Home

Services

About us

Blog

Contacts

From Office to Cab: Harnessing Komatsu Smart Construction Remote for Next-Gen Site Efficiency

- Remote Connectivity & Workflow Transformation

- Top Features & Performance Gains of Komatsu Smart Construction Remote

- Implementation Considerations & How A-Bots.com Can Support Your Deployment

- Conclusion — Engineering the Connected Future

At A-Bots.com, we specialize in custom software and mobile app development tailored for advanced construction technologies. If you are working with cutting-edge machine-control ecosystems like Komatsu Smart Construction, we bring deep expertise in field-to-office workflows, remote operator interfaces and cloud-connected fleet data. Whether you need a custom ground-station app, integration with Komatsu’s Smart Construction modules, or full testing and deployment support, we stand ready.

Our team understands not only mobile app architecture but the unique demands of heavy-equipment sites: intermittent connectivity, offline-first design, rugged UI, multi-operator access and machine-telemetry integration. With A-Bots.com you get both the construction-domain insight and agile delivery of industrial-grade software.

We can assist in three primary modes: (1) custom frontend/mobile apps for the Komatsu Smart Construction ecosystem; (2) bespoke backend integrations (cloud APIs, data pipelines, machine telemetry aggregation); (3) full lifecycle testing, commissioning and on-site pilot support of ground-stations and remote-control apps. From prototype to full rollout, we ensure your Smart Construction solution is robust, extensible and field-ready.

If you’re exploring how Komatsu Smart Construction technology can be adapted to your fleet, asset-type or site-configuration, let’s talk. A-Bots.com is ready to partner in concept-validation, software building, and site-integration to help you drive productivity, reduce travel time, and unlock remote-control capabilities for real-world results.

1. Remote Connectivity & Workflow Transformation

The core of Komatsu Smart Construction Remote lies not merely in transferring data but in transforming how the construction ecosystem operates. For decades, the connection between field and office has been defined by geography, paperwork, and physical intervention. With Smart Construction Remote, Komatsu redefines this connection — turning a once-linear process into a fluid, data-rich network of machines, people, and decisions.

Modern construction projects often span multiple sites, subcontractors, and shifting schedules. Engineers, surveyors, and operators traditionally rely on manual updates or physical visits to synchronize machine control data, design plans, or progress reports. This creates latency — the time gap between a design decision in the office and its execution in the field. Komatsu Smart Construction Remote attacks that latency head-on, collapsing distances through digital synchronization. It enables engineers to instantly push updated 3D design files, observe machine behavior in real time, and support operators without ever leaving the office.

“The future of construction isn’t about bigger machines — it’s about smarter connections,” says Toshio Miyake, a senior systems engineer at Komatsu. “Every kilometer you don’t drive to a job site saves not just fuel, but coordination time, carbon emissions, and mental effort. Remote is the new efficiency.”

The Shift from Physical Presence to Digital Oversight

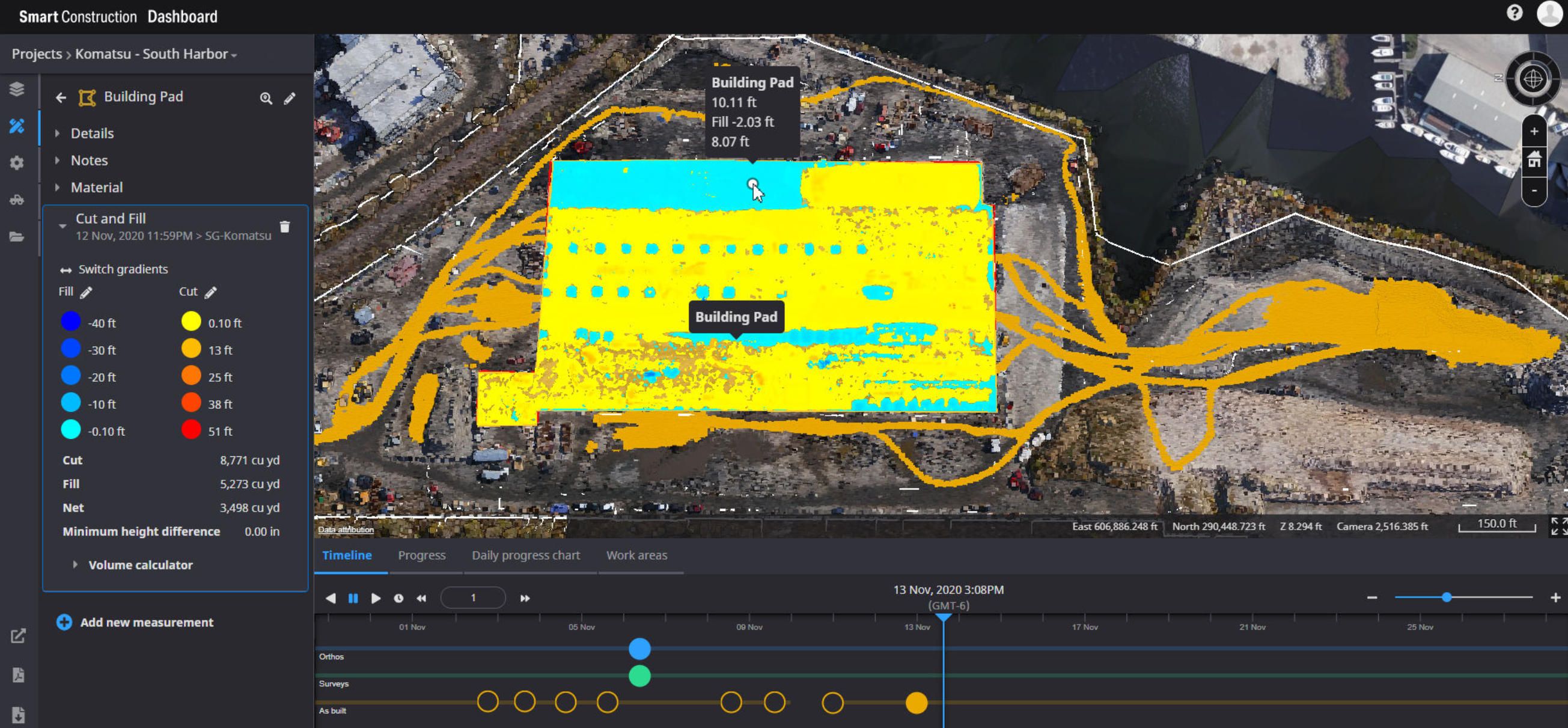

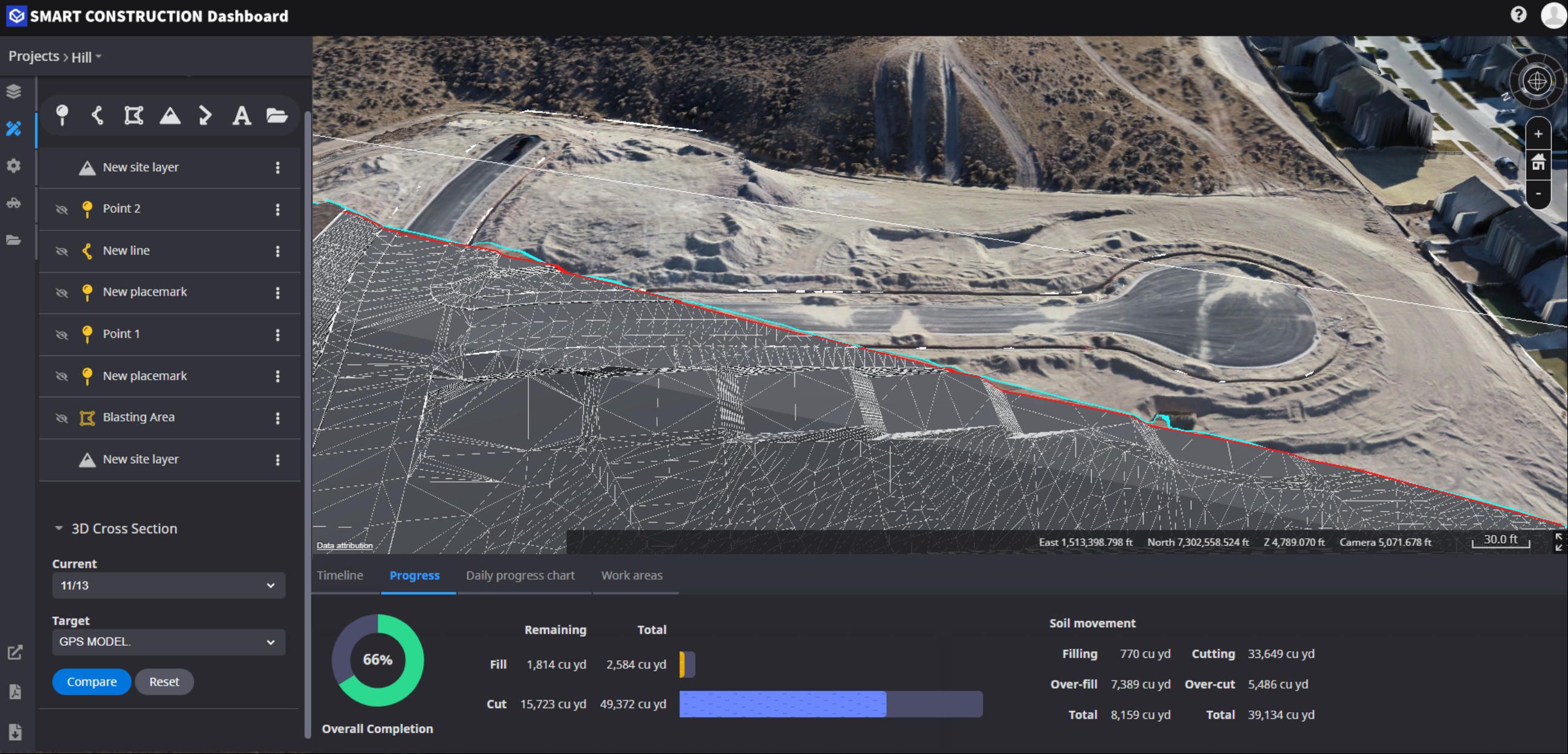

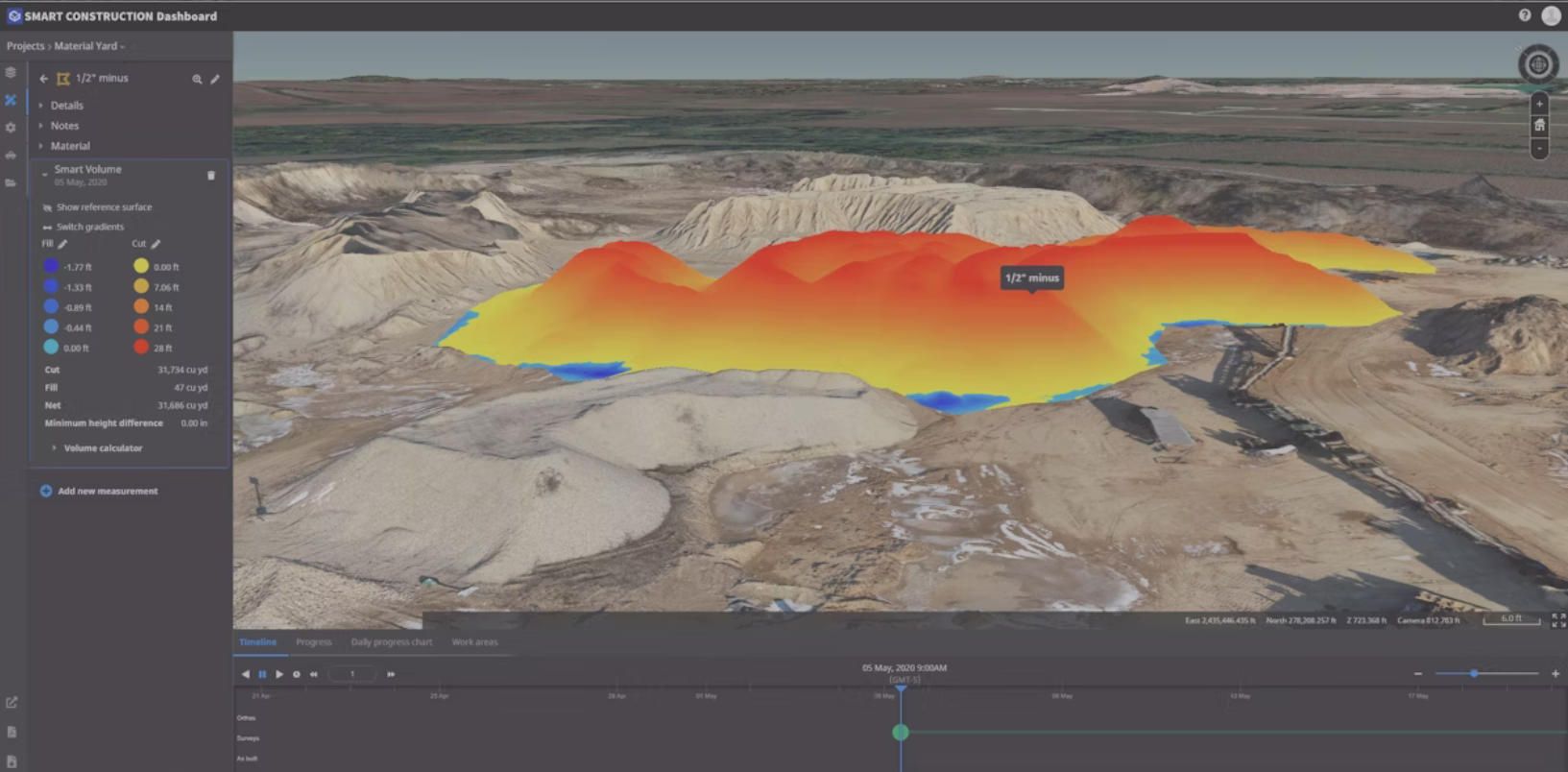

At its essence, Smart Construction Remote transforms presence from a physical state into a digital one. Rather than being on-site, a project manager now “exists” through a digital twin of the construction environment — a live feed of machines, file versions, progress markers, and telemetry data. Each machine becomes a node in an intelligent network that responds to commands, receives updates, and communicates status in real time.

Komatsu’s ecosystem leverages cloud-based storage and encrypted connectivity to maintain this constant dialogue. The result is a seamless digital handshake between the field and the office — a workflow that mirrors aviation or logistics networks rather than the traditional earthmoving cycle. When operators encounter inconsistencies between terrain and design, the office team can view their screen, analyze GNSS coordinates, compare model layers, and send corrections instantly.

In practical terms, that means fewer site visits for engineers and supervisors. A report from Machinery Movers Ireland (2024) indicates that companies adopting Komatsu Smart Construction workflows reduced non-essential site travel by up to 38 % in the first year — directly cutting travel expenses and increasing the productive use of engineering time.

The implications extend beyond efficiency. Remote connectivity supports resilience. Construction sites often operate under tight timelines and unpredictable variables: weather, soil conditions, supply delays. When communication and control rely on physical travel, each disruption compounds delays. By contrast, Smart Construction Remote keeps digital pathways open, allowing teams to coordinate even under restricted mobility — as was critically demonstrated during pandemic-era lockdowns, when remote oversight kept projects moving.

Layered Communication and Cross-Team Collaboration

Another transformation lies in communication quality. In the analog era, messages between field and office passed through intermediaries — foremen, inspectors, or paperwork. Smart Construction Remote replaces this with layered, transparent communication. Every interaction — a file transfer, screen view, or operator request — is logged and synchronized through Komatsu’s Smart Construction Cloud.

This architecture not only improves traceability but also creates collective situational awareness. Everyone involved, from surveyor to superintendent, sees the same information. Instead of fragmented updates, the team interacts with a unified model of the site, enriched by machine data, design revisions, and production metrics.

“Real-time visibility eliminates the silence between actions,” noted Peter Alvarsson, project integration consultant at Skanska. “When a grader operator calls in from the field, and the engineer sees the same screen instantly, the delay between question and resolution disappears. That’s collaboration reborn.”

In practice, this shared visibility transforms decision-making. Design changes can be validated visually before execution, machine utilization can be optimized through live fleet data, and issue resolution times shrink dramatically. The result is a shift from reactive management to predictive orchestration.

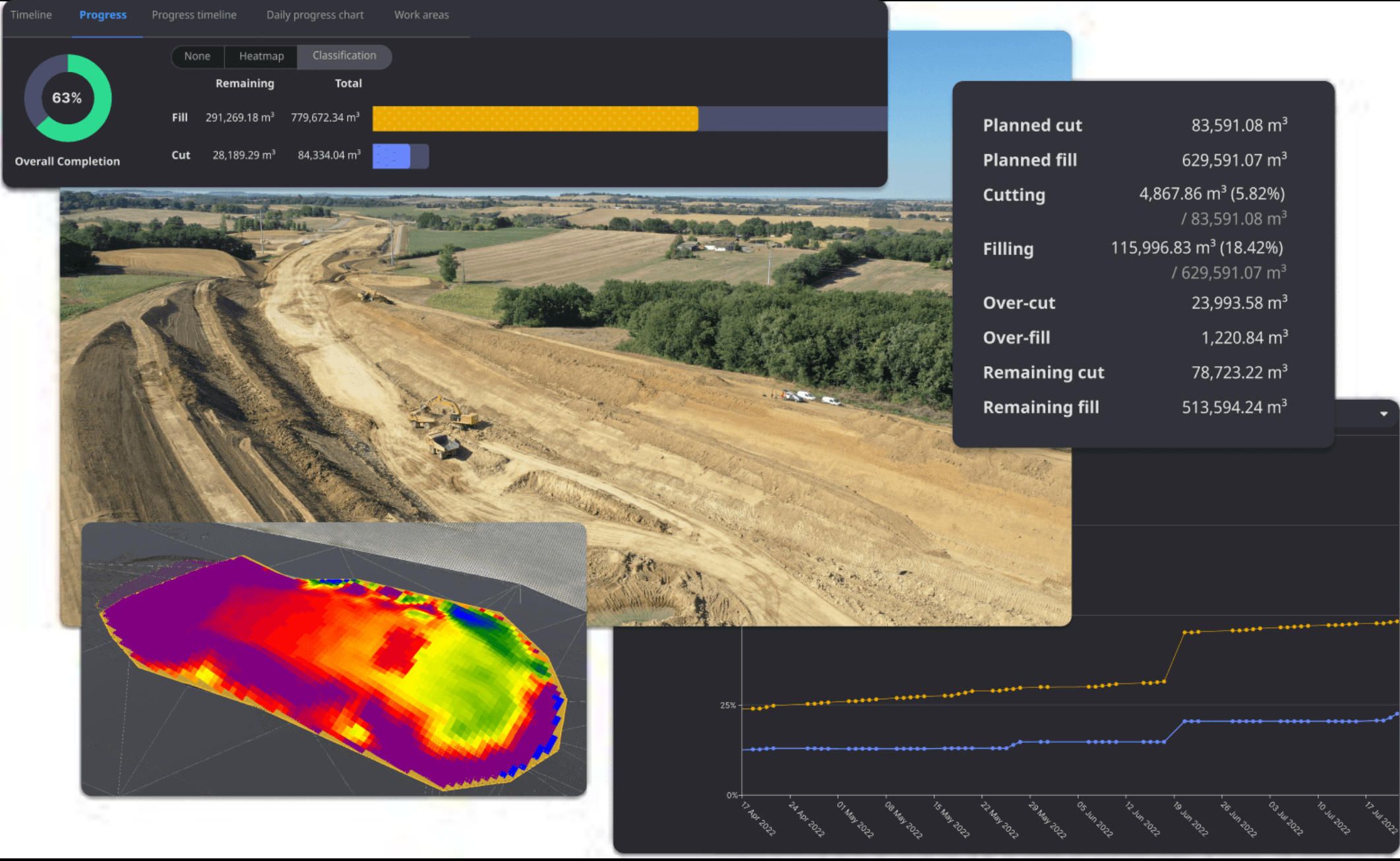

Data as the New Construction Material

Perhaps the most profound shift is philosophical: data becomes a construction material. Just as steel and concrete form the physical structure, data now forms the operational skeleton. Komatsu Smart Construction Remote continuously collects telematics, usage statistics, design overlays, and location data from connected machines. When aggregated, this information evolves into performance intelligence — enabling analytics on fuel efficiency, operator performance, and site productivity.

Engineers can now quantify field-office synchronization with measurable KPIs:

Tsync=Tpush+Tnetwork+Tconfirm (Formula 1)

where Tsync represents total synchronization time between model update and on-machine confirmation. Under Smart Construction Remote, this duration can fall below 90 seconds, compared to several hours under manual workflows.

That difference cascades into ROI gains. Each synchronization event avoided — such as a drive to the field — saves on fuel, vehicle depreciation, and labour hours. Over hundreds of updates per year, the savings accumulate significantly.

This also enables cross-project learning. Because Komatsu’s cloud aggregates anonymized data, contractors can analyze trends across multiple job sites: average machine utilization, model change frequency, or delay patterns. Predictive analytics then suggest optimal times for model updates or operator interventions.

Sustainability and Safety Impacts

Remote operation is not merely a convenience; it represents a sustainability breakthrough. By reducing travel and idle time, Smart Construction Remote aligns with corporate decarbonization goals. Komatsu’s internal sustainability reports note reductions of up to 9 tons of CO₂ annually per active remote-enabled fleet, depending on site distance and vehicle type.

Safety benefits are equally substantial. In traditional workflows, technical staff enter active work zones to perform updates or troubleshoot grade-control systems — exposing themselves to moving equipment and environmental hazards. Remote access removes that necessity, lowering incident probability while maintaining machine precision.

This “safety by architecture” approach embodies the next evolution of construction technology: designing systems that prevent exposure, rather than mitigate it afterward.

Global Adoption Momentum

By 2025, Komatsu had integrated Smart Construction Remote as standard across all new intelligent Machine Control (iMC) and guidance systems. This decision signals both confidence in the technology and a recognition of its inevitability. The Asia-Pacific market, where connectivity infrastructure is rapidly expanding, saw adoption rates double between 2022 and 2024. In North America and Europe, contractors are integrating Komatsu’s remote workflows with their existing BIM and ERP systems.

Data from the Asia-Pacific Journal of Construction Automation indicates that 44 % of Smart Construction users report measurable productivity improvement within six months of deployment. Those gains include faster design-file iteration cycles, fewer surveyor site visits, and tighter alignment between digital models and as-built conditions.

Such adoption is not limited to mega-projects. Small and mid-sized contractors are leveraging Komatsu’s Smart Construction Remote through subscription-based access — turning what was once enterprise-exclusive technology into an accessible SaaS-level tool.

Challenges and the Road Ahead

Despite its clear benefits, the transition to fully remote workflows is not frictionless. Contractors must adapt not just technically but culturally. Remote collaboration challenges long-standing habits: supervisors accustomed to on-site presence must trust digital visibility; operators must be trained to interact confidently with remote engineers. Data governance and cybersecurity also come to the forefront — encryption, access rights, and network resilience become as crucial as machine maintenance.

Here, the opportunity for custom software development becomes critical. Many companies operate mixed fleets or maintain legacy systems that don’t natively communicate with Komatsu’s APIs. Bridging these ecosystems requires custom middleware, mobile dashboards, and hybrid offline-online architectures — precisely the expertise that firms like A-Bots.com bring.

Toward a Connected Construction Future

Ultimately, Komatsu Smart Construction Remote symbolizes more than a technological upgrade — it represents a cultural evolution in how construction perceives control, responsibility, and data. The traditional boundaries between office and field dissolve, replaced by a continuum of shared information and digital oversight.

The next frontier lies in integration: connecting Smart Construction Remote not only with Komatsu’s intelligent machines but with drones for site mapping, IoT sensors for soil monitoring, and AI-driven predictive maintenance systems. Each connection expands the data graph, making the construction site a living digital organism rather than a static workplace.

A-Bots.com envisions this future clearly. By developing custom remote-operation interfaces, telemetry visualizations, and cross-platform mobile apps, developers can amplify Komatsu’s ecosystem — adapting it to regional networks, niche fleets, and enterprise data environments. The synergy of remote control, automation, and analytics is where the next leap in construction productivity will unfold.

Komatsu has already proven that digital presence can rival — and often surpass — physical presence. The companies that learn to leverage this principle today will dominate the construction landscape tomorrow. As Miyake’s early quote reminds us, the future belongs not to those who move earth the fastest, but to those who connect data the smartest.

2. Top Features & Performance Gains of Komatsu Smart Construction Remote

The strength of Komatsu Smart Construction Remote is not in any single innovation, but in the synthesis of multiple technologies — connectivity, visualization, cloud integration, and real-time analytics — fused into one seamless ecosystem. Together, these components reshape how construction equipment is managed, operated, and optimized. For the first time, site control becomes a hybrid of software intelligence and mechanical precision.

Komatsu’s approach is pragmatic: empower human operators with digital leverage rather than replace them. Smart Construction Remote creates a digital nervous system across the job site, allowing engineers, supervisors, and operators to act as synchronized nodes within a shared environment. Each action generates data; each data point refines the next decision.

“Smart Construction Remote is not about replacing people,” said Masashi Takahashi, General Manager at Komatsu’s Digital Transformation Division. “It’s about connecting them in ways that make every second of their expertise matter.”

Core Feature Set — Building the Digital Bridge

1. Remote File Management and Synchronization

At the heart of the system lies its ability to transfer design and machine-control files directly between office and equipment. What once required physical SD cards or USB drives can now be handled wirelessly through Komatsu’s secure cloud. Design updates, linework, 3D terrain models, or revised grade-control data are sent from the office to the dozer or excavator within minutes.

This capability turns time into throughput. On large-scale projects, design updates can occur several times daily. With Smart Construction Remote, these updates are synchronized automatically, eliminating hours of waiting and multiple trips to the field. The system also validates file versions, ensuring that the operator always works with the latest model.

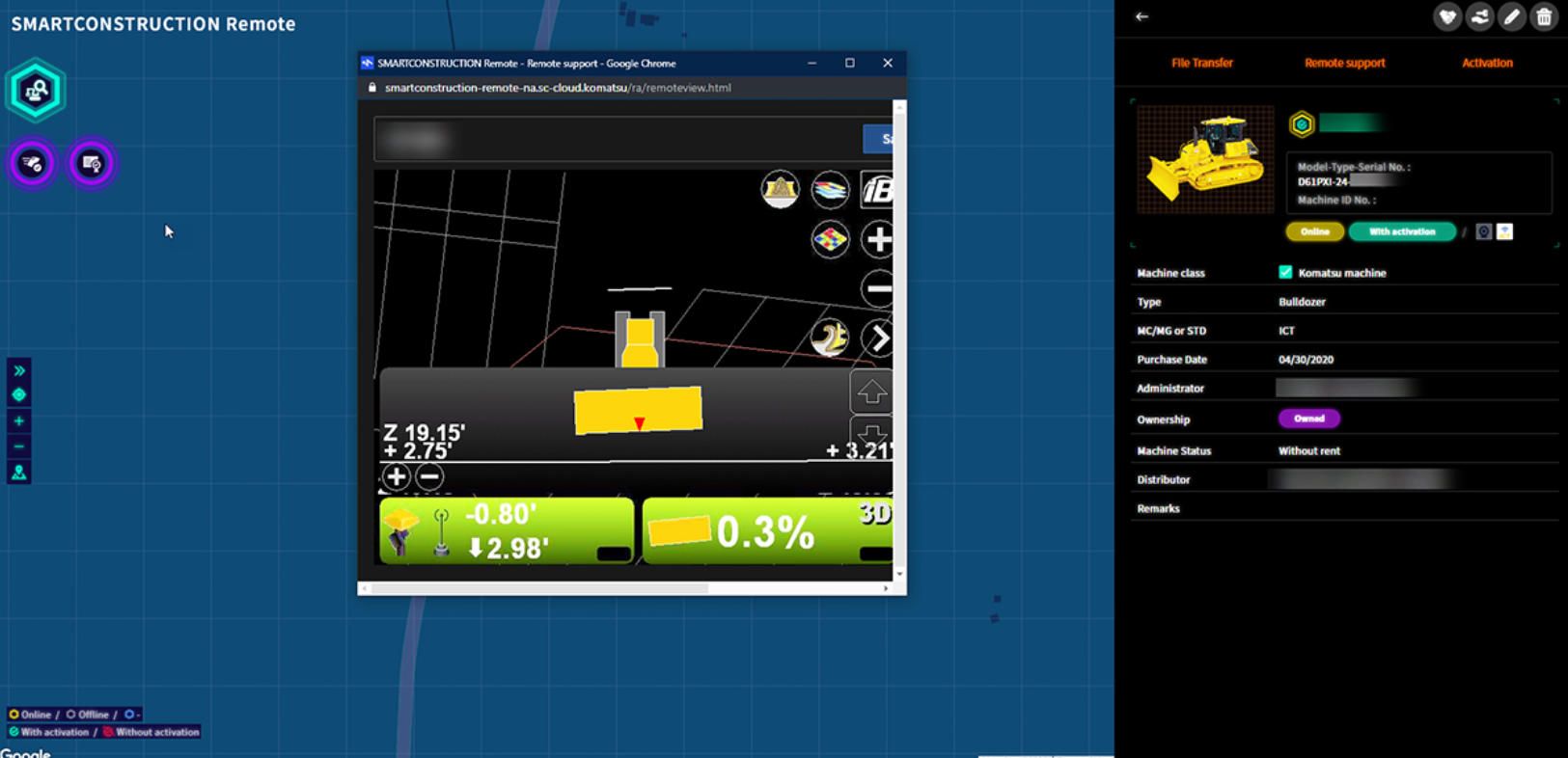

2. Live Operator Screen Viewing and Guidance

Perhaps the most visible feature of Smart Construction Remote is the operator’s shared screen — a real-time window into the cabin interface. Engineers or support staff can log in from the office and see exactly what the operator sees: control panels, grade information, and navigation lines.

This feature dramatically reduces miscommunication. Instead of describing an issue verbally, the office team can visually identify the problem — whether it’s an incorrect model selection, a GPS drift, or a misaligned benchmark. The visual context accelerates troubleshooting and keeps the operator focused on productive work.

Moreover, this visibility turns every remote connection into a learning session. Engineers can demonstrate adjustments directly on-screen, while operators gain confidence by seeing the digital workflow in action. The effect compounds over time: fewer mistakes, more trust, and continuous skill reinforcement.

3. Machine Access and Diagnostics

Beyond guidance, Smart Construction Remote allows remote diagnostics and parameter checking. Maintenance teams can read system status, verify sensor calibration, and even initiate basic resets without dispatching personnel. This predictive and preventive maintenance capability adds an important operational layer — proactive intervention instead of reactive repairs.

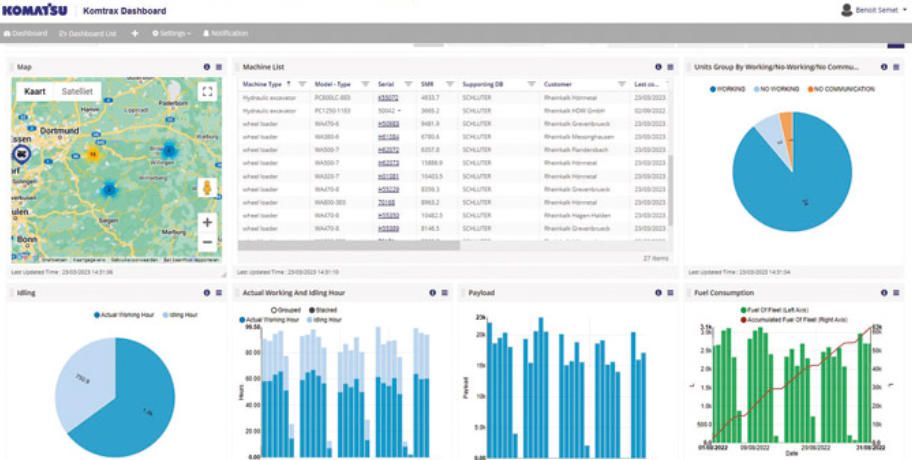

The system’s telemetry feeds directly into Komatsu’s Smart Construction Cloud, where machine data is aggregated and analyzed. Engine hours, fuel burn, hydraulic temperatures, and error codes feed predictive models that flag anomalies before they impact productivity. Contractors gain visibility not just into what a machine is doing, but what it will need in the coming days.

4. Mixed-Fleet Compatibility and API Extensibility

A critical development came in 2024, when Komatsu announced that Smart Construction Remote would support mixed-fleet operations — connecting to non-Komatsu machines through standardized data protocols and third-party adapters. This flexibility acknowledges a key reality: most contractors manage heterogeneous fleets.

With the expanded compatibility, Smart Construction Remote becomes an integration layer rather than a brand-locked utility. Through open APIs and file exchange standards (e.g., LandXML, DXF, KML), the platform connects with other OEM control systems such as Trimble Earthworks, Leica iCON, and Topcon 3D-MC.

This interoperability paves the way for custom software extensions — areas where A-Bots.com can deliver specialized value. By developing custom connectors or visualization dashboards, A-Bots.com helps contractors unify Smart Construction Remote with their legacy systems, ERP databases, or IoT platforms. The result is a truly vendor-neutral command environment, designed around workflow rather than brand.

5. Cloud-Based Access and Asset Overview

Through Komatsu’s Smart Construction Cloud, users can log in from any device — desktop, tablet, or smartphone — to access connected assets. Each machine appears as a digital entity with metadata: model, location, status, connected files, and current task. Engineers can view project layouts, identify active machines, and monitor progress in real time.

From a managerial standpoint, this turns the fleet into a living map. Instead of dozens of independent units, the contractor sees a geospatially organized ecosystem, where every machine’s performance and workload are visible. Historical data and performance logs remain accessible, supporting audits, compliance reports, and productivity analytics.

6. Remote Troubleshooting and Training Mode

A lesser-known but highly valuable aspect is Smart Construction Remote’s potential for training simulation. During off-hours or in “ghost” sessions, trainers can connect to machines virtually, replicating operator conditions for skill development without physical risks. For organizations managing large fleets or seasonal staff, this digital apprenticeship model reduces onboarding costs and safety incidents.

“Smart Construction Remote is the classroom of tomorrow,” remarks James Porter, head of operations at an Australian civil engineering firm. “Our operators learn from real projects in real time — no downtime, no risk. Every remote session doubles as training.”

Tangible Performance Gains

The practical benefits of Smart Construction Remote are measurable across operational, financial, and environmental dimensions. Komatsu’s internal data, supplemented by independent studies, provides a framework for quantifying these gains.

1. Reduced Downtime and Response Latency

Traditional workflows require physical travel for every update, fix, or support request. If an operator encounters a file issue, it might take half a day for an engineer to reach the site, resolve the problem, and restart work. With remote connectivity, that response time shrinks to minutes.

Field trials conducted in Japan and Europe showed average troubleshooting time reductions of 65–80 %, depending on network conditions. Over a month of operation, this equates to several additional production hours per machine — effectively increasing project throughput without adding equipment.

2. Operational Efficiency and Cost Savings

Fuel consumption from engineer and surveyor vehicles used for site visits represents a hidden cost in most projects. Assuming an average of 100 km round trip per update and a fleet of 20 machines, switching to Smart Construction Remote can eliminate over 1,500 km of travel weekly. At current diesel prices and vehicle emissions factors, this saves roughly $1,200–1,800 USD per week and up to 3 tons of CO₂ — small individually, massive cumulatively.

Beyond logistics, remote synchronization increases daily productive hours per machine. Because updates and corrections no longer halt operations for extended periods, Komatsu reports up to 11 % gain in effective working time across Smart Construction projects.

3. Design Accuracy and Error Reduction

When files are transferred manually, version mismatches often occur — an operator working from “Model _v2” while the office has already issued “Model _v3”. Smart Construction Remote’s automatic version verification ensures that only the latest approved design is active, reducing grading errors and rework. Contractors have reported a reduction of 25 % in re-excavation events, especially on high-precision earthworks.

4. Predictive Maintenance and Fleet Longevity

Machine downtime caused by preventable failures is among the costliest inefficiencies in heavy construction. Komatsu’s predictive diagnostics identify wear patterns, hydraulic anomalies, and idling inefficiencies early. By integrating this data into maintenance schedules, contractors extend component lifespan and reduce emergency repairs by up to 40 %.

5. Safety and Workforce Well-Being

The fewer people required on site for supervision, the fewer potential incidents. Smart Construction Remote aligns directly with ISO 45001 safety objectives, as it minimizes physical presence in active zones. In addition, psychological stress on operators decreases when they have immediate remote support, improving concentration and retention.

Technological Underpinnings — How It Works

Komatsu Smart Construction Remote relies on a secure cloud-edge architecture:

- The machine terminal acts as an edge device, capturing GNSS data, machine-control commands, and operator interactions.

- The Smart Construction Remote gateway encrypts and transmits this data through a cellular or satellite link to Komatsu’s cloud servers.

- The Smart Construction Cloud manages authentication, user permissions, and synchronization with office systems.

- Finally, client applications (web or mobile) visualize machine data, allow remote screen access, and handle file transfers.

Latency optimization plays a crucial role. Komatsu employs differential synchronization protocols similar to those used in high-frequency trading systems — transmitting only incremental data changes rather than entire files. This minimizes bandwidth usage and ensures smooth operation even on low-bandwidth networks common to remote construction sites.

The system’s resilience is enhanced by local caching: if a connection drops mid-transfer, the machine terminal temporarily stores updates and pushes them when the link is restored. This “offline-first” logic ensures operational continuity — a design philosophy shared by A-Bots.com in its own industrial app development.

The Economics of Smart Construction Remote

Smart Construction Remote doesn’t merely digitize operations; it redefines the economic equation of construction management. Using simplified ROI modeling, we can express the return on investment as:

ROI=((St+Sf+Se)−Ci)/Ci (Formula 2)

where:

St - time savings (converted to monetary value),

Sf - fuel and travel savings,

Se - efficiency gains from reduced errors,

Ci - implementation cost (hardware, software, and training).

Empirical case studies published in Asia-Pacific Journal of Construction Automation show ROI ratios between 2.6 : 1 and 4.1 : 1 within the first two years of deployment. For large-scale contractors managing multiple sites, this payback period can shrink below twelve months.

In the broader context, this ROI metric is not only financial but strategic. Firms deploying Smart Construction Remote position themselves as data-driven contractors, capable of real-time coordination and remote quality assurance — advantages increasingly required in competitive public tenders and sustainability certifications.

Strategic Advantages in the Industry

The construction industry is undergoing its own version of Industry 4.0. Just as manufacturing shifted from manual control to automation and data integration, construction is moving from site-based decision-making to centralized orchestration. Komatsu Smart Construction Remote is a cornerstone of this evolution — a proof that real-time, remote-managed heavy machinery is both feasible and profitable.

Contractors adopting Smart Construction Remote gain a threefold strategic advantage:

- Speed — Real-time updates and troubleshooting eliminate dead time between design and execution.

- Visibility — Cloud dashboards provide a panoramic view of fleet activity, enabling proactive management.

- Adaptability — Open APIs and cross-brand compatibility allow seamless scaling and integration into broader digital ecosystems.

These advantages multiply when paired with custom extensions. For instance, an A-Bots.com-developed analytics module can plug into Komatsu’s telemetry stream, delivering advanced KPIs such as energy-per-cubic-meter moved or predictive soil compaction variance. By merging Komatsu’s machine intelligence with A-Bots.com’s software expertise, clients can unlock performance layers beyond the native platform.

The Broader Impact — Sustainability, Scalability, and Skill Evolution

Sustainability is fast becoming a contractual requirement, not a choice. Remote operation contributes directly to ESG compliance by cutting travel emissions and optimizing fuel use. Moreover, Smart Construction Remote democratizes access to skilled expertise: a single top-tier engineer can now supervise multiple job sites remotely, improving the knowledge distribution within organizations.

This scalability redefines workforce strategy. Instead of deploying additional staff, companies scale intelligence, not headcount. The outcome is a more sustainable balance between human oversight and machine autonomy.

And as the technology matures, integration with AI-powered systems — autonomous path planning, automatic grading correction, environmental sensing — will push the boundary further. A-Bots.com’s R&D focus in computer vision, IoT telemetry, and remote-control UX design positions it as an ideal collaborator for such integrations.

In summary, Komatsu Smart Construction Remote represents a mature convergence of hardware stability and software intelligence. It reduces waste, increases uptime, enhances accuracy, and elevates safety — all measurable, all scalable. Yet its true promise lies in extensibility: the capacity for custom interfaces, analytics modules, and integrations that fit each contractor’s workflow.

For innovators seeking to maximize these benefits, A-Bots.com stands ready to build the missing link — the customized software layer that connects Smart Construction Remote to your enterprise systems, your data vision, and your future.

3. Implementation Considerations & How A-Bots.com Can Support Your Deployment

Adopting Komatsu Smart Construction Remote is not simply a matter of buying a subscription or installing new firmware. It is a digital transformation process, one that touches connectivity, security, workflow design, and human adaptation. The organizations that succeed in this transition treat Smart Construction Remote as a strategic system, not a gadget. It becomes the backbone of how they coordinate field operations, update design data, and manage mixed fleets in real time.

Core Implementation Challenges

Every construction company’s digital maturity level is different. For some, Komatsu Smart Construction Remote is the first true cloud-based tool in their workflow; for others, it must integrate with existing ERP, BIM, or IoT telemetry systems. Implementation success depends on addressing a few key dimensions early:

1. Connectivity and Redundancy

Remote control relies on stable data links — cellular, satellite, or hybrid mesh. Yet job sites are often located in valleys, tunnels, or high-latency regions. A resilient deployment must include offline caching and intelligent retry logic. Komatsu’s infrastructure already offers differential data synchronization, but contractors need a secondary communication strategy (e.g., LTE-over-satellite gateways or portable repeaters).

2. Security and Data Integrity

Smart Construction Remote transfers sensitive information: 3D design files, equipment telemetry, operator credentials. Each connection must use end-to-end encryption and multi-factor authentication. A-Bots.com often helps clients implement zero-trust architecture, where every data packet is verified before access is granted. This approach not only prevents intrusion but also aligns with ISO 27001 and GDPR compliance requirements.

3. Human-Machine Interface (HMI) Design

Operators, field engineers, and project managers all view Smart Construction Remote through different lenses. The on-machine interface must remain intuitive under stress; the remote dashboard must prioritize clarity over complexity. A-Bots.com designs HMI and UX layers adapted to the cognitive load of field work — large tactile buttons, minimal menu nesting, and contextual alerts.

“Good interface design in heavy industry is about keeping the human calm,” notes Alexei Fedorov, senior UX researcher at A-Bots.com. “If the user must think about the software instead of the task, the software has failed.”

Steps Toward a Successful Rollout

To help clients avoid typical pitfalls, A-Bots.com structures Smart Construction Remote deployments as four progressive phases rather than a one-time installation:

-

Assessment & Integration Mapping

The first step is understanding the client’s current ecosystem — types of machines, control systems (Komatsu iMC, Trimble, Topcon, Leica), network coverage, and internal IT standards. Our engineers build a connectivity matrix identifying which machines can connect natively and where adapters or middleware are needed. -

Custom Software Development

In many deployments, clients require proprietary features: an internal reporting dashboard, multilingual interfaces, or integration with ERP systems like SAP or Oracle. A-Bots.com builds these components using modular APIs, ensuring compatibility with Komatsu’s Smart Construction Cloud. -

Field Testing & Optimization

A-Bots.com sends a mobile team to pilot sites, validating latency, telemetry accuracy, and operator usability. Issues such as poor cellular signal or VPN conflicts are addressed on the ground. Performance metrics — sync times, data packet loss, and user feedback — feed continuous improvement cycles. -

Training & Long-Term Support

Finally, success depends on people. A-Bots.com conducts multi-level training for operators, engineers, and administrators. The goal is not only to use Smart Construction Remote but to own it — to treat digital workflows as natural extensions of daily practice.

Integration Scenarios

Smart Construction Remote shines brightest when connected with complementary systems. Some common integration patterns include:

- Fleet management systems: linking remote telemetry to fuel tracking and maintenance modules.

- GIS and drone data: importing terrain updates and orthophotos into Komatsu’s design layers.

- Project management suites: connecting schedule progress (e.g., Primavera, Procore) to actual on-site production metrics.

A-Bots.com has developed APIs that act as middleware between Komatsu’s ecosystem and such external platforms, ensuring smooth data flow without manual re-entry. This integration eliminates one of construction’s oldest inefficiencies: siloed data.

Key Business Benefits

While the technical gains of Smart Construction Remote — fewer trips, quicker updates, improved accuracy — are well documented, the strategic benefits often emerge later. After six to twelve months, most A-Bots.com clients report:

- Standardized operations across multiple sites, allowing centralized supervision.

- Quantifiable ROI, with reduced downtime translating into measurable profit margins.

- Improved compliance documentation, since every remote command and update is logged automatically.

- Higher talent retention, as digital tools make technical staff more effective and confident.

This evolution changes company culture. Field teams stop perceiving “remote control” as surveillance and begin to see it as support. Engineers appreciate instant feedback; managers appreciate transparency; sustainability officers appreciate reduced carbon metrics.

A-Bots.com’s Role in Future-Ready Smart Construction

A-Bots.com is not a passive integrator — it is a development partner that extends Komatsu’s Smart Construction Remote capabilities. Our engineers build:

- Custom mobile apps for Android / iOS with offline-first architecture.

- Edge computing modules that preprocess telemetry near the machine, reducing cloud latency.

- Visualization dashboards powered by 3D WebGL and digital-twin frameworks.

- AI assistants that analyze remote-operation logs to suggest efficiency improvements.

By merging these technologies with Komatsu’s base platform, A-Bots.com clients achieve deeper insight into how each machine, operator, and project interacts.

“Digital transformation succeeds when hardware and software evolve together,” says Elena Novikova, product director at A-Bots.com. “Komatsu built the physical intelligence — we build the cognitive layer that learns from it.”

Conclusion — Engineering the Connected Future

Implementing Komatsu Smart Construction Remote marks a decisive step toward connected, data-driven job sites. Yet technology alone is never enough. Success lies in tailoring the system to human workflow, ensuring resilience in harsh environments, and extracting actionable intelligence from every packet of machine data.

This is where A-Bots.com excels: translating complex industrial systems into usable, reliable digital ecosystems. From the first feasibility study to full fleet rollout, from mobile UI design to predictive analytics, A-Bots.com helps construction companies not just deploy Smart Construction Remote — but master it.

As global construction accelerates toward automation and sustainability, those who combine Komatsu’s mechanical precision with custom software intelligence will define the next era of efficiency. And for that synthesis — A-Bots.com is the partner ready to code the future of your connected site.

✅ Hashtags

#KomatsuSmartConstruction

#SmartConstructionRemote

#ConstructionTechnology

#MachineControl

#RemoteOperations

#FleetManagement

#SmartJobsite

#IoTforConstruction

#ABots

#CustomSoftwareDevelopment

#ConstructionAutomation

#DigitalTransformation

Other articles

Raven Industries Precision Agriculture: Viper 4+, Slingshot Raven Industries leads precision agriculture application control technology with specialized ground control solutions acquired by CNH Industrial in 2021. This comprehensive guide examines Viper 4+ display (10.4-inch touchscreen, ISOBUS Universal Terminal, $3,800-$4,800), Slingshot cloud connectivity platform enabling real-time fleet monitoring and remote support, Field Hub precision application controllers managing up to 128 independent sections, Hawkeye individual nozzle control with integrated flow verification, and emerging Raven Autonomy supervised autonomous equipment systems. Real-world performance data shows 8-15% input reduction through advanced section control, 60-80% herbicide savings with selective spraying, and 40-60% labor cost reduction through autonomous implementations. Complete coverage of CNH integration, installation procedures, competitive positioning, and system costs. A-Bots.com provides custom ground control station development, Slingshot API integration, and testing services for Raven systems.

Case IH Advanced Farming Systems: Complete AFS AccuGuide and AFS Connect Precision Agriculture Guide Case IH Advanced Farming Systems pioneered integrated precision agriculture since 1994 with factory-installed ground control solutions. This comprehensive guide examines AFS AccuGuide automated steering (2.5 cm RTK repeatability), AFS Pro 700 display (7-inch, $4,200-$5,200) and AFS Pro 1200 display (12.1-inch premium), AFS Connect cloud platform enabling real-time fleet monitoring and remote support, multiple receiver options (Pro 300/600/700), and correction services (WAAS free, RTX $1,800-$2,400, RTK $1,500-$3,000 annually). Real-world data shows 8-12% input reduction, 25-35% productivity gains, and 3-6 bushel yield increases. Complete coverage of CNH-Raven technology integration, AutoTrac Turn Automation, AFS Repeat controlled traffic technology, Machine Sync coordination, factory installation advantages, and system costs. A-Bots.com provides custom AFS Connect integration, mobile development, and testing services.

Leica Geosystems Machine Control: Complete iCON Excavate and iCON Grade 3D Construction Leica Geosystems leads construction machine control through Swiss precision engineering and Hexagon integration. This comprehensive guide examines Leica iCON excavate 3D excavator guidance (±20mm accuracy, $23,500-$37,000), Leica iCON grade automated blade control for dozers/graders ($30,000-$40,500), Leica iCON site office software for design management, and positioning technologies including iCG80/iGG4 Plus GNSS receivers with RTK corrections. Real-world performance data shows 30-50% productivity improvements, 22% reduced excavation cycle times, and ±15-20mm grade accuracy. Complete coverage of universal equipment compatibility with Caterpillar, Komatsu, Volvo, Hitachi excavators and dozers, installation procedures, SmartLink satellite corrections ($1,800-$2,400 annually), ConX cloud platform integration, and quality control verification. A-Bots.com provides custom ground control station development, ConX API integration, design automation tools, and testing services.

Caterpillar Command: Remote Control and Ground Station Software Caterpillar Command defines the global standard for remote-operation of heavy machinery, combining safety, precision, and connectivity. This in-depth article explains its architecture, performance data, and evolution toward hybrid autonomy. It also highlights how A-Bots.com builds custom software for ground control stations—creating operator interfaces, telemetry pipelines, and AI-ready analytics that integrate seamlessly with existing Caterpillar Command systems. For contractors and OEM partners seeking flexible, secure, and scalable remote-operation platforms, A-Bots.com delivers the software intelligence behind next-generation construction automation.

Trimble Earthworks: Smart Grade Control and Custom Solutions Trimble Earthworks represents the future of intelligent earthmoving—where precision, automation, and data converge. The system combines GNSS, 3D modeling, and cloud connectivity to deliver centimeter-level accuracy and operational efficiency. This in-depth A-Bots.com article examines the evolution of Trimble Earthworks, from its role in transforming global construction to its next frontier in AI and autonomy. It also reveals how A-Bots.com develops tailored solutions—mobile apps, analytics dashboards, and embedded software—that enhance and customize Earthworks-class technology for contractors, OEMs, and developers around the world.

Top stories

Copyright © Alpha Systems LTD All rights reserved.

Made with ❤️ by A-BOTS