of eyes” that enhances rather than replaces skill.

A Trimble user interview from 2024 captured it perfectly:

“The screen feels like a game, but the stakes are real. You don’t guess anymore; you watch the color turn green and you know it’s perfect.”

The emphasis on visual cognition — rather than numeric input — means the system communicates through intuition. The combination of gesture-based control, simplified menus, and multilingual support allows global deployment without complex retraining programs.

2D and 3D Operating Modes

Trimble Earthworks accommodates both 2D and 3D project environments, giving contractors flexibility depending on complexity and budget.

In 2D mode, the system references a laser or sonic elevation plane — ideal for smaller pads, parking lots, or flat work. Operators control height and slope manually or with limited automation.

In 3D mode, Earthworks imports digital terrain models (DTMs) from design files (e.g., LandXML, DXF, or IFC). GNSS antennas mounted on the machine determine position within that model, while IMUs measure tilt and rotation. The software calculates in three dimensions — X, Y, Z — and commands hydraulic actuators automatically to maintain the design surface.

This dual-mode approach makes Earthworks scalable. A small contractor can begin with 2D and upgrade to 3D as projects evolve, reusing much of the same hardware.

Machine Versatility: One Platform, Many Configurations

Trimble Earthworks is not limited to a single type of equipment. The same software platform powers excavators, dozers, graders, compact track loaders, and even landfill compactors. This universality is possible through modular sensor configurations and customizable display profiles.

For instance:

- Excavators: Sensors mounted on the boom, stick, and bucket measure angles and elevation, allowing real-time depth calculation. Semi-automatic control keeps the bucket on target slope while the operator controls swing and travel.

- Dozers: Dual GNSS antennas ensure blade-tip precision even during aggressive blade pitch changes. Automatic hydraulic adjustment maintains consistent grade.

- Graders: Real-time blade cross-slope control and side-shift automation produce finish-grade surfaces meeting ±2 cm tolerances.

- Compact Equipment (Earthworks GO!): A mobile-app-driven version that turns a smartphone into a control interface using portable sensors — a major innovation for small contractors.

The ability to standardize across multiple machine types is crucial for fleet operators who manage mixed brands. Instead of running separate systems for each OEM, Earthworks becomes the common digital layer, simplifying data management, maintenance, and operator training.

Seamless Cloud Connectivity

Trimble’s genius was not just in machine-level control but in connecting that control to enterprise workflows. Through Trimble WorksManager and WorksOS, Earthworks ties every machine to the project office.

This connectivity allows:

- Real-time design updates: When engineers revise a model, the new file is pushed to every relevant machine instantly.

- Remote monitoring: Supervisors view machine positions, task progress, and operator performance from anywhere.

- Automated data logging: Every pass, cut, and fill operation is recorded and stored for auditing or payment verification.

- Fleet analytics: Productivity metrics — cubic meters moved per hour, idle ratios, grade accuracy — become KPIs visible in cloud dashboards.

Before such integration, these data points were either unavailable or fragmented across different devices. Earthworks converts them into actionable intelligence.

The strategic implication is enormous. A contractor no longer guesses whether a site is “on schedule” — they see it quantified on a dashboard in near real time. Combined with Trimble Connect and Business Center, this cloud linkage forms a digital-twin feedback loop, where physical progress instantly informs design adjustments.

Semi-Automatic and Automatic Control

Trimble Earthworks can operate in several control levels: manual, assisted, and automatic. In manual mode, the system serves purely as guidance — displaying grade information while the operator controls hydraulics. In assisted mode, Earthworks restricts motion outside target slopes, acting as a safety net. In automatic mode, the system directly manipulates hydraulic valves, achieving precise grade autonomously.

The automatic mode uses proportional-control algorithms refined over decades of Trimble research. The control logic accounts for hydraulic latency, blade inertia, and soil resistance to avoid overshoot — maintaining consistent performance even in variable terrain.

This capability defines what industry analysts call “hands-off precision.” It reduces operator fatigue and enables consistent quality across shifts and operators. In practical terms, the same accuracy can be maintained whether the operator has one year or twenty years of experience.

Real-Time Visualization and Data Layers

Beyond navigation, Trimble Earthworks provides operators with multi-layer visualization — not just the current grade, but subgrade layers, compaction targets, and material boundaries. The operator can toggle between different design surfaces to match the current construction phase (e.g., subbase, asphalt, or drainage).

This layer awareness is particularly powerful for complex projects like airports or industrial foundations, where multiple layers must align within millimeters. In those cases, Earthworks acts as the single visual reference that unites surveyors, machine operators, and engineers under one shared model.

Furthermore, the display can show cross-sections, profiles, and 3D wireframes simultaneously. This multi-view capacity gives operators immediate spatial context — an enormous advantage compared to 2D line references.

Productivity and ROI Features

What makes Trimble Earthworks more than a control system is how it tracks and optimizes productivity. The platform records data continuously — time on grade, number of passes, cycle times, idle hours — transforming every machine into a sensor node in a broader operational network.

Contractors can then analyze this data to identify inefficiencies. For example, if an excavator consistently over-cuts by 4 cm, the system can flag the deviation, prompting recalibration or operator feedback. Similarly, fuel usage and idle time metrics help reduce unnecessary engine hours.

Real-world deployments have shown:

- 10–20% reduction in total operating time per task.

- 15% less fuel consumption, leading to lower emissions and cost.

- 25–40% higher grade accuracy, minimizing rework and material overrun.

By quantifying productivity at this granularity, Earthworks transforms construction management from reactive oversight into proactive optimization.

Compatibility and Expandability

Trimble Earthworks is designed with future integration in mind. Its modular software structure allows expansion via software updates rather than hardware replacement. New capabilities — such as automatic tilt control or material mapping — are released periodically and can be installed over-the-air.

Moreover, Earthworks supports open data standards like LandXML and IFC, ensuring interoperability with major design tools (Autodesk Civil 3D, Bentley OpenRoads, Trimble Business Center). This openness is essential for modern BIM-compliant projects, where collaboration across multiple software platforms is mandatory.

In addition, Trimble offers APIs that allow third-party developers — such as A-Bots.com — to create customized extensions. These can include:

- Mobile apps for field supervisors integrating Earthworks data.

- Custom analytics dashboards tailored to client KPIs.

- Specialized visual overlays for safety or maintenance alerts.

This extensibility transforms Earthworks from a closed product into an adaptable platform — one that grows alongside its users and their business models.

Ergonomics, Safety, and Operator Well-Being

Though often overlooked, the ergonomic and psychological benefits of Earthworks are substantial. By providing immediate, intuitive feedback, the system reduces cognitive load and decision fatigue. Operators no longer strain to interpret grade stakes or decipher cryptic symbols. Instead, they respond to color and motion — universal cues that require minimal training.

The system also enhances safety by minimizing the need for ground personnel near active machinery. Surveyors can remain outside danger zones while verifying progress remotely. Integrated alarms alert operators if the machine approaches exclusion zones or exceeds slope thresholds, preventing rollovers and collisions.

In projects where safety regulations are strict — mining, urban construction, or rail development — these features aren’t optional; they’re essential compliance tools.

Integration with Autonomy and AI

Trimble Earthworks is more than a present-day control platform; it’s a gateway to full autonomy. The same architecture that manages hydraulics today will manage fully autonomous excavators and dozers tomorrow. In 2025, Trimble demonstrated prototype integrations combining Earthworks control logic with AI-driven perception modules, enabling machines to detect obstacles and adjust paths autonomously.

As artificial intelligence evolves, Earthworks will leverage predictive analytics to anticipate machine behavior, terrain difficulty, and even soil type variations. Future versions will likely incorporate camera-based terrain recognition and self-optimizing algorithms that learn from operator patterns.

This continuous evolution ensures that investments in Trimble Earthworks remain future-proof, aligned with the emerging vision of Construction 4.0 — where connected, intelligent machines collaborate seamlessly to build digital twins of the world’s infrastructure.

The A-Bots.com Perspective

For technology innovators such as A-Bots.com, the robust architecture of Trimble Earthworks provides an exceptional foundation for custom solutions. Because it already integrates GNSS, cloud synchronization, and mobile interfaces, developers can extend it with custom AI modules, telematics dashboards, or augmented-reality operator training tools.

A-Bots.com specializes in precisely this frontier — crafting bespoke software that enhances and customizes intelligent control systems. From predictive maintenance modules to mobile companion apps that replicate the Earthworks UI for remote monitoring, the company’s engineering expertise bridges the gap between Trimble’s industrial precision and the specific operational needs of each client.

For construction OEMs, fleet managers, or startups aiming to create their own earthmoving control ecosystem, A-Bots.com can develop compatible software layers — building upon Trimble-like architectures to deliver tailored, interoperable systems that maintain accuracy while adding business intelligence.

The core features of Trimble Earthworks represent the culmination of decades of geospatial innovation and user-experience refinement. It fuses the mathematical precision of GNSS with the tactile intuition of mobile UX, creating a workflow where machines act as smart collaborators rather than blunt instruments.

Every element — from the touch interface to cloud connectivity, from semi-automatic control to open-API expandability — reflects a vision of the modern jobsite as a connected, data-driven ecosystem.

As contractors worldwide move toward automation and AI-enabled construction, platforms like Trimble Earthworks will serve as both blueprint and backbone. And as those platforms evolve, A-Bots.com stands ready to develop, customize, and enhance the next generation of intelligent earthmoving software, ensuring that every pass of the blade is not just accurate, but meaningful.

4. The Future of Grade Control and Earthmoving

The evolution of Trimble Earthworks is not simply a story of software updates and better sensors; it is a preview of how the next decade of construction will look. The convergence of automation, artificial intelligence, and environmental accountability is pushing earthmoving into a new era where machines are not merely guided but are becoming intelligent, adaptive participants in the building process. The future of grade control will not be about who can dig faster—it will be about who can interpret data, anticipate terrain dynamics, and collaborate seamlessly across digital ecosystems.

In the coming years, the concept of grade control will expand far beyond its current definition. Until now, it meant keeping the blade or bucket aligned with a digital design. Soon, that digital model will evolve into a “living twin”—an intelligent entity that learns from every pass, recalibrates designs based on real-time conditions, and communicates continuously with other machines. Trimble Earthworks is already laying this groundwork. It represents one of the first systems in the construction industry where data flows in both directions: from the office to the field and back again. The next step is for that data to become predictive, autonomous, and interconnected on a scale that mirrors modern manufacturing or aviation systems.

The foundation for this transformation lies in artificial intelligence. With the growing power of edge computing and cloud synchronization, AI algorithms can already process soil density, hydraulic pressure, and machine vibration to predict inefficiencies. Within a few years, Trimble Earthworks-class systems will interpret not only the current surface but also the physical properties beneath it. Imagine a grader that senses moisture, identifies material hardness, and automatically adjusts blade angle and hydraulic force to maintain optimal efficiency without human input. Such functionality is no longer theoretical—research prototypes are already operating on controlled test sites.

Machine autonomy will play an equally transformative role. The trajectory from semi-automatic to fully autonomous machinery is accelerating. Current systems that automatically adjust hydraulic valves are early manifestations of a future where dozers and excavators coordinate independently across the jobsite. Multiple machines will share one dynamic model, synchronizing their work like an orchestra following a single digital conductor. In this environment, Trimble Earthworks evolves from a control system into a command layer—an operational intelligence hub that harmonizes human supervision and robotic execution.

These advances also imply new forms of human–machine collaboration. The operator’s role will not disappear; it will shift from manual control to strategic oversight. The future cab may resemble a cockpit or mission station where the operator manages workflows, supervises multiple autonomous units, and intervenes only when conditions exceed algorithmic parameters. The intuitive design principles already perfected by Trimble Earthworks—its 3D visualization, touch gestures, and cognitive simplicity—will be critical to this transition. They will ensure that humans remain confidently in command of increasingly complex systems.

Data connectivity will define competitive advantage. In tomorrow’s construction landscape, the ability to share accurate data in real time will separate leaders from laggards. High-speed 5G networks and satellite-based IoT channels will make latency negligible. Each machine will stream positional, hydraulic, and material data to centralized cloud services, where AI will aggregate insights for project managers. The data feedback loop that Trimble Earthworks pioneered will mature into a fully autonomous digital infrastructure: an ecosystem where every decision—whether by human or machine—is informed by live analytics.

Sustainability will also become inseparable from productivity. Governments, investors, and clients are imposing stricter environmental regulations, and carbon transparency is fast becoming a contractual requirement. Future grade-control platforms will quantify emissions, material use, and energy consumption as easily as they now calculate depth or slope. Here again, Trimble Earthworks shows the direction. By minimizing rework and optimizing machine movement, it already reduces fuel burn and CO₂ output. The next generation will expand these features into full environmental dashboards that calculate sustainability metrics in real time, allowing project owners to verify compliance instantly. The jobsite of the future will therefore be as much an ecological monitoring network as a construction zone.

Interoperability is another frontier. The days of closed ecosystems are ending. Infrastructure projects now involve dozens of stakeholders—surveyors, designers, contractors, equipment manufacturers, regulators—each using different digital tools. The success of Trimble Earthworks lies partly in its open data philosophy, supporting common formats like LandXML and IFC. In the future, open APIs and data standards will be mandatory. Machine-control systems will communicate seamlessly with BIM platforms, logistics applications, and environmental databases. A road project in Australia might share its grading data directly with a remote digital-twin simulation in Europe; both systems will recognize the same design parameters and environmental constraints.

Augmented and mixed reality will redefine visualization. Operators and engineers will no longer interpret 2D plans on screens; they will see holographic projections of design layers superimposed on the terrain. Imagine wearing AR glasses that display real-time guidance from Trimble Earthworks directly on the machine’s windshield, highlighting the precise contour lines, slope boundaries, and safety zones. Supervisors standing on the jobsite will view the same digital overlay, instantly verifying whether the current grade matches the model. This will create a shared visual language between humans and machines, reducing misunderstanding and dramatically improving coordination.

Economically, this digital evolution will restructure entire business models. Instead of one-time equipment sales, OEMs and contractors will transition toward subscription-based service ecosystems. Software, rather than hardware, will become the primary driver of profitability. The success of Trimble Earthworks subscriptions already illustrates this trend: contractors increasingly prefer scalable, updateable software to permanent installations. As AI modules and autonomous capabilities expand, such models will allow incremental upgrades without replacing machinery—a sustainable, future-proof strategy.

The role of data ownership will simultaneously grow in importance. As every movement of the blade, every cubic meter of soil, and every liter of fuel becomes quantifiable, the value of that data will rival that of the project itself. Contractors will use analytics not just to optimize internal efficiency but also to offer new services—predictive maintenance, carbon reporting, or digital twin verification. The groundwork that Trimble Earthworks has laid for secure data capture and cloud synchronization positions it as a central player in this emerging data economy.

In parallel, safety will be reimagined through automation. Most on-site accidents occur due to limited visibility, fatigue, or miscommunication. With AI-assisted systems constantly monitoring blind spots and predicting risky movements, the next generation of control platforms will reduce incidents dramatically. Machines guided by Trimble Earthworks-grade intelligence will sense proximity to personnel, adjust trajectories, or even halt autonomously to prevent collisions. This proactive safety architecture will make digital oversight as natural to construction as seatbelts are to driving.

Education and workforce transformation will follow suit. As digital tools replace manual methods, a new generation of “tech-operators” will emerge. They will combine mechanical skill with software literacy, managing algorithms as comfortably as levers. Training programs built around simulation environments that replicate Trimble Earthworks interfaces will become standard. These programs will teach not only operation but also interpretation—how to analyze data, validate models, and make real-time decisions based on intelligent feedback. The next decade’s most successful equipment operators will likely resemble drone pilots or data analysts more than traditional heavy-equipment drivers.

From a broader perspective, the technological evolution of grade control mirrors humanity’s ongoing migration from reactive work to predictive systems. Just as autonomous cars redefined mobility and industrial robots redefined manufacturing, intelligent grading will redefine construction logistics. Trimble Earthworks embodies the transitional phase: machines are no longer extensions of the operator—they are partners, each capable of self-correction, learning, and communication. As the technology matures, the jobsite will become a distributed intelligence network, where the boundaries between machine, software, and human decision-making blur.

A fascinating byproduct of this shift is the possibility of global benchmarking. Because systems like Trimble Earthworks standardize data collection, productivity metrics from a highway project in California could be compared with one in Singapore or Oslo. Such benchmarking will give rise to new global performance indices, similar to what already exists in manufacturing or logistics. Contractors will compete not only on cost and schedule but also on efficiency scores derived from machine telemetry. The industry will become more transparent, more measurable, and ultimately more accountable.

For developers and integrators such as A-Bots.com, this future opens an unprecedented field of innovation. As construction hardware becomes more standardized, the competitive edge shifts to software intelligence—the ability to analyze, customize, and visualize. Companies that can create specialized mobile applications, remote monitoring tools, or AI-driven prediction modules built on top of platforms like Trimble Earthworks will define the next wave of industry leaders. It is a landscape where creativity meets engineering: turning complex data into actionable insights, and turning insights into tangible ground movement.

In the long view, the trajectory of grade control represents more than a technical advancement—it reflects a philosophical one. It embodies the transition from human labor to human design, from controlling machines to designing systems that control themselves responsibly. Trimble Earthworks has proven that automation can coexist with craftsmanship, precision with intuition, and digital workflows with human oversight. The challenge for the next decade is to maintain this balance as autonomy increases. The ultimate goal is not to remove the human element but to elevate it—to allow engineers, operators, and developers to focus on creativity, safety, and sustainability while the machines handle repetition and precision.

The future of earthmoving, then, is neither mechanical nor digital—it is hybrid. It will be built on trust between intelligent systems and the people who design them. As algorithms learn from experience, and humans learn to interpret algorithmic logic, the boundary between man and machine will become collaborative rather than competitive. And when that equilibrium is reached, the term “grade control” may no longer describe what these systems do. They will not simply control—they will understand, predict, and construct in harmony with the world around them. Trimble Earthworks stands today as the clearest blueprint of that future.

5. Customization and Deployment: How A-Bots.com Can Help

The journey from concept to a fully functional intelligent grade-control environment does not end with installation. Every construction company, equipment manufacturer, or technology integrator faces unique operational realities—different fleets, terrains, workflows, and regulatory contexts. That is precisely where customization becomes the key to unlocking the full potential of Trimble Earthworks-class technology. While Trimble has built an exceptional platform, adapting it to a company’s ecosystem requires expertise in software development, data engineering, and field integration. This is the space where A-Bots.com operates.

At its core, A-Bots.com specializes in transforming powerful yet general solutions into tailored, business-specific systems. The company’s engineers approach grade-control software not as a static product but as a foundation—an architecture on which smarter, faster, and more intuitive layers can be built. For contractors who need proprietary dashboards, fleet-management applications, or AI-based performance monitoring, A-Bots.com can design and deploy custom modules that integrate seamlessly with the existing control environment. The goal is to make technology invisible to the operator yet invaluable to the enterprise.

Customization begins with understanding the operational DNA of each client. A mining company working in the rugged terrain of Western Australia will have different sensor requirements, interface layouts, and data-latency challenges than a civil-engineering firm constructing urban subways in Europe. A-Bots.com begins every engagement with a technical and environmental audit: what types of machines are in use, what data connectivity exists, how operators interact with their displays, and how management consumes performance reports. From that foundation, developers design adaptive software that extends the logic of Trimble Earthworks into the customer’s own digital ecosystem.

Integration is both an art and a science. Earthmoving machines already generate immense data flows—GNSS coordinates, hydraulic pressures, temperature, vibration, and engine telemetry. A-Bots.com develops middleware that aggregates this information, cleans it, and synchronizes it with cloud databases or on-premise servers. The result is a continuous, verified data stream that feeds into analytics dashboards and predictive-maintenance tools. With this architecture, a company can monitor not only whether a blade is on grade but also how efficiently each operator, crew, or site performs over time. The same data can feed into project-management software, cost-tracking systems, or sustainability reports, creating a fully connected operational picture.

Equally important is the human interface. The company’s design philosophy emphasizes clarity and ergonomics. Whether it’s a custom mobile app for site managers or a digital-twin visualization for clients, the interface must be intuitive enough to interpret complex metrics at a glance. A-Bots.com combines its experience in UI/UX design with practical knowledge of field conditions, ensuring that every button, graph, and alert works under real-world constraints—dust, vibration, sunlight, and gloves on touchscreens. This attention to usability transforms advanced technology into an everyday tool rather than an occasional specialty system.

Testing and deployment represent the final—and often most critical—stage. A-Bots.com conducts field validation alongside client teams, calibrating sensors, adjusting algorithms, and refining communication links to achieve stable, repeatable accuracy. The company’s iterative testing model ensures that custom applications remain robust even under unpredictable jobsite conditions. Once the system is fully integrated, ongoing technical support and software updates keep it aligned with both new equipment and evolving operational goals.

What differentiates A-Bots.com is its ability to translate software innovation into tangible construction performance. It bridges the world of digital design with the realities of moving earth, merging the precision of code with the physical power of machinery. For organizations seeking to harness the intelligence of Trimble Earthworks while maintaining their own identity and workflows, A-Bots.com provides the rare combination of creative development, engineering depth, and practical deployment experience. The outcome is not merely technology adoption—it is transformation.

In the modern landscape of connected construction, customization is no longer optional. It is the mechanism that turns universal platforms into competitive advantages. With its cross-disciplinary expertise in mobile development, IoT integration, and field robotics, A-Bots.com is prepared to deliver that transformation. Each project becomes a collaboration between human ingenuity and machine precision, between the structured logic of software and the unpredictable nature of terrain. In that balance lies the true future of earthmoving—intelligent, adaptive, and seamlessly interconnected. And through that balance, powered by the foundation of Trimble Earthworks, A-Bots.com helps its partners build not only better sites but smarter industries.

✅ Hashtags

#TrimbleEarthworks

#MachineControl

#SmartConstruction

#AldigitalJobsite

#ConnectedConstruction

#EarthmovingSoftware

#GradeControl

#ConstructionAutomation

#AIinConstruction

#GNSSGuidance

#ABots

#CustomSoftwareDevelopment

Other articles

Trimble GFX Agriculture Guidance and AutoPilot Systems Trimble AutoPilot and Trimble GFX systems dominate aftermarket precision agriculture with hundreds of thousands of installations worldwide. This comprehensive technical guide examines the complete product lineup including GFX 350 entry display, GFX 750 mid-range system, GFX 1060 large-format console, and premium GFX 1260. Detailed specifications for NAV 500 and NAV 900 navigation controllers cover GNSS accuracy levels, correction services (RangePoint RTX, CenterPoint RTX, RTK), and terrain compensation technology. Real-world performance data shows 8-12% fuel savings, 10-15% overlap reduction, and 1-2 year payback periods. Multi-brand compatibility works with John Deere, Case IH, AGCO, and all tractor manufacturers. Complete installation procedures, cost breakdowns, competitive comparisons, and maintenance requirements. A-Bots.com offers custom software development, API integration, and testing services for Trimble implementations.

Ag Leader InCommand 800 and 1200 Precision Agriculture Displays Ag Leader InCommand displays dominate independent aftermarket precision agriculture with tens of thousands of installations worldwide. This comprehensive technical guide examines InCommand 800 (8-inch display, quad-core processor, $3,500-$4,500) and InCommand 1200 (12.1-inch screen, hexa-core processor, $5,500-$7,000) systems including detailed specifications, capabilities, and performance characteristics. Complete coverage of SureDrive automated steering achieving 2-4 cm RTK accuracy, SMS farm management software for prescription creation and data analysis, and universal compatibility with John Deere, Case IH, AGCO, and all equipment brands. Real-world performance data shows 12% input reduction, 10-15% fuel savings, and 1-2 year payback periods. Installation procedures, correction service options, competitive comparisons, and maintenance requirements included. A-Bots.com provides custom software development, API integration, and testing services for Ag Leader implementations.

Raven Industries Precision Agriculture: Viper 4+, Slingshot Raven Industries leads precision agriculture application control technology with specialized ground control solutions acquired by CNH Industrial in 2021. This comprehensive guide examines Viper 4+ display (10.4-inch touchscreen, ISOBUS Universal Terminal, $3,800-$4,800), Slingshot cloud connectivity platform enabling real-time fleet monitoring and remote support, Field Hub precision application controllers managing up to 128 independent sections, Hawkeye individual nozzle control with integrated flow verification, and emerging Raven Autonomy supervised autonomous equipment systems. Real-world performance data shows 8-15% input reduction through advanced section control, 60-80% herbicide savings with selective spraying, and 40-60% labor cost reduction through autonomous implementations. Complete coverage of CNH integration, installation procedures, competitive positioning, and system costs. A-Bots.com provides custom ground control station development, Slingshot API integration, and testing services for Raven systems.

Case IH Advanced Farming Systems: Complete AFS AccuGuide and AFS Connect Precision Agriculture Guide Case IH Advanced Farming Systems pioneered integrated precision agriculture since 1994 with factory-installed ground control solutions. This comprehensive guide examines AFS AccuGuide automated steering (2.5 cm RTK repeatability), AFS Pro 700 display (7-inch, $4,200-$5,200) and AFS Pro 1200 display (12.1-inch premium), AFS Connect cloud platform enabling real-time fleet monitoring and remote support, multiple receiver options (Pro 300/600/700), and correction services (WAAS free, RTX $1,800-$2,400, RTK $1,500-$3,000 annually). Real-world data shows 8-12% input reduction, 25-35% productivity gains, and 3-6 bushel yield increases. Complete coverage of CNH-Raven technology integration, AutoTrac Turn Automation, AFS Repeat controlled traffic technology, Machine Sync coordination, factory installation advantages, and system costs. A-Bots.com provides custom AFS Connect integration, mobile development, and testing services.

Leica Geosystems Machine Control: Complete iCON Excavate and iCON Grade 3D Construction Leica Geosystems leads construction machine control through Swiss precision engineering and Hexagon integration. This comprehensive guide examines Leica iCON excavate 3D excavator guidance (±20mm accuracy, $23,500-$37,000), Leica iCON grade automated blade control for dozers/graders ($30,000-$40,500), Leica iCON site office software for design management, and positioning technologies including iCG80/iGG4 Plus GNSS receivers with RTK corrections. Real-world performance data shows 30-50% productivity improvements, 22% reduced excavation cycle times, and ±15-20mm grade accuracy. Complete coverage of universal equipment compatibility with Caterpillar, Komatsu, Volvo, Hitachi excavators and dozers, installation procedures, SmartLink satellite corrections ($1,800-$2,400 annually), ConX cloud platform integration, and quality control verification. A-Bots.com provides custom ground control station development, ConX API integration, design automation tools, and testing services.

Caterpillar Command: Remote Control and Ground Station Software Caterpillar Command defines the global standard for remote-operation of heavy machinery, combining safety, precision, and connectivity. This in-depth article explains its architecture, performance data, and evolution toward hybrid autonomy. It also highlights how A-Bots.com builds custom software for ground control stations—creating operator interfaces, telemetry pipelines, and AI-ready analytics that integrate seamlessly with existing Caterpillar Command systems. For contractors and OEM partners seeking flexible, secure, and scalable remote-operation platforms, A-Bots.com delivers the software intelligence behind next-generation construction automation.

Top stories

Copyright © Alpha Systems LTD All rights reserved.

Made with ❤️ by A-BOTS