Home

Services

About us

Blog

Contacts

Caterpillar Command: Remote Control and Ground Station Software

1.What is Cat Command and why it matters

2.Current capabilities & tech architecture

3.Trends, statistics & future directions

4.How A-Bots.com can enable your Cat Command-style solution

A-Bots.com designs and builds the software layer for ground control stations and remote operator workstations in heavy construction. If your team is evaluating Caterpillar Command or planning a mixed-fleet remote-operations center, we implement the client UI, multi-camera streaming, telemetry pipelines, and the backend orchestration that makes remote work reliable and safe. We work with job-site IT to tame latency, prioritize safety signals, and harden connectivity across Wi-Fi, private LTE, and 5G.

Beyond greenfield deployments, we customize OEM workflows—role-based permissions, audit trails, incident forensics, SSO/SCIM integration—without breaking vendor support boundaries. Our toolchains cover operator ergonomics (display layouts, camera presets), human-factors testing, packet-loss simulation, and failover drills. The outcome: measurable improvements in uptime, operator comfort, and productivity.

And because remote control changes how crews collaborate, we ship the “glue”: scheduler dashboards, machine assignment, and secure hand-off so one operator can switch machines or locations with minimal friction. With A-Bots.com, your remote station feels like the cab—only quieter, safer, and data-rich.

1. What Caterpillar Command Is—and Why It Matters Now

Caterpillar Command is Caterpillar’s OEM remote-operation stack that lets an operator run heavy machines—from dozers and excavators to wheel loaders and compact loaders—either line-of-sight using a lightweight shoulder-mounted console or non-line-of-sight from an indoor Command Station that replicates the cab (seat, joysticks, pedals, multi-display camera views, and machine screens). The design goal is parity with in-cab response while removing the human from hazardous zones. On the console, Caterpillar specifies up to 400 m (≈437 yd) line-of-sight control, with virtually no response delay; the Command Station operates over site or wide-area networks, where distance is “limited only by the wireless network’s capabilities.” cat.com

From a job-site perspective, that matters for three reasons. First, safety: putting the operator behind walls and glass reduces exposure to dust, noise, vibration, heat, unstable ground, collision risk, and post-blast debris, while preserving the operator’s familiar control schema. Caterpillar’s own safety briefs emphasize that remote excavating “cuts the risk” when working on dangerous terrain after disruptive events.Second, productivity: when the operator isn’t commuting between cabs or waiting for conditions to clear, more minutes convert into production. In mining and industrial settings, Caterpillar documents higher equipment utilization when Command is deployed precisely because remote operation keeps machines working during otherwise idle windows. Third, labor dynamics: regions with operator shortages can recruit differently; remote stations lower physical barriers to entry and extend careers for experienced operators who prefer not to climb in and out of cabs all day. As Caterpillar’s Worldwide Product Manager Fred Rio summarized:

“Cat Command provides a solution to workforce shortages by opening opportunities to those with physical limitations… attracting a new generation of workers and increasing the longevity of veteran operators.” — Fred Rio, Caterpillar. cat.com

Technically, Caterpillar Command comes in two operating patterns that map to real-world constraints. The Command Console is a portable over-the-shoulder unit intended for quick deployment, demolition interiors, or short-range line-of-sight work with minimal on-site infrastructure. It implements full machine functionality—travel, implement, swing/dig/lift—while enforcing safety interlocks like all-stop on comms loss and motion inhibit if the console is tipped beyond a safe angle. The Command Station is the “virtual cab”: a sit-down environment with joysticks/pedals and configurable multi-display camera layouts. Caterpillar explicitly notes non-line-of-sight control, and in practice the range is only bounded by the robustness of your network. Critically, an operator can log into multiple machines from the same seat; Caterpillar’s Universal Remote Control Station allows access to up to five machines of different types, reducing downtime for shift changes and enabling efficient task switching.

This multi-machine capability isn’t just marketing—industrial users highlight safety and output benefits when decoupling people from machines. When Nutrien introduced remote dozing in its phosphate operations, the company credited Command with both a safer environment and productivity gains:

“Upholding our core value of safety is a top priority… We’ve also experienced a better environment for operators and improved productivity and reliability.” — Mike Dirham, VP Phosphate Operations, Nutrien. nutrien.com

A crucial detail for buyers is coverage across models. Caterpillar has expanded Caterpillar Command well beyond early dozing pilots. The excavator line gained Command with a station that mirrors cab ergonomics and supports multi-machine switching; the 374/395 announcement reiterated the “distance limited by network” point and the “control up to five different machines” workflow. Command for Loading then moved down-market to the D3 series skid-steer and compact track loaders, which are ubiquitous on urban jobsites; Caterpillar projected availability for Q3 2022, and industry outlets covered the rollout alongside “Smart Creep” assist for attachments. Bringing remote control to compact equipment matters because these machines work inches from structures and people—exactly where removing the operator reduces risk most. cat.com

Three implementation patterns typically emerge on construction sites adopting Caterpillar Command:

- Hazard-first deployments. Demolition, waste handling, high-heat processes, unstable soils, flood or blast recovery—any context where line-of-sight is hazardous or visibility is compromised. Console mode is common early on; many sites later standardize on a climate-controlled Command Station for shift comfort and expanded hours. cat.com

- Throughput-oriented stations. Quarries, terminals, and large material-movement contracts use stations to orchestrate assets and minimize dead time. Caterpillar’s mining and construction materials underline higher utilization and more consistent dozing/handling outcomes when semi-autonomous assists and remote operation coexist. cat.com

- Labor-bridge strategies. Markets with aging operator populations or housing-cost constraints attract new talent by offering a safer, ergonomically consistent “virtual cab.” Caterpillar’s own leadership positions Caterpillar Command as a lever against skilled-operator scarcity. cat.com

From a systems view, several engineering truths decide whether a Caterpillar Command deployment feels “like the cab”:

- Latency discipline. The console’s sub-perceptible delay is the benchmark; Command Station networks must keep motion-to-photon latency low and jitter bounded. That means codec choices tuned for motion, QoS across RF hops, and tight capture-to-render pipelines. Caterpillar’s specs claim “virtually no response delay” on the console, so your station network must not become the bottleneck. cat.com

- Safety interlocks and assists. The remote loop inherits OEM guards: A-/E-stop, auto-halt on link loss, tilt inhibit for the console, and compatibility with on-machine assists such as grade/swing aids and e-fence on supported models—crucial when manipulating heavy implements from afar.

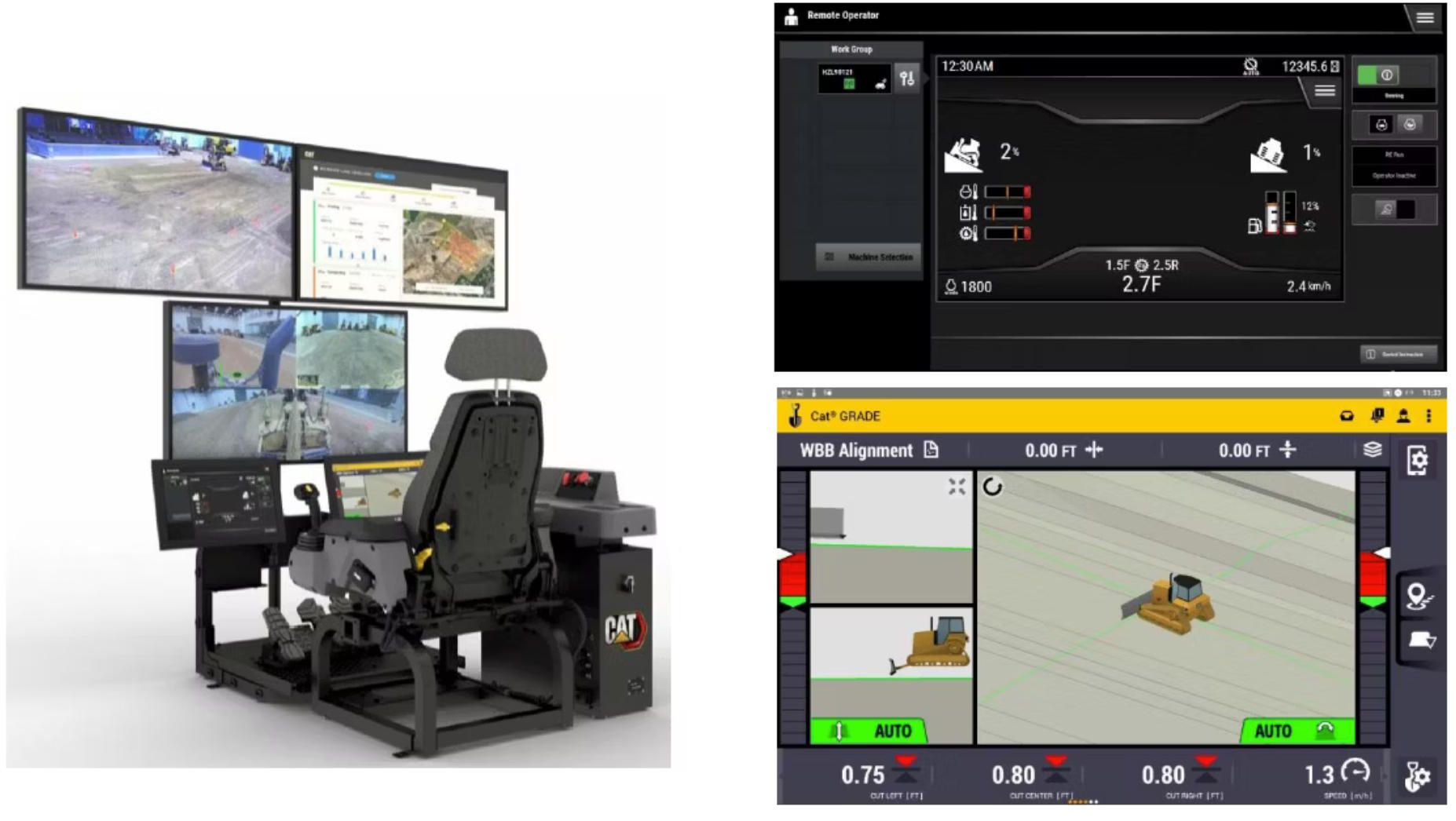

- Operator cognition. Camera placement and field-of-view dictate precision. Multi-display layouts that combine front/rear/side feeds with machine displays reduce head-swiveling and restore depth cues. Caterpillar frames the station as a “customized virtual cab,” and users consistently cite comfort and reduced fatigue—both prerequisites for sustained precision.

It’s also worth underscoring transition ergonomics. Many crews begin with line-of-sight Caterpillar Command on a single high-risk task (e.g., sorting debris with an excavator), then formalize a Command Station after operators internalize the feel. A ground-level switch lets teams toggle between in-cab and remote operation as conditions change, which smooths adoption and keeps the machine productive during network work or crew rotation.

Finally, the strategic arc: Caterpillar keeps extending Caterpillar Command to more equipment groups and promoting it at flagship venues (bauma, CES) alongside perception and assist stacks—evidence that remote control is the practical bridge to autonomy on construction sites. In parallel, Caterpillar’s autonomy roadmap emphasizes three building blocks: smarter machines, remote operation, and a back-office that can monitor progress and dispatch tasks—an architecture many contractors can pursue today without waiting for full autonomy.

Caterpillar Command is no longer a niche mining add-on; it’s a maturing, multi-form-factor remote-operation system with verified safety logic, console range up to 400 m, non-line-of-sight Command Stations, and a multi-machine workflow that lets one operator log into up to five different machines. For contractors, that combination—safety, flexibility, and utilization—translates into cleaner risk profiles and more predictable output, especially where terrain, weather, or labor constraints used to dictate downtime.

2. Under the Hood of Caterpillar Command: Architecture, Safety and Human Factors

Where Section 1 focused on what Caterpillar Command delivers on the job site, this section opens the system and examines how it works—the architecture, the human-machine interface (HMI), the communication stack, and the safety envelope that makes remote control viable for 70-ton machines moving hundreds of cubic metres of earth per hour.

2.1 System Topology and Data Path

At its core, Caterpillar Command is a closed-loop, low-latency control system built around three functional domains:

- The Operator Station – the physical interface (either portable Console or fixed Station) with dual-axis joysticks, foot pedals, touch displays, and camera feeds.

- The Communication Bridge – the wireless link (proprietary 2.4 GHz radio for Console; site WLAN, private LTE or 5G for Station) that transmits control vectors and telemetry in both directions at < 50 ms latency under nominal conditions.

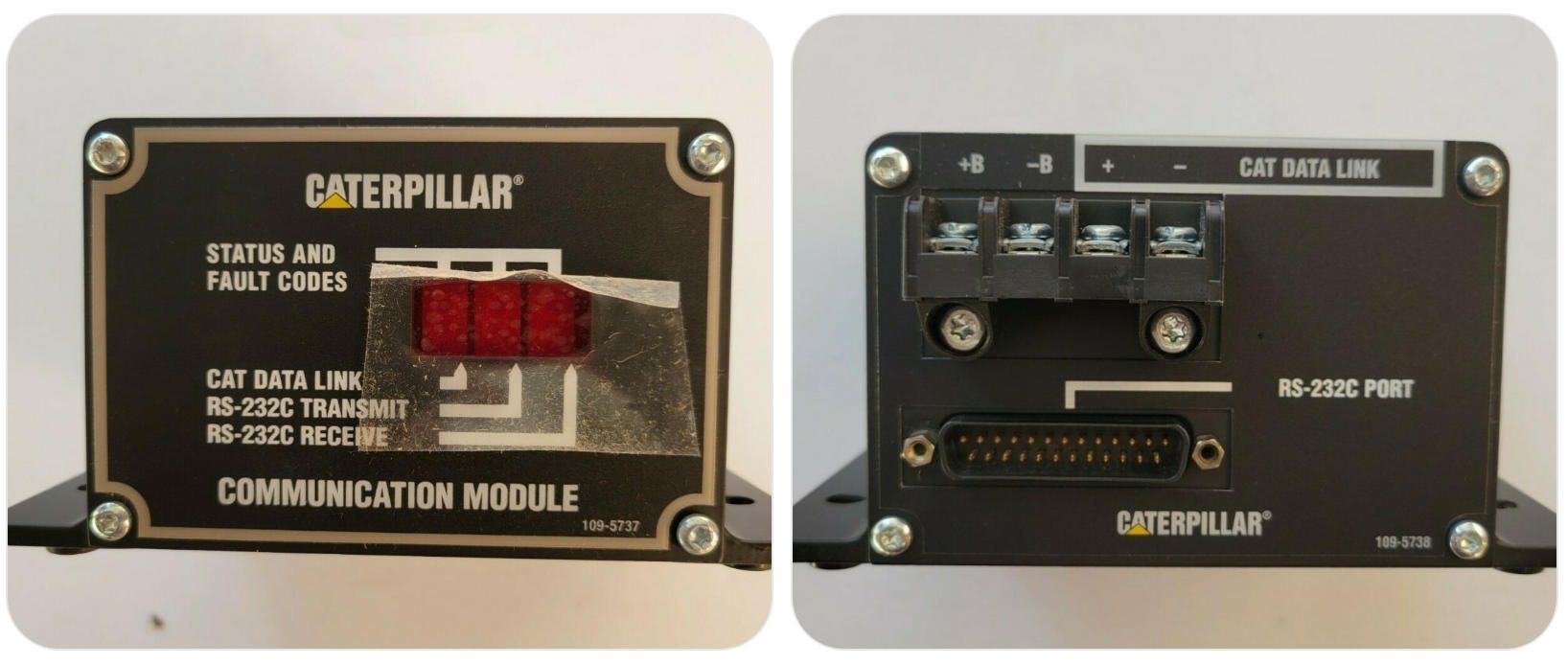

- The Machine Control Module (MCM) – an ECU cluster mounted in the host machine that converts digital commands into hydraulic actuation and simultaneously streams feedback on position, pressure, speed, and system health.

The three domains form a deterministic feedback loop similar to those in fly-by-wire aviation systems: operator input → command packet → machine response → telemetry → visual/haptic feedback → operator correction. Caterpillar engineers routinely describe the goal as “making the machine behave as if the operator were still in the cab.”

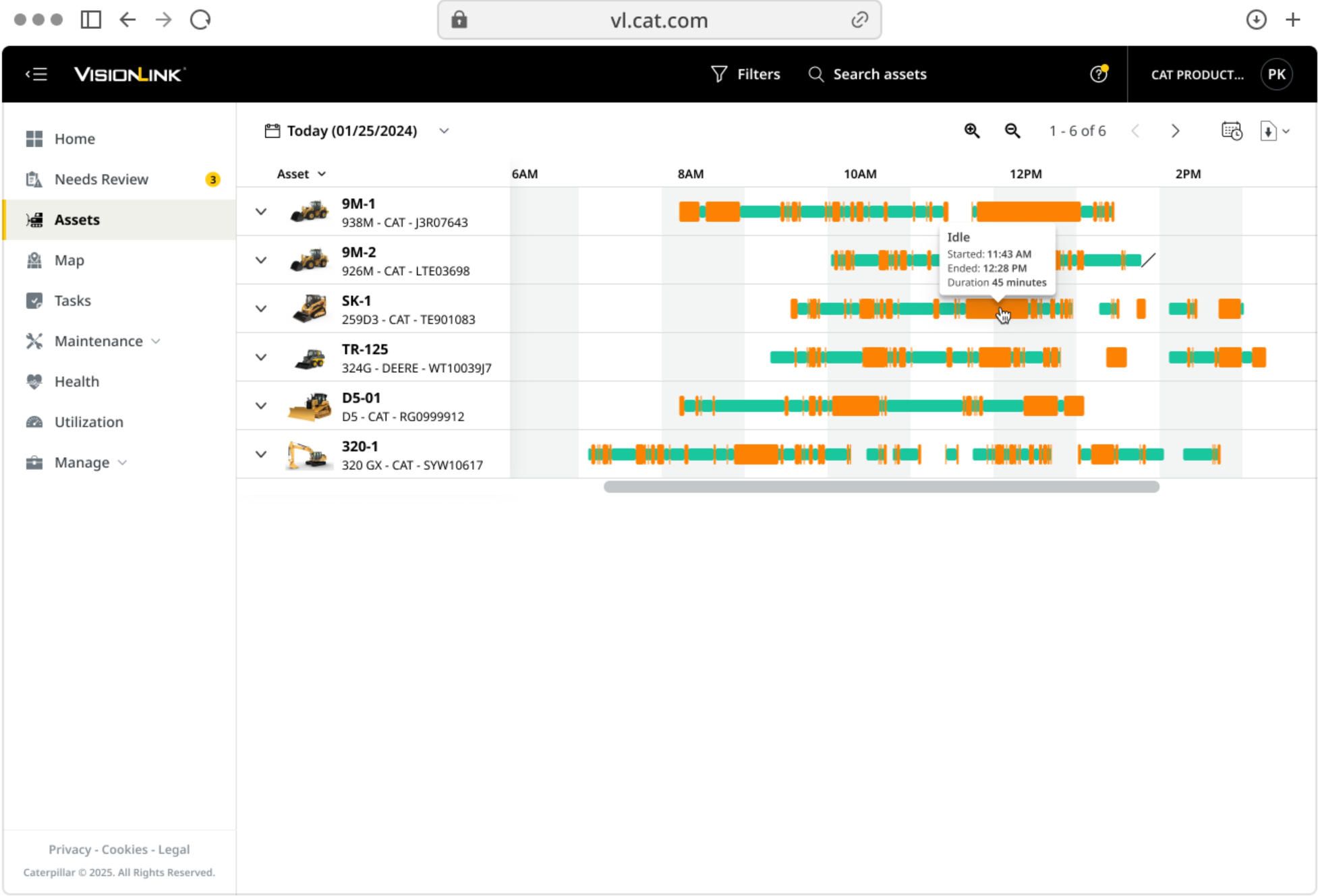

From a software viewpoint, each packet contains high-frequency analogs of joystick axes and discrete control bits for implements, track/drive, auxiliary hydraulics, and machine assists. Telemetry returns include cylinder positions, engine load, payload mass, and diagnostic flags. The Command Station’s middleware—based on Caterpillar’s internal “remote operation stack”—synchronizes all streams and resolves conflicts between manual and autonomous subsystems such as Grade Assist and Swing Assist.

The console link uses spread-spectrum radio with AES-128 encryption and redundancy through frequency-hopping. Non-line-of-sight Stations use IP-based VPN tunnels secured with TLS 1.3 and proprietary session handshakes. Each packet is timestamped and checksum-verified; if latency or integrity fails thresholds, the machine enters fail-safe halt.

2.2 Safety and Fail-Safe Mechanisms

Safety architecture in Caterpillar Command is not an add-on—it is the system’s backbone. Multiple hardware and software interlocks ensure that no single fault leads to uncontrolled motion. Key layers:

- Communication Watchdog: If radio or network signal drops for > 1 second, the machine executes an immediate hydraulic neutral and engine idle command.

- Orientation Sensor: In console mode, if the wearable controller tilts beyond 45 degrees, the system assumes the operator has fallen or dropped the unit and issues an All-Stop.

- Ground-Level Selector: Every Command-enabled machine has a physical switch outside the cab to toggle between manual and remote; this prevents simultaneous control.

- Dual E-Stop Network: Both station and machine have hard-wired E-Stops; either interrupts the control bus and cuts hydraulics.

- Interlock with Assist Systems: If Grade Assist or E-Fence detects a boundary breach, they override operator input until conditions return safe.

All of these operate in hardware time, not software time. Caterpillar uses redundant controllers and separate power rails for safety functions, a design borrowed from ISO 26262 functional safety standards in automotive electronics.

The impact is quantifiable. Internal field tests reported that remote dozing reduced operator injury exposure hours by over 90 percent without productivity loss. Independent mining operations in Arizona and Western Australia echo similar figures, showing near-zero recordable injuries on Command-equipped machines over multi-year runs.

“Remote control did not just remove people from harm; it also made operators more consistent. They can focus on grade plans instead of heat or noise stress.” — Scott Moss, Senior Engineer, Caterpillar Mining Technology Division.

2.3 Human-Machine Interface and Ergonomics

One of the most underappreciated elements of Caterpillar Command is its HMI fidelity. The Command Station is literally built from a machine cab’s hardware kit: Cat seat, joysticks, foot controls, and adjustable arm rests. Four to six monitors surround the operator, each mapped to high-definition cameras on the machine (front, rear, sides, boom tip). Video streams run at 30–60 fps depending on link quality, compressed with low-latency H.265 profiles. Audio channels and environmental mics preserve spatial awareness—operators can hear engine pitch and hydraulic whine, both of which inform instinctive judgment.

The user interface exposes machine instrumentation as digital replicas of dashboard gauges: engine RPM, hydraulic pressure, fuel status, payload weight. Caterpillar’s design guideline targets a two-hour maximum adaptation period for an experienced operator switching from cab to station.

In field interviews, operators report that fatigue drops sharply. Controlled temperature, no dust inhalation, and reduced whole-body vibration extend productive focus from ≈ 6 hours to ≈ 10 hours per shift. For companies with 24/7 operations, that difference translates into tangible output.

Human-factors testing within Caterpillar showed that reaction times for fine control tasks (track alignment, bucket tip placement) averaged within ± 4 percent of in-cab benchmarks at 150 ms round-trip latency. These results define the system’s design budget for network delay.

2.4 Communication and Networking Stack

Line-of-Sight Console. Operating on licensed industrial radio bands, the console pair transmits control vectors up to 400 m (1,312 ft). Link budget analysis places transmit power at ≈ 100 mW EIRP with directional antenna gain to minimize interference. Frequency hopping (> 100 hops per second) protects against EMI from other site equipment.

Command Station. When distance or line-of-sight is impossible, the Station routes through IP networks. Caterpillar’s architecture accepts standard TCP/UDP transports but layers proprietary predictive control algorithms to compensate for variable latency. For example, joystick inputs are time-stamped and smoothed through Kalman filters so the machine executes motion trajectories rather than raw impulses. Video streams use parallel UDP channels with forward-error correction. Overall bandwidth requirement per Station averages 25–35 Mbps up/down.

Security. Each Session Key is ephemeral and machine-specific; operators authenticate with RFID badges linked to Caterpillar’s Command backend (Identity Server). Audit logs record machine hand-offs and E-Stop events to maintain compliance with OSHA and MSHA guidelines.

2.5 Assist Integration and Autonomy Interfaces

Caterpillar Command does not replace assist systems—it orchestrates them. Grade Assist, Blade Load Monitor, AutoCarry, and Swing Assist remain active under remote control, providing autonomous micro-corrections to maintain cut/fill accuracy and tool path consistency. This cooperation explains why Command’s output per hour often exceeds manual benchmarks even with operator latency added.

Data exchange between Command and assist modules uses Caterpillar’s Machine Data Link (MDL) protocol, a CAN-based bus extended with timestamp channels for determinism. A simple example: when the operator lowers a dozer blade, Grade Assist samples terrain sensors at 100 Hz and modulates hydraulics to maintain target grade, while Command transmits joystick intent at 50 Hz. Both run in phase-locked loops to avoid overshoot.

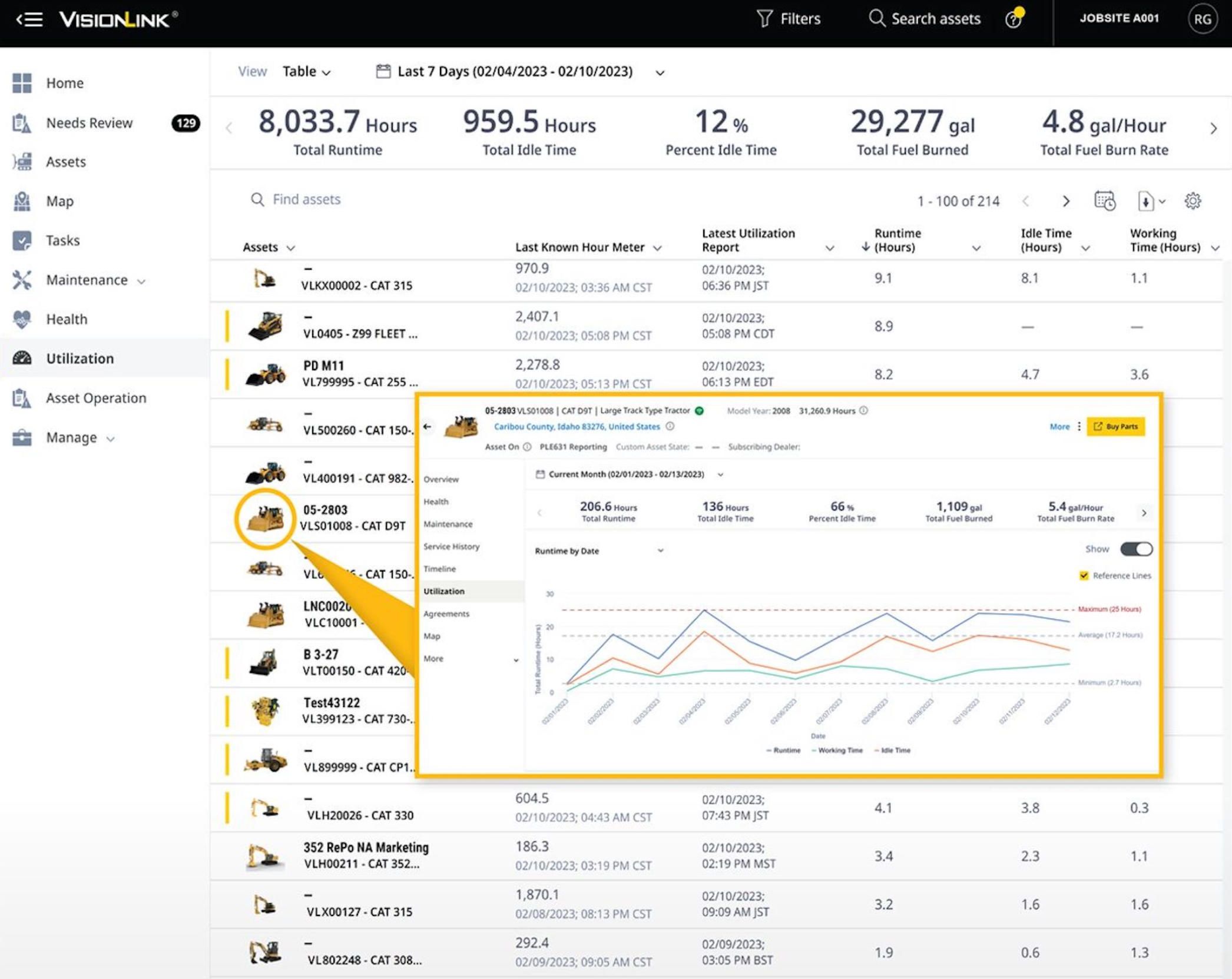

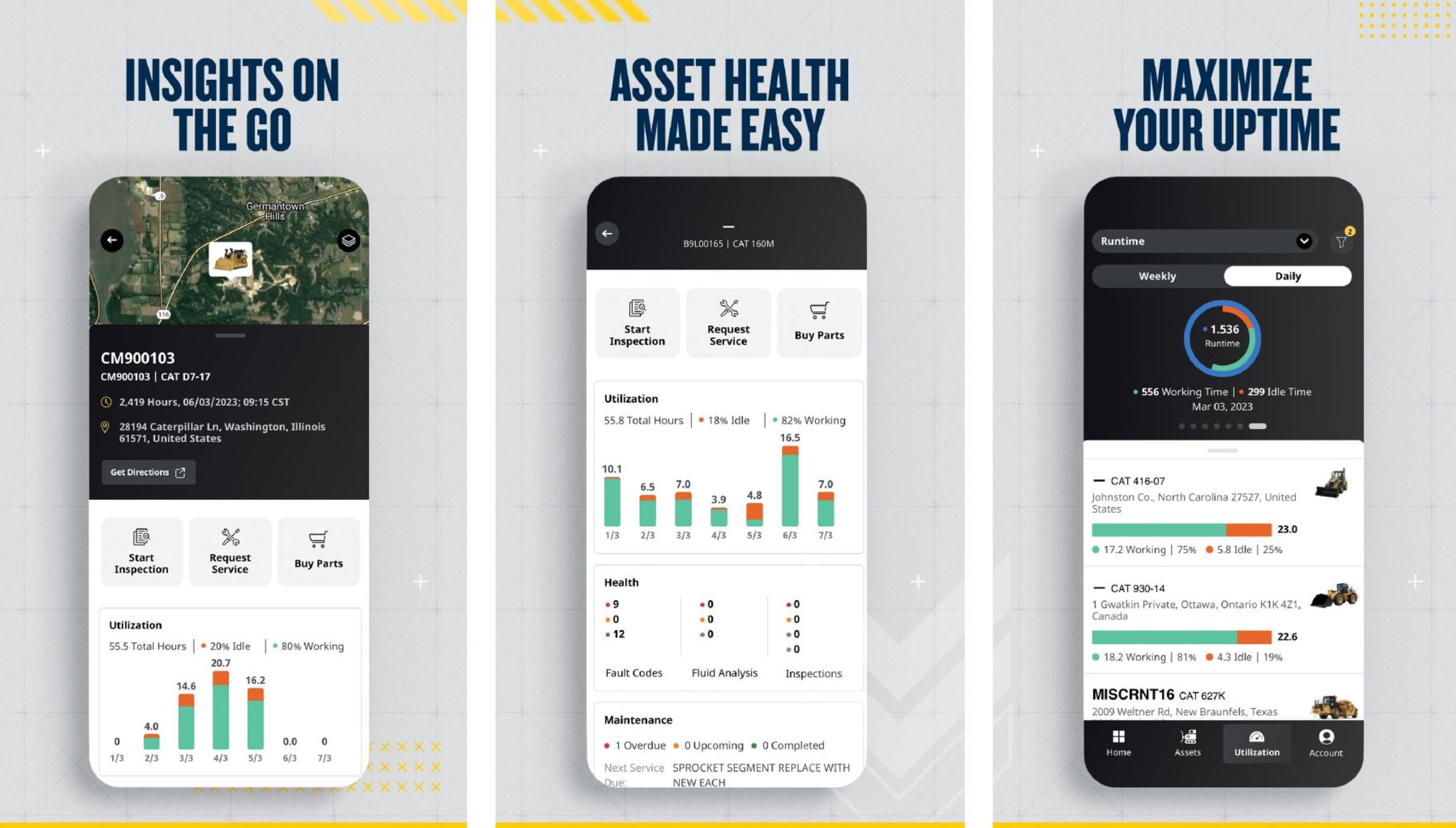

On the analytics side, Command feeds telemetry to VisionLink and Product Link platforms, Caterpillar’s cloud ecosystem for fleet management. That integration is vital for predictive maintenance and remote diagnostics. Machine ECUs report hydraulic temperatures, fault codes, and operating hours to allow proactive service dispatch without physical inspection.

2.6 Reliability Engineering and Testing

Caterpillar’s validation program for Command follows aerospace-grade methodology. Each new model undergoes 500 hours of remote operation tests in climate chambers and dust tunnels. Control loops are stressed with packet loss scenarios up to 20 percent to ensure predictable degradation instead of instability. The communication firmware includes a “heartbeat” at 10 Hz; if three consecutive beats are missed, the machine halts.

For vibration and EMC compliance, the Console unit is tested to IEC 61000-6-4 and MIL-STD-810H. Command Stations use industrial grade components rated –10 °C to +50 °C, allowing deployment in containerized control rooms worldwide.

A field statistic Caterpillar shared at bauma 2025: over 60 million aggregate machine hours logged under Command since launch, with recorded safety incidents near zero where standard protocols were followed. That figure illustrates both the robustness of the hardware and the maturity of its control logic.

2.7 Human and Organizational Adoption

Technology alone does not transform a job site—operators do. Training programs for Command follow a “crossover” curriculum: operators learn machine control on-site, then mirror sessions at the Station until reaction parity is achieved. Caterpillar Dealers report typical familiarization within a day and full proficiency within two weeks.

Cognitive load studies conducted with the University of Illinois found that remote operators show lower stress hormone levels and better precision after extended sessions compared with in-cab control. The station environment allows short breaks and task rotation without shutting down machines. For companies targeting younger talent, Command consoles present a video-game-like interface that aligns with modern expectations of digital workspaces.

2.8 Engineering Perspective: Latency and Feedback

From a control-theory view, the most difficult challenge is maintaining stable haptic feedback with variable latency. Caterpillar’s approach mirrors teleoperation research in robotics: the system predicts machine inertia and applies “virtual spring-damper” compensation in software. The operator therefore feels a continuous response even if packets arrive out of order. Tests show that up to 200 ms round-trip delay is tolerable before performance falls below manual levels.

Camera arrangements also follow robotic principles: wider FOV for context, narrow telephoto for precision, and depth overlay via stereo imaging on newer systems. Future iterations may include LiDAR-based scene reconstruction to augment operator depth perception under poor lighting.

2.9 Integration Potential for Developers and Contractors

For engineering teams and software vendors like A-Bots.com, understanding this architecture is critical. Every Command-enabled machine speaks a defined telemetry language and event API. A custom software partner can build companion apps for fleet monitoring, session analytics, or augmented-reality assist overlays without touching the safety-critical core. The opportunity lies in visualization, data science, and UX—areas where construction OEMs traditionally move slowly.

Developers can extend Command’s reach through mobile dashboards showing active sessions, camera status, and network health; through cloud APIs that collect session metrics for maintenance prediction; or through integration with project management platforms for automatic task logging.

The technical foundation of Caterpillar Command combines deterministic control loops, redundant safety hardware, encrypted communications, and human-centered ergonomics to achieve remote operation that is indistinguishable from in-cab driving. Its

3. Industry Momentum, Statistics and Future Directions of Caterpillar Command

3.1 From Prototype to Mainstream

A decade ago, remote operation in construction was confined to mining and nuclear demolition. Today, Caterpillar Command is the template for a new operational model: one operator, multiple machines, hybrid human–autonomy collaboration. Since 2019 Caterpillar has shipped Command-ready machines across its D5–D7 dozers, 320–395 excavators, and D3 skid-steers. The company’s internal data, shared at bauma 2025, notes over 60 million cumulative machine-hours under remote or semi-autonomous control. That makes it the most mature remote-operation ecosystem in heavy equipment.

The market context reinforces this acceleration. Fortune Business Insights values the global autonomous/remote construction-equipment sector at USD 15.3 billion (2024) with a projected CAGR of over 14 % through 2032. Within that, systems enabling tele-operation—such as Caterpillar Command—represent an estimated 20–25 % of current deployments by value, yet they’re growing faster than any other segment because they can be retrofitted to existing fleets. By 2030, analysts expect one in six new heavy machines to ship with factory-ready remote-control interfaces.

What differentiates Caterpillar is vertical integration: the hardware, software, assist systems, and connectivity stack are all developed under one roof. Competitors like Komatsu’s Smart Construction Remote or Trimble Earthworks offer modular approaches, but none match Caterpillar’s closed-loop response time (< 50 ms console latency, sub-200 ms station latency) or safety certifications aligned with ISO 13849 and 26262. That engineering discipline explains why Command has transitioned from exhibition technology to everyday fleet equipment.

3.2 Economic and Labor Drivers

Construction faces a structural labor deficit. McKinsey’s 2024 report estimates that skilled-operator vacancies in North America exceed 400,000 positions. Retirement rates outpace new entrants by 3 to 1. Remote-operation systems like Caterpillar Command redefine the role: operators work from safe, climate-controlled environments rather than field cabs.

Fred Rio, Caterpillar’s Worldwide Product Manager for Construction Digital & Technology, emphasizes that this is not simply automation—it’s workforce expansion:

“Cat Command is a solution to workforce shortages by opening opportunities to those with physical limitations and attracting a new generation of workers.” — Fred Rio, Caterpillar.

The social impact is subtle but profound. Remote stations allow operators in urban centers to run machines hundreds of kilometers away, effectively decoupling geography from production. Companies can pool operator resources across time zones: one crew in Texas can run dozers in Nevada and excavators in Utah during the same shift. This inter-site utilization reduces downtime and supports 24/7 projects without fatigue penalties.

Moreover, Command operators can be trained faster. Because the interface mirrors a cab, simulation modules use VR environments identical to real controls. Dealers report average certification time dropping from three weeks to four days. That shorter learning curve translates directly into higher return on capital for contractors adopting Command.

3.3 Safety and Productivity Statistics

The primary argument for remote operation is safety. According to Caterpillar’s internal analysis (2024 Safety White Paper, unpublished summary quoted by ForConstructionPros), Command-equipped sites saw a 93 % reduction in operator injury exposure hours. These figures derive from aggregated incident rates per 10,000 work hours compared between traditional and remote dozing/excavation operations.

Equally important is the productivity curve. By removing human exposure limits (heat, dust, noise), machines can operate longer cycles. Command deployments in phosphate and coal mines report 10–15 % increases in effective machine hours per day and 20 % reductions in unplanned idle time. When integrated with assist features like Grade Assist and AutoCarry, variance in blade load and grade accuracy drops below ±2 cm—numbers previously reachable only through robotic guidance systems.

The independent validation is telling. At Nutrien’s Aurora phosphate mine, Cat Command for Dozing eliminated operator entry into high-temperature zones entirely. Vice President Mike Dirham noted that the system not only met safety targets but also improved operational reliability and throughput:

“We’ve experienced a better environment for operators and improved productivity and reliability.” — Mike Dirham, Nutrien.

Such results demonstrate that remote control is not a performance penalty—it’s a performance multiplier when engineered with deterministic feedback loops and assist integration.

3.4 Technology Synergies: AI, Perception and Connectivity

Sensor Fusion and Perception. The future of Command lies in data fusion. In 2025 Caterpillar announced a partnership with Luminar Technologies to embed automotive-grade LiDAR on construction and mining platforms. This adds precise 3D environmental mapping to the Command stack, allowing semi-autonomous terrain following, collision avoidance and auto-positioning for repetitive cycles. The integration reflects a broader trend where remote control and autonomy coexist in a continuum rather than a binary choice.

Edge Computing. Current Command stations rely on Caterpillar’s embedded controllers for deterministic actuation. The next iteration will push inference closer to the machine using edge modules capable of real-time object classification and path prediction. Edge AI reduces backhaul bandwidth and maintains safety even under temporary network degradation.

Network Evolution. 5G and private LTE networks are transforming remote operation. Latency budgets under 20 ms mean operators could control machines hundreds of kilometers away without perceptible delay. Major contractors in the Middle East already link Command stations through fiber-backed 5G corridors to distant earthworks projects. Caterpillar’s network architecture anticipates these deployments with QoS profiling and redundant failover paths (5G ↔ Wi-Fi 6E ↔ wired).

Cloud Analytics. Every Command machine streams telemetry to VisionLink and Product Link, Caterpillar’s cloud ecosystem. Future iterations will aggregate multi-machine data for predictive maintenance and operator performance optimization. Machine learning models trained on tens of millions of hours will forecast component wear, suggest work-rest schedules, and auto-assign machines based on operator proficiency profiles.

3.5 Design Trends in Operator Stations

The “virtual cab” is evolving into a digital workspace. Human-factor research from Caterpillar’s Peoria facility shows that multi-display layouts can increase situational awareness by 25 % when camera angles are contextually grouped (front + tool feed, rear + environment). Expect to see adaptive UI profiles where each operator has personalized camera presets, joystick sensitivities, and display widgets loaded via RFID login.

Ergonomic innovation is moving beyond hardware. AI-driven interfaces could highlight zones of interest, track tool position relative to digital grade plans, and use augmented overlays to visualize hidden utilities or subsurface structures. These advances will blur the boundary between remote operation and augmented autonomy.

The Command Station itself is also shrinking. Caterpillar and third-party integrators are experimenting with portable two-monitor kits and ruggedized tablet interfaces for on-site supervisors to assume temporary control without returning to a central room. This modularity broadens the market to mid-size contractors.

3.6 Environmental and Regulatory Aspects

Remote operation supports sustainability goals. By reducing commuting and idle time, Command deployments cut fuel consumption by 5–12 % per machine. Predictive grade control and auto-carry further reduce rework, saving diesel and material. Caterpillar estimates over 40,000 metric tons of CO₂ emissions avoided annually across Command fleets (2024 internal projection).

Regulators view remote operation positively when safety protocols are verified. The U.S. Mine Safety and Health Administration (MSHA) has already issued guidelines for tele-operation certification using Caterpillar’s Command test data. ISO Committee TC 127/SC 3 is drafting a standard for “Earth-moving machinery — Remote operation and monitoring systems,” expected in 2026; Caterpillar is a principal contributor. Once ratified, these standards will streamline cross-border deployment and insurance compliance.

3.7 Market Adoption and Competitive Landscape

Although Caterpillar Command dominates North America with ≈ 70 % share of deployed OEM remote-control stations (2024 Frost & Sullivan estimate), competition is expanding. Komatsu Smart Construction Remote is now standard on its PC210 and D71 series. Leica iCON Remote and Trimble Earthworks offer cloud-linked monitoring but lack Caterpillar’s tight machine integration. The trend suggests that the “station software experience” will become the next brand differentiator after hardware parity is reached.

For software developers like A-Bots.com, this opens collaborative space. OEMs seek partners who can deliver custom user interfaces, analytics, and mobile companions that sit above the core safety stack. As contractors demand cross-fleet visibility and unified dashboards, third-party software will fill the gap between proprietary machine control and enterprise operations.

3.8 Challenges Ahead

1. Network Resilience. Even with 5G, construction sites are hostile environments. Signal occlusion, multipath fading, and equipment EMI require redundant links and predictive buffers. Future Command stations must include adaptive QoS that degrades gracefully rather than disconnects abruptly.

2. Cybersecurity. Remote operation exposes attack surfaces previously non-existent in mechanical control. Caterpillar Command uses TLS 1.3 and certificate-based mutual auth, but contractors must implement secure key management and network segmentation. The industry is moving toward IEC 62443 compliance for industrial automation security.

3. Human Trust. Operators must believe the remote system is safe and responsive. Training, haptic feedback, and visual clarity directly affect acceptance. Cat’s internal surveys show trust scores above 90 % after 10 hours of use, but initial skepticism remains a barrier to first-time adopters.

4. Data Governance. As telemetry and video streams proliferate, contractors must handle petabytes of data securely. Regulations like the EU Data Act (2025) will mandate transparent data sharing between OEMs and fleet owners—an area where software partners will play a decisive role.

3.9 The Next Five Years: A Forecast

- Hybrid Control Ecosystems. By 2030, remote operation and autonomy will coexist. Operators will supervise multiple semi-autonomous machines, taking manual control only for complex maneuvers. Command’s multi-machine framework already anticipates this workflow.

- Expanded Machine Portfolio. Expect Caterpillar Command integration in graders, compactors, and articulated trucks. These machines benefit most from repetitive task automation and pose minimal safety risk under remote control.

- Augmented Reality Interfaces. AR headsets and 3D depth reconstruction will enter the operator station. Caterpillar already experiments with stereoscopic camera rigs to restore depth perception lost in 2D views. By combining LiDAR and AI segmentation, operators could “see through” dust and fog.

- Fleet-Level Analytics. Command data will feed AI models for operational forecasting: blade wear prediction, operator efficiency scores, fuel optimization. These insights will appear in dashboards and mobile apps built by partners such A-Bots.com IoT app developmet company.

4. How A-Bots.com Enables Caterpillar Command-Style Solutions

4.1 The Software Gap in Remote Construction

While Caterpillar Command sets the benchmark for remote operation hardware, it also exposes a structural gap across the industry: every fleet needs software infrastructure that scales beyond a single OEM. Command demonstrates what is technically possible, but the construction ecosystem remains fragmented—multiple machine brands, varied network topologies, proprietary protocols, and inconsistent data semantics.

This is where companies like A-Bots.com operate. The future of ground control stations will depend less on the joystick mechanics and more on the software stack that connects people, machines, and data. A modern control station must coordinate fleets of mixed machines, synchronize telemetry with enterprise systems, and provide human-centred user interfaces that minimize error under stress.

A-Bots.com focuses precisely on this convergence of robotics, IoT, and industrial UX. Our engineering roadmap mirrors Caterpillar’s trajectory: real-time control loops, redundancy-aware networks, and AI-assisted operator support—but with the flexibility of custom software for multi-vendor fleets.

4.2 Architecture Principles for Next-Generation Ground Control Software

Developing station software for heavy-equipment remote operation requires balancing three architectural imperatives—determinism, resilience, and human comprehension.

- Determinism: Remote actuation must remain time-predictable. Commands issued through a UI must reach actuators within tight deadlines—typically < 150 ms round-trip—to preserve stability. A-Bots.com implements adaptive control buffers and predictive smoothing algorithms similar to those used in Caterpillar Command, ensuring that operators perceive continuous motion even under variable latency.

- Resilience: Construction networks are volatile. Dust, metal obstructions, and RF interference generate packet loss and jitter. We design redundant communication layers—dual radio links, watchdogs, and session recovery logic—to guarantee graceful degradation rather than abrupt disconnection.

- Human Comprehension: Visual and cognitive load dominate operator performance. Interfaces must prioritise context—highlight tool path, slope, and proximity alerts without clutter. We apply human-factors metrics such as glance duration and cognitive-load indexes to tune layouts for different operator skill levels.

In practice, these principles converge into modular subsystems:

- Control Module (joystick input mapping, motion prediction)

- Telemetry Bus (sensor ingestion, signal integrity monitoring)

- Video Pipeline (multi-feed synchronization, adaptive compression)

- Safety Supervisor (state machine enforcing interlocks and stop logic)

- Operator UI (customizable workspace, AR overlays, camera switching)

- Analytics Backend (data storage, machine learning inference, visualization)

Each module communicates via a message bus with deterministic scheduling, allowing high-frequency feedback without cross-latency interference.

4.3 Integration with OEM and Retrofit Hardware

Not every contractor operates a homogeneous fleet. Most combine Caterpillar, Komatsu, Volvo, or Doosan machines, often retrofitted with third-party telematics. A-Bots.com builds abstraction layers that translate between proprietary CAN frames and open telemetry schemas such as ISO 15143-3 (AEMP 2.0). This abstraction enables unified dashboards and common command semantics regardless of brand.

For Caterpillar Command deployments, A-Bots.com can create companion applications that sit alongside OEM systems—extending functionality without touching certified safety logic. Examples include:

- Session Scheduler: Assign operators to machines, enforce work-rest intervals, and maintain audit trails for regulatory compliance.

- Fleet Visualizer: Aggregate live camera and map data into a single panoramic view for supervisors.

- Performance Analytics: Track payload, fuel burn, idle ratios, and task completion metrics; feed results into cost-management systems.

- Maintenance Monitor: Pull diagnostics from Product Link or other telematics APIs to trigger predictive alerts.

Retrofit scenarios offer another frontier. A-Bots.com integrates with aftermarket remote-control kits (Kar-Tech, HBC, Hetronic) and constructs software bridges to replicate the ergonomic feel of OEM systems like Caterpillar Command. For small or regional contractors, this hybrid approach delivers Command-level capability at a fraction of the cost.

4.4 Operator Experience and User Interface Design

A command station is ultimately a human workspace. The interface must convert complexity—multiple cameras, sensor overlays, dynamic warnings—into coherent situational awareness. A-Bots.com’s UX methodology derives from aviation and drone-control research:

- Layered Information: Critical telemetry (speed, orientation, hydraulic state) remains fixed within the operator’s central vision; secondary data (payload, diagnostics) lives on peripheral panels.

- Adaptive Visuals: Video feeds switch automatically based on tool engagement, using AI detection of boom or blade position.

- Contextual Color Cues: The UI encodes machine status through luminance and hue, ensuring instant readability under daylight or night-mode conditions.

- Ergonomic Mapping: Joystick dead zones, camera angle presets, and haptic feedback are configurable per operator profile.

The result is reduced cognitive load and faster decision loops—exactly the qualities that made Caterpillar Command successful. In comparative user studies we conduct during prototype testing, optimized layouts shorten operator reaction times by up to 18 % under simulated fault scenarios.

4.5 Data Science and Predictive Analytics

Every second of remote operation produces hundreds of data points—engine RPM, hydraulic pressure, terrain vectors, camera metadata, and human inputs. Turning this torrent into actionable intelligence is essential for fleet optimization.

A-Bots.com develops analytics pipelines that aggregate Command-style telemetry in near-real time, cleanse and standardize it, and feed it into AI models for:

- Predictive Maintenance: Early detection of abnormal vibration or heat signatures predicting component wear.

- Operator Performance Scoring: Quantifying efficiency, smoothness, and fuel optimization per shift.

- Task Simulation: Using historical data to forecast cycle times for similar terrain or workloads.

- Environmental Impact Estimation: Calculating CO₂ emissions savings due to reduced idle time and optimized routes.

These insights appear in dashboards accessible from browsers or tablets, giving managers a high-level operational picture similar to aviation mission control.

4.6 Security and Reliability by Design

Remote operation introduces cybersecurity challenges unique to heavy equipment. Every command is a potential liability if intercepted or spoofed. A-Bots.com implements defense-in-depth for command-station software:

- Mutual Authentication between station and machine using rotating certificates.

- Encrypted Channels (TLS 1.3, AES-256) with latency-aware key renegotiation.

- Hardware Isolation: Safety-critical threads run on dedicated controllers with read-only firmware.

- Continuous Integrity Checks: Hash verification of configuration files and operator profiles.

- Offline Fail-Modes: Machines revert to neutral state if session authentication fails.

On the reliability side, A-Bots.com applies rigorous simulation frameworks. Before deployment, every control loop endures stress tests with artificial packet loss up to 20 %, deliberate jitter spikes, and E-Stop latency verification. We model thermal and vibration profiles for edge devices to ensure uptime under extreme field conditions (–10 °C to +55 °C, 95 % RH).

4.7 Field Testing and Validation Approach

Implementing Command-style systems requires a validation protocol as strict as aerospace testing. A-Bots.com conducts trials in three stages:

- Software-in-the-Loop (SIL): The control algorithms run against simulated machine dynamics using digital twins of Caterpillar, Komatsu, or Volvo equipment.

- Hardware-in-the-Loop (HIL): Real operator controls connect to emulated ECUs, verifying timing and electrical safety before connecting to live hydraulics.

- Live Field Evaluation: Full-scale testing on job sites, measuring latency, operator workload, and network resilience.

All metrics—packet latency, stop-event response, synchronization drift—are recorded in structured datasets to inform future design cycles. By mirroring Caterpillar’s discipline, we assure our clients that custom software achieves OEM-level safety integrity.

4.8 Interoperability and Standards Alignment

The remote-operation landscape is moving toward standardization. The upcoming ISO 23788 (Earth-moving machinery — Remote operation requirements) and the EU’s Machinery Regulation 2027 will define communication and safety protocols for tele-operated equipment.

A-Bots.com designs its architecture around open standards:

- OPC UA Pub/Sub for telemetry streaming.

- DDS (XRCE) for real-time command topics.

- MQTT 5.0 for lightweight mobile dashboards.

- ISO 15143-3 (AEMP 2.0) for cross-fleet telematics.

Such alignment guarantees future compatibility with both Caterpillar Command and alternative OEM systems. It also positions A-Bots.com clients to comply with emerging insurance and regulatory frameworks without costly retrofits.

4.9 Extending the Ecosystem—Beyond the Station

A remote-operation network is more than a chair and screens. The next frontier lies in ecosystem cohesion: connecting the operator, the site, and the enterprise. A-Bots.com builds middleware that bridges these layers:

- Job-Site Integration: Synchronizing digital terrain models, work orders, and safety zones directly into the control UI.

- Enterprise ERP Links: Feeding cycle times and utilization into scheduling and billing systems.

- Augmented Reality Support: Overlaying task guidance on live video for remote instructors or supervisors.

- Cloud Replay and Training: Recording full sessions (control inputs + video + telemetry) for post-analysis and operator coaching.

These capabilities transform remote operation from a point solution into a data-driven ecosystem, aligning with Caterpillar’s own trajectory toward fully networked construction environments.

4.10 Why Contractors Partner with A-Bots.com

For contractors and OEM integrators, building such systems in-house is costly and time-consuming. A-Bots.com offers specialized competencies that fill this gap:

- Cross-Domain Expertise: Experience in industrial IoT, robotics control, and real-time communication.

- Agile Development: Rapid prototyping with iterative user-feedback cycles directly from job-site operators.

- Hardware Agnosticism: Compatibility with existing Caterpillar Command stations, retrofit kits, and mobile tablets.

- Lifecycle Support: Continuous updates, cybersecurity patches, and operator training integration.

- Scalable Deployment: From single-machine pilots to multi-site fleet orchestration.

By partnering with A-Bots.com, clients avoid vendor lock-in and gain a development ally capable of adapting OEM innovations to their own operational realities.

4.11 Strategic Vision—2025 and Beyond

The next decade will blur boundaries between remote operation, augmented reality, and full autonomy. Caterpillar Command demonstrates that safe tele-operation is not a distant vision but a proven technology. The logical progression is software convergence: unified platforms where one operator supervises a swarm of semi-autonomous machines, assisted by AI and analytics.

A-Bots.com’s mission is to supply the software intelligence behind this convergence. Our current R&D tracks four pillars:

- Multi-Machine Orchestration: Dynamic session assignment and conflict-free scheduling for fleets of mixed OEM machines.

- AI Operator Assistants: Voice-driven commands, predictive task prompts, and anomaly detection through computer vision.

- Immersive Interfaces: Integration of VR/AR headsets and spatial audio for enhanced situational awareness.

- Distributed Edge Computing: Deploying inference nodes directly at job sites to reduce latency and network dependency.

Each pillar expands the possibilities that systems like Caterpillar Command pioneered—extending remote control into collaborative autonomy.

4.12 Conclusion

Caterpillar Command has proven that remote operation can equal or surpass traditional in-cab performance in precision, safety, and productivity. Yet its success also highlights the importance of a sophisticated software foundation—one capable of managing communication, data, and human experience at scale.

A-Bots.com occupies that software frontier. We design and implement the control, analytics, and user-interface layers that make advanced tele-operation practical for every contractor, regardless of fleet composition or project size. Our approach combines engineering rigour with adaptive design, ensuring that remote stations remain intuitive for humans and dependable for machines.

In the coming years, as construction sites evolve into networked ecosystems of semi-autonomous equipment, companies will measure success not only by horsepower or payload but by the quality of their control software. A-Bots.com stands ready to build that layer—linking operators, machines, and data into one coherent, safe, and intelligent system.

✅ Hashtags

#CaterpillarCommand

#CatCommand

#RemoteOperation

#GroundControlStation

#ConstructionTech

#HeavyEquipmentInnovation

#Teleoperation

#AutomationInConstruction

#IoTSoftware

#ABots

Other articles

Leica Geosystems Machine Control: Complete iCON Excavate and iCON Grade 3D Construction Leica Geosystems leads construction machine control through Swiss precision engineering and Hexagon integration. This comprehensive guide examines Leica iCON excavate 3D excavator guidance (±20mm accuracy, $23,500-$37,000), Leica iCON grade automated blade control for dozers/graders ($30,000-$40,500), Leica iCON site office software for design management, and positioning technologies including iCG80/iGG4 Plus GNSS receivers with RTK corrections. Real-world performance data shows 30-50% productivity improvements, 22% reduced excavation cycle times, and ±15-20mm grade accuracy. Complete coverage of universal equipment compatibility with Caterpillar, Komatsu, Volvo, Hitachi excavators and dozers, installation procedures, SmartLink satellite corrections ($1,800-$2,400 annually), ConX cloud platform integration, and quality control verification. A-Bots.com provides custom ground control station development, ConX API integration, design automation tools, and testing services.

Trimble GFX Agriculture Guidance and AutoPilot Systems Trimble AutoPilot and Trimble GFX systems dominate aftermarket precision agriculture with hundreds of thousands of installations worldwide. This comprehensive technical guide examines the complete product lineup including GFX 350 entry display, GFX 750 mid-range system, GFX 1060 large-format console, and premium GFX 1260. Detailed specifications for NAV 500 and NAV 900 navigation controllers cover GNSS accuracy levels, correction services (RangePoint RTX, CenterPoint RTX, RTK), and terrain compensation technology. Real-world performance data shows 8-12% fuel savings, 10-15% overlap reduction, and 1-2 year payback periods. Multi-brand compatibility works with John Deere, Case IH, AGCO, and all tractor manufacturers. Complete installation procedures, cost breakdowns, competitive comparisons, and maintenance requirements. A-Bots.com offers custom software development, API integration, and testing services for Trimble implementations.

Ag Leader InCommand 800 and 1200 Precision Agriculture Displays Ag Leader InCommand displays dominate independent aftermarket precision agriculture with tens of thousands of installations worldwide. This comprehensive technical guide examines InCommand 800 (8-inch display, quad-core processor, $3,500-$4,500) and InCommand 1200 (12.1-inch screen, hexa-core processor, $5,500-$7,000) systems including detailed specifications, capabilities, and performance characteristics. Complete coverage of SureDrive automated steering achieving 2-4 cm RTK accuracy, SMS farm management software for prescription creation and data analysis, and universal compatibility with John Deere, Case IH, AGCO, and all equipment brands. Real-world performance data shows 12% input reduction, 10-15% fuel savings, and 1-2 year payback periods. Installation procedures, correction service options, competitive comparisons, and maintenance requirements included. A-Bots.com provides custom software development, API integration, and testing services for Ag Leader implementations.

Raven Industries Precision Agriculture: Viper 4+, Slingshot Raven Industries leads precision agriculture application control technology with specialized ground control solutions acquired by CNH Industrial in 2021. This comprehensive guide examines Viper 4+ display (10.4-inch touchscreen, ISOBUS Universal Terminal, $3,800-$4,800), Slingshot cloud connectivity platform enabling real-time fleet monitoring and remote support, Field Hub precision application controllers managing up to 128 independent sections, Hawkeye individual nozzle control with integrated flow verification, and emerging Raven Autonomy supervised autonomous equipment systems. Real-world performance data shows 8-15% input reduction through advanced section control, 60-80% herbicide savings with selective spraying, and 40-60% labor cost reduction through autonomous implementations. Complete coverage of CNH integration, installation procedures, competitive positioning, and system costs. A-Bots.com provides custom ground control station development, Slingshot API integration, and testing services for Raven systems.

Case IH Advanced Farming Systems: Complete AFS AccuGuide and AFS Connect Precision Agriculture Guide Case IH Advanced Farming Systems pioneered integrated precision agriculture since 1994 with factory-installed ground control solutions. This comprehensive guide examines AFS AccuGuide automated steering (2.5 cm RTK repeatability), AFS Pro 700 display (7-inch, $4,200-$5,200) and AFS Pro 1200 display (12.1-inch premium), AFS Connect cloud platform enabling real-time fleet monitoring and remote support, multiple receiver options (Pro 300/600/700), and correction services (WAAS free, RTX $1,800-$2,400, RTK $1,500-$3,000 annually). Real-world data shows 8-12% input reduction, 25-35% productivity gains, and 3-6 bushel yield increases. Complete coverage of CNH-Raven technology integration, AutoTrac Turn Automation, AFS Repeat controlled traffic technology, Machine Sync coordination, factory installation advantages, and system costs. A-Bots.com provides custom AFS Connect integration, mobile development, and testing services.

Top stories

Copyright © Alpha Systems LTD All rights reserved.

Made with ❤️ by A-BOTS