Home

Services

About us

Blog

Contacts

Augmented-Reality Maintenance Apps for Industrial Cobots: Reducing Downtime with AR Guides

1. Introduction: The Evolving Landscape of Industrial Cobots and Maintenance Challenges

2. How Augmented-Reality Maintenance Apps Transform Cobot Servicing

3. Quantifiable Benefits: Reducing Downtime, Costs, and Errors with AR Guides

4. Building the Future: Integrating AR with IoT, AI, and Predictive Maintenance

5. Why A-Bots.com is Your Partner for AR Maintenance App Development

1. Introduction: The Evolving Landscape of Industrial Cobots and Maintenance Challenges

In recent years, the industrial automation sector has witnessed a profound transformation, driven primarily by the rise of collaborative robots (cobots). Unlike traditional industrial robots, cobots are designed to work alongside human operators, enhancing productivity, flexibility, and safety. According to a recent market analysis by IMARC Group, the global collaborative robot market was valued at approximately USD 3.7 billion in 2024 and is projected to soar to USD 60.3 billion by 2033, reflecting an astonishing CAGR of 36.47% during the forecast period. This exponential growth is fueled by increasing demands for automation across manufacturing, logistics, aerospace, and healthcare sectors.

However, with the growing adoption of cobots comes a new set of challenges. One of the most critical issues is maintenance and downtime management. Despite their collaborative nature and advanced capabilities, cobots are not immune to mechanical failures, software glitches, or hardware wear and tear. In highly competitive industries, even minimal equipment downtime can translate into significant financial losses. It is estimated that unplanned downtime costs industrial manufacturers an average of USD 50 billion annually, with equipment failure accounting for 42% of that unplanned downtime.

Traditional Maintenance Methods Are No Longer Sufficient

Historically, cobot maintenance has relied on conventional methods such as scheduled preventive maintenance, paper-based manuals, on-site technician visits, and hands-on troubleshooting. While effective to some extent, these approaches are often time-consuming, prone to human error, and inefficient in modern high-speed industrial environments.

For example, technicians must often interpret complex diagrams or lengthy instruction manuals while simultaneously performing intricate maintenance tasks. The cognitive load involved in processing this information while troubleshooting can lead to mistakes, incomplete repairs, and extended downtime. Moreover, finding experienced technicians who are familiar with specific cobot models can be a major bottleneck, especially in geographically dispersed operations.

As cobot systems become more sophisticated, traditional maintenance practices struggle to keep pace with the need for real-time, accurate, and accessible support.

Augmented Reality (AR) Emerges as a Game-Changer

Enter Augmented Reality (AR) — a technology that superimposes digital information, such as 3D models, instructions, and alerts, onto the user's real-world view through devices like smartphones, tablets, or smart glasses. In the context of industrial cobots, AR offers the ability to revolutionize maintenance procedures by delivering real-time, step-by-step guidance directly at the point of need.

Imagine a technician approaching a malfunctioning cobot and, through an AR-enabled device, instantly visualizing animated repair sequences, safety alerts, or virtual "x-ray" views of internal components. Instead of flipping through manuals or awaiting remote support, the technician can receive contextual information overlayed on the physical machine, significantly improving both speed and accuracy.

According to studies, implementing AR-assisted maintenance procedures can lead to up to 50% improvement in task performance and a 50% reduction in downtime compared to traditional methods. Furthermore, AR enables less-experienced workers to perform complex maintenance tasks, democratizing technical knowledge and reducing dependency on a limited pool of expert technicians.

Setting the Stage for a New Era

The integration of AR into industrial maintenance workflows signals a paradigm shift in how companies approach equipment servicing. By bridging the gap between digital knowledge and physical operations, AR not only enhances efficiency but also improves safety, compliance, and overall equipment effectiveness (OEE).

As we delve deeper into this article, we will explore how augmented-reality maintenance apps for industrial cobots are reshaping maintenance strategies, reducing downtime, and empowering industries to achieve new levels of operational excellence. From real-world case studies to emerging technological trends, the future of cobot maintenance is here — and it is augmented.

2. How Augmented-Reality Maintenance Apps Transform Cobot Servicing

The traditional maintenance landscape in industrial environments often involves complex documentation, extensive technician training, and significant human effort. With the introduction of Augmented Reality (AR) maintenance apps, however, the dynamics of servicing industrial cobots are undergoing a transformative shift. These innovative solutions bridge the gap between physical machinery and digital intelligence, providing technicians with real-time, interactive guidance directly within their operational environment.

Understanding AR Maintenance Apps for Cobots

Augmented Reality maintenance apps integrate real-world views of cobots with superimposed digital instructions, animations, and data overlays. Using devices like tablets, smartphones, or AR glasses (such as Microsoft HoloLens 2), technicians can see layered information on the cobot they are servicing. These visual aids replace traditional manuals and static schematics with dynamic, contextual, and highly intuitive support.

At the core of these applications lies a combination of 3D modeling, machine learning, sensor integration, and cloud connectivity. By synchronizing real-time cobot data with AR interfaces, maintenance apps ensure that technicians have immediate access to:

- Diagnostic information and fault codes

- Step-by-step repair guides with visual cues

- Interactive exploded views of components

- Safety warnings and compliance reminders

- Remote expert assistance via live AR annotations

Enhancing Maintenance Efficiency

The impact of AR maintenance apps on cobot servicing is profound. Tasks that traditionally required multiple steps, cross-referencing manuals, and expert consultation are now streamlined through a unified AR interface. Studies have shown that technicians using AR guides can complete maintenance procedures up to 30% faster compared to those relying on conventional documentation.

Moreover, the intuitive nature of AR interfaces reduces cognitive load, allowing technicians to focus more on hands-on activities rather than interpreting complex instructions. Real-time visualizations help avoid common mistakes, enhancing both the speed and quality of maintenance work.

Empowering Non-Expert Technicians

One of the most significant advantages of AR maintenance apps is the empowerment of non-expert personnel. In the past, servicing cobots often required highly specialized knowledge, limiting maintenance capabilities to a small pool of experts. AR apps democratize access to technical know-how by offering clear, accessible, and interactive guidance that even less experienced workers can follow.

This capability is especially critical for organizations facing labor shortages or operating across multiple locations where expert resources are scarce. By leveraging AR, companies can upskill their existing workforce rapidly and cost-effectively, ensuring that cobot maintenance remains consistent and reliable.

Real-World Applications and Case Studies

Several leading organizations have already implemented AR-based maintenance solutions with remarkable success. For instance, Howden, a global engineering company, used PTC's Vuforia Studio to develop AR maintenance instructions for its industrial equipment. The result was a reduction in technician training time by 30% and a significant decrease in downtime.

Another noteworthy example is the Air-Cobot project, where a collaborative robot equipped with AR capabilities assists in aircraft maintenance inspections. By integrating AR overlays with automated inspection routines, Air-Cobot has improved maintenance accuracy and reduced inspection times.

A Paradigm Shift in Maintenance Culture

The adoption of AR maintenance apps signifies more than just technological innovation; it represents a cultural shift in industrial maintenance practices. Organizations are moving away from reactive maintenance models toward proactive, data-driven, and visually enhanced service strategies.

As cobots continue to become more integral to industrial operations, the importance of minimizing downtime and maximizing operational efficiency cannot be overstated. Augmented Reality maintenance apps provide the tools needed to achieve these goals, ushering in a new era of smarter, safer, and more effective cobot servicing.

In the next section, we will dive deeper into the measurable benefits of AR maintenance apps, exploring how they reduce downtime, cut costs, and elevate overall maintenance performance.

3. Quantifiable Benefits: Reducing Downtime, Costs, and Errors with AR Guides

In the high-stakes world of industrial automation, every minute of downtime translates to lost revenue, operational bottlenecks, and potential damage to brand reputation. Industrial cobots, despite their reliability, are not immune to unexpected malfunctions, scheduled maintenance, or servicing errors. Augmented-Reality (AR) Maintenance Apps offer a compelling, data-backed solution that addresses these challenges head-on, delivering tangible operational and financial benefits.

Reducing Downtime: Measurable Improvements

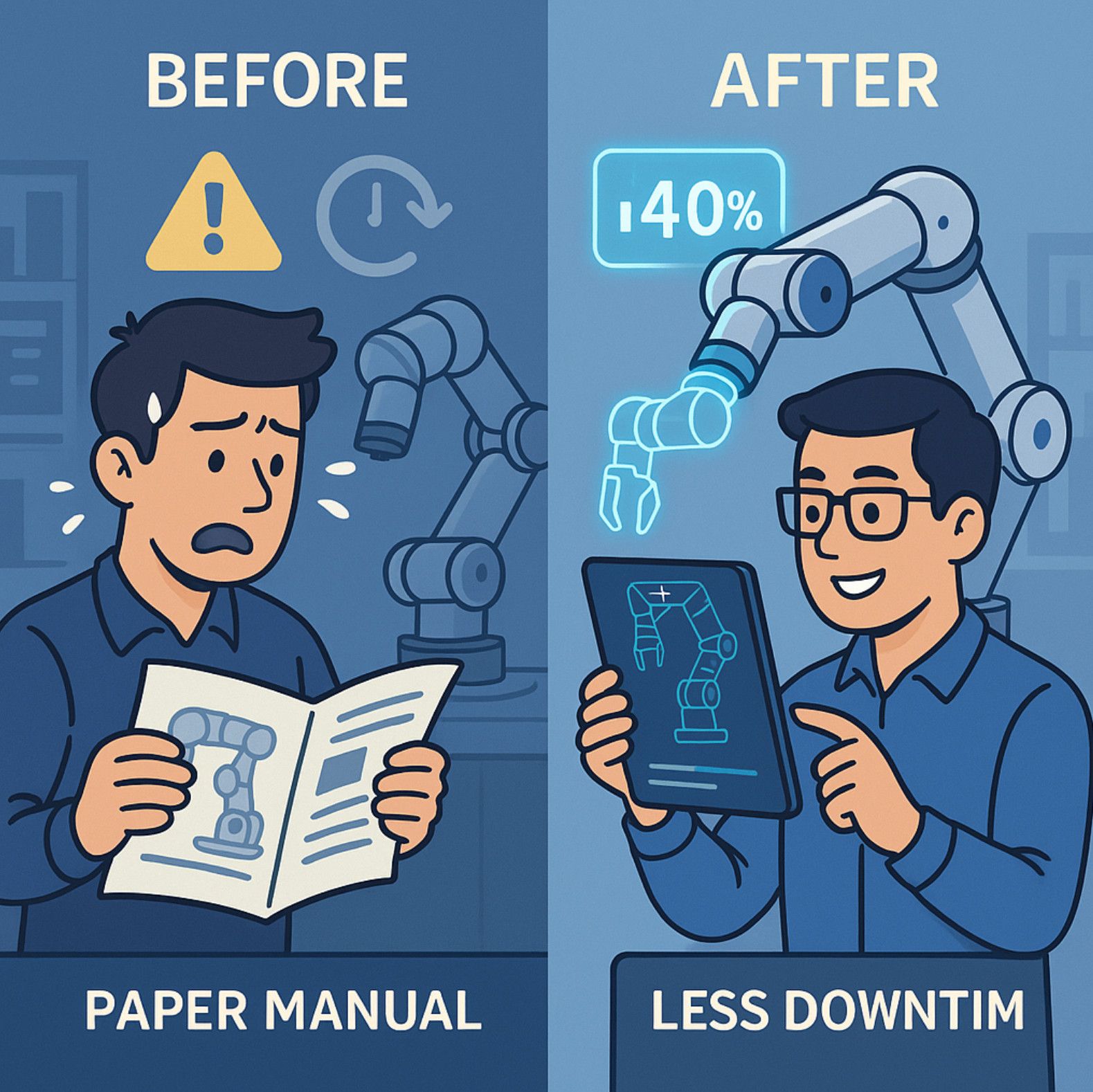

One of the most significant impacts of AR maintenance guides is the drastic reduction in equipment downtime.

-

Downtime Cut by up to 50%: Field studies, such as those conducted by companies like Howden, have demonstrated that AR-guided maintenance can reduce downtime by as much as 50% compared to traditional methods. The ability to quickly diagnose problems, visualize solutions, and perform corrective actions in real-time accelerates the entire servicing cycle.

-

First-Time Fix Rates Improved by 30-40%: Maintenance teams using AR applications achieve much higher first-time fix rates. By having context-sensitive information directly in their field of view, technicians are far less likely to overlook critical steps or misdiagnose issues, which translates into fewer repeat service visits.

-

Faster Troubleshooting: According to PTC's Vuforia reports, troubleshooting times can be reduced by up to 40% when technicians are equipped with AR guidance instead of relying solely on written manuals or verbal instructions.

In industries where cobots are central to operations, even marginal improvements in maintenance efficiency can result in savings of tens of thousands—or even millions—of dollars annually.

Cutting Maintenance Costs: Leaner, Smarter Operations

Cost reduction is another major advantage of integrating AR into cobot maintenance routines.

-

Labor Cost Savings: By minimizing the need for senior engineers to supervise basic tasks, AR democratizes maintenance skills across the workforce. Junior technicians, armed with AR apps, can execute complex procedures with minimal oversight, reducing the dependency on expensive expert resources.

-

Reduced Training Expenses: AR also cuts down on training costs. Studies show that AR-based training programs reduce training time by an average of 25-30%, leading to faster onboarding of new maintenance personnel without sacrificing quality or safety.

-

Remote Expert Support Savings: Remote AR collaboration eliminates the need for flying specialists to distant facilities for minor issues. A McKinsey study estimated that remote AR support could save companies up to 20–25% of their annual maintenance budget by reducing travel expenses and downtime costs.

By trimming both direct and indirect costs associated with cobot maintenance, companies can realize a faster return on investment (ROI) from both their robotic systems and AR implementations.

Minimizing Human Errors: Enhancing Safety and Compliance

Human error is one of the leading causes of maintenance-related downtime and accidents. AR maintenance apps directly address this problem:

-

Error Reduction Rates of 40-60%: Research published in the Journal of Manufacturing Systems showed that AR-assisted maintenance processes reduced errors by up to 60%, significantly enhancing both reliability and worker safety.

-

Enhanced Compliance and Reporting: AR apps often include automatic checklists and maintenance logs, ensuring technicians adhere strictly to prescribed procedures. This leads to better compliance with safety standards and regulatory requirements.

-

Intuitive Learning Curves: AR-guided procedures eliminate language barriers, complex jargon, and ambiguous instructions. Even technicians with limited experience or language proficiency can accurately perform intricate maintenance tasks.

By improving precision and consistency, AR solutions help companies maintain the high operational standards demanded in industries such as automotive manufacturing, electronics assembly, and food production.

Real-World Case Studies: Proving the Value of AR Maintenance

-

Boeing’s AR-Enhanced Wiring Assembly: Boeing reported a 25% reduction in time spent on wiring assemblies for aircraft after implementing AR instructions. While not specific to cobots, this case underscores the cross-industry relevance of AR-guided maintenance efficiency.

-

Siemens Mobility's AR Pilot Program: Siemens Mobility used AR apps for train servicing and found that maintenance task times were reduced by up to 30%, while technician errors were nearly halved. These outcomes are directly applicable to cobot maintenance scenarios.

These examples not only validate the theoretical benefits of AR maintenance tools but also demonstrate their transformative potential across a variety of industrial domains.

A Strategic Investment for the Future

In an era where industrial uptime, workforce flexibility, and operational resilience are more critical than ever, adopting AR maintenance apps is not just a technological upgrade—it’s a strategic imperative. Companies that invest early in AR-guided cobot maintenance position themselves to outperform competitors, weather workforce challenges, and maximize the value of their automation assets.

By quantifying the benefits of downtime reduction, cost savings, and error minimization, the business case for AR maintenance apps becomes indisputable.

4. Building the Future: Integrating AR with IoT, AI, and Predictive Maintenance

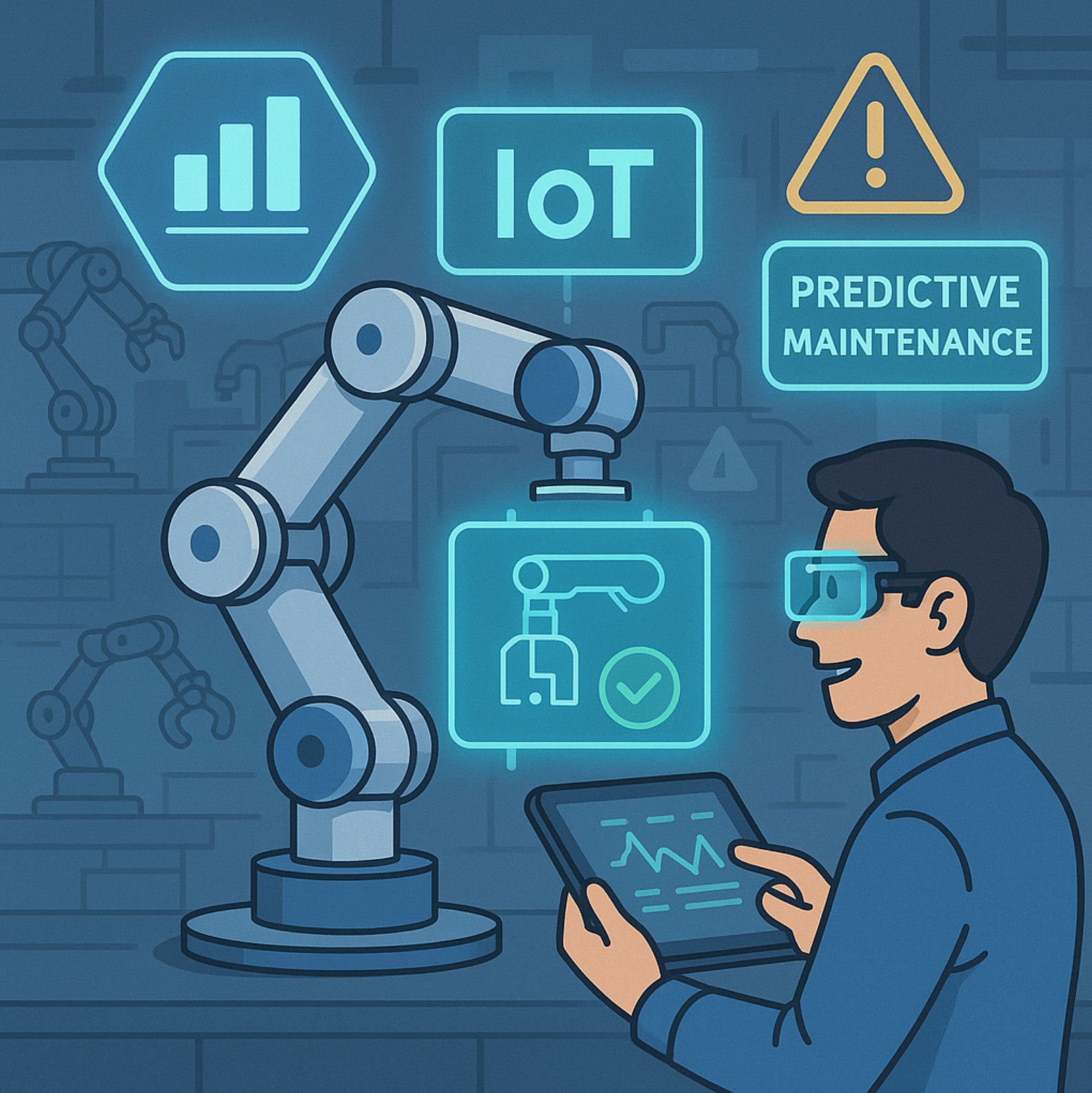

As industries move deeper into the era of Industry 4.0, the combination of Augmented Reality (AR), the Internet of Things (IoT), Artificial Intelligence (AI), and Predictive Maintenance is shaping the next frontier in industrial automation. The integration of these technologies holds the promise not merely of incremental improvements, but of fundamental changes to how industrial cobots are serviced, managed, and optimized across their lifespans.

At the core of this transformation is the use of IoT sensors embedded into collaborative robots and associated equipment. These sensors continuously monitor critical parameters such as temperature, vibration, cycle counts, energy consumption, and operational anomalies. When paired with AR maintenance apps, this data becomes accessible in real time, displayed visually over the cobot itself, providing maintenance technicians with unprecedented situational awareness. Instead of consulting dense diagnostic reports, workers can instantly see problem indicators, historical trends, and maintenance alerts layered directly onto the physical machine through their smart glasses or tablets.

This sensory fusion enhances not only visibility but decision-making. Artificial Intelligence algorithms analyze the massive data streams generated by IoT devices, predicting failures before they occur. AR applications act as the perfect delivery mechanism for AI insights, guiding technicians with precise, context-sensitive instructions tailored to the specific issue at hand. As the CEO of an industrial automation company recently stated, "When AI-driven predictive analytics meet AR-delivered maintenance workflows, downtime shifts from being a disruptive event to a preventable anomaly."

Predictive maintenance powered by IoT and AI, when visualized through AR interfaces, transforms traditional service models from reactive to proactive. Maintenance is no longer scheduled based merely on elapsed time or usage estimates; it becomes a dynamic, intelligence-driven process where interventions occur precisely when needed—and only then. This dramatically optimizes resource utilization, extends equipment life, and slashes unnecessary servicing costs.

Another profound advantage is the human-centric design of AR solutions. As smart factories become increasingly complex, the cognitive burden on human operators grows. AR serves as an intuitive intermediary between human technicians and sophisticated machine systems. By contextualizing complex AI insights and IoT data streams into easily understandable visual guidance, AR lowers the skill threshold required for high-quality maintenance, democratizing access to expertise across an organization. As one study in the Journal of Industrial Information Integration emphasized, "The synergy of AR and predictive analytics represents a cognitive augmentation for maintenance teams, enhancing decision-making speed, precision, and confidence."

Looking ahead, the integration of blockchain technology for immutable maintenance recordkeeping and the use of 5G networks for ultra-low-latency AR experiences are poised to further enhance the ecosystem. Companies like Microsoft with its HoloLens 2 and PTC with Vuforia are already pushing the boundaries of what AR can deliver in industrial settings, and we are only at the beginning of the adoption curve.

The future of cobot maintenance will not be defined by fragmented toolsets or isolated data silos, but by seamlessly interconnected ecosystems where machines, data, intelligence, and human expertise coalesce. AR maintenance apps will serve as the visualization and action layer on top of these interconnected systems, ensuring that cobot downtime is minimized, efficiency is maximized, and competitive advantage is secured.

Organizations that embrace this convergence early will find themselves not merely keeping up with technological trends but setting the pace of innovation. As the technologies mature, the focus will shift from technology adoption to optimization, integration, and continuous improvement. In this vision of the future, AR is not just a supplementary tool—it becomes an indispensable cornerstone of industrial cobot maintenance.

5. Why A-Bots.com is Your Partner for AR Maintenance App Development

Choosing the right development partner is a critical decision when embarking on a journey to create Augmented-Reality (AR) maintenance applications for industrial cobots. The complexity of merging cutting-edge technologies—AR visualization, IoT integration, predictive analytics, and AI-driven workflows—requires a development team that not only has the technical expertise but also a profound understanding of industrial environments. This is where A-Bots.com stands apart, offering a unique combination of innovation, experience, and commitment that makes us the ideal partner for businesses aiming to future-proof their maintenance operations.

At A-Bots.com, we recognize that every industrial environment is unique, and every cobot system comes with its own set of challenges and requirements. This is why we do not believe in one-size-fits-all solutions. Instead, our approach is grounded in close collaboration with our clients, where we dive deep into understanding the operational realities, maintenance pain points, and business goals that shape the need for an AR maintenance application. Through detailed discovery phases, workshops, and feasibility studies, we design bespoke AR solutions that are not only technically robust but also perfectly aligned with the client’s workflow and industry-specific regulations.

One of the defining strengths of A-Bots.com is our multi-disciplinary expertise. Our team brings together specialists in AR/VR development, mobile app engineering, IoT integration, AI analytics, industrial design, and UX/UI architecture. This convergence of skillsets ensures that every project we undertake is approached holistically, taking into account not just the functionality of the app but its usability, scalability, security, and long-term maintainability. We are proud to develop applications that are not just visually impressive, but operationally impactful—tools that directly enhance technician efficiency, reduce machine downtime, and improve overall productivity.

When developing AR maintenance applications, user experience is paramount. Technicians, engineers, and maintenance personnel must be able to intuitively interact with AR overlays, quickly comprehend instructions, and trust the system to guide them accurately. Our UX/UI designers, working in tandem with our AR engineers, craft interfaces that are clean, ergonomic, and specifically tailored to the high-pressure, time-sensitive nature of industrial maintenance tasks. Whether accessed via smartphones, tablets, or AR headsets like the Microsoft HoloLens 2, our applications are designed to be immediately usable with minimal training, enhancing adoption rates and return on investment.

Moreover, A-Bots.com understands the critical importance of data security and system interoperability in industrial settings. Our applications are built with enterprise-grade security protocols, ensuring that sensitive operational data collected through IoT sensors or maintenance logs is fully protected. We design solutions that can seamlessly integrate with existing Manufacturing Execution Systems (MES), Enterprise Resource Planning (ERP) platforms, and Asset Management Systems (AMS), ensuring that AR maintenance tools become a seamless extension of the client’s digital ecosystem rather than a disconnected silo.

Another key differentiator is our commitment to future-readiness. Technology evolves rapidly, and industrial organizations cannot afford to be locked into static systems that become obsolete in a few years. At A-Bots.com, we architect our AR applications with modularity and scalability in mind. This means that as clients' needs evolve—whether that involves expanding to additional cobot models, incorporating new predictive analytics tools, or upgrading to more advanced AR hardware—our solutions can evolve right alongside them with minimal disruption and cost.

Our project management approach is equally rigorous. We employ agile methodologies that prioritize transparency, flexibility, and continuous feedback. Clients are involved at every critical stage, from initial prototyping to full deployment and post-launch support. By maintaining clear communication and iterative development cycles, we ensure that the final product not only meets but exceeds client expectations. As one of our clients remarked after a successful AR maintenance app deployment, "A-Bots.com wasn't just a vendor; they became an extension of our innovation team."

In addition to technical excellence, what truly sets A-Bots.com apart is our passion for industrial innovation. We view every project as an opportunity to push the boundaries of what is possible—to deliver solutions that not only solve immediate problems but also open new avenues for operational excellence and competitive advantage. We are inspired by the transformative power of AR, IoT, and AI, and we are committed to bringing that transformation to the industrial sector with craftsmanship, integrity, and strategic insight.

When you partner with A-Bots.com, you are not just hiring a development company; you are aligning with a team that is invested in your success, attentive to your operational realities, and relentless in our pursuit of creating technologies that make a measurable difference. Whether your goal is to reduce downtime, cut maintenance costs, enhance technician training, or lay the foundation for a fully predictive maintenance ecosystem, we have the expertise, the vision, and the passion to help you achieve it.

In the ever-accelerating world of Industry 4.0, standing still is not an option. Those who embrace the convergence of AR, IoT, and AI will lead the next wave of industrial performance and resilience. A-Bots.com is ready to be your partner on that journey—crafting AR maintenance apps that turn today's maintenance challenges into tomorrow’s strategic advantages.

✅ Hashtags

#AugmentedReality

#CobotMaintenance

#IndustrialAutomation

#PredictiveMaintenance

#ARApps

#IoTIntegration

#IndustrialCobots

#SmartMaintenance

#ARGuides

#Industry40

#MaintenanceTechnology

#ABots

Other articles

Mobile App Development for Smart Pet Feeders Smart pet feeders are no longer luxury gadgets — they are becoming vital tools in modern pet care. But their true power is unlocked only through intuitive, connected mobile apps. This article explores how custom software development elevates the user experience far beyond off-the-shelf solutions. From feeding schedules to AI-driven health monitoring, we break down what pet owners truly expect. We analyze the market, dissect real product cases, and outline the technical architecture behind dependable smart devices. Most importantly, we show why hardware manufacturers need the right digital partner. A-Bots.com delivers the kind of app experience that builds trust, loyalty, and long-term value.

Mobile App Development for Scales Smart scales have evolved into intelligent health companions, offering far more than weight data. Today’s users demand full-body insights, AI-driven feedback, and smooth integration with other devices. This article explores how mobile apps transform smart scales into personalized wellness ecosystems. We analyze the market growth, user expectations, and technical architecture needed for success. Real-world case studies and forward-looking trends are covered in depth. We also reveal why brands must prioritize custom software over generic solutions. If you're building the future of digital health, it starts with your app.

Custom Mobile App Development for Window-Cleaning Robots Window-cleaning robots are moving from novelty to necessity as glass facades dominate modern architecture. But hardware alone cannot deliver safety, efficiency, or user trust. This article explains why a powerful mobile app—built for AI navigation, cloud analytics, and multi-device control—is now the true differentiator. We track a market expected to surpass $1.5 billion, analyze leading models, and expose the gaps in off-the-shelf software. You’ll see how custom apps cut maintenance costs, unlock fleet-level dashboards, and turn sensor data into product vision. The technical deep-dive shows exactly how BLE, Wi-Fi, and OTA updates converge inside a secure, scalable stack. If you manufacture cleaning robots, the path to premium positioning starts with smarter software.

Custom Mobile App Development for Smart Dog Collars The future of pet care is connected—and mobile apps are at the heart of it. This article explores how smart dog collars are evolving into real-time safety hubs, with integrated GPS, cameras, microphones, and LED displays. We analyze the global pet-tech boom and explain why software, not just hardware, drives loyalty and recurring revenue. You'll discover what pet owners want, what competitors miss, and how custom mobile apps turn simple sensors into premium services. A-Bots.com reveals the technical and UX patterns that create trust, conserve battery, and unlock delight. From bark detection to programmable LED scrolls, the app is where peace of mind happens. Learn how we help manufacturers lead the pack.

Mobile Apps for E-Bike or Scooter Urban mobility is shifting from private cars to agile fleets of shared e-bikes and scooters. Yet hardware alone cannot deliver uptime, safety, or profitability. The real engine is a custom mobile platform that unifies GPS, battery health, rider scoring, and dynamic pricing. This article dissects a market projected to exceed $50 billion by 2030 and shows why off-the-shelf dashboards fall short. We map the technical stack—from vehicle CAN-bus to real-time payment APIs—and expose hidden revenue levers like predictive maintenance and congestion-aware geofencing. Real-world examples illustrate both the growth hacks and the compliance pitfalls. Finally, we explain how A-Bots.com turns data exhaust into ROI for operators and safer rides for cities.

Mobile Apps for Baby Monitors AI baby monitors are redefining nursery care, but hardware alone can’t deliver true peace of mind. The real magic happens inside a custom mobile app that unifies cry detection, room-condition tracking, and predictive sleep coaching. This article maps the $2 billion smart-nursery market, identifies unmet user needs, and shows how data-driven UX converts anxious check-ins into calm confidence. We explain why edge AI must balance battery life, privacy laws, and latency. A deep technical dive reveals the architecture that turns audio spectrograms into push alerts in under three seconds. Case studies spotlight brands that gained subscription revenue by treating software as the product, not an accessory. Finally, we outline how A-Bots.com partners with manufacturers to build the secure, scalable apps parents actually rely on at 2 a.m.

Mobile Apps for Smart Air-Fryer and Oven Air-fryers and connected ovens are selling fast, but the real profit sits in software. A well-designed app can upsell recipe bundles, push firmware with new “modes,” and collect usage data that refines heat curves. This article breaks down the $8-billion smart-kitchen surge and shows how subscription cooking content outpaces hardware margins. Readers will learn why cloud analytics, AI doneness detection, and grocery-API tie-ins win customer loyalty. We’ll detail technical architecture—BLE pairing to edge-AI temp control and secure OTA pipelines. Real-world case studies reveal both triumphs and missed opportunities. Finally, we explain why manufacturers partner with A-Bots.com to cook up recurring revenue.

Top stories

Copyright © Alpha Systems LTD All rights reserved.

Made with ❤️ by A-BOTS