Home

Services

About us

Blog

Contacts

Raven Industries Precision Agriculture Systems: Ground Control Solutions for Modern Farming

Developing advanced ground control solutions for Raven precision agriculture systems? A-Bots.com specializes in custom software development for Raven Industries equipment and ground control station technologies. Whether you need custom mobile applications integrating with Raven Slingshot connectivity platform, API development connecting Viper 4+ displays to enterprise farm management systems, automated workflow solutions for Raven Autonomy implementations, data visualization dashboards processing telemetry from Field Hub controllers, or comprehensive testing and validation of Raven equipment compatibility across diverse fleet configurations, our development team delivers production-ready solutions. We create tailored ground control interfaces for remote equipment monitoring, develop custom prescription management tools, build cloud integration layers for Slingshot data synchronization, implement advanced analytics transforming operational data into actionable insights, and provide quality assurance testing ensuring flawless system performance. From independent farms to agricultural technology companies and equipment dealers, A-Bots.com enhances Raven implementations through expert software development addressing your unique operational requirements and maximizing precision agriculture technology investments.

Raven Industries: Precision Agriculture Innovation Pioneer

Raven Industries established itself as a precision agriculture technology innovator beginning in 1956, initially manufacturing high-altitude research balloons before pivoting to agricultural applications in the 1980s. The company pioneered several groundbreaking technologies including early boom section control systems, precision application controllers, and field computer displays when precision agriculture barely existed as a concept.

In 2021, CNH Industrial acquired Raven Industries for $2.1 billion, integrating Raven's technology portfolio into CNH's Case IH and New Holland equipment lines while maintaining Raven as an independent brand serving aftermarket and multi-brand applications. This acquisition combined Raven's application control expertise with CNH's global manufacturing scale and dealer network, accelerating technology development and market expansion.

Raven's technology philosophy emphasizes practical innovation solving real farmer problems rather than pursuing technology for its own sake. The company focuses heavily on application control, autonomous systems, and connectivity solutions - areas where they've established market leadership positions. While competitors like John Deere and Trimble offer broader precision agriculture portfolios, Raven concentrates on specific technology domains where they deliver best-in-class performance.

The Raven product ecosystem centers on ground control stations including the Viper 4+ display serving as the primary operator interface, Slingshot connectivity platform providing telemetry and remote monitoring, Field Hub application controllers managing implement functions, and emerging Raven Autonomy systems enabling supervised autonomous equipment operation. These components integrate creating comprehensive precision agriculture solutions working across all equipment brands.

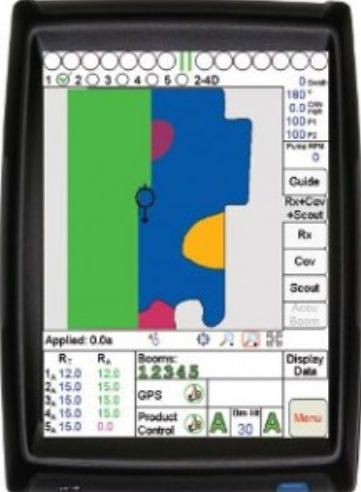

Raven Viper 4+ Display: Command Center for Precision Agriculture

The Raven Viper 4+ represents the latest generation of Raven's agricultural display technology, serving as the primary ground control interface for equipment operators. This ruggedized touchscreen display provides guidance, application control, data documentation, and implement management from a single consolidated interface.

Technical Specifications

Display Characteristics:

- Screen Size: 10.4 inches diagonal

- Resolution: 1024 x 768 pixels (XGA)

- Display Technology: TFT LCD with LED backlight

- Brightness: 1000 nits with automatic ambient light adjustment

- Touchscreen: Resistive multi-touch supporting glove operation

- Viewing Angles: 170 degrees horizontal, 160 degrees vertical

- Operating Temperature: -30°C to +70°C

- Storage Temperature: -40°C to +85°C

- Humidity: 5% to 95% non-condensing

- Ingress Protection: IP67 (dust-tight, water immersion resistant)

- Shock Resistance: MIL-STD-810G certified

- Vibration Resistance: 5 Grms continuous

- Power Input: 10-32 VDC with reverse polarity protection

- Power Consumption: 15W typical, 22W maximum

- Dimensions: 285 mm x 210 mm x 55 mm

- Weight: 1.5 kg

- Mounting: AMPS hole pattern, RAM mount compatible

Processing and Memory:

- Processor: Quad-core ARM Cortex-A9 at 1.2 GHz

- Graphics: Integrated Mali-400 GPU

- Memory: 2 GB DDR3 RAM

- Storage: 16 GB eMMC flash storage

- Operating System: Embedded Linux with real-time kernel

Connectivity Options:

- USB 2.0: Two host ports for data transfer and accessories

- Ethernet: 10/100 Mbps RJ45 for network connections

- Wi-Fi: 802.11 b/g/n 2.4 GHz wireless

- Bluetooth: 4.0 LE for peripheral connections

- Serial: RS-232 for legacy equipment compatibility

- CAN Bus: Dual ISO 11783 (ISOBUS) interfaces

- Auxiliary: Four configurable digital input/output channels

Core Functionality

Guidance Capabilities:

The Viper 4+ provides manual and automated guidance through integration with Raven steering controllers. Manual guidance displays visual light bar indicators and directional arrows showing operators the correct path to follow. When coupled with Raven steering systems, automated guidance maintains paths with accuracy dependent on GNSS receiver quality and correction services employed.

Guidance patterns include straight A-B lines for traditional row crop operations, adaptive curves following field contours for terraced or irregular terrain, circle patterns for center-pivot irrigation fields, and custom recorded paths for specialized applications. The system stores unlimited guidance lines per field with automatic selection based on equipment approach angle and position.

The display calculates real-time guidance information at 10 Hz (ten times per second), providing smooth steering indicators for manual operation or feeding steering controllers at rates ensuring precise automated path following. Turn compensation algorithms adjust guidance calculations during headland turns, maintaining accurate positioning through complex maneuvers.

Application Control:

Raven built its reputation on application control technology, and the Viper 4+ continues this heritage with sophisticated section control and variable-rate application capabilities. The display interfaces with Raven Field Hub controllers or ISOBUS-compliant implements managing up to 128 individual control sections - the highest capacity in the industry.

Section control automatically activates and deactivates implement sections based on coverage history, preventing over-application on field boundaries, point rows, and previously covered areas. The system tracks coverage across multiple operations with different equipment widths, maintaining application accuracy regardless of approach angles or implement size changes.

Variable-rate application adjusts input rates based on prescription maps created in desktop software or imported from third-party agronomic platforms. The Viper 4+ accepts ISO-XML prescription files, Shapefile formats with rate attributes, and proprietary formats from major farm management software. Rate changes execute within 0.3 seconds of crossing prescription zone boundaries, ensuring accurate application even during ground speed variations.

The display logs actual applied rates versus prescribed rates at sub-second intervals, generating detailed as-applied maps documenting what occurred in every square meter of each field. This documentation supports agronomic analysis, regulatory compliance, and identification of equipment calibration issues requiring attention.

ISOBUS Universal Terminal:

The Viper 4+ functions as a certified ISOBUS Universal Terminal (UT) complying with ISO 11783 standards and certified by the Agricultural Industry Electronics Foundation (AEF). This certification ensures compatibility with ISOBUS-compliant implements from any manufacturer worldwide, allowing farmers to control diverse equipment through a single display rather than managing multiple manufacturer-specific terminals.

ISOBUS support enables consolidated operation where the Viper 4+ simultaneously manages guidance, application control, and implement-specific functions including seed meter speeds, downforce adjustments, or boom height controls. This consolidation reduces cab clutter, simplifies operator workflow, and ensures consistent interfaces across different implement types.

The display supports ISOBUS Task Controller (TC-BAS, TC-GEO, TC-SC) functionality managing section control and variable-rate application for any compliant implement. Aux-N implement control allows operating hydraulic functions, adjusting settings, and monitoring implement status through the Viper 4+ interface regardless of implement manufacturer.

Data Management:

The Viper 4+ captures comprehensive operational data including coverage maps, as-applied rate maps, yield information (when connected to yield monitoring systems), and operational summaries. All documentation automatically associates with fields defined in the display's database, organizing information chronologically and by operation type.

Storage capacity accommodates hundreds of fields with years of operational history. The 16 GB internal memory provides ample space for typical farming operations, though large-scale farms with thousands of fields across decades may eventually require data archiving to external storage.

Data export occurs through USB connections, Wi-Fi file transfer, or automatic synchronization via Raven Slingshot connectivity. The display exports standard formats including ISO-XML, Shapefile, GeoTIFF, and CSV ensuring compatibility with virtually all farm management software platforms.

Installation and Mounting

The Viper 4+ mounts in equipment cabs using versatile mounting systems accommodating various cab configurations. The standard AMPS hole pattern on the display back accepts RAM mounts, articulating arms, and custom brackets. Most installations position displays to the operator's right within comfortable reach for touchscreen interaction without obstructing critical OEM gauges or controls.

Power connection uses weatherproof connectors mating with supplied wiring harnesses. The reverse polarity protection prevents damage from incorrect wiring during installation. Communication connections include CAN bus cables linking to implement controllers, USB cables for GNSS receivers or steering controllers, and network cables for connectivity features.

Typical installation time runs 2-4 hours including mounting, wiring, and initial configuration. Experienced installers often complete installations in 90 minutes. The modular design allows operators to transfer displays between equipment relatively easily, protecting investment value when equipment fleets change.

Performance in Field Conditions

The Viper 4+ delivers reliable performance across harsh agricultural environments. The resistive touchscreen works consistently with gloves, wet hands, and dust-covered screens where capacitive touchscreens often fail. The 1000-nit brightness remains readable in direct sunlight, while automatic dimming reduces eye strain during nighttime operations.

Temperature performance spans extreme ranges encountered in agriculture. The display operates reliably at -30°C during winter operations and withstands +70°C cab temperatures during summer without thermal shutdown or performance degradation. The IP67 rating ensures complete dust protection and water resistance withstanding high-pressure washdown during equipment cleaning.

Vibration tolerance meets military specifications, preventing screen flickering, connection failures, or component damage during rough field operations. The rugged construction withstands years of continuous vibration exposure that would destroy consumer electronics within months.

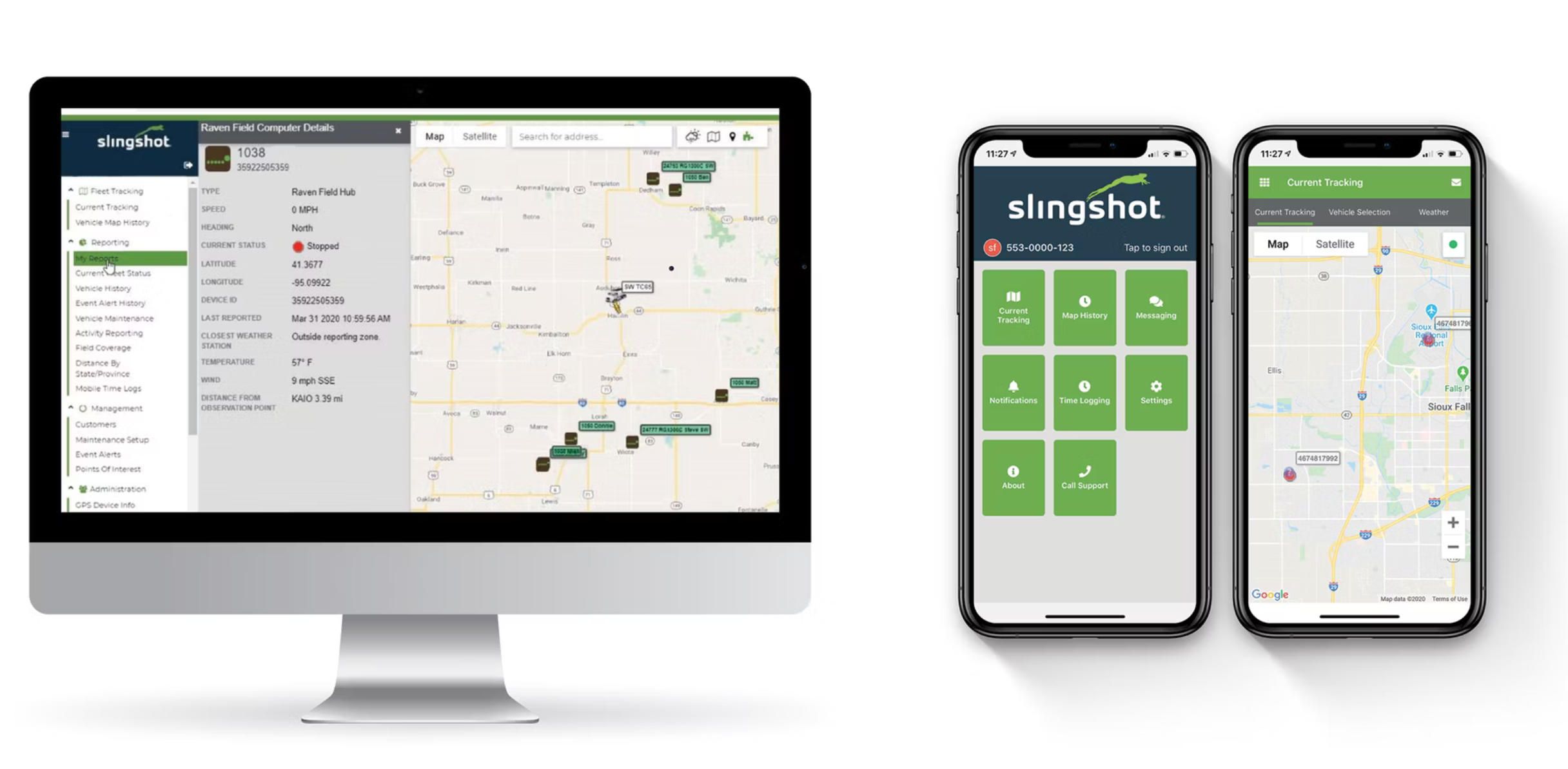

Raven Slingshot: Connected Farm Intelligence Platform

Raven Slingshot transforms individual equipment into connected nodes within a comprehensive farm intelligence network. This cloud-based platform provides real-time equipment monitoring, automatic data synchronization, remote support capabilities, and fleet management tools accessible from desktop computers, tablets, and smartphones.

Architecture and Connectivity

Slingshot utilizes cellular modems installed on equipment providing continuous connectivity when operating within cellular coverage areas. The modems communicate with Viper 4+ displays and other Raven components through CAN bus connections, collecting operational data, position information, and system status continuously.

Data transmits to secure cloud servers through encrypted cellular connections, ensuring information privacy and preventing unauthorized access. The system operates on multiple cellular networks automatically selecting the strongest available signal, maximizing connectivity across diverse geographic regions and carrier coverage areas.

When operating in areas without cellular coverage, Slingshot queues data locally, automatically uploading when connectivity restores. This store-and-forward architecture ensures complete data capture without gaps from temporary connectivity interruptions common in rural agricultural areas.

Real-Time Fleet Monitoring

Equipment Location Tracking:

Slingshot displays real-time positions for all connected equipment on interactive maps. Farm managers view where tractors currently operate, which fields receive attention, and equipment movement patterns throughout the day. Historical track logs show where equipment traveled over previous days, weeks, or entire seasons.

Location tracking supports multiple operational benefits beyond simple awareness. Managers coordinate multiple machines avoiding conflicts or inefficient positioning. Recovery of stolen equipment becomes significantly easier with real-time tracking capabilities. Insurance companies increasingly offer premium discounts for farms utilizing GPS tracking on high-value equipment.

Operational Status Monitoring:

Beyond position, Slingshot monitors operational status including whether equipment is actively working, traveling, or idle. The system distinguishes productive field time from non-productive activities like transport, refueling, or maintenance. This visibility enables identifying efficiency opportunities and documenting productive hours supporting operational planning and cost allocation.

The platform monitors operational parameters including ground speed, area covered, application rates, and yield data (from harvest equipment). Managers track progress toward daily goals, identify underperforming equipment or operators requiring attention, and adjust resource allocation optimizing fleet utilization.

Alert and Notification System:

Configurable alerts notify managers when important events occur. Geofence alerts trigger when equipment enters or exits defined areas, supporting security monitoring and verifying operators work in assigned fields. Idle time alerts identify equipment sitting unproductively beyond specified thresholds, revealing inefficiencies or problems requiring investigation.

Operational alerts notify managers about application rate deviations, coverage gaps, equipment faults, or other issues requiring attention. The notification system sends alerts via email, SMS text messages, or push notifications to mobile apps, ensuring timely awareness regardless of manager location.

Automatic Data Synchronization

Slingshot automatically uploads operational data from Viper 4+ displays to cloud storage eliminating manual USB data transfer. As-applied maps, coverage documentation, yield information, and operational summaries populate the cloud database without operator intervention, ensuring consistent data capture and reducing administrative workload.

The synchronization occurs continuously during field operations when cellular connectivity exists, providing near-real-time data availability. Managers access current operational information without waiting for equipment to return to farmsteads, enabling immediate issue identification and response.

Bidirectional synchronization supports wireless prescription map downloads. Agronomists or managers create or modify prescriptions in office software, upload to Slingshot, and prescriptions automatically transfer to Viper 4+ displays when equipment connects. This wireless workflow eliminates USB drive handling, reduces errors from wrong files or outdated prescriptions, and accelerates operational responsiveness.

Remote Support and Diagnostics

Slingshot enables remote technical support where dealers or Raven support staff connect to Viper 4+ displays through secure internet connections. Support technicians view operator screens exactly as they appear in the cab, diagnose configuration issues, adjust settings, and guide operators through procedures without farm visits.

This remote capability dramatically reduces downtime during critical operational windows. Issues requiring hours or days for on-site service calls often resolve within minutes through remote sessions. The capability proves particularly valuable during peak planting or harvest seasons when equipment downtime causes significant financial impact.

Diagnostic data collection occurs automatically, with Slingshot uploading system logs, configuration files, and error reports. When operators contact support, technicians access relevant diagnostic information before conversations begin, accelerating troubleshooting and issue resolution.

Mobile and Web Access

Slingshot provides access through multiple interfaces addressing different use cases and user preferences. The web portal accessed through standard browsers offers comprehensive functionality including detailed maps, extensive data analysis tools, report generation, and administrative functions. Desktop or laptop computers provide comfortable interfaces for extended analysis sessions and planning activities.

Mobile applications for iOS and Android devices enable field-level access from smartphones and tablets. The mobile interface focuses on essential monitoring and documentation functions, presenting information optimized for small screens and touch interaction. Managers monitor operations, review progress, and respond to alerts without returning to offices or accessing computers.

The mobile apps work offline, caching relevant data for current operations. Operators document field observations, capture geo-tagged photos, and record notes without cellular connectivity. Changes synchronize automatically when connection restores, ensuring no data loss in remote locations.

Integration with Farm Management Software

Slingshot integrates with major farm management software platforms through API connections and standard data formats. Operations using Climate FieldView, Granular, SST Software, or other platforms synchronize data between Slingshot and these systems, maintaining information consistency and eliminating duplicate entry.

The integration supports bidirectional workflows where prescription maps created in agronomic software automatically transfer to Slingshot for wireless delivery to equipment, while as-applied maps and operational documentation flow from Slingshot back to farm management platforms for analysis and record-keeping.

Open API access allows custom integrations for operations with specialized requirements or internal software systems. A-Bots.com develops custom API connections linking Slingshot with ERP platforms, accounting systems, cooperative management tools, and proprietary agricultural databases, creating seamless data flow across complete operational technology ecosystems.

Raven Autonomy: Supervised Autonomous Equipment Solutions

Raven Autonomy represents the company's entry into autonomous agriculture, providing supervised autonomy systems where operators monitor equipment from remote locations while machines execute field tasks independently. This approach balances automation benefits with practical implementation realities and regulatory requirements maintaining human oversight.

Autonomous System Architecture

Perception Systems:

Raven Autonomy utilizes multi-sensor fusion combining GNSS positioning, computer vision, LiDAR, and radar technologies creating comprehensive environmental awareness. The perception system operates redundantly - multiple independent sensors observe the environment with disparate technologies, ensuring system reliability even when individual sensors encounter challenging conditions.

Cameras provide high-resolution visual information identifying crops, obstacles, field boundaries, and operational conditions. Machine learning algorithms trained on millions of agricultural images recognize plants, weeds, equipment, people, animals, buildings, and other relevant objects. The vision system operates across lighting conditions including full sunlight, twilight, and darkness using near-infrared imaging.

LiDAR sensors generate three-dimensional point clouds measuring distances to surrounding objects with centimeter precision. These sensors detect obstacles regardless of visual characteristics, identifying objects invisible to cameras due to camouflage, similar colors, or poor lighting. The LiDAR provides reliable detection in dust, light rain, and other conditions challenging camera-based systems.

Radar sensors detect moving objects at extended ranges, identifying approaching vehicles, people, or animals before they enter immediate vicinity. The radar works reliably in heavy rain, fog, dust, or darkness where visual sensors struggle. Multi-frequency radar distinguishes object types based on reflection characteristics, differentiating metal equipment from organic materials or people.

Navigation and Path Planning:

The autonomous system plans routes optimizing coverage efficiency while respecting field boundaries, obstacles, and operational constraints. Path planning algorithms account for implement width, turning radius, headland requirements, and obstacle avoidance generating efficient field coverage patterns.

Dynamic replanning occurs continuously as conditions change. When the system detects unexpected obstacles - equipment, people, animals, or field anomalies - it recalculates paths avoiding these hazards while maintaining operational efficiency. The replanning happens in milliseconds, enabling real-time response to dynamic environments.

GNSS positioning with RTK corrections provides 2-3 cm accuracy enabling precise path following required for controlled traffic farming, row crop cultivation, or operations requiring year-over-year repeatability. Integration with Viper 4+ displays and existing Raven guidance infrastructure leverages proven positioning technology reducing development complexity and ensuring reliability.

Control Systems:

Autonomous control manages steering, speed, implement functions, and system modes executing planned operations without operator input. The control architecture implements multiple safety layers ensuring safe operation even when individual components fail.

Primary control runs on high-reliability processors with watchdog timers and self-monitoring detecting processor faults, software errors, or communication failures. Redundant secondary controllers monitor primary system operation, taking control if anomalies are detected. Independent emergency stop systems operating on separate power supplies halt equipment immediately upon detecting unsafe conditions.

Control authority transfers seamlessly between autonomous and manual modes. Operators resuming control encounter no delays or complex procedures - simply grabbing the steering wheel or pressing controls immediately disengages autonomy and returns full authority to the operator. This instant manual override ensures safety during unexpected situations.

Remote Monitoring and Supervision

Supervision Station Interface:

Raven Autonomy provides ground control station software running on desktop computers, laptops, or tablets enabling operators to monitor and supervise autonomous equipment from remote locations. The interface displays real-time equipment positions, camera feeds, operational status, and system health information for multiple machines simultaneously.

The supervision interface presents information density enabling one operator to oversee 3-5 autonomous machines performing similar tasks in proximate locations. This productivity multiplication represents the core economic value proposition for autonomous systems - reducing labor requirements while maintaining operational capacity.

Camera feeds from autonomous equipment stream to supervision stations providing visual verification of system operation. Operators observe what machines see, confirming correct crop tracking, verifying obstacle avoidance, and monitoring work quality. Multiple camera angles cover complete equipment surroundings, eliminating blind spots and ensuring comprehensive situational awareness.

Intervention Capabilities:

Supervisors intervene when situations require human judgment or when autonomous systems encounter scenarios beyond their operational parameters. Intervention occurs through simple interfaces - clicking locations on maps directs equipment to specific positions, dragging boundaries adjusts field limits, or pressing controls pauses operations for issue investigation.

Remote control capability allows supervisors to operate equipment directly when autonomous systems cannot handle specific situations. The control interface resembles video game controllers with joysticks and buttons familiar to most operators, minimizing training requirements. Lag-free control requires robust network connectivity, limiting remote operation to situations where cellular or Wi-Fi provides adequate bandwidth and low latency.

Emergency stop functionality remains accessible at all times through prominent interface elements. Activating emergency stop immediately halts all equipment functions regardless of operational state, providing ultimate safety authority to human supervisors.

Operational Scenarios and Applications

Primary Tillage:

Autonomous systems excel at primary tillage operations involving repetitive straight passes across large fields with minimal obstacles. The operations require accurate path following but limited real-time decision-making, making them ideal candidates for early autonomous adoption.

Economic analysis shows primary tillage automation delivering fastest ROI due to extended operating hours enabled by autonomous systems. Equipment operates continuously through nights and weekends when labor availability constrains traditional operations, completing time-sensitive tillage within narrow windows between harvest and freeze-up or between frost and planting.

Grain Cart Operation:

Autonomous grain carts coordinate with manually-operated combines, positioning automatically for unloading without separate operators. The system tracks combine positions, anticipates when unloading is needed based on hopper fill levels, and autonomously navigates to optimal catch positions.

This application eliminates one operator from harvest crews without reducing capacity. Combines continue operating continuously while autonomous grain carts handle transport, unloading operators to focus on combine management or other harvest tasks. The labor savings accumulate particularly during extended harvest campaigns running multiple weeks.

Specialty Crop Applications:

High-value specialty crops including vegetables, tree fruits, and vineyards benefit from autonomous cultivation, targeted spraying, and selective harvest support. These applications require precision positioning and potentially complex implement control but often occur in structured environments with well-defined rows and predictable layouts.

The premium value of specialty crops justifies autonomous technology investments while the predictable environments enable reliable autonomous operation. Growers report successful autonomous implementations on lettuce cultivation, vineyard spraying, and berry harvest assistance applications.

Regulatory Compliance and Safety

Raven Autonomy systems comply with emerging autonomous agricultural equipment regulations in the United States and Canada. The systems implement safety standards from ISO, ASABE, and industry working groups developing autonomous agriculture guidelines. Compliance includes:

- Human supervision requirements maintaining operator oversight

- Geofencing limiting operations to approved areas

- Emergency stop systems independent of primary control

- Obstacle detection with automatic stopping

- Comprehensive data logging supporting incident investigation

- Regular safety system testing and validation

The supervised autonomy approach satisfies current regulatory frameworks requiring human monitoring while providing substantial automation benefits. As regulations evolve toward fully autonomous operation, Raven systems include architecture supporting future capability activation through software updates rather than hardware replacement.

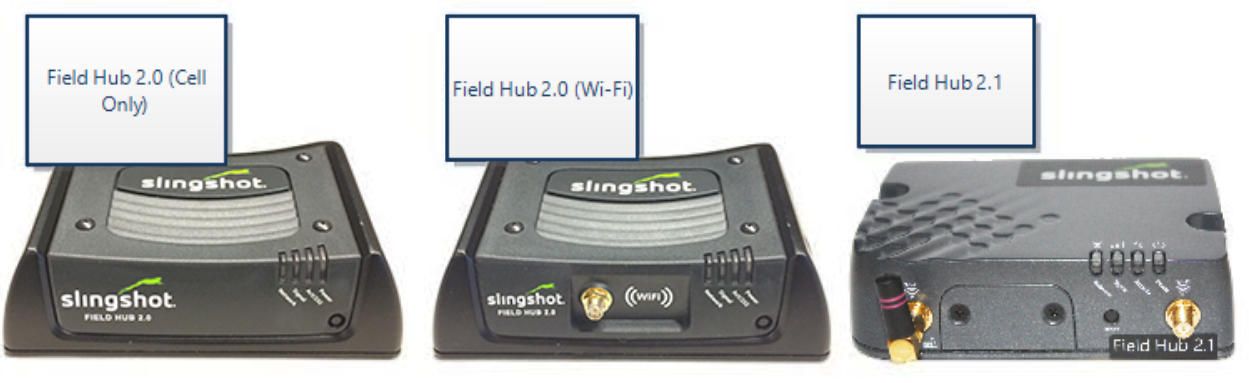

Raven Field Hub: Precision Application Controller

The Raven Field Hub serves as the precision application controller managing implement functions, section control, and variable-rate application. This ground control component translates commands from Viper 4+ displays into precise implement actuation, forming the bridge between operator intent and physical equipment response.

Technical Specifications

Physical Characteristics:

- Dimensions: 180 mm x 140 mm x 55 mm

- Weight: 0.8 kg

- Enclosure: Aluminum housing with conformal coating

- Ingress Protection: IP69K (high-pressure, high-temperature washdown resistant)

- Operating Temperature: -40°C to +85°C

- Storage Temperature: -40°C to +100°C

- Shock: MIL-STD-810G compliant

- Vibration: 10 Grms continuous

- Power Input: 9-32 VDC

- Power Consumption: 5W typical, 12W maximum with all outputs active

Control Capabilities:

- Section Control: Up to 128 independent sections

- Control Output Types: PWM, on/off solenoid, motor drive

- Output Current: 3A per channel, 40A total

- Update Rate: 20 Hz control loop

- Response Time: <50 milliseconds from command to output change

- Sensor Inputs: 16 analog or digital configurable channels

- Communication: ISO 11783 (ISOBUS) and Raven CAN protocols

Section Control Functionality

Field Hub implements sophisticated section control algorithms automatically activating and deactivating implement sections based on coverage history and real-time positioning. The system tracks previous passes with different equipment widths, approach angles, and implement types, preventing over-application regardless of operational complexity.

The 128-section capacity accommodates the largest agricultural implements including 120-foot sprayer booms with individual nozzle control, 48-row planters with row-by-row management, or wide fertilizer spreaders with numerous gates. This capacity exceeds most competitive controllers supporting 64 sections or fewer.

Section control operates with sub-meter accuracy when coupled with RTK or premium satellite corrections, enabling point-row efficiency approaching 100% coverage with minimal overlap. The system reduces input usage by 8-15% through overlap elimination alone, delivering measurable economic and environmental benefits.

Look-ahead algorithms anticipate section control requirements based on planned paths and coverage history, executing section changes before reaching boundaries rather than reacting after crossing. This proactive approach prevents over-application strips at field edges and ensures uniform coverage approaching boundaries.

Variable-Rate Application Control

Field Hub adjusts application rates in real-time based on prescription maps and ground speed changes. The controller accepts prescriptions with up to 10,000 management zones per field, supporting detailed soil-based prescriptions or high-resolution imagery-derived zone delineations.

Rate control algorithms compensate for ground speed variations maintaining prescribed rates regardless of speed changes during turns, slopes, or varying field conditions. The system monitors actual flow rates through sensors, comparing measured rates against targets and adjusting control outputs maintaining accuracy within ±3% of prescribed rates.

Multi-product control manages two independent products simultaneously, common in liquid fertilizer applications applying nitrogen solutions and additives concurrently. Each product maintains independent rate control responding to separate prescriptions, allowing complex nutrient management strategies.

Implement Integration

Sprayer Applications:

Field Hub integrates with boom sprayers controlling individual nozzle solenoids or multi-nozzle body selectors. The system monitors boom section pressures, flow rates, and nozzle status detecting plugged nozzles, pressure deviations, or component failures requiring operator attention.

Integration with pressure-based flow meters enables automatic section-by-section flow verification. The controller compares expected flow (based on nozzle specifications, pressure, and speed) against measured flow, identifying discrepancies indicating equipment problems. Alerts notify operators about sections requiring inspection or service.

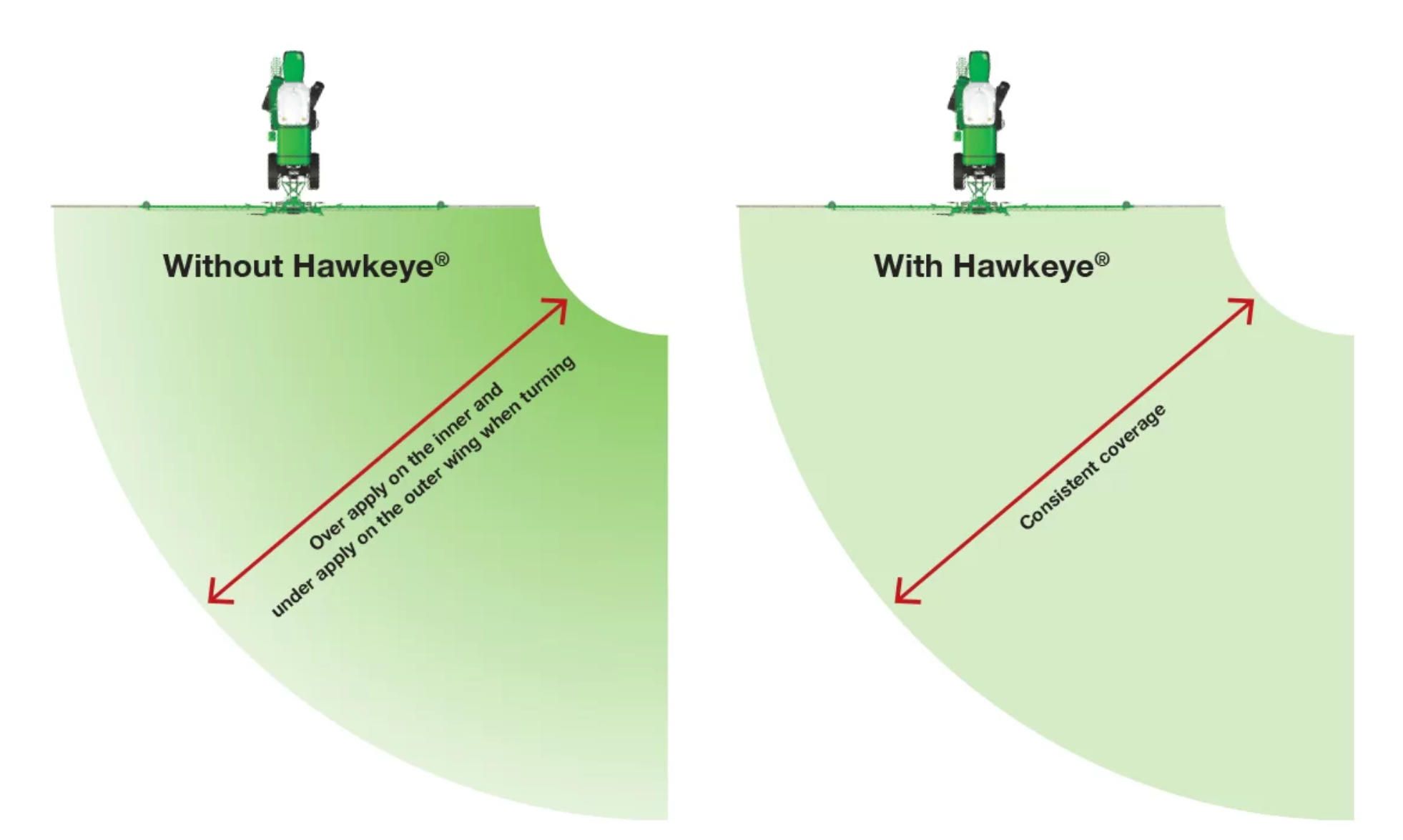

Advanced features include turn compensation automatically adjusting outer boom sections during turns maintaining proper application rates and preventing over-application on inside turns or under-application on outside boom sections. This compensation dramatically improves application uniformity approaching field boundaries and navigating irregular field shapes.

Planter Applications:

Integration with electric-drive seed meters enables individual row-unit control and monitoring. Field Hub manages meter speeds maintaining prescribed populations as ground speed varies or when crossing variable-rate prescription zones. Row-by-row monitoring tracks actual seed spacing, singulation quality, and population achievement.

Downforce control systems integrate with Field Hub managing pneumatic or hydraulic downforce maintaining consistent seed depth across varying soil conditions. The controller adjusts pressures automatically based on load cell measurements, ensuring optimal seed-to-soil contact without excessive compaction.

Population prescription execution occurs seamlessly with Field Hub translating agronomic population targets into appropriate meter speeds accounting for seed size, plate selection, and operational parameters. The system logs achieved populations versus prescribed targets, documenting actual planting for comparison against yield outcomes.

Fertilizer Applications:

Dry fertilizer spreaders utilize Field Hub for gate control and spinner speed management. Variable-rate prescriptions adjust fertilizer rates by modulating gate openings or changing spinner speeds maintaining proper distribution patterns across rate changes.

Liquid fertilizer systems employ flow control valves regulated by Field Hub maintaining prescribed rates regardless of speed variations or prescription zone transitions. Multiple product systems manage independent tanks with separate prescriptions enabling complex fertility programs applying nitrogen, phosphorus, potassium, and micronutrients at individually prescribed rates.

Hawkeye Nozzle Control System

Raven's Hawkeye technology represents advanced boom section control utilizing individual nozzle management and precision flow monitoring. This system elevates application accuracy beyond traditional boom section control, providing nozzle-level precision and real-time application verification.

System Architecture

Hawkeye installs directly on sprayer booms, positioning control modules at regular intervals managing small groups of nozzles. This distributed architecture locates control electronics near nozzles rather than centralizing control at the boom center, enabling faster response times and higher control resolution.

Each Hawkeye module controls 3-5 individual nozzles, managing solenoid valves and monitoring application through integrated flow sensors. The modules communicate with Field Hub controllers via CAN bus networks running along boom structures, forming coordinated control systems managing 100+ nozzles across boom widths exceeding 100 feet.

Individual Nozzle Control

Traditional boom section control divides booms into 10-20 sections, each section spanning 5-10 feet. Hawkeye increases resolution to individual nozzles spaced 15-20 inches apart, multiplying control precision by 3-6 times. This enhanced resolution further reduces overlap particularly on irregular field boundaries, point rows, and obstacle margins.

The individual control enables sophisticated application strategies impossible with conventional section control. Selective nozzle shutdown creates spray-free zones protecting sensitive areas, buildings, water sources, or non-target vegetation. Alternating nozzle patterns reduce drift risk by deactivating nozzles during crosswind conditions while maintaining partial coverage.

Nozzle-level control supports emerging computer vision applications where cameras identify weeds or plant health conditions and activate only nozzles positioned over treatment targets. This selective application reduces herbicide usage by 60-80% while maintaining weed control efficacy, delivering substantial economic and environmental benefits.

Flow Verification

Integrated flow sensors on each Hawkeye module measure actual application rates at nozzle-level resolution. The system compares measured flow against expected values (calculated from nozzle specifications, pressure, and speed), identifying deviations indicating equipment problems.

Plugged nozzles cause flow reductions detected within seconds, triggering immediate operator alerts. The system identifies specific nozzle locations requiring attention rather than generic boom section warnings, accelerating problem diagnosis and repair. Early detection prevents under-application strips that waste field area and reduce yields.

Flow monitoring verifies application rate accuracy across the boom width. Pressure variations, nozzle wear, or control system issues causing rate deviations are identified automatically. The monitoring provides continuous quality assurance confirming equipment delivers intended applications rather than assuming correct operation.

Application Quality Metrics

Hawkeye generates comprehensive application quality reports documenting coverage uniformity, rate accuracy, and system performance. The reports quantify actual application versus prescription targets showing percentage of field receiving proper treatment, areas with over-application or under-application, and statistical summaries of rate accuracy.

Quality metrics support multiple operational objectives. Agronomic analysis correlates application quality with yield outcomes, identifying whether rate variations impact crop performance. Regulatory compliance documentation proves proper pesticide application supporting licensing requirements. Equipment performance trending identifies degradation requiring maintenance or calibration before causing application problems.

Integration with Competitive Systems

Raven technology integrates with precision agriculture systems from other manufacturers, enabling mixed-technology implementations and providing flexibility for diverse equipment fleets.

Compatibility with OEM Displays

Raven Field Hub controllers and Hawkeye nozzle control systems integrate with factory displays from John Deere, Case IH, New Holland, AGCO, and other equipment manufacturers through ISOBUS protocols. Farmers utilizing OEM displays access Raven's advanced application control without replacing cab displays or navigation systems.

This compatibility allows operations to leverage OEM investment in guidance and displays while adding Raven's application control expertise. The approach particularly suits operations purchasing new equipment with factory precision agriculture packages who want enhanced application capabilities beyond OEM offerings.

Configuration occurs through ISOBUS Universal Terminal interfaces, with Raven controllers appearing as connected implements controllable through OEM displays. The integration provides functional implement control and monitoring though typically with less refined interfaces compared to native Raven displays designed specifically for these controllers.

Integration with Trimble and Topcon

Raven controllers work with Trimble and Topcon guidance systems and displays through ISOBUS and NMEA connections. Operations running Trimble GFX or Topcon X-Series displays add Raven application control, combining preferred guidance platforms with Raven's control expertise.

The integration maintains complete functionality including section control, variable-rate application, coverage documentation, and as-applied mapping. Data synchronization between systems occurs through standard formats ensuring information consistency across platforms.

Mixed-vendor implementations require careful configuration ensuring communication protocol compatibility and proper data mapping between systems. Experienced dealers knowledgeable about multi-vendor integration provide valuable assistance ensuring reliable operation and complete functionality.

CNH Industrial Integration

Following CNH's acquisition of Raven, particularly tight integration exists with Case IH and New Holland equipment. Newer CNH equipment often includes factory provisions for Raven technology installation, simplifying integration and reducing installation costs.

Case IH Advanced Farming Systems (AFS) and New Holland PLM (Precision Land Management) systems increasingly incorporate Raven technology, creating synergies where CNH guidance works seamlessly with Raven application control. This integration path benefits CNH equipment owners providing OEM-quality implementation of advanced Raven capabilities.

The CNH relationship accelerates Raven technology development and deployment at scale. CNH's global manufacturing reach and dealer network expand Raven availability to markets previously underserved by independent aftermarket channels. However, Raven maintains independent product lines serving multi-brand applications and competitive equipment owners.

Real-World Performance and Applications

Raven systems deliver measurable performance benefits documented through university research, independent testing, and farmer testimonials across diverse agricultural applications.

Input Reduction Through Precision Application

Research from Iowa State University and University of Nebraska documented that Raven section control systems reduce fertilizer and chemical usage by 8-12% through overlap elimination on typical row crop fields. For operations applying $100,000 in inputs annually, this represents $8,000-$12,000 in direct savings plus environmental benefits from reduced chemical loading.

Hawkeye individual nozzle control increases savings further. Field testing demonstrates additional 3-5% input reduction compared to conventional section control, with savings concentrated on irregular field boundaries and obstacle margins where nozzle-level precision provides greatest advantage.

Computer vision applications utilizing Hawkeye for selective weed spraying report 60-80% herbicide reduction while maintaining equivalent weed control. Early adopters document $30-50 per acre herbicide savings on applications where selective spraying proves feasible, though technology limitations currently restrict use to specific crops, weeds, and operational conditions.

Operational Efficiency Gains

Slingshot connectivity enables operational efficiency improvements beyond direct input savings. Fleet monitoring reduces non-productive time by 15-20% through better coordination, faster issue identification, and elimination of unnecessary travel or idle time. For operations running $500,000 in annual labor costs, efficiency improvements worth $75,000-$100,000 prove achievable.

Remote support via Slingshot reduces equipment downtime during critical operational windows. Issues requiring hours or days for on-site service visits often resolve within minutes remotely through remote technical assistance. During peak planting or harvest seasons when every hour counts, downtime reduction delivers value far exceeding Slingshot subscription costs.

Autonomous systems demonstrate productivity multiplication where one operator supervises 3-4 autonomous machines simultaneously. Early adopters report labor cost reductions of 40-60% for applicable operations while maintaining or increasing total acres covered. The economic impact compounds over years as labor availability challenges intensify and wage costs rise.

Application Quality Improvements

Hawkeye flow monitoring improves application quality by detecting problems immediately rather than discovering issues after completing entire fields. Plugged nozzles identified within seconds prevent under-application strips that reduce yields or require expensive retreatment. Operations report 25-35% reduction in application quality issues after implementing Hawkeye monitoring.

Consistent application accuracy documented through Hawkeye data supports agronomic optimization. Knowing actual application rates with certainty allows adjusting prescriptions confidently, fine-tuning nutrient programs, and correlating inputs with yield outcomes. The data quality enables precision agriculture to progress beyond basic implementation toward continuous improvement and optimization.

Case Studies

Large-Scale Corn and Soybean Operation - Illinois:

A 4,500-acre operation implemented complete Raven systems including Viper 4+ displays, Slingshot connectivity, and Field Hub controllers across their equipment fleet in 2022. Results after two full seasons:

- 11% reduction in herbicide costs through section control ($24,000 annual savings)

- 14% reduction in fertilizer costs through variable-rate application ($38,000 savings)

- 18% improvement in operational efficiency through Slingshot fleet monitoring

- Complete payback of $87,000 system investment in 18 months

- Continued annual savings exceeding $60,000

The farm manager reported: "Raven systems deliver John Deere or Trimble functionality at significantly lower cost. The Viper 4+ displays provide everything we need without unnecessary complexity. Slingshot fleet monitoring transformed our operational efficiency - we coordinate equipment better, respond to issues faster, and eliminate wasted time."

Custom Application Service - Kansas:

A three-operator custom spraying business covering 35,000 acres annually equipped sprayers with Raven Viper 4+ displays, Field Hub controllers, and Hawkeye nozzle control. The investment totaled $52,000 across three machines. Outcomes:

- 22% reduction in chemical usage through Hawkeye individual nozzle control

- Ability to charge premium pricing ($2-3 per acre) for documented application quality

- Client retention improved from 78% to 94% due to detailed documentation

- As-applied mapping providing liability protection and performance verification

- Annual revenue increase of $85,000 justifying technology investment multiple times over

The business owner stated: "Hawkeye individual nozzle control differentiates our service from competitors still using conventional boom sections. We demonstrate application quality through data rather than just claiming it. Clients pay premium pricing when they see documented proof of superior application accuracy."

Autonomous Grain Cart Implementation - Iowa:

A 6,000-acre grain farm implemented Raven Autonomy on two grain carts during 2023 harvest. The autonomous carts operated continuously coordinating with manually-operated combines. Results:

- Elimination of two seasonal operators (labor savings $25,000)

- Harvest capacity increased 35% through continuous operation

- Combines spent 92% of time harvesting versus 73% previously (less waiting for grain carts)

- Grain cart operators reassigned to truck driving and equipment maintenance

- Technology investment ($145,000 per cart) projected to pay back within 3 years

The farm technology manager reported: "Autonomous grain carts solved our seasonal labor shortage while increasing harvest efficiency. Combines run continuously without waiting for carts, operators focus on combine management rather than cart coordination, and we complete harvest faster with fewer people."

Cost Analysis and Investment Considerations

Understanding complete ownership costs helps farmers evaluate whether Raven systems fit their operational requirements and budgets.

Initial Investment Breakdown

Basic Guidance System:

- Raven Viper 4+ display: $3,800-$4,800

- GNSS receiver with RTK capability: $2,500-$4,000

- Steering controller and actuators: $2,000-$3,500

- Installation and calibration: $800-$1,500

- Total basic system: $9,100-$13,800

Advanced Application Control System:

- Viper 4+ display: $3,800-$4,800

- Field Hub controller: $1,800-$2,400

- Boom section control hardware: $2,500-$4,000 (depending on section count)

- Rate control valves: $1,200-$2,500

- Installation and configuration: $1,200-$2,000

- Total application system: $10,500-$15,700

Premium Hawkeye System:

- Viper 4+ display: $3,800-$4,800

- Field Hub controller: $1,800-$2,400

- Hawkeye nozzle control modules: $8,000-$12,000 (varies by boom size)

- Installation and configuration: $1,500-$2,500

- Total Hawkeye system: $15,100-$21,700

Slingshot Connectivity:

- Cellular modem hardware: $600-$900 per machine

- Installation: $200-$400

- Annual service subscription: $400-$800 per machine

Raven Autonomy:

- Autonomous system package: $80,000-$150,000 per machine (depending on equipment type)

- Supervision station software: $5,000-$8,000

- Installation and commissioning: $8,000-$15,000

- Total autonomy implementation: $93,000-$173,000

Annual Operating Costs

Correction Services:

- Free WAAS: $0 (basic accuracy)

- Premium satellite corrections: $1,200-$2,000 per receiver annually

- RTK network subscriptions: $1,500-$3,000 per receiver annually

- Own RTK base station: $8,000-$12,000 initial, $300-$600 annually for cellular connectivity

Software and Connectivity:

- Slingshot annual subscription: $400-$800 per connected machine

- Software updates: Typically included with hardware warranty, free afterward

- Cloud storage: Included with Slingshot subscription

Maintenance:

- Routine inspection and cleaning: $100-$200 per machine annually

- Calibration verification: Usually performed by operators, minimal cost

- Component replacement: $200-$500 annually average (cables, connectors, minor parts)

Total Annual Operating Costs:

- Basic system: $1,500-$3,200 per machine

- Advanced system with Slingshot: $2,300-$4,500 per machine

- Premium Hawkeye system: $2,500-$5,000 per machine

Return on Investment Analysis

ROI Calculation Example - 2,500 Acre Operation:

Annual Benefits:

- Input savings (10% reduction on $75,000): $7,500

- Labor efficiency (15% on $60,000): $9,000

- Yield improvement (3% on $450,000 gross): $13,500

- Reduced equipment hours and fuel: $4,000

- Total annual benefit: $34,000

System Investment:

- Two tractors with guidance and application control: $48,000

- One sprayer with Hawkeye system: $21,000

- Slingshot connectivity (3 machines): $4,500

- Total initial investment: $73,500

Annual Operating Costs:

- Correction subscriptions (3 receivers): $5,400

- Slingshot subscriptions (3 machines): $1,800

- Maintenance and support: $900

- Total annual operating: $8,100

First Year Analysis:

- Total first year cost: $81,600

- Total first year benefit: $34,000

- Net first year: -$47,600

Second Year and Beyond:

- Annual benefit: $34,000

- Annual operating cost: $8,100

- Net annual benefit: $25,900

Payback Period: 3.1 years (initial investment divided by net annual benefit)

Operations with higher input costs, larger acreages, or implementing autonomous systems typically achieve faster payback periods of 1-2 years. Smaller farms under 1,000 acres may experience 4-5 year payback depending on cropping intensity and input levels.

Installation and Technical Support

Successful Raven system implementations require proper installation procedures and access to competent technical support.

Dealer Network and Installation Services

Raven sells exclusively through authorized dealers providing sales, installation, training, and service support. Following CNH's acquisition, Raven technology is available through both CNH equipment dealers (Case IH and New Holland) and independent precision agriculture specialists.

Dealer capabilities vary significantly. CNH equipment dealers often prioritize equipment sales over precision agriculture specialization, potentially providing basic Raven support while lacking deep expertise. Independent precision agriculture dealers typically offer more specialized knowledge, extensive experience with multi-brand installations, and focused attention on technology implementation.

When selecting dealers, evaluate:

- Years of experience installing Raven systems

- Number of installations completed annually

- Technician certifications and training

- In-season support responsiveness and availability

- Demo equipment availability for trial before purchase

- References from existing customers

Professional installation typically costs $800-$2,500 depending on system complexity and equipment configuration. Installation includes mounting displays, running wiring harnesses, installing controllers and sensors, integrating with equipment electronics, calibrating steering systems, configuring application control, and providing operator training.

Many mechanically skilled farmers successfully install basic guidance systems themselves, saving installation costs. However, application control systems with numerous sensors, complex wiring, and hydraulic integration typically benefit from professional installation ensuring proper operation and avoiding troubleshooting during critical field seasons.

Training Programs

Raven provides training resources through multiple channels:

Dealer Training: Most dealers offer hands-on training during installation covering basic operation, system navigation, guidance setup, application control configuration, and data management. Quality dealers provide 3-4 hours of comprehensive training ensuring operators understand essential functions before field deployment.

Online Resources: Raven maintains video libraries, technical documentation, and interactive tutorials accessible through their website. The online materials cover product operation, troubleshooting procedures, calibration instructions, and advanced features. Self-paced learning allows operators to develop expertise gradually as operational experience accumulates.

Technical Support: Raven offers phone and email technical support during business hours (7:00 AM to 6:00 PM Central Time). Support specialists guide operators through troubleshooting procedures, answer configuration questions, and coordinate dealer service when necessary. Email support provides documented responses suitable for complex issues requiring detailed instructions or reference materials.

Webinar Series: Periodic webinars address specific topics including new product introductions, software updates, seasonal preparation procedures, and advanced operational techniques. Live webinars allow participant questions while recorded sessions remain accessible for future reference.

System Maintenance

Raven systems require minimal routine maintenance but benefit from periodic inspection:

Seasonal Preparation:

- Update software to latest versions

- Verify GNSS antenna mounting security and cable integrity

- Clean displays and inspect touchscreen responsiveness

- Check all electrical connections for corrosion

- Test steering system operation and recalibrate if needed

- Verify application control functionality and flow meter calibration

In-Season Maintenance:

- Clean displays weekly during intensive use

- Inspect wiring and connections monthly

- Monitor correction service subscription status

- Back up operational data regularly

- Review Slingshot connectivity and resolve connection issues

Off-Season Storage:

- Remove and store displays in temperature-controlled environments

- Protect electronic components from moisture and extreme temperatures

- Archive complete season data to external storage

- Review season performance and identify improvement opportunities

- Plan equipment upgrades or additions for following season

Warranty and Support

Raven provides standard two-year limited warranties on hardware covering defects in materials and workmanship. The warranty includes:

- Display units: Complete coverage for electronics, touchscreens, and mechanical components

- Controllers: Full coverage for processing hardware, communication interfaces, and control outputs

- Sensors and accessories: Coverage for included components and mounting hardware

Warranty excludes damage from accidents, misuse, environmental exposure beyond specifications, or modifications by unauthorized parties. Normal wear including touchscreen sensitivity degradation over time falls outside warranty coverage.

Extended warranty programs available through dealers add 1-3 years of coverage for 10-15% of purchase price. Extended coverage proves valuable for operations running equipment in harsh conditions or wanting predictable budgeting without unexpected repair costs.

Service occurs through authorized dealers. Warranty claims begin with dealer diagnosis determining whether issues qualify for warranty coverage. Raven typically resolves warranty claims within 5-7 business days, with dealers providing loaner equipment during peak seasons minimizing operational impact.

Conclusion

Raven Industries occupies a distinctive position in precision agriculture as a technology specialist focusing on application control, connectivity, and emerging autonomy. While broader competitors like John Deere, Trimble, and Ag Leader offer comprehensive precision agriculture portfolios, Raven concentrates on specific domains where they deliver market-leading performance.

The Viper 4+ display provides capable ground control functionality for guidance, application management, and operational documentation at competitive prices. The 10.4-inch touchscreen, ISOBUS Universal Terminal certification, and robust construction deliver reliability and capability suitable for professional agricultural operations. While lacking the screen size options and premium features of Trimble's highest-end displays, the Viper 4+ satisfies most farming operations' requirements without unnecessary complexity or cost.

Raven Slingshot connectivity transforms equipment into networked assets providing real-time visibility, remote support capabilities, and automatic data synchronization. The platform delivers immediate operational benefits through fleet coordination, issue identification, and efficiency optimization. As agriculture increasingly embraces connectivity and data-driven decision making, Slingshot positions Raven favorably for evolving farmer needs.

Field Hub controllers and Hawkeye nozzle control represent Raven's strongest competitive advantages. The 128-section capacity, individual nozzle control, and integrated flow verification exceed capabilities of most competitive application controllers. Operations prioritizing application quality, input efficiency, and documented performance find compelling value in Raven's application control technology.

Raven Autonomy positions the company at the forefront of autonomous agriculture development. The supervised autonomy approach balances automation benefits with practical implementation and regulatory realities. Early autonomous implementations demonstrate labor savings, productivity improvements, and operational flexibility supporting continued development and broader deployment.

CNH Industrial's acquisition provides Raven with manufacturing scale, global distribution, and financial resources accelerating technology development while maintaining independence serving multi-brand markets. This dual strategy benefits Case IH and New Holland equipment owners through integrated solutions while preserving aftermarket options for competitive equipment operators.

For operations prioritizing application control excellence, those implementing autonomous systems, or farms seeking capable precision agriculture at competitive prices, Raven systems warrant serious consideration alongside traditional market leaders. The technology specialization, competitive pricing, and CNH support create compelling value propositions for qualifying operations.

Enhance your Raven precision agriculture systems with custom software development from A-Bots.com. Our specialized development services maximize Raven technology investments through tailored solutions:

Ground Control Station Development - Create custom supervision interfaces for Raven Autonomy systems optimizing operator workflows, enhancing situational awareness, and enabling multi-machine coordination beyond standard capabilities. We design intuitive control stations processing real-time telemetry, integrating multiple data sources, and presenting information exactly as supervisors need to see it.

Slingshot Integration Services - Build custom API connections linking Raven Slingshot connectivity with ERP systems, accounting platforms, cooperative management tools, and proprietary agricultural databases. Our integration solutions eliminate manual data entry, ensure information consistency across systems, and create seamless workflows connecting field operations with business management.

Custom Mobile Applications - Develop iOS and Android applications extending Slingshot capabilities with specialized tools for field documentation, equipment inspection, maintenance tracking, and operational planning. Mobile apps complement Viper 4+ displays with functionality addressing unique operational requirements unavailable in standard software.

Viper 4+ Interface Customization - Modify display interfaces creating optimized operator experiences for specific workflows, implementing automation shortcuts, developing specialized screens for particular operations, and simplifying complex procedures through custom interface design.

Advanced Data Analytics - Build sophisticated analysis tools processing data from Field Hub controllers, generating insights impossible with standard reports, supporting agronomic decision-making through custom algorithms, and creating predictive models leveraging years of operational history.

Hawkeye Integration Solutions - Develop custom applications utilizing Hawkeye flow monitoring data, creating quality assurance systems, generating client reporting for custom applicators, and implementing advanced analytics correlating application quality with agronomic outcomes.

Testing and Quality Assurance - Comprehensive compatibility testing ensuring Raven systems work flawlessly with your specific equipment configurations, implement combinations, and operational procedures. We validate system performance, identify potential issues before field deployment, and ensure technology investments deliver expected benefits.

Automation Workflow Development - Implement automated processes reducing manual tasks, streamlining data transfers, automating prescription generation, and creating efficient workflows eliminating repetitive operations and human error.

Training Content Creation - Develop custom training materials, video tutorials, interactive guides, and documentation tailored to your operation's specific Raven configuration and operational procedures. Effective training maximizes technology adoption and ensures operators utilize system capabilities fully.

With expertise in agricultural automation protocols, autonomous system supervision, precision agriculture workflows, and ground control station development, A-Bots.com transforms Raven systems from standard equipment into optimized solutions perfectly matching your operational requirements. Our team understands the unique challenges of agricultural technology implementation and delivers practical solutions that work reliably in real-world farming conditions. Contact us to discuss how custom software development enhances your Raven precision agriculture capabilities and maximizes return on technology investments.

References

- Iowa State University Extension and Outreach - "Precision Application Technology Research and Economics" - https://www.extension.iastate.edu/

- University of Nebraska-Lincoln Department of Biological Systems Engineering - "Autonomous Agricultural Equipment Studies" - https://bse.unl.edu/

- Raven Industries Official Website - Product Documentation and Technical Specifications - https://ravenind.com/

- Agricultural Industry Electronics Foundation (AEF) - "ISOBUS Standards and Certification" - https://www.aef-online.org/

- CNH Industrial Corporate Communications - "Raven Industries Acquisition and Integration Updates" - https://www.cnhindustrial.com/

- Precision Farming Dealer - "Raven Technology Analysis and Market Coverage" - https://www.precisionfarmingdealer.com/

✅ Hashtags

#RavenIndustries,

#RavenViper4,

#RavenSlingshot,

#RavenAutonomy,

#HawkeyeControl,

#FieldHub,

#PrecisionAgriculture,

#GroundControlStation,

#AutonomousAgriculture,

#ApplicationControl,

#CNHIndustrial,

#PrecisionSpraying,

#AgTech,

#SmartFarming,

#FarmAutomation,

#AgriculturalTechnology,

#ConnectedFarming

Other articles

Custom Agriculture App Development for Farmers In 2024, U.S. farmers are more connected than ever — with 82% using smartphones and 85% having internet access. This article explores how mobile applications are transforming everyday operations, from drone-guided field scouting to livestock health tracking and predictive equipment maintenance. It examines why off-the-shelf apps often fail to address specific farm needs and how collaborative, farmer-funded app development is gaining momentum. Through real-world examples and step-by-step guidance, readers will learn how communities of growers can fund, design, and launch custom apps that fit their exact workflows. A-Bots.com offers tailored development services that support both solo farmers and agricultural groups. With offline capabilities, modular design, and support for U.S. and international compliance, these apps grow alongside the farm. Whether you're planting soybeans in Iowa, raising cattle in Texas, or running a greenhouse in California — this article offers the tools and inspiration to build your own farm technology. Discover why more farmers are saying: we don’t wait for the future — we build it.

App Development Companies for Startups: USA, EU and Nordics Guide This guide examines app development companies for startups across USA, European, and Scandinavian markets. American developers excel in rapid scaling and real-time architecture, with projects ranging from $30,000 to $250,000+. European partners specialize in GDPR compliance, fintech solutions, and multi-language applications. Nordic companies lead in impact-driven development, deep tech expertise, and sustainable technology practices. The article analyzes market-specific expectations, development methodologies, and emerging trends including AI integration, low-code platforms, and 5G capabilities. Features expert quotes from industry leaders, authoritative market data, and practical frameworks for evaluating technical expertise, cultural alignment, and post-launch support when selecting development partners.

John Deere Operations Center, AutoTrac and StarFire GPS John Deere Operations Center, AutoTrac automated steering, and StarFire GPS receivers form the industry-leading precision agriculture ecosystem with proven performance across millions of acres. This comprehensive 2025 guide examines system architecture, hardware components, correction service options (SF1/SF2/SF3/RTK), and cloud-based farm management capabilities. Real-world data shows 15-20% efficiency improvements, 59% herbicide reduction, and $15.70 per acre savings. We analyze retrofit costs ($12,000-$18,000), subscription fees ($1,800-$2,400 annually), and adoption statistics (58-82% penetration on large farms). Technical comparison with Trimble, Case IH, AGCO, and Topcon alternatives helps farmers make informed decisions. A-Bots.com offers custom mobile app development, system integration, and testing services for precision agriculture technology enhancement.

Trimble GFX Agriculture Guidance and AutoPilot Systems Trimble AutoPilot and Trimble GFX systems dominate aftermarket precision agriculture with hundreds of thousands of installations worldwide. This comprehensive technical guide examines the complete product lineup including GFX 350 entry display, GFX 750 mid-range system, GFX 1060 large-format console, and premium GFX 1260. Detailed specifications for NAV 500 and NAV 900 navigation controllers cover GNSS accuracy levels, correction services (RangePoint RTX, CenterPoint RTX, RTK), and terrain compensation technology. Real-world performance data shows 8-12% fuel savings, 10-15% overlap reduction, and 1-2 year payback periods. Multi-brand compatibility works with John Deere, Case IH, AGCO, and all tractor manufacturers. Complete installation procedures, cost breakdowns, competitive comparisons, and maintenance requirements. A-Bots.com offers custom software development, API integration, and testing services for Trimble implementations.

Ag Leader InCommand 800 and 1200 Precision Agriculture Displays Ag Leader InCommand displays dominate independent aftermarket precision agriculture with tens of thousands of installations worldwide. This comprehensive technical guide examines InCommand 800 (8-inch display, quad-core processor, $3,500-$4,500) and InCommand 1200 (12.1-inch screen, hexa-core processor, $5,500-$7,000) systems including detailed specifications, capabilities, and performance characteristics. Complete coverage of SureDrive automated steering achieving 2-4 cm RTK accuracy, SMS farm management software for prescription creation and data analysis, and universal compatibility with John Deere, Case IH, AGCO, and all equipment brands. Real-world performance data shows 12% input reduction, 10-15% fuel savings, and 1-2 year payback periods. Installation procedures, correction service options, competitive comparisons, and maintenance requirements included. A-Bots.com provides custom software development, API integration, and testing services for Ag Leader implementations.

Top stories

Copyright © Alpha Systems LTD All rights reserved.

Made with ❤️ by A-BOTS