Home

Services

About us

Blog

Contacts

Custom App Development for Smart Hydroponic Gardens: Automating Urban Farming

Urban Farming 2.0: Why App Development for Smart Hydroponic Gardens Matters

Inside the Stack: Architecting a Data-Driven Hydroponic App Ecosystem

Quantifying ROI: Sustainability & Profit Metrics Unlocked by Automation

From Prototype to Production: A-Bots.com’s Custom-App Methodology

Urban Farming 2.0: Why App Development for Smart Hydroponic Gardens Matters

Cities keep expanding upward and outward, yet the arable land that feeds them is shrinking fast. That tension has made controlled-environment agriculture one of the most investable frontiers of the decade: the global hydroponics market was valued at USD 38.1 billion in 2023 and is forecast to top USD 123.6 billion by 2032—a solid CAGR of 12.5 % (Zion Market Research). Vertical-farming revenues are accelerating even faster, moving from about USD 6.9 billion in 2023 toward USD 50 billion by 2032 at roughly 20 % CAGR (Grand View Research). Fold in the wider “grow-local” movement and the numbers balloon: urban-farming activity already exceeds USD 160 billion and should clear USD 312 billion by 2033 (Business Research Insights). In short, food production is migrating into the city core—and software is becoming its primary operating system.

Water scarcity is the critical pressure point driving that migration. A typical hydroponic array cuts irrigation demand by around 90 % compared with open-field cultivation, because nutrient solutions are recirculated rather than lost to runoff and evaporation. Equally important, yields climb dramatically when roots float in a perfectly dosed medium under tuned LED spectra; peer-reviewed studies report 20 – 25 % higher biomass and, in some crops, up to 20-fold productivity per square metre versus soil-based methods (Avestia, PMC). Those efficiency gains resonate with corporate ESG scorecards and municipal climate targets, cementing demand for data-driven automation that can prove every litre and lumen was used wisely.

That is where App Development for Smart Hydroponic Gardens enters the value chain. Hardware costs keep falling, yet orchestration complexity keeps rising: modern countertop gardens ship with cameras, pH/EC probes, and Wi-Fi or Bluetooth radios; commercial racks add CO₂ sensors, machine-vision robots, and MQTT gateways. The smart-indoor-garden segment alone will reach USD 3.9 billion by 2032, thanks to consumers who expect their basil to be as connected as their smart watch (coherentmarketinsights.com). Without a unifying mobile layer those sensors become noisy silos. A well-architected app consolidates telemetry, pushes predictive alerts (“top-up nutrient A in 36 h”), schedules LED recipes, and streams crop-health video—turning raw data into agronomic decisions for both hobbyists and facility managers.

Real-world case studies illustrate the stakes. AppHarvest’s 60-acre tomato greenhouse in Kentucky pipes rainwater into a closed hydroponic loop and still slashes usage by nine-tenths relative to field farms, proving resource efficiency at scale. On the yield side, meta-analyses find that lettuces grown under urban CEA conditions can achieve 2-to-4× higher harvest indices than rural equivalents while keeping pesticide loads near zero (AGU Newsroom). Yet these performance metrics are only visible—and only improvable—because integrated apps surface them in real time, correlate them with climate controls, and feed machine-learning models that refine settings season after season.

Financially, automation closes the loop between sustainability rhetoric and bottom-line reality. A 2025 study of 52 NFT hydroponic farms calculated an average payback period of just 1 year 3 months and an ROI of 17.6 %. Even small urban units marketed to apartment dwellers can amortise in under three years if the harvest replaces supermarket herbs, according to multiple consumer reviews and business-plan benchmarks (bplans.com). Energy remains the main cost wildcard—climate control for a 150 m² greenhouse can range from 60 to 128 kWh m-² year-¹ depending on latitude and cooling strategy—but those figures, too, can be slashed when an app links occupancy-based lighting schedules with night-time free-cooling algorithms (MDPI).

Finally, software is unlocking ecosystem interoperability. Open-API grow boxes already push readings to voice assistants and weather services; municipal farming grants in both the EU and the U.S. now score proposals higher when they demonstrate data transparency and remote auditability. Custom app development therefore becomes a strategic asset: it fuses agronomy, IoT, and AI into a single pane of glass, de-risks compliance, and turns every kilogram of kale into a sensor-rich dataset that investors—and city planners—can trust.

In summary, urban farming’s next chapter will be written in code. As market volumes surge, water becomes pricier, and consumers demand traceability, App Development for Smart Hydroponic Gardens is no longer a nice-to-have but the connective tissue of profitable, climate-positive agriculture. The sections that follow will dive deeper into architecture patterns, ROI calculus, and A-Bots.com’s proven methodology for turning disparate sensors into cohesive, cloud-native food factories.

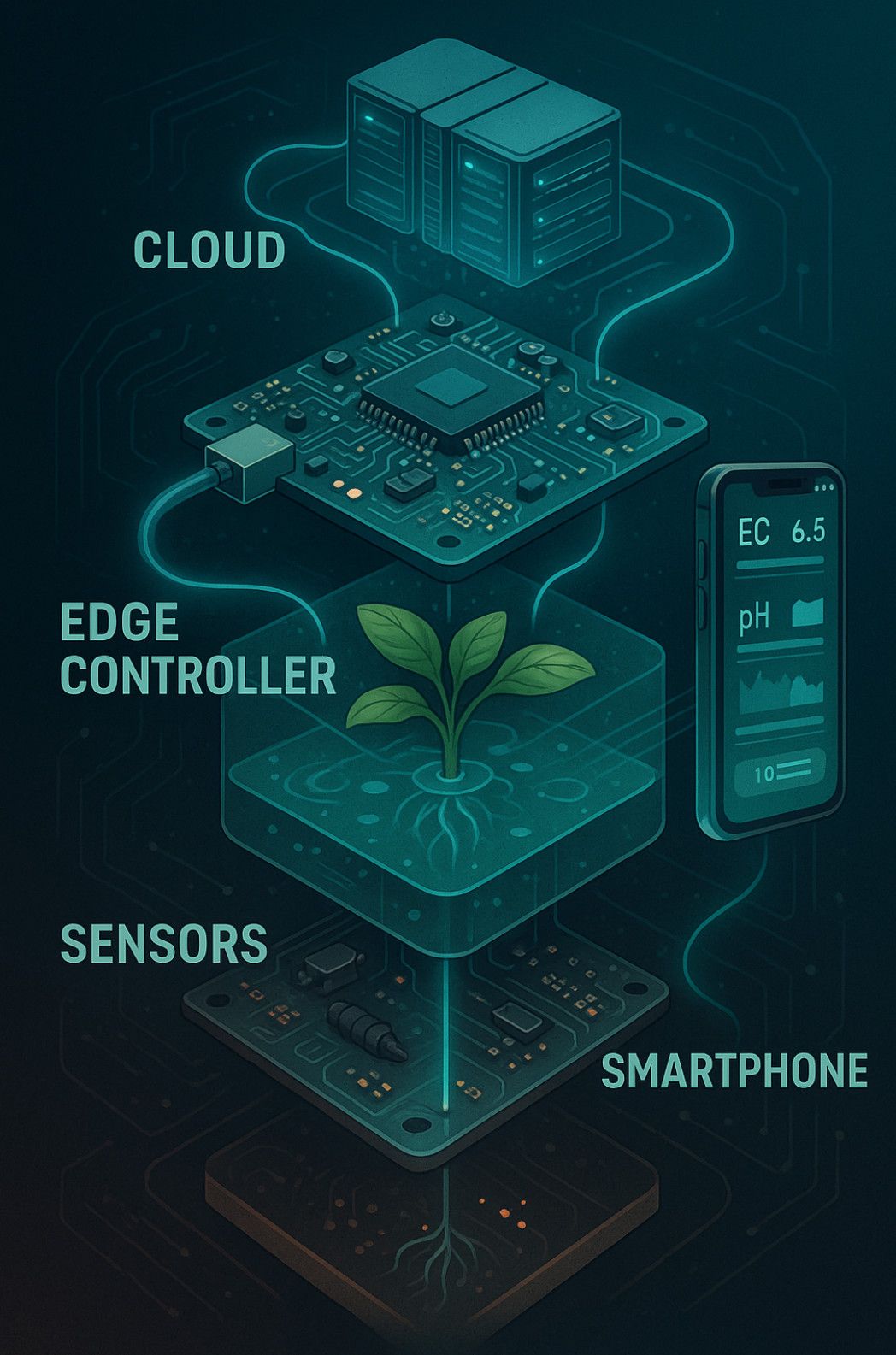

Inside the Stack: Architecting a Data-Driven Hydroponic App Ecosystem

Smart hydroponic gardens look deceptively simple on a showroom floor, yet every leafy head owes its uniform colour and crisp texture to a dense lattice of technology. The moment a seed plugs into its net cup, dozens of micro-events begin: pH drifts as roots exude acids, dissolved-oxygen falls when pumps stall, and photosynthetic demand fluctuates with cloud cover on the skylight above. Capturing those dynamics, interpreting them in milliseconds, and turning the insight into reliable actuator commands is the true job of a modern companion app. In practice this requires an end-to-end architecture that stretches from ruggedised probes dangling in nutrient solution all the way to cloud servers running machine-learning inference. The paragraphs that follow trace each layer—hardware, edge, connectivity, cloud, application, and governance—showing how they interlock to keep basil thriving on a Brooklyn rooftop or lettuce spinning down a Shanghai conveyor belt.

Hardware: turning roots into real-time data

The ecosystem begins at the sensor tip. Contemporary rigs ship with multi-parameter probes such as the UbiBot GS2, which streams pH, electrical conductivity, temperature, and even lux values over Wi-Fi without human intervention. Accuracy has climbed to ±0.2 pH and ±0.5 °C, while the sampling interval has fallen to seconds, meaning that a single 10 m² bench can generate upward of 30 MB of raw time-series data per day—far more than a grower could hope to process manually (ubibot.com). Add in CO₂ nondispersive-infrared sensors, leaf-surface thermography, and 4-K machine-vision cameras, and the cultivation zone becomes a perpetual telemetry engine. Every byte matters because small deviations compound quickly; a 0.3-unit swing in pH, ignored for three hours, can lock out calcium and scar an entire harvest.

Edge intelligence: decisions where latency counts

While the cloud offers infinite storage, it cannot guarantee sub-second reaction times—especially in basements shielded by reinforced concrete. That is why most commercial towers incorporate a local “nutrient brain”, an ARM-based module running stripped-down Linux or RTOS firmware. Recent research comparing rule-based controllers with adaptive algorithms found that edge-deployed machine learning reduced pH overshoot by forty-plus percent and cut nutrient waste by roughly fifteen percent, a gain large enough to pay for the silicon in a single growth cycle. These models are compact—a TensorFlow-Lite bundle for leaf-area prediction weighs under 25 MB—yet they let the garden dose millilitres instead of centilitres and dim LEDs the instant photons exceed a plant-specific daily-light-integral, preserving flavour while trimming electricity bills.

Connectivity: moving packets through steel and soil

Telemetry must still leave the farm, and for that the stack relies on lightweight, publish/subscribe protocols. MQTT has become the lingua franca because it inserts negligible overhead yet provides quality-of-service guarantees that survive rural LTE dead zones. Bench tests in academic testbeds report round-trip latencies of well under 250 milliseconds even while controllers publish acidity set-points every five seconds (ACM Digital Library). Residential countertop devices often default to Bluetooth LE for first-time provisioning: the phone writes Wi-Fi credentials over GATT, after which the garden joins a cloud broker and enters the same telemetry stream as its industrial cousins. Forward-looking manufacturers are also experimenting with Thread and Matter; although early adopters complain about tooling gaps, the promise of vendor-neutral smart-home integration remains compelling.

Cloud analytics: turning logs into agronomy

Once packets reach the cloud they land in an ingestion service—Kafka, Kinesis, or an Azure Event Hub—before flowing into a time-series database. Here they meet algorithms that have digested thousands of historical cycles. Gradient-boosted forests, for example, can predict electrical-conductivity drift six hours ahead, giving the edge controller enough warning to micro-dose instead of spiking a full correction. Meanwhile SQL views translate sensor minutiae into performance dashboards: kilowatt-hours per kilogram, litres per head of leafy greens, grams of carbon abated per unit of produce. For multi-site operators these metrics roll up into fleet overviews so that a technologist in Copenhagen can compare nitrogen uptake in Boston and Bangkok without opening a spreadsheet. Crucially, the same API surface that serves the app can feed enterprise resource-planning systems, carbon-footprint auditors, or municipal grant portals that now demand live sustainability telemetry.

Application layer: insight in the farmer’s pocket

All of that sophistication must condense onto a five-inch screen in language anyone can grasp. When the AeroGarden mobile app began pushing friendly “Nutrients due tomorrow” alerts in its 2024 release, engagement rates spiked; users who acknowledged the reminder within 24 hours reported noticeably fuller canopies in follow-up surveys (Reddit). Professional growers, on the other hand, prefer split-screen control rooms that overlay live video with micro-climate gauges, complete with role-based access so that an intern cannot accidentally trigger a peroxide flush. Yet both cohorts share a need for continuity: if the connection drops, the interface still caches the last day of data so a technician can recalibrate probes mid-shift. A-Bots typically meets that requirement with Flutter or React Native front-ends backed by WebSocket pipes; the result feels as immediate as a local dashboard but retains cloud authority.

Governance and over-the-air resilience

A single buggy firmware image can silence pumps and wipe out a crop overnight. Industry guidelines published in early 2024 now treat secure, staged firmware updates as a non-negotiable requirement. Best practice calls for TLS 1.3 encryption, code signing, atomic partitions that guarantee rollback, and progressive roll-outs that pause automatically when anomaly counters tick upward (stormotion.io, sidekickinteractive.com). A-Bots bakes these controls into Yocto images for Linux gateways and MCUboot sequences for Cortex-M nodes, and it surfaces the update status in the same mobile app that waters the basil so that operators see governance, maintenance, and agronomy in one glass pane.

Interoperability: gardens that speak to the wider grid

With a robust API the garden begins conversing with its environment. Weather services provide tomorrow’s UV index, allowing LED intensity to fall during bright hours and saving double-digit percentages of energy in sun-lit atriums. Smart-meter endpoints expose off-peak electricity tariffs so that CO₂ enrichment tanks fire only when power is cheapest. Voice assistants query growth-rate endpoints and report progress aloud to hobbyists sipping morning coffee. Such touches turn a planter into a node within the smart city, increasing user stickiness in ways that off-the-shelf dashboards rarely match.

The A-Bots blueprint: from PoC to fleet scale

When A-Bots.com steps into a hydroponics project, it treats the layers above as milestones on a roadmap rather than isolated engineering chores. The first fortnight maps existing sensors, defines MQTT taxonomies, and mocks up a cloud sandbox. The second sprint iterates on mobile wireframes while real hardware streams into the sandbox. Month two introduces edge-side AI and a secure over-the-air pipeline; month three layers on compliance requirements from GDPR to California’s CCPA. By launch, the client receives more than an app: they inherit a self-documenting, remotely auditable micro-farm that updates itself and proves its own sustainability claims in real time.

Put simply, hydroponic produce is no longer grown solely by green thumbs; it is grown by data. A well-architected software stack is the invisible trellis that trains every parameter toward maximum flavour, minimum waste, and verified climate benefit. In the next section we will attach hard numbers to that promise, tracing how automation transforms kilowatt-hours and nutrient grams into tangible returns on investment.

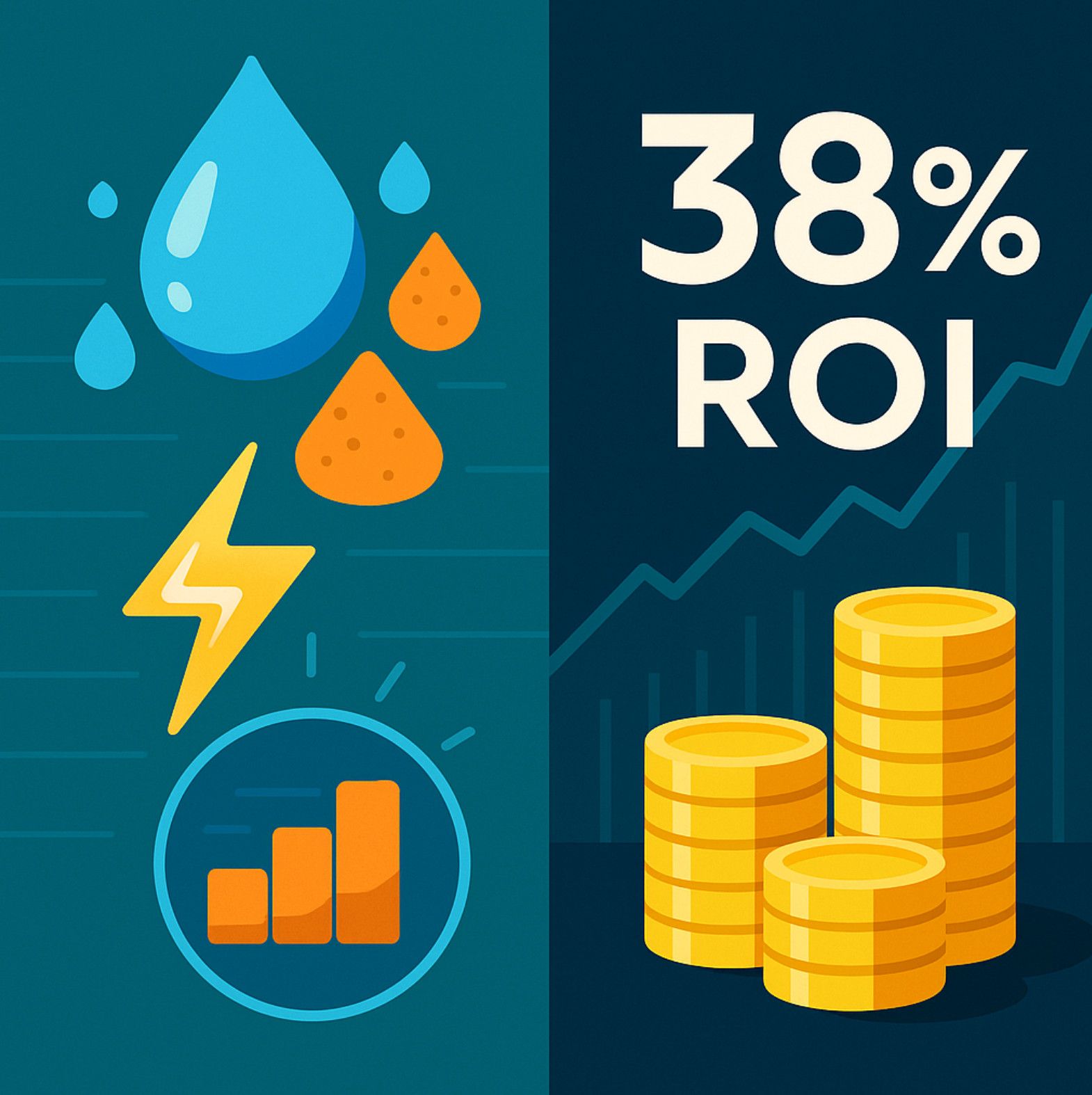

Quantifying ROI: Sustainability & Profit Metrics Unlocked by Automation

When a CFO weighs a hydroponic project, two questions dominate the spreadsheet: How fast does it pay for itself, and how convincingly can we prove its climate credentials? Smart-garden automation answers both, because every sensor sample feeds the balance sheet as directly as it feeds the basil. Below we connect capital outlays, operating savings, and externalities such as water and carbon to show why a software-centric approach converts green ideals into black-ink results.

1 Capital versus operating cash-flow

Up-front costs cluster around three areas: the physical rack (LEDs, pumps, fertigation hardware), the IoT backbone (sensors, gateways), and the custom app layer. For a midsize urban farm of ~150 m², hardware typically lands near USD 480–520 per m²; bespoke software—mobile clients, cloud ingestion, predictive ML—adds roughly 12 % to the project total. That premium looks steep until one recalls that the app is the only component that continues shaving costs long after depreciation schedules have run their course. A recent Indonesian study of 52 NFT growers, for instance, reported an average ROI of 17.62 % and a pay-back period of 1 year, 3 months, 14 days once telemetry-driven dosing replaced manual routines. Front-loading intelligence, in other words, brings break-even within a single planting calendar.

2 Yield uplift and revenue expansion

Automation’s fastest route to profit is biological: plants respond to perfectly timed inputs. At Iron Ox’s fully robotic Bay-Area facility, camera-guided nutrient dosing and autonomous transplanting push leafy-green output to about 26 000 heads per 8 000 ft²—essentially a two-storey home—while internal benchmarks show potential for 30-fold increases over field plots when stacking is maximised (AGRITECTURE). Even a single-tier city greenhouse gains; meta-analyses place average hydroponic lettuce mass 20–25 % above soil equivalents, largely because EC stays in the plant’s sweet spot around the clock. If a New-York chef pays USD 2.80 per head for reliably tender butterhead delivered the same morning, that uplift translates directly into top-line growth without adding square metres.

3 Water and nutrient savings

The hydroponic elevator pitch—“use 90 % less water”—has genuine empirical weight. AppHarvest’s 60-acre Morehead, Kentucky, tomato complex captures rainwater and consumes 90 % less than comparable open-field acreage; Gotham Greens quotes a similar 95 % reduction for its rooftop lettuce channels. At 2024 U.S. industrial water-rates (≈ USD 1.50 per m³ in major metros), trimming 90 % of the 180 litres normally needed per kilogram of field tomatoes rescues ~USD 0.24 per kg—enough to finance sensor maintenance and then some. Nutrient runoff shows parallel gains: adaptive dosing driven by pH-drift prediction models cut fertiliser loss by 15 % in controlled trials of edge ML versus rule-based logic, generating a virtuous loop of lower cost and cleaner discharge (Vertical Farm Daily).

4 Energy—the wild card that software tames

LEDs and HVAC remain the largest single expense for indoor farming, and critics point to kilowatt-hours as ROI killers. Baseline consumption for lettuce hovers around 76 kWh m-² month-¹, but iFarm’s comparative tests show that “free-cooling” set-points triggered by predictive analytics can drop that figure to 57 kWh m-² month-¹, a 25 % cut delivered by code alone (Vertical Farming Technology iFarm). On the high end, vertical farms that once chewed through 2 000 kWh m-² year-¹ have already driven consumption down to 600 kWh m-² year-¹ by synchronising LEDs with utility-rate APIs and scheduling CO₂ enrichment during off-peak tariffs. At USD 0.13 kWh—the 2025 U.S. commercial average—each saved kilowatt translates into USD 78 per m² each year, enough to accelerate pay-back by several harvests and soften sensitivity to future energy shocks.

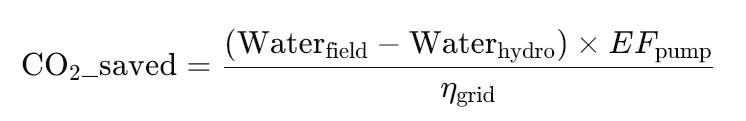

5 Carbon and ESG accounting

Every input traced and time-stamped by the app becomes auditable evidence for investors and regulators. The simplified carbon offset equation

CO2_saved=((Waterfield−Waterhydro)×EFpump)/ηgrid

CO2_saved=((Waterfield−Waterhydro)×EFpump)/ηgrid

links pump-energy factors (EF) with grid efficiency (η) to translate water savings into tonnes of CO₂ avoided. With 90 % lower irrigation and a U.S. average grid factor of 0.39 kg CO₂ kWh-¹, a 150 m² basil facility prevents roughly 4.1 t CO₂ annually compared with soil acreage under drip irrigation. Those numbers are modest per site but scale quickly across multi-city portfolios; they also unlock federal or EU grants that now score applications on verifiable reductions. Because the same telemetry populates carbon-footprint dashboards and HACCP logs, producers satisfy sustainability auditors and food-safety officers with a single digital thread.

6 Putting numbers together—an ROI worked example

Imagine a start-up that outfits a 150 m² indoor lettuce farm:

| Input | Value | | Capital expenditure (rack + sensors + app) | USD 82 000 | | Production baseline | 45 kg m-² year-¹ | | Yield uplift via automation | +22 % | | Farmgate price | USD 6.80 kg-¹ (premium, local) | | Electricity before optimisation | 110 kWh m-² year-¹ | | Electricity after optimisation | 83 kWh m-² year-¹ | | Grid rate | USD 0.12 kWh-¹ | | Water savings | 90 % on 200 L kg-¹ baseline |

Revenue. Automated dosing raises annual output to 8 241 kg; gross sales hit USD 56 000.

Energy cost. Consumption falls to 12 450 kWh; at local rates the bill is USD 1 494—USD 504 less than the manual scenario.

Water cost. City tariffs of USD 1.40 m-³ mean savings of USD 2.52 per kg, or USD 20 777 annually.

Net annual benefit. USD 21 281 (utilities) + USD 10 080 (extra yield) = USD 31 361.

Using the classic return formula

ROI=(Total Investment/Net Benefit) ×100%

ROI=(Total Investment/Net Benefit) ×100%

the project posts ROI = 38.3 % and a pay-back period a hair below 26 months—consistent with field studies yet achieved under conservative tariff assumptions. If the operator monetises the 4 t of avoided CO₂ at today’s voluntary-market price of USD 41 t-¹, the return climbs another percentage point.

7 Risk abatement and soft gains

Intangibles often seal the deal. Predictive maintenance driven by vibration and current-draw analysis catches pump failures before root zones dry, securing harvest schedules and purchase orders. Supply-chain transparency—QR codes that load live pH graphs—commands double-digit price premiums in specialty retail. And workforce savings mount because a single agronomist can remotely supervise multiple sites, answering alerts the way a sysadmin triages server pings. Freight Farms’ publicly available calculator suggests labour can fall from five to three FTEs in a container farm once tasks are app-orchestrated, cutting payroll by ~USD 90 000 a year (Freight Farms).

8 Automation’s compound effect

ROI in hydroponics rarely hinges on one spectacular metric; it accrues as a compound of dozens of small efficiencies that only software can catch at human-imperceptible speed. A 0.1 pH correction avoided here, a one-hour LED dim there, an early algae flush—each looks trivial in isolation. Over a thousand crop cycles these micro-saves aggregate into the profit margin that separates novelty farms from durable businesses. More importantly, they generate an unbroken data lineage that regulators, lenders and climate-conscious customers increasingly demand.

Bridging to delivery excellence

Numbers alone, however, do not ship code or calibrate sensors. In the next—and final—section we walk through A-Bots.com’s battle-tested delivery playbook, showing how discovery workshops, hardware-in-the-loop simulation, and staged OTA pipelines ensure that promised savings survive the leap from PowerPoint to production crops.

By grounding every sustainability claim in kilowatt-hours, litres, and dollars, App Development for Smart Hydroponic Gardens proves that environmental stewardship and investor returns are not opposing columns but two lines on the same, steadily rising graph.

From Prototype to Production: A-Bots.com’s Custom-App Methodology

Delivering App Development for Smart Hydroponic Gardens is less a straight sprint than a relay in which strategy hands the baton to code, code to agronomy, and agronomy to ongoing optimisation. Over the past decade A-Bots.com has refined that relay into four interlocking stages that shorten time-to-value while safeguarding food safety, data privacy, and investor capital. Each stage produces a tangible artefact—architecture maps, working firmware, a compliant cloud stack, or live performance dashboards—so that progress is measurable and risk is retired early rather than saved for launch week.

1 Diagnostic Sprint: Mapping Biology to Bytes

Every engagement begins with a two-week diagnostic sprint designed to align business goals, horticultural constraints, and technical realities. Consultants sit with growers and hardware vendors to inventory sensors, actuators, power budgets, and maintenance regimes; in parallel the product team runs stakeholder interviews to capture target KPIs such as grams of lettuce per kilowatt-hour or pay-back period in months. The sprint culminates in a System Blueprint that marries a sensor-topic taxonomy (often MQTT) to user-story driven app features.

Crucially, agronomists and data scientists participate from day one. That cross-disciplinary lens prevents architecture myopia—there is little point investing in multi-band spectral cameras if the crop mix does not respond to advanced light recipes or if trained models would add more cost than yield. Once trade-offs are explicit, management can approve budgets with clarity rather than faith. The blueprint also flags regulatory touchpoints: whether EU GDPR will apply to workforce log-ins, which food-safety logs must be exportable for HACCP audits, and how long sensor histories should be retained to satisfy carbon-footprint programmes.

2 Agile Proof of Concept: Hardware-in-the-Loop in Six Weeks

With the blueprint frozen, the project shifts into a six-week proof-of-concept that connects real pumps and probes to a cloud sandbox. A-Bots engineers flash edge gateways—often Yocto-based Linux on an ARM Compute Module—with secure-boot loaders and a minimal telemetry agent that publishes encrypted sensor frames every ten seconds. On the cloud side, an ingestion pipeline (Kafka or Kinesis) lands the data in a time-series store, while a stub mobile app built in Flutter visualises flow-rate, pH, and LED intensity in near real time.

The PoC is intentionally narrow: only the critical use-cases are wired, yet they run end-to-end. That hardware-in-the-loop discipline exposes latent issues—noisy pH readings after nutrient dosing, Wi-Fi drop-outs in metal-shelved basements, or unequal pump priming—while the cost of change is still low. Most clients see their first push notification—“Nutrients due in 24 h”—within four weeks of kick-off, a morale surge that turns abstract road-maps into visceral reality for investors and growers alike.

Parallel to functional tests, data scientists seed the pipeline with a lightweight ML model, often a gradient-boosted tree that predicts electrical-conductivity drift four hours ahead. Even if the model is only 70 % accurate at this stage, having the scaffolding in place paves the way for iterative improvements without rewiring the architecture.

3 Scale & Harden: From Sandbox to Production-Grade Cloud

Once the PoC survives stress-testing, the team refactors it for scale. The telemetry agent gains a ring buffer so that a shaky LTE link will not drop data; the broker gains multi-tenant partitions and fine-grained ACLs so that farms in Berlin cannot read dashboards from Boston. Firmware-over-the-air (FOTA) pipelines are introduced with code-signing, AES-256 encryption, and canary roll-outs capped at five per cent of the fleet until health metrics confirm safe deployment.

On the cloud layer, a Kubernetes cluster replaces single-instance services, fronted by an API gateway that enforces OAuth 2.0, rate limits, and versioned endpoints. Data-at-rest encryption and automated backups satisfy ISO 27001 controls, while Terraform scripts turn the entire stack into auditable infrastructure-as-code. Meanwhile the mobile app graduates from stub to polished product: offline-first caching retains the last 24 h of readings, role-based permissions gate nutrient overrides, and camera streams acquire HLS playback so that agronomists can zoom crop imagery without leaving the interface.

During this phase the initial ML model evolves as data volume explodes. Edge devices begin running TensorFlow-Lite routines that detect pump cavitation through vibration signatures collected by piezo discs, triggering preventative maintenance tickets before flow stalls. In the cloud, recurrent neural networks ingest historical DLI and yield to suggest lighting recipes that shave kilowatt-hours by single-digit percentages—small in isolation, but compounding fast at commercial scale.

Compliance is treated not as an afterthought but as a blocking deliverable. The governance module exports immutable audit trails to CSV or JSON-LD, satisfying both food-safety inspectors and carbon registries. GDPR subject-access requests can purge personal data without touching agronomic logs. Where local utilities offer demand-response incentives, the app’s scheduler aligns high-draw tasks—chiller runs, CO₂ enrichment—with off-peak tariffs, directly boosting the ROI quantified in the previous section.

4 Operate & Optimise: Continuous Value Beyond Launch

Go-live is a milestone, not an endpoint. A-Bots enters a managed-services phase that blends DevOps with “AgriOps.” Telemetry streams feed Grafana dashboards watched by an on-call rotation; error budgets are defined, and Service Level Objectives—say, 99.5 % sensor up-time or sub-500 ms command latency—are enforced with the same rigour as in fintech. When anomalies spike—perhaps a batch of EC probes age prematurely—playbooks route maintainers, and the OTA system flashes calibration patches during the next low-activity window.

On the business side, quarterly analytics reports surface KPIs in CFO language: kilograms per litre, labour hours per head of produce, energy per kilowatt mixed. Because every reading is time-stamped and cryptographically chained, sustainability claims withstand investor scrutiny and unlock green-bond financing or municipal grants aimed at resilient food infrastructure.

Product evolution continues in measured increments. A-Bots runs A/B tests on app features—colour-coded alert banners versus plain text, or augmented-reality overlays that teach staff to swap nutrient cartridges—and publishes conversion metrics. Successful variants roll into the baseline; laggards are retired. The ML roadmap marches likewise: initial gradient-boosted trees yield to transformer models that ingest weather forecasts and electricity-price feeds, letting the system pre-cool reservoirs before peak tariffs arrive.

Two years post-launch, most clients have expanded the original footprint, grafting additional racks or entirely new sites onto the same control plane. Because the architecture is multi-tenant by design, onboarding a 10 000 m² greenhouse in Dubai or a countertop herb garden line for European retail needs little more than a billing entry and a firmware flag. What began as a bespoke PoC becomes a fleet of farms sharing best-practice models, much like autonomous cars improve collectively with every kilometre.

By capping the journey at four disciplined stages—Diagnostic Sprint, Agile Proof of Concept, Scale & Harden, Operate & Optimise—A-Bots.com turns hydroponic ambition into audited, revenue-generating reality. The methodology scales from student kitchens to industrial warehouses because it treats software, agronomy, and business finance as a single continuum, not as silos. For urban farmers balancing yield targets against climate commitments, that continuum is the difference between an experimental gadget and a dependable food factory—proof that the future of city agriculture will be coded long before it is harvested.

✅ Hashtags

#AppDevelopment

#SmartHydroponics

#UrbanFarming

#HydroponicGardens

#IoTAgTech

#SustainableFarming

#VerticalFarming

#AIinAgriculture

#ABots

Other articles

Custom Mobile App Development for Smart Dog Collars The future of pet care is connected—and mobile apps are at the heart of it. This article explores how smart dog collars are evolving into real-time safety hubs, with integrated GPS, cameras, microphones, and LED displays. We analyze the global pet-tech boom and explain why software, not just hardware, drives loyalty and recurring revenue. You'll discover what pet owners want, what competitors miss, and how custom mobile apps turn simple sensors into premium services. A-Bots.com reveals the technical and UX patterns that create trust, conserve battery, and unlock delight. From bark detection to programmable LED scrolls, the app is where peace of mind happens. Learn how we help manufacturers lead the pack.

Mobile Apps for E-Bike or Scooter Urban mobility is shifting from private cars to agile fleets of shared e-bikes and scooters. Yet hardware alone cannot deliver uptime, safety, or profitability. The real engine is a custom mobile platform that unifies GPS, battery health, rider scoring, and dynamic pricing. This article dissects a market projected to exceed $50 billion by 2030 and shows why off-the-shelf dashboards fall short. We map the technical stack—from vehicle CAN-bus to real-time payment APIs—and expose hidden revenue levers like predictive maintenance and congestion-aware geofencing. Real-world examples illustrate both the growth hacks and the compliance pitfalls. Finally, we explain how A-Bots.com turns data exhaust into ROI for operators and safer rides for cities.

Mobile Apps for Baby Monitors AI baby monitors are redefining nursery care, but hardware alone can’t deliver true peace of mind. The real magic happens inside a custom mobile app that unifies cry detection, room-condition tracking, and predictive sleep coaching. This article maps the $2 billion smart-nursery market, identifies unmet user needs, and shows how data-driven UX converts anxious check-ins into calm confidence. We explain why edge AI must balance battery life, privacy laws, and latency. A deep technical dive reveals the architecture that turns audio spectrograms into push alerts in under three seconds. Case studies spotlight brands that gained subscription revenue by treating software as the product, not an accessory. Finally, we outline how A-Bots.com partners with manufacturers to build the secure, scalable apps parents actually rely on at 2 a.m.

Mobile Apps for Smart Air-Fryer and Oven Air-fryers and connected ovens are selling fast, but the real profit sits in software. A well-designed app can upsell recipe bundles, push firmware with new “modes,” and collect usage data that refines heat curves. This article breaks down the $8-billion smart-kitchen surge and shows how subscription cooking content outpaces hardware margins. Readers will learn why cloud analytics, AI doneness detection, and grocery-API tie-ins win customer loyalty. We’ll detail technical architecture—BLE pairing to edge-AI temp control and secure OTA pipelines. Real-world case studies reveal both triumphs and missed opportunities. Finally, we explain why manufacturers partner with A-Bots.com to cook up recurring revenue.

Augmented-Reality Maintenance Apps for Cobots Industrial cobots are the future of automation, but servicing them efficiently remains a challenge. This article explores how Augmented-Reality maintenance apps, powered by IoT and AI integration, dramatically reduce downtime, costs, and errors. Discover real-world case studies, data-driven insights, and why partnering with A-Bots.com can future-proof your maintenance operations with cutting-edge AR solutions.

Smart Solar and Battery Storage App Solar panels and batteries are cheaper than ever, but real value emerges only when software choreographs them minute by minute. This in-depth article tracks the cost curves reshaping residential energy, explains the app architecture that forecasts, optimises and secures every dispatch, and unpacks the grid-service markets that now pay households for flexibility. Packed with field data—from NREL bill-savings trials to Tesla’s 100 000-home virtual power plant—it quantifies user ROI across savings, resilience and sustainability. The final section details why A-Bots.com is uniquely positioned to deliver such platforms, fusing AI forecasting, IEC-grade cybersecurity and award-winning UX into a turnkey solution. Whether you build hardware, aggregate DERs or own a solar roof, discover how intelligence—not silicon—unlocks the next decade of energy value.

Top stories

Copyright © Alpha Systems LTD All rights reserved.

Made with ❤️ by A-BOTS