Home

Services

About us

Blog

Contacts

Trimble GFX Agriculture Guidance and AutoPilot Systems: Complete Technical Guide

Need custom precision agriculture solutions for your operation? A-Bots.com specializes in developing tailored software for agricultural guidance systems and ground control stations. Whether you need to integrate Trimble GFX displays with your existing farm management platform, create custom mobile applications for fleet monitoring, develop API connections between Trimble systems and third-party software, or conduct comprehensive compatibility testing across mixed equipment brands, our development team delivers production-ready solutions. We work with agricultural technology companies, equipment dealers, and farming operations to enhance Trimble implementations through custom interfaces, data visualization tools, automated workflows, and seamless multi-platform integration. From retrofit installations to advanced telemetry systems, A-Bots.com bridges the gap between off-the-shelf precision agriculture technology and your specific operational requirements.

Trimble's Position in Precision Agriculture Market

Trimble holds the second-largest market position in agricultural guidance systems globally, directly behind John Deere. The company's strength lies in its aftermarket dominance and universal compatibility across all equipment brands. While John Deere focuses on integrated factory solutions for its own machinery, Trimble GFX systems work seamlessly with tractors, combines, and sprayers from any manufacturer including John Deere, Case IH, New Holland, AGCO, Fendt, Massey Ferguson, Kubota, and virtually every other agricultural equipment brand worldwide.

This multi-brand compatibility makes Trimble the preferred choice for independent farmers operating mixed fleets and those seeking flexibility to change equipment brands without replacing their entire precision agriculture infrastructure. The installed base spans hundreds of thousands to millions of units across North America, Europe, Australia, and emerging agricultural markets.

Trimble's agricultural division evolved from decades of positioning technology leadership in surveying, construction, and geospatial applications. This heritage provides robust GNSS technology, correction services, and positioning algorithms that deliver professional-grade accuracy for farming operations.

Understanding Trimble AutoPilot Automated Steering

Trimble AutoPilot represents the company's flagship automated steering solution, providing hands-free tractor guidance with sub-inch repeatability. The system integrates with the vehicle's hydraulic or electric steering through several installation methods depending on equipment type and age.

AutoPilot System Architecture

AutoPilot consists of three core components working together:

GNSS Receiver - Captures satellite signals from GPS, GLONASS, Galileo, and BeiDou constellations, applies correction algorithms, and outputs precise position data. Trimble offers multiple receiver models with varying capabilities and price points.

Steering Controller - Interfaces with the vehicle's steering system through hydraulic valve integration or electric motor actuation. The controller receives position data from the GNSS receiver and navigation commands from the display, then executes steering adjustments to maintain the guidance line.

Display Console - Provides the operator interface for system control, guidance line creation, field boundary management, and application control. The Trimble GFX series serves as the primary display family for agricultural applications.

AutoPilot Installation Methods

Integrated Hydraulic Steering - Premium installation method connecting directly to the tractor's hydraulic steering circuit through proportional valves. This approach delivers the highest accuracy (2.5 cm with RTK) and smoothest steering control. Compatible with most modern tractors featuring electrohydraulic steering.

Electric Motor Steering - Aftermarket solution mounting an electric motor on the steering column. This method suits older tractors lacking electronic steering systems or equipment where hydraulic integration isn't feasible. Accuracy typically achieves 5-8 cm depending on mechanical condition of the steering components.

Factory Integration - Some equipment manufacturers offer Trimble-ready platforms with pre-installed wiring harnesses and mounting provisions. These factory preparations simplify installation and often provide better integration than pure aftermarket retrofits.

Correction Service Options

Trimble AutoPilot accuracy depends heavily on the correction service utilized:

RangePoint RTX - Satellite-delivered corrections providing 15-30 cm pass-to-pass accuracy without requiring local base stations. Suitable for tillage, mowing, and broadcast applications. Subscription costs approximately $800-$1,200 annually per receiver.

CenterPoint RTX - Premium satellite correction service delivering 2-5 cm accuracy for planting, sidedressing, and precision applications. Annual subscription ranges $1,800-$2,400 per receiver. Signal acquisition takes 15-30 minutes for full accuracy convergence.

RTK (Real-Time Kinematic) - Achieves 2.5 cm repeatable accuracy using local base station or CORS network. Requires either purchasing and maintaining your own base station ($8,000-$15,000) or subscribing to a regional RTK network ($1,500-$3,000 annually). Provides instant accuracy upon signal lock.

WAAS/EGNOS - Free basic correction through government satellite systems. Delivers 30-60 cm accuracy suitable only for basic guidance where precision isn't critical.

Trimble GFX Display Family Overview

The Trimble GFX product line encompasses multiple display models addressing different operation sizes, feature requirements, and budget constraints. Each Trimble GFX console runs the same core software with feature access determined by hardware capabilities and purchased licenses.

Trimble GFX 350 Entry-Level Display

The Trimble GFX 350 serves as the entry point into Trimble's precision agriculture ecosystem. This 7-inch touchscreen display provides essential guidance functionality at an accessible price point targeting small to medium-sized operations or those beginning precision agriculture adoption.

Technical Specifications:

- Screen Size: 7 inches diagonal

- Resolution: 800 x 480 pixels

- Processor: Dual-core ARM processor

- Memory: 2 GB RAM, 8 GB storage

- Operating Temperature: -20°C to +60°C

- Ingress Protection: IP65 (dust-tight, water spray resistant)

- Power Input: 9-32 VDC

- Dimensions: 210 mm x 140 mm x 45 mm

- Weight: 0.9 kg

Core Features:

- Manual guidance with visual lightbar

- A-B line, adaptive curve, and pivot guidance patterns

- Field boundary recording and storage

- Basic documentation of coverage and application

- Bluetooth and Wi-Fi connectivity

- USB data transfer support

Limitations: The Trimble GFX 350 does not support automated steering activation - it functions as a guidance-only display. Operators must manually steer while following the visual guidance cues. This display also lacks ISOBUS implement control and advanced application management features present in higher-end models.

Ideal Applications: Small farms under 500 acres, hay operations, livestock operations requiring occasional crop work, and operators wanting to experience precision agriculture benefits before investing in full automation. The Trimble GFX 350 provides an upgrade path - the same display can activate additional features through software licenses as operational needs expand.

Trimble GFX 750 Mid-Range Display

The Trimble GFX 750 represents the most popular display in Trimble's agricultural lineup, balancing comprehensive features with reasonable cost. This 8-inch touchscreen supports automated steering, implement control, and documentation capabilities required by serious production agriculture.

Technical Specifications:

- Screen Size: 8 inches diagonal

- Resolution: 1280 x 800 pixels (WXGA)

- Processor: Quad-core ARM Cortex processor

- Memory: 4 GB RAM, 32 GB storage

- Operating Temperature: -30°C to +70°C

- Ingress Protection: IP67 (dust-tight, immersion resistant)

- Power Input: 9-36 VDC with reverse polarity protection

- Display Brightness: 1000 nits (sunlight readable)

- Dimensions: 235 mm x 165 mm x 52 mm

- Weight: 1.2 kg

- Connectivity: Dual USB ports, Bluetooth 4.2, Wi-Fi, Ethernet, CAN bus

Core Features:

- AutoPilot automated steering support with all correction services

- ISOBUS-UT (Universal Terminal) for implement control

- Field-IQ crop input control for section control and variable rate application

- Multiple guidance patterns including contour, headland, and custom paths

- Terrain compensation for sloped operations

- Trimble Connected Farm data synchronization

- Real-time yield monitoring display

- Task management with ISO-XML import/export

- Multi-language support (20+ languages)

Advanced Capabilities: The Trimble GFX 750 serves as a complete farm management tool beyond basic guidance. Operators can document as-applied maps for all field operations, view real-time application rates across sections, adjust rates on-the-fly based on field observations, and transfer data wirelessly to office computers or cloud storage. The system stores hundreds of fields with associated boundaries, guidance lines, and historical data.

Performance Characteristics: When paired with appropriate GNSS receivers and correction services, the Trimble GFX 750 enables pass-to-pass accuracy of 2.5 cm with RTK or 3-5 cm with CenterPoint RTX. The display updates guidance at 10 Hz, providing smooth steering response even at higher field speeds. The quad-core processor handles complex calculations for multi-field operations without lag or delays.

Market Position: The Trimble GFX 750 dominates the mid-range precision agriculture display market. Its feature set satisfies 80-90% of farming operations' needs while maintaining reasonable cost compared to premium displays. Most Trimble dealers stock the GFX 750 as their standard recommendation for customers implementing comprehensive precision agriculture programs.

Typical pricing for a complete Trimble GFX 750 system including display, NAV-900 controller, GNSS receiver, and installation kit ranges $8,000-$12,000 depending on receiver model and dealer location.

Trimble GFX 1060 Large-Format Display

The Trimble GFX 1060 provides a 10-inch touchscreen optimized for operations requiring enhanced visibility or running multiple information screens simultaneously. This display targets larger equipment operators, custom applicators, and farmers managing complex variable-rate prescriptions.

Technical Specifications:

- Screen Size: 10.1 inches diagonal

- Resolution: 1920 x 1200 pixels (WUXGA)

- Processor: Quad-core ARM Cortex-A72 processor at 1.5 GHz

- Memory: 8 GB RAM, 64 GB storage

- Operating Temperature: -30°C to +70°C

- Ingress Protection: IP67

- Power Input: 9-36 VDC with surge protection

- Display Brightness: 1200 nits with adaptive brightness

- Dimensions: 285 mm x 195 mm x 55 mm

- Weight: 1.6 kg

- Connectivity: Triple USB 3.0 ports, Bluetooth 5.0, dual-band Wi-Fi, Gigabit Ethernet, dual CAN bus

Enhanced Features:

- Split-screen display showing guidance plus implement status simultaneously

- Higher resolution prescription map display with detailed zone visualization

- Video input support for backup cameras or implement monitoring

- Extended memory supporting 1000+ fields and unlimited guidance lines

- Advanced diagnostics and system monitoring

- Simultaneous multi-GNSS constellation tracking display

- Enhanced graphics processing for complex overlay rendering

Performance Advantages: The larger screen and higher resolution make the Trimble GFX 1060 particularly valuable for operators managing variable-rate prescriptions with numerous zones or monitoring multiple implement functions simultaneously. The split-screen capability allows viewing guidance on one half while watching application rates, section control status, or yield data on the other half without switching screens.

The additional processing power enables faster map rendering when zooming or panning, smoother transitions between fields, and quicker prescription loading. Operations running large planters with individual row monitoring or sprayers with boom section cameras benefit significantly from the Trimble GFX 1060's expanded capabilities.

Target Applications: Custom applicators serving multiple clients with different prescription maps, large-scale farming operations over 5,000 acres, contractors running complex seeding prescriptions, precision agriculture researchers requiring detailed data logging, and operations utilizing advanced sensing technologies like yield monitoring with moisture mapping or crop health imaging.

Trimble GFX 1260 Premium Display System

The Trimble GFX 1260 sits at the top of the consumer agricultural display lineup, offering maximum screen size and processing capability for the most demanding operations. This 12-inch touchscreen provides desktop-computer-level performance in a ruggedized agricultural package.

Technical Specifications:

- Screen Size: 12.1 inches diagonal

- Resolution: 1920 x 1200 pixels (WUXGA)

- Processor: Hexa-core ARM Cortex processor at 2.0 GHz

- Memory: 16 GB RAM, 128 GB SSD storage

- Operating Temperature: -30°C to +70°C

- Ingress Protection: IP67

- Power Input: 9-36 VDC with advanced power conditioning

- Display Brightness: 1500 nits with auto-dimming

- Dimensions: 330 mm x 225 mm x 60 mm

- Weight: 2.1 kg

- Connectivity: Quad USB 3.1 ports, Bluetooth 5.1, Wi-Fi 6, Gigabit Ethernet, dual CAN bus, HDMI output

Premium Features:

- Quad-screen split display capability

- 4K external monitor output for in-office planning

- Advanced machine learning algorithms for predictive guidance

- Enhanced battery backup (60 minutes of operation)

- Premium audio output for alerts and navigation

- Configurable dashboard with widgets and custom layouts

- Advanced data analytics with graphical reporting

- Remote support capability with screen sharing

Professional Applications: The Trimble GFX 1260 serves professional-tier operations including large agribusiness farms, agricultural research institutions, precision agriculture service providers, and technology demonstration farms. The system handles enterprise-level data management with thousands of fields, unlimited prescriptions, and multi-year historical data analysis.

Research operations particularly value the Trimble GFX 1260's detailed data logging capabilities, including sub-second position recording, full implement sensor data capture, and integration with specialized research equipment through CAN bus and Ethernet connections.

The external monitor output allows using the Trimble GFX 1260 as an office planning station during off-season months, connecting to a large monitor for comfortable prescription creation and field planning without hunching over a small display.

Pricing for the Trimble GFX 1260 typically starts around $6,000-$8,000 for the display unit alone, with complete systems including navigation components reaching $15,000-$20,000.

Trimble NAV Controller Family

Trimble NAV controllers serve as the navigation processing units that handle steering calculations and implement the physical steering actuation. These devices receive positioning data from GNSS receivers, navigation instructions from displays, and output steering commands to the vehicle's hydraulic or electric steering system.

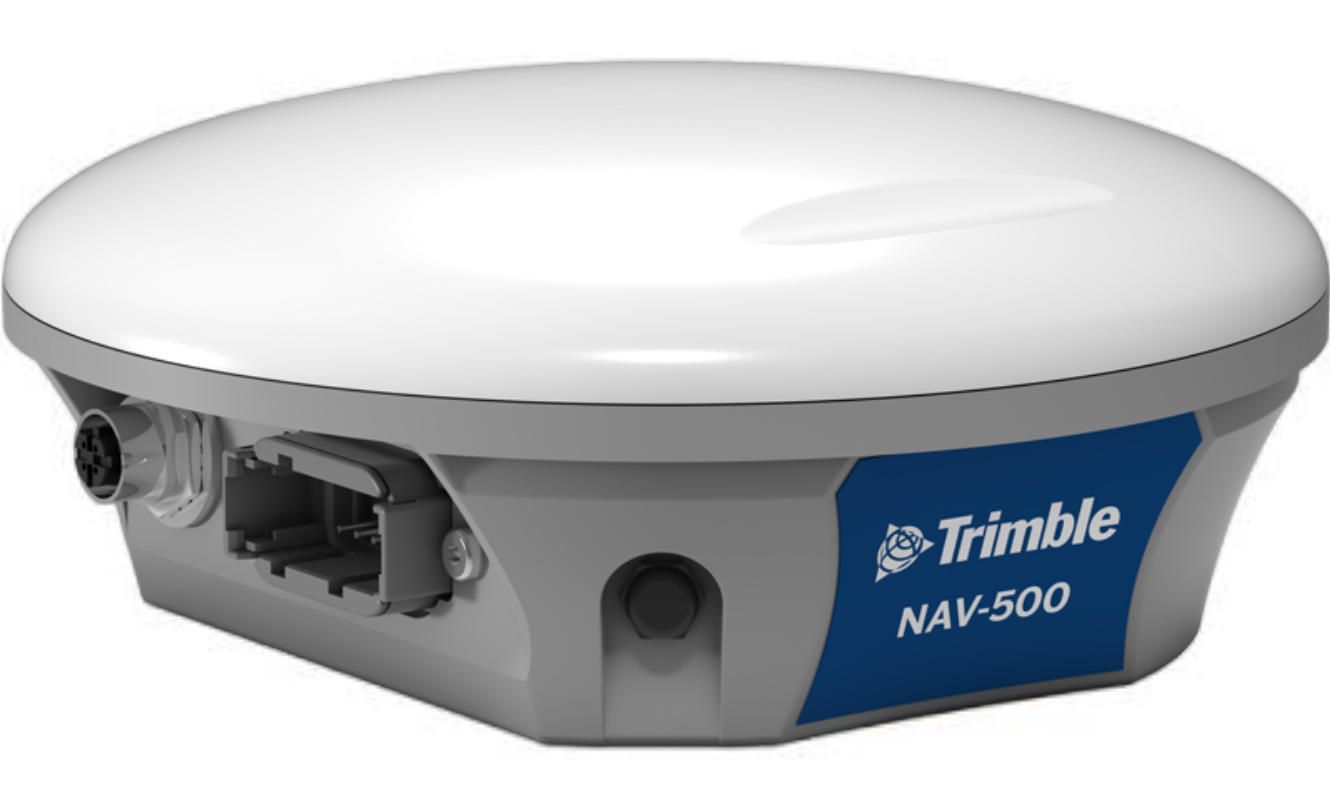

Trimble NAV 500 Integrated Controller

The Trimble NAV 500 represents an integrated solution combining GNSS receiver and steering controller in a single compact unit. This all-in-one approach simplifies installation and reduces cab clutter compared to separate receiver and controller boxes.

Technical Specifications:

- GNSS Channels: 220 channels

- Satellite Systems: GPS (L1/L2), GLONASS (L1/L2)

- Update Rate: 10 Hz position output

- Correction Support: WAAS/EGNOS, RangePoint RTX, SBAS

- Accuracy: 15-30 cm with RangePoint RTX

- Operating Temperature: -40°C to +75°C

- Ingress Protection: IP69K (high-pressure, high-temperature washdown resistant)

- Power Input: 9-36 VDC

- Dimensions: 180 mm x 140 mm x 65 mm

- Weight: 1.1 kg

- Steering Interface: Proportional hydraulic valve control or PWM motor control

- Connectivity: CAN bus, USB, Bluetooth

Integration Features:

- Single-cable connection to Trimble GFX displays

- Integrated IMU (Inertial Measurement Unit) for terrain compensation

- Internal radio modem option for local RTK corrections

- Built-in compass for initial heading determination

- Simultaneous tracking of all visible satellites across supported constellations

Performance Characteristics: The Trimble NAV 500 delivers reliable guidance for applications where 15-30 cm accuracy suffices including tillage, broadcast fertilizing, and general field work. The integrated design reduces installation time by approximately 30% compared to separate components, making it popular for retrofit applications on older equipment.

The device includes initialization technology that establishes accurate heading within one meter of forward movement, eliminating the need for long straight-line calibration runs required by some competing systems. This feature particularly benefits operations with small fields or limited straight-run opportunities.

Market Positioning: The Trimble NAV 500 targets budget-conscious operators seeking automated steering without premium correction service costs, retrofit applications where simplicity matters, and backup systems for operations wanting redundancy across multiple tractors. The device works well for farms in the 500-2,000 acre range performing primarily tillage and application work.

Typical complete system pricing with Trimble NAV 500, GFX 350 or GFX 750 display, antenna, and installation kit ranges $6,000-$9,000.

Trimble NAV 900 Advanced Navigation Controller

The Trimble NAV 900 represents the premium navigation controller in Trimble's agricultural portfolio, supporting the highest accuracy levels and most demanding applications. This controller enables RTK accuracy and provides the processing capability for advanced features like terrain compensation and multi-antenna configurations.

Technical Specifications:

- GNSS Channels: 440 channels

- Satellite Systems: GPS (L1/L2/L5), GLONASS (L1/L2), Galileo (E1/E5a/E5b), BeiDou (B1/B2/B3)

- Update Rate: 20 Hz position output

- Correction Support: All Trimble corrections including CenterPoint RTX and RTK

- Accuracy: 2.5 cm repeatable with RTK, 3-5 cm with CenterPoint RTX

- Position Initialization: <5 seconds with RTK, <20 minutes with RTX

- Operating Temperature: -40°C to +85°C

- Ingress Protection: IP69K

- Power Input: 9-36 VDC with wide voltage tolerance

- Dimensions: 185 mm x 145 mm x 70 mm

- Weight: 1.3 kg

- Steering Interface: Proportional hydraulic valve with closed-loop feedback, brushless DC motor control

- Connectivity: Dual CAN bus, Ethernet, USB host and device, Bluetooth 5.0, Wi-Fi

Advanced Capabilities:

- Multi-frequency, multi-constellation tracking for maximum reliability

- Integrated 9-axis IMU providing pitch, roll, and yaw data

- Terrain compensation maintaining 2.5 cm accuracy on slopes up to 45 degrees

- Dual-antenna support for instant heading determination

- Internal radio modem supporting multiple frequency bands for RTK reception

- NTRIP client for cellular RTK corrections

- Advanced filtering algorithms reducing position noise in challenging conditions

Professional Features: The Trimble NAV 900 includes proprietary technology maintaining position accuracy during brief satellite outages or interference. When passing under trees, near buildings, or through areas with partial sky view, the integrated IMU bridges position gaps using inertial sensors, maintaining guidance accuracy for 10-15 seconds without full GNSS lock.

The controller supports advanced steering algorithms optimizing path following for different vehicle types, speeds, and field conditions. Operators can tune steering aggressiveness, look-ahead distance, and turn anticipation parameters to match specific equipment characteristics and personal preferences.

For research applications, the Trimble NAV 900 outputs raw positioning data and steering commands at 20 Hz, enabling detailed analysis of equipment performance and path tracking accuracy. This capability supports academic research into autonomous vehicle behavior and precision agriculture system evaluation.

Premium Applications: The Trimble NAV 900 serves operations requiring maximum accuracy including controlled traffic farming systems, specialty crop production with narrow row spacing, research agriculture, high-value vegetable production, transplanting operations, and contractors demanding year-over-year repeatability for tile line following or permanent traffic lanes.

The controller particularly excels in challenging terrain where slopes, rolling hills, or uneven ground make maintaining accurate paths difficult. The terrain compensation system adjusts steering calculations based on real-time vehicle attitude data, preventing implement drift and maintaining consistent paths regardless of ground contour.

Pricing for the Trimble NAV 900 typically ranges $3,500-$4,500 depending on included options and dealer markup. When combined with a premium Trimble GFX display, GNSS antenna, and installation components, complete system costs reach $12,000-$18,000.

Trimble Connected Farm Platform

Trimble Connected Farm serves as the cloud-based farm management system complementing in-cab hardware. This platform aggregates data from Trimble GFX displays, provides remote fleet monitoring, enables wireless data transfer, and offers analytical tools for agronomic decision-making.

Core Platform Capabilities

Equipment Tracking - Real-time location display for all connected equipment shows where machines operate, current status (working, idle, traveling), and operator information. Fleet managers monitor multiple operations across distant fields without radio communication or phone calls.

Automatic Documentation - Field operations upload automatically via cellular or Wi-Fi connections, eliminating manual data transfer through USB drives. As-applied maps, coverage documentation, and operational summaries populate the cloud database without operator intervention.

Agronomic Analysis - Historical data comparison tools show yield performance trends, identify problem areas recurring across seasons, and correlate outcomes with management practices. The platform generates reports highlighting fields exceeding or underperforming benchmarks.

Prescription Management - Create variable-rate application maps using built-in tools or import prescriptions from third-party agronomic software. Transfer maps wirelessly to equipment, eliminating USB drive handling and reducing errors from wrong files or outdated prescriptions.

Data Integration

Trimble Connected Farm supports standard data formats including ISO-XML, Shapefile, and GeoTIFF, enabling integration with popular farm management software platforms. The system imports field boundaries, soil data, yield information, and prescription maps from Climate FieldView, Ag Leader SMS, SST Software, and other agricultural data systems.

API access allows custom integrations for operations with specialized requirements or internal software systems. A-Bots.com develops custom API connections linking Trimble Connected Farm with ERP systems, cooperative management platforms, and proprietary agricultural databases, creating seamless data flow across an operation's complete technology stack.

Mobile Access

iOS and Android applications provide field-level access to Connected Farm functionality. Operators document field observations, capture geo-tagged photos, record notes, and view real-time equipment status without returning to the office. Agronomists and farm managers access data remotely, reviewing progress, checking application rates, and identifying issues requiring attention.

The mobile interface supports offline operation, caching relevant data for field areas without cellular coverage. Changes and documentation captured offline synchronize automatically when connectivity restores, ensuring no data loss in remote locations.

Installation and Setup Process

Installing Trimble AutoPilot and Trimble GFX systems requires mechanical, electrical, and software configuration steps. The process complexity varies based on equipment type, chosen components, and existing cab configurations.

Pre-Installation Assessment

Successful installations begin with thorough equipment evaluation. Dealers inspect the steering system, hydraulic circuits, electrical systems, and cab space before recommending specific components. Older tractors may require power steering upgrades, additional hydraulic circuits, or electrical system enhancements before supporting automated steering.

Critical evaluation points include:

- Steering system type (manual, hydraulic, electrohydraulic, electric)

- Available hydraulic pressure and flow capacity

- Electrical system voltage and available amperage

- Cab interior space and mounting locations

- Existing precision agriculture equipment and compatibility

- Operator comfort with technology and training needs

Hardware Installation Steps

GNSS Antenna Mounting - Position the antenna on the cab roof with unobstructed sky view. The antenna must mount directly over the vehicle's reference point (usually rear axle centerline for tractors). Metal structures, ROPS, or radio antennas within two meters can cause signal reflection or interference, degrading accuracy. Most installations use magnetic or bolt-on mounts attached to cab roof sheet metal.

Display Mounting - Secure the Trimble GFX console in the operator's natural viewing angle without obstructing critical gauges or controls. RAM mounts or custom brackets position displays for comfortable viewing while seated. Route power and communication cables through cab structure to protect from pinching or damage. Connection points typically locate at the base of the seat post or along existing equipment harness channels.

Steering Controller Installation - Mount the NAV controller in a protected location away from moisture, heat, and vibration. Common mounting spots include under the seat, behind the dash panel, or in dedicated electronics boxes. Connect the controller to the steering system via hydraulic control valves for integrated installations or mounting hardware for electric motor systems.

Hydraulic Integration - Integrated steering installations require tapping into the tractor's hydraulic circuit with proportional control valves. These valves must install downstream of the manual steering valve, allowing operator override at any time. Flow capacities typically require 15-25 liters per minute at 150-200 bar pressure for adequate steering response.

Electric Motor Installation - Aftermarket electric steering mounts a brushless DC motor to the steering column with anti-rotation brackets preventing system movement. The motor connects through universal joints matching the steering shaft diameter. Proper alignment and secure mounting prevent binding, noise, and premature wear.

Software Configuration and Calibration

After hardware installation, system calibration establishes the relationship between GNSS position, steering actuation, and vehicle movement. The calibration procedure typically requires 20-30 minutes in a flat, open area.

Calibration Steps:

- Initialize GNSS receiver and allow position lock (2-10 minutes depending on correction service)

- Drive straight forward 50-100 meters at normal field speed

- Turn 180 degrees and return along the same path

- System records position offsets and calculates steering response characteristics

- Repeat the process at 90-degree orientation to characterize turning behavior

- Verify calibration by engaging AutoPilot on a straight path and observing tracking accuracy

Fine-Tuning Parameters:

Modern Trimble systems include adjustable parameters allowing operators to tune steering behavior:

- Aggressiveness: Controls how quickly the system corrects path deviations

- Look-ahead distance: Determines how far ahead the system anticipates path changes

- Turn anticipation: Adjusts how early the system begins steering into curves

- Speed-dependent behavior: Modifies steering response based on ground speed

Most operators run default settings initially, then adjust parameters based on personal preferences and specific equipment characteristics. More aggressive settings provide tighter path tracking but may feel jerky or over-reactive, particularly on sensitive steering systems. Conservative settings feel smoother but allow larger path deviations before correcting.

Real-World Performance and ROI

Trimble AutoPilot and Trimble GFX systems deliver measurable benefits documented through university research and operational data from thousands of farms worldwide.

Efficiency Improvements

According to research from Iowa State University and Purdue University, automated steering systems reduce overlap from typical manual operation levels of 10-15% down to 1-2%. For a 1,000-acre corn operation applying fertilizer, herbicide, and insecticide across multiple passes, this overlap reduction saves $15,000-$25,000 annually on input costs alone.

Fuel consumption decreases by 8-12% through more efficient field coverage, reduced turning time, and optimized travel patterns. A farm burning 10,000 gallons of diesel annually saves 800-1,200 gallons worth $2,400-$3,600 at typical fuel prices. Additional savings accrue from reduced engine hours and decreased mechanical wear on steering components.

Operator fatigue reduction extends working hours during critical windows. Many farmers report operating 12-14 hours daily during planting or harvest when using automated steering versus 8-10 hours with manual operation. This productivity increase allows covering more acres with existing equipment or reducing the machinery fleet size required for time-sensitive operations.

Accuracy Benefits

Precise path following enables controlled traffic farming where equipment travels identical paths across seasons, concentrating compaction to specific lanes while leaving crop zones undisturbed. Research demonstrates controlled traffic farming increases yields by 5-15% through improved root development, better water infiltration, and enhanced soil structure in growing zones.

The 2.5 cm repeatability achieved with Trimble NAV 900 and RTK correction enables year-over-year path tracking for:

- Following tile lines for drainage maintenance or modification

- Establishing permanent traffic lanes in alfalfa or hay production

- Precision nutrient banding 5-7 cm from crop rows

- Mechanical weed cultivation in narrow-row crops

- Specialty crop production with precise bed spacing

Investment Return Timeline

Typical Trimble system investment ranges $10,000-$16,000 for a complete retrofit installation including Trimble GFX 750 display, NAV 900 controller, GNSS antenna, steering hardware, and installation labor. Annual correction subscriptions add $1,800-$2,400 for CenterPoint RTX or $2,500-$3,500 for RTK network access.

ROI calculation example for a 1,500-acre corn/soybean operation:

Input savings from overlap reduction: $20,000/year Fuel savings: $3,000/year

Increased productivity value: $5,000/year Total annual benefit: $28,000

System cost: $14,000 initial + $2,200 annual subscription Net first-year benefit: $11,800 Payback period: Immediate (first season)

Operations below 500 acres or those with simple cropping systems requiring few field passes may experience longer payback periods of 2-3 years. Conversely, custom applicators, large farms over 3,000 acres, or specialty crop producers often achieve payback in a single season.

Trimble vs Competitive Systems

Farmers evaluating precision agriculture systems frequently compare Trimble against integrated OEM solutions and alternative aftermarket providers. Each option presents distinct advantages depending on operational characteristics and priorities.

Trimble vs John Deere

Trimble Advantages: Multi-brand compatibility allows using identical systems across mixed fleets, maintaining consistent operator training and data formats regardless of equipment manufacturer. Initial hardware costs typically run 15-25% lower than equivalent John Deere systems. Portability enables transferring systems between tractors as operational needs change, protecting investment value.

John Deere Advantages: Tighter integration with John Deere equipment provides seamless implement control and factory-calibrated steering performance. Operations Center offers more sophisticated analytics and agronomic tools compared to Trimble Connected Farm. Dealer support from John Deere agricultural equipment dealers may exceed support from dedicated precision agriculture dealers, particularly in rural areas.

Verdict: Choose Trimble for mixed equipment fleets, portable applications across multiple tractors, or operations preferring independence from equipment manufacturers. Select John Deere for all-Deere fleets requiring maximum integration depth and those valuing Operations Center capabilities.

Trimble vs Case IH AFS

Case IH AFS systems use Trimble technology through licensing agreements, creating significant overlap in capabilities. AFS AccuGuide essentially rebrands Trimble hardware with Case IH-specific software and integration.

Trimble Advantages: Direct Trimble purchase often costs less than equivalent AFS systems. Updates and new features typically release to Trimble customers before filtering through Case IH's integration timeline. Compatibility extends beyond CNH Industrial equipment to all brands.

Case IH AFS Advantages: Factory integration with Case IH tractors, combines, and implements provides optimal implementation quality. Single-source support through Case IH dealers simplifies warranty and service issues. AFS-specific features like AccuTurn headland automation integrate deeply with Case IH machinery.

Verdict: Case IH equipment owners benefit from AFS when buying new equipment with factory installation. Existing equipment retrofits or mixed-brand operations favor direct Trimble purchase for maximum flexibility and value.

Trimble vs Topcon Agriculture

Topcon competes directly with Trimble in the aftermarket precision agriculture space, offering similar multi-brand compatibility and universal mounting solutions.

Trimble Advantages: Larger dealer network provides better geographic coverage and more accessible support. CenterPoint RTX and RangePoint RTX correction services offer broader satellite coverage than Topcon alternatives. Trimble Connected Farm provides more robust cloud-based farm management compared to Topcon Agriculture Platform.

Topcon Advantages: More competitive pricing particularly for entry-level systems like the recently-introduced Value Line Steering. Some dealers report simpler setup and calibration procedures with Topcon systems. Specialty crop features including transplanting control receive greater development focus at Topcon.

Verdict: Operations prioritizing maximum accuracy and premium features select Trimble. Budget-conscious farms, specialty crop producers, and those with strong local Topcon dealer support may prefer Topcon solutions.

Advanced Features and Capabilities

Beyond basic automated steering, Trimble GFX systems support advanced functionality enhancing productivity and precision across diverse agricultural applications.

Trimble NextSwath Turn Automation

NextSwath technology automates headland maneuvers, controlling equipment at the end of each pass without operator input. When the tractor reaches the field boundary, NextSwath automatically:

- Reduces ground speed to preset turning speed

- Lifts implements to transport position

- Calculates and executes the optimal turn path

- Lowers implements when positioned for the next pass

- Resumes field speed automatically

This automation eliminates repetitive operator inputs during long days in the field, reduces fatigue, and ensures consistent headland execution. Operators initially program turn sequences defining implement lift points, speed transitions, and path patterns. The system then replicates these sequences identically on every pass.

NextSwath proves particularly valuable on large-scale operations where operators make hundreds of turns daily or when training less experienced operators requiring assistance with complex headland maneuvers.

Field-IQ Crop Input Control

Field-IQ provides comprehensive application management including section control, variable-rate application, and prescription execution. The system interfaces with planters, sprayers, spreaders, and applicators through ISOBUS connections or manufacturer-specific protocols.

Section Control automatically activates and deactivates implement sections based on previously covered areas, eliminating overlap on point rows, waterways, and irregular boundaries. The system tracks coverage history across multiple operations, preventing double-application when covering fields with different equipment widths or approach angles.

Section control typically reduces seed, fertilizer, and chemical usage by 5-8% through overlap elimination. For operations applying $100,000 in inputs annually, this represents $5,000-$8,000 in direct savings.

Variable-Rate Application adjusts input rates based on prescription maps created from soil data, yield history, or remote sensing imagery. Field-IQ accepts standard prescription formats and controls application rates in real-time as equipment crosses zone boundaries.

The system logs actual application rates versus prescribed rates, generating as-applied maps documenting what actually occurred in the field. This documentation supports agronomic analysis, regulatory compliance, and identifying equipment calibration issues requiring attention.

Terrain Compensation Technology

Trimble's terrain compensation system maintains positioning accuracy on sloped terrain where standard GPS calculations become less reliable. When operating on hillsides, the GNSS antenna position doesn't accurately represent the ground contact point where implements work.

The integrated IMU (Inertial Measurement Unit) in Trimble NAV controllers measures vehicle pitch, roll, and yaw continuously. Compensation algorithms adjust the calculated ground position based on antenna height, mounting location, and real-time vehicle attitude. This technology maintains 2.5 cm accuracy on slopes up to 45 degrees where uncorrected systems might experience 10-20 cm errors.

Terrain compensation proves essential for:

- Hill country farming where level ground rarely exists

- Contour farming following elevation curves rather than straight lines

- Specialty crops on sloped land requiring precise row spacing

- Drainage work where accurate elevation data drives design decisions

Multi-Machine Coordination

Advanced Trimble GFX systems support coordination between multiple machines operating simultaneously. Common coordination scenarios include:

Harvest Operations - Combine communicates position and speed to grain cart tractor, which automatically positions itself for unloading without radio commands or manual coordination. The grain cart maintains optimal offset distance and matches combine speed, maximizing unloading efficiency.

Tandem Tillage - Multiple tractors running tillage implements maintain precise spacing and alignment, ensuring complete coverage without gaps or excessive overlap. This capability enables covering large acreages quickly during narrow weather windows.

Formation Spraying - Multiple sprayers work in coordinated patterns maintaining precise separation, preventing gaps in coverage or boom overlap between adjacent machines. This coordination supports high-speed spraying operations covering 200-300 acres hourly with multiple machines.

Data Management and Export

Modern farming operations generate extensive data from precision agriculture systems. Trimble GFX displays capture position, application rates, yield information, and operational parameters at sub-second intervals throughout field operations.

On-Board Data Storage

Trimble GFX displays store complete operational history including:

- Coverage maps showing every location where equipment traveled

- As-applied maps documenting seed, fertilizer, and chemical application rates

- Yield maps from harvest operations with yield and moisture data

- Field boundaries, guidance lines, and waypoints

- Prescription maps and task data

- System diagnostics and operational logs

Storage capacity varies by display model. The Trimble GFX 750 stores approximately 1,000 fields and unlimited operations within each field. The GFX 1260 expands capacity to accommodate enterprise-scale operations with thousands of fields and decades of historical data.

Data Export and Compatibility

Trimble systems export data in industry-standard formats ensuring compatibility with third-party farm management software:

ISO-XML - Standard format for task data and as-applied information, supported by virtually all agricultural software platforms. This format preserves complete operational details including timing, rates, and equipment configuration.

Shapefile - Geographic data format widely used in GIS applications and many farm management systems. Shapefiles store field boundaries, sampling points, and zone definitions with associated attributes.

CSV (Comma-Separated Values) - Tabular data format opening in spreadsheet applications for custom analysis. Raw yield data, application logs, and operational summaries export as CSV for maximum flexibility.

GeoTIFF - Raster image format for prescription maps and yield data visualization. Many agronomic software packages generate variable-rate prescriptions as GeoTIFF files that Trimble GFX displays import directly.

Cloud Synchronization

Trimble Connected Farm automates data transfer through cellular or Wi-Fi connections, eliminating manual USB data transfer. As-applied maps, coverage documentation, and operational summaries upload automatically when connectivity is available.

The synchronization system queues data during periods without connectivity, uploading automatically when connection restores. This approach ensures reliable data capture even when operating in remote areas with limited cellular coverage.

Common Applications and Use Cases

Trimble AutoPilot and Trimble GFX systems serve diverse agricultural applications, each benefiting from automated steering and precision control in specific ways.

Primary Tillage Operations

Tillage represents the highest-value application for automated steering due to large implement widths and significant overlap costs. A 40-foot disk operating manually with typical 10% overlap wastes 4 feet of width on every pass. Automated steering reduces this overlap to under 1 foot, effectively increasing implement capacity by 7-8%.

The fuel savings from reduced overlap and optimized turning patterns accumulate rapidly during deep tillage operations consuming 3-5 gallons per acre. A 2,000-acre tillage program saves 4,000-7,000 gallons of diesel annually through automated steering efficiency.

Tillage operations tolerate the lower accuracy levels provided by RangePoint RTX correction (15-30 cm), making them economical entry points for precision agriculture adoption. Many operations begin with tillage guidance, then expand to planting and application after experiencing the benefits.

Planting and Seeding

Planting accuracy directly impacts yield potential through optimal plant spacing and emergence uniformity. Automated steering maintains precise row spacing, eliminates gaps and doubles, and enables subsequent operations to follow identical paths for cultivation or sidedressing.

Planting requires higher accuracy than tillage, typically demanding CenterPoint RTX (3-5 cm) or RTK (2.5 cm) correction services. The investment in premium correction justifies itself through:

- Reduced seed costs from eliminating doubles and skips

- Improved emergence uniformity supporting even maturity

- Precise row tracking for mechanical cultivation

- Accurate placement for subsequent fertilizer applications

Controlled traffic farming systems utilizing planting path repeatability show yield increases of 5-15% through reduced compaction in growing zones. These systems require RTK correction maintaining year-to-year repeatability within 2.5 cm.

Spraying and Application

Chemical application benefits significantly from section control and variable-rate capabilities enabled by Trimble GFX systems. Section control prevents over-application on point rows and irregular boundaries, directly reducing chemical costs while supporting environmental stewardship.

According to research published by Iowa State University Extension, farmers using Trimble precision spraying technology with section control reduce herbicide usage by 8-12% through overlap elimination alone. When combined with variable-rate application based on weed pressure maps or crop vigor zones, total chemical reductions reach 15-25%.

High-speed spraying operations at 15-20 mph particularly benefit from automated steering maintaining precise paths. Manual steering at these speeds creates significant deviation from intended paths, resulting in gaps or excessive overlap. Automated steering maintains 3-5 cm accuracy even at elevated speeds, ensuring uniform coverage.

Specialty Crop Production

Specialty crop operations including vegetables, tree fruits, and vineyards require extreme precision for transplanting, cultivation, and harvest operations. Trimble GFX systems supporting RTK correction enable:

Transplanting - Precise plant placement with 2.5 cm accuracy ensures uniform spacing and straight rows facilitating mechanical cultivation and harvest. Trimble offers specialized transplanting control interfacing with automated transplanters for crops like lettuce, broccoli, and tobacco.

Mechanical Cultivation - Close-proximity cultivation between crop rows removes weeds without damaging plants. The 2.5 cm repeatability allows running cultivators within 5-7 cm of crop rows safely, eliminating herbicide dependence in organic production systems.

Selective Harvest - Some specialty crops utilize machine vision systems for selective harvest based on size, color, or ripeness. These systems require precise positioning to correlate sensor observations with plant locations, making Trimble's repeatable guidance essential.

Technical Support and Training

Successful Trimble system implementation requires appropriate training and ongoing technical support. Trimble provides multiple support channels addressing different user needs and experience levels.

Dealer Network

Trimble partners with agricultural equipment dealers and precision agriculture specialists throughout North America, Europe, Australia, and emerging markets. These dealers provide local sales, installation, training, and service support.

Dealer capabilities vary significantly. Some dealers maintain dedicated precision agriculture departments with certified technicians specializing in guidance system installation and troubleshooting. Others offer basic sales and installation with limited in-depth technical support.

Evaluating dealer capabilities before purchasing proves critical. Questions to ask prospective dealers include:

- How many Trimble systems does your dealership install annually?

- What certifications do your precision agriculture technicians hold?

- What is your typical response time for in-season service calls?

- Do you offer demo equipment for trial before purchase?

- What training programs do you provide for new customers?

Strong dealer relationships significantly impact long-term satisfaction with Trimble systems. Dealers providing responsive in-season support, proactive training, and knowledgeable troubleshooting assistance create better ownership experiences than dealers treating precision agriculture as a sideline product.

Online Training Resources

Trimble maintains comprehensive online training materials including:

Video Tutorials - Step-by-step instructional videos covering system setup, calibration procedures, feature operation, and troubleshooting common issues. The video library spans basic guidance concepts through advanced features like prescription creation and multi-machine coordination.

Interactive Simulations - Web-based simulators allow practicing system operation without physical equipment access. These simulations help operators become familiar with display interfaces, menu structures, and feature locations before using systems in the field.

Documentation Library - Downloadable user manuals, quick-start guides, and technical specifications provide reference materials for all Trimble agricultural products. These documents include detailed procedures for installation, calibration, operation, and maintenance.

Webinar Series - Live online training sessions cover specific topics with opportunities for participant questions. Trimble conducts regular webinars addressing new product introductions, software updates, and advanced techniques.

Technical Support Channels

Trimble offers multiple technical support options:

Phone Support - Direct access to Trimble technical support specialists during business hours provides troubleshooting assistance for operational issues, software problems, and configuration questions.

Email Support - Submit detailed technical questions with screenshots or diagnostic files for comprehensive responses from support engineers. This channel suits non-urgent issues requiring detailed investigation.

Remote Assistance - Support technicians can connect directly to Trimble GFX displays through internet connections, viewing the exact screen operators see and making configuration changes remotely. This capability dramatically reduces resolution time for software-related issues.

Dealer Service - For hardware problems or complex issues requiring hands-on diagnosis, local dealers provide on-site service. Mobile service vehicles visit farms during peak seasons, minimizing equipment downtime.

Software Updates and Future Development

Trimble continuously develops new features and capabilities through software updates. The company's update approach differs from competitors in several important ways.

Update Delivery Methods

Over-the-Air Updates - Trimble GFX displays with cellular or Wi-Fi connectivity receive software updates automatically when connected. The system notifies operators of available updates, downloads files in the background, and prompts for installation at convenient times. This approach ensures operators run current software without visiting dealers for manual updates.

Dealer Updates - Dealers can update systems during service visits or pre-season preparations for operators without reliable internet connectivity. Technicians load updates via USB drives or direct computer connections.

Recent Feature Additions

Trimble's update history demonstrates commitment to enhancing existing hardware through software improvements:

Enhanced Terrain Compensation - Recent updates improved slope performance, extending accurate guidance to 50-degree slopes versus previous 45-degree limits. This expansion benefits hill country operations and specialty crop producers on terraced ground.

Improved RTK Convergence - Algorithm refinements reduced time to full RTK accuracy from 60 seconds to under 30 seconds, enabling operators to begin work faster each morning or after satellite signal interruptions.

Expanded ISOBUS Support - Updates added compatibility with newer implement electronics, particularly advanced planter monitoring systems and sprayer boom height controls from various manufacturers.

Machine Learning Integration - Recent Trimble GFX 1260 updates incorporate machine learning algorithms that adapt steering behavior based on observed equipment characteristics, automatically optimizing performance without manual tuning.

Future Direction

Trimble's precision agriculture roadmap emphasizes autonomy, artificial intelligence, and enhanced data integration. Public statements and beta programs indicate development focus on:

Supervised Autonomy - Systems allowing operators to monitor automated equipment from remote locations while machines complete repetitive tasks. This technology enables one operator supervising multiple machines simultaneously.

Computer Vision Integration - Camera systems providing real-time crop health monitoring, weed detection, and plant counting integrated directly with Trimble GFX displays for immediate operator access.

Advanced Analytics - Artificial intelligence algorithms analyzing years of operational data to generate agronomic recommendations, predict optimal timing for field operations, and identify emerging problems before they impact yields.

Expanded Connectivity - 5G cellular integration supporting real-time video streaming from equipment, lower-latency remote control capabilities, and faster data synchronization between field equipment and cloud platforms.

System Maintenance and Longevity

Trimble systems require minimal routine maintenance but benefit from periodic inspection and care ensuring long-term reliability.

Routine Maintenance Requirements

Antenna Care - Inspect GNSS antenna mounting quarterly for secure attachment and corrosion-free connections. Clean antenna surfaces annually removing accumulated dirt, crop residue, or chemical deposits that might affect signal reception. Verify antenna cables show no signs of damage, pinching, or rodent activity.

Display Maintenance - Clean Trimble GFX touchscreens weekly during heavy-use seasons using microfiber cloths and approved screen cleaning solutions. Avoid harsh chemicals or abrasive materials damaging anti-glare coatings. Inspect mounting hardware monthly for tight connections preventing vibration damage.

Controller Inspection - Examine NAV controller mounting and connections annually during off-season maintenance. Ensure protective covers remain sealed, preventing moisture or dust intrusion. Check hydraulic connections for leaks and electrical connections for corrosion.

Calibration Verification - Verify system calibration accuracy at the beginning of each season. Drive straight test passes observing guidance line tracking. If accuracy degrades, recalibrate following standard procedures before field operations begin.

Expected Service Life

Trimble agricultural equipment demonstrates excellent longevity when properly maintained:

GNSS Antennas - 10-15 years typical service life. These components contain no moving parts and resist environmental degradation through weather-resistant construction. Most failures result from physical damage (equipment contact) or cable damage rather than antenna failure.

Displays - 7-10 years expected operational life. Touchscreen performance may degrade over time from accumulated use and exposure to vibration. Processing capability becomes limiting factor as software demands increase, but displays remain functionally operational long after newer models offer better performance.

NAV Controllers - 10-15 years typical service life. Solid-state electronics resist wear, making these components highly reliable. Most replacements occur due to obsolescence rather than failure, as newer controllers offer capabilities impossible to retrofit into older hardware.

Overall System - Complete Trimble systems regularly remain operational 8-12 years with minimal component replacement. Many operations run first-generation Trimble equipment from the early 2000s, though performance and features significantly trail current products.

Upgrade Paths

Trimble designs systems with upgrade paths protecting investment value:

Display Upgrades - Newer Trimble GFX displays often work with existing NAV controllers and antennas, allowing display-only upgrades accessing new features without complete system replacement. For example, operators running older GFX-750 displays can upgrade to GFX-1060 units while retaining NAV-900 controllers and GNSS antennas.

Software Feature Unlocking - Many features exist in system firmware but require software license activation. Operators purchase additional capabilities like Field-IQ section control or Trimble NextSwath turn automation without hardware changes, simply activating these features through dealer-supplied license codes.

Correction Service Upgrades - Switching between correction service levels (RangePoint RTX to CenterPoint RTX, or adding RTK capability) typically requires only subscription changes without hardware modification, assuming the installed receiver supports desired correction types.

Cost Analysis and Total Ownership

Understanding complete costs including initial investment, annual subscriptions, and long-term ownership expenses helps farmers make informed decisions about Trimble system adoption.

Initial Investment Breakdown

Typical costs for new Trimble system installation on a tractor:

Trimble GFX 750 Display - $4,500-$5,500 Trimble NAV 900 Controller - $3,500-$4,200

GNSS Antenna and Cable - $800-$1,200 Steering Hardware - $1,500-$2,500 (varies significantly by tractor model) Installation Labor - $800-$1,500 Initial Calibration and Training - $300-$600 Total System Cost - $11,400-$15,500

Budget-conscious operations can reduce initial costs through:

- Selecting Trimble GFX 350 display ($2,000-$2,800) with manual guidance only

- Choosing NAV 500 controller ($2,200-$2,800) accepting lower accuracy

- Installing electric motor steering ($1,200-$1,800) versus hydraulic integration

- Self-installation saving $800-$1,500 labor charges

- Minimum system cost with economy components: $6,200-$8,400

Premium installations with top-tier components cost more:

- Trimble GFX 1260 display ($6,500-$8,000)

- Dual-antenna configuration for instant heading ($1,500 additional)

- Professional hydraulic integration with custom valve manifolds ($3,500-$5,000)

- Premium installation package: $15,000-$20,000

Annual Operating Costs

Correction Service Subscriptions - Annual fees maintain positioning accuracy:

- RangePoint RTX: $800-$1,200 per receiver

- CenterPoint RTX: $1,800-$2,400 per receiver

- RTK Network: $1,500-$3,000 per receiver (varies by provider)

- Own RTK Base Station: $500-$1,000 annually for cellular modem and data plan

Software Subscriptions - Optional services add annual costs:

- Trimble Connected Farm Premium: $500-$1,200 per operation

- Advanced Analytics: $300-$800 annually

- Multi-user access: $200-$500 per additional user

Maintenance and Support - Ongoing service expenses:

- Annual dealer inspection and calibration check: $200-$400

- Software updates and technical support: Typically included with correction subscriptions

- Parts replacement (cables, connectors): $50-$200 annually average

Total Annual Operating Cost - $1,350-$4,800 depending on correction service level and optional subscriptions

Long-Term Value Retention

Trimble equipment maintains resale value better than many agricultural electronics due to:

Upgrade Compatibility - Older components often integrate with newer equipment, maintaining functionality even as technology advances. A 5-year-old NAV-900 controller works perfectly with the latest GFX displays, creating continued value.

Active Secondary Market - Strong demand exists for used Trimble components as farmers expand precision agriculture adoption. Complete systems sell for 40-60% of original value after 3-5 years, individual components retain 50-70% value over similar periods.

Transferability - Systems move easily between tractors, allowing farmers to repurpose components as equipment fleets change. This flexibility maintains value compared to integrated systems permanently tied to specific machines.

Conclusion

Trimble AutoPilot and Trimble GFX systems represent proven precision agriculture technology with the second-largest installed base globally. The combination of multi-brand compatibility, robust accuracy, comprehensive features, and competitive pricing makes Trimble the logical choice for operations valuing flexibility and independence from equipment manufacturers.

The Trimble GFX display family addresses diverse operational needs from entry-level guidance through enterprise-scale farm management. Whether selecting the economical GFX 350 for basic guidance, the versatile GFX 750 for complete precision agriculture capability, or premium GFX 1060/1260 displays for maximum functionality, operators access the same core technology platform with appropriate feature levels for their specific requirements.

Trimble NAV controllers provide the positioning and steering control foundation supporting all accuracy levels from economical RangePoint RTX through premium RTK repeatability. The ability to upgrade correction services without hardware changes protects investment as operational needs evolve.

Mixed-brand equipment fleets particularly benefit from Trimble's universal compatibility, maintaining consistent guidance technology regardless of tractor manufacturer. This consistency simplifies operator training, standardizes data formats, and enables equipment decisions based purely on agronomic needs rather than precision agriculture compatibility constraints.

For operations committed to specific equipment brands with strong factory integration, manufacturer-specific solutions like John Deere AutoTrac or Case IH AFS may offer advantages. However, the majority of agricultural operations benefit from Trimble's flexibility, proven reliability, and comprehensive aftermarket support network.

Transform your Trimble implementation with custom development from A-Bots.com. Our agricultural technology development services enhance Trimble systems through tailored solutions addressing your unique operational requirements. We specialize in:

Custom Mobile Applications - iOS and Android apps integrating with Trimble Connected Farm, providing field crews with specialized data collection tools, real-time equipment monitoring, and simplified task management interfaces designed for your specific workflows.

Enterprise Integration - Connect Trimble GFX systems with ERP platforms, accounting software, and cooperative management systems through custom API development, eliminating manual data transfer and creating seamless information flow across your complete technology infrastructure.

Advanced Analytics Development - Build sophisticated data analysis tools processing Trimble operational data, generating insights impossible with standard reporting tools, and supporting agronomic decision-making through custom algorithms and visualization.

Multi-Platform Compatibility Solutions - Create unified interfaces managing Trimble alongside other precision agriculture systems, providing single-pane visibility across mixed technology fleets and enabling coordinated operations between different guidance platforms.

Testing and Quality Assurance - Comprehensive compatibility testing ensuring Trimble systems work flawlessly with your specific equipment configurations, identifying potential issues before field deployment, and validating system performance against operational requirements.

Training Program Development - Custom operator training materials, interactive tutorials, and documentation tailored to your operation's specific Trimble configuration and workflow requirements.

With expertise in agricultural IoT protocols, GNSS positioning systems, ISOBUS implementation, and precision agriculture workflows, A-Bots.com delivers solutions that maximize the value of your Trimble investment. Contact our development team to discuss how custom software can enhance your precision agriculture capabilities.

References

- Iowa State University Extension and Outreach - "Precision Agriculture Technology Adoption and Benefits" - https://www.extension.iastate.edu/

- Purdue University Agricultural and Biological Engineering - "Automated Steering System Performance Research" - https://www.purdue.edu/

- Trimble Agriculture Official Website - Technical Specifications and Product Information - https://agriculture.trimble.com/

- American Society of Agricultural and Biological Engineers (ASABE) - "GNSS Guidance Systems Standards" - https://www.asabe.org/

- Farm Equipment Magazine - "Precision Agriculture Market Analysis 2024-2025" - https://www.farm-equipment.com/

- Precision Farming Dealer - "Trimble Technology Updates and Industry Analysis" - https://www.precisionfarmingdealer.com/

✅ Hashtags

#TrimbleGFX,

#TrimbleAutoPilot,

#TrimbleAgriculture,

#PrecisionAgriculture,

#GPSGuidance,

#AutomatedSteering,

#RTKPositioning,

#TractorGPS,

#FarmAutomation,

#AgTech,

#SmartFarming,

#PrecisionFarming,

#AgriculturalTechnology,

#FarmEfficiency,

#CropManagement,

#DigitalFarming

Other articles

John Deere Operations Center, AutoTrac and StarFire GPS John Deere Operations Center, AutoTrac automated steering, and StarFire GPS receivers form the industry-leading precision agriculture ecosystem with proven performance across millions of acres. This comprehensive 2025 guide examines system architecture, hardware components, correction service options (SF1/SF2/SF3/RTK), and cloud-based farm management capabilities. Real-world data shows 15-20% efficiency improvements, 59% herbicide reduction, and $15.70 per acre savings. We analyze retrofit costs ($12,000-$18,000), subscription fees ($1,800-$2,400 annually), and adoption statistics (58-82% penetration on large farms). Technical comparison with Trimble, Case IH, AGCO, and Topcon alternatives helps farmers make informed decisions. A-Bots.com offers custom mobile app development, system integration, and testing services for precision agriculture technology enhancement.

Custom Agriculture App Development for Farmers In 2024, U.S. farmers are more connected than ever — with 82% using smartphones and 85% having internet access. This article explores how mobile applications are transforming everyday operations, from drone-guided field scouting to livestock health tracking and predictive equipment maintenance. It examines why off-the-shelf apps often fail to address specific farm needs and how collaborative, farmer-funded app development is gaining momentum. Through real-world examples and step-by-step guidance, readers will learn how communities of growers can fund, design, and launch custom apps that fit their exact workflows. A-Bots.com offers tailored development services that support both solo farmers and agricultural groups. With offline capabilities, modular design, and support for U.S. and international compliance, these apps grow alongside the farm. Whether you're planting soybeans in Iowa, raising cattle in Texas, or running a greenhouse in California — this article offers the tools and inspiration to build your own farm technology. Discover why more farmers are saying: we don’t wait for the future — we build it.

Logistics and Truck App Development for Self Driving Semi Trucks The logistics industry is entering a new era where automated trucking and self driving semi trucks reshape global supply chains. Success in this transformation depends on advanced logistics and truck app development—apps that manage fleets, integrate IoT, enable predictive maintenance, and provide seamless control of autonomous semi trucks. At A-Bots.com, we specialize in building tailor-made solutions that combine safety, compliance, and innovation. From end-to-end custom development to outsourced testing and QA, our expertise ensures that companies in the U.S., Europe, and China are ready for the future of driverless semi trucks. Explore how mobile platforms are becoming the command centers of modern logistics and discover why A-Bots.com is the trusted logistics app development company for forward-thinking enterprises.

Farmer App Development Company - Smart Farming Apps and Integrations Looking for an app for agriculture that crews will actually open at dawn? A-Bots.com builds lean, offline-first farming applications that slot into what you already run—John Deere Operations Center, Climate FieldView, Trimble—so plans flow into cabs and clean records flow back. As a specialist farmer app development company, we start with a nucleus that pays back quickly: tasks that close the loop, imagery/weather signals that become guided tickets, and auditor/buyer-ready exports. Then we expand through a plugin architecture—labor & QC for orchards and berries, virtual fencing & grazing timelines, or contract-aware traceability/carbon modules—without breaking operator muscle memory. Your smart farming app comes with plain-language data contracts (who sees what, for how long, and why), one-tap export/revocation, and role-based access for advisors, landlords, and buyers. Serving the US, Canada, Scandinavia, and EU, we respect mixed fleets and regional policy, mapping to ADAPT/ISOBUS and EU data expectations by design. Budget tight? We help structure cooperative or buyer-aligned crowdfunding so critical plugins ship sooner—under clear ownership. Build beside the best farmer apps, not against them—and turn season pressure into repeatable wins.

Top stories

Copyright © Alpha Systems LTD All rights reserved.

Made with ❤️ by A-BOTS