Home

Services

About us

Blog

Contacts

From Soil to Screen: Real-Time Agronomic Insights through IoT-Driven Mobile Analytics

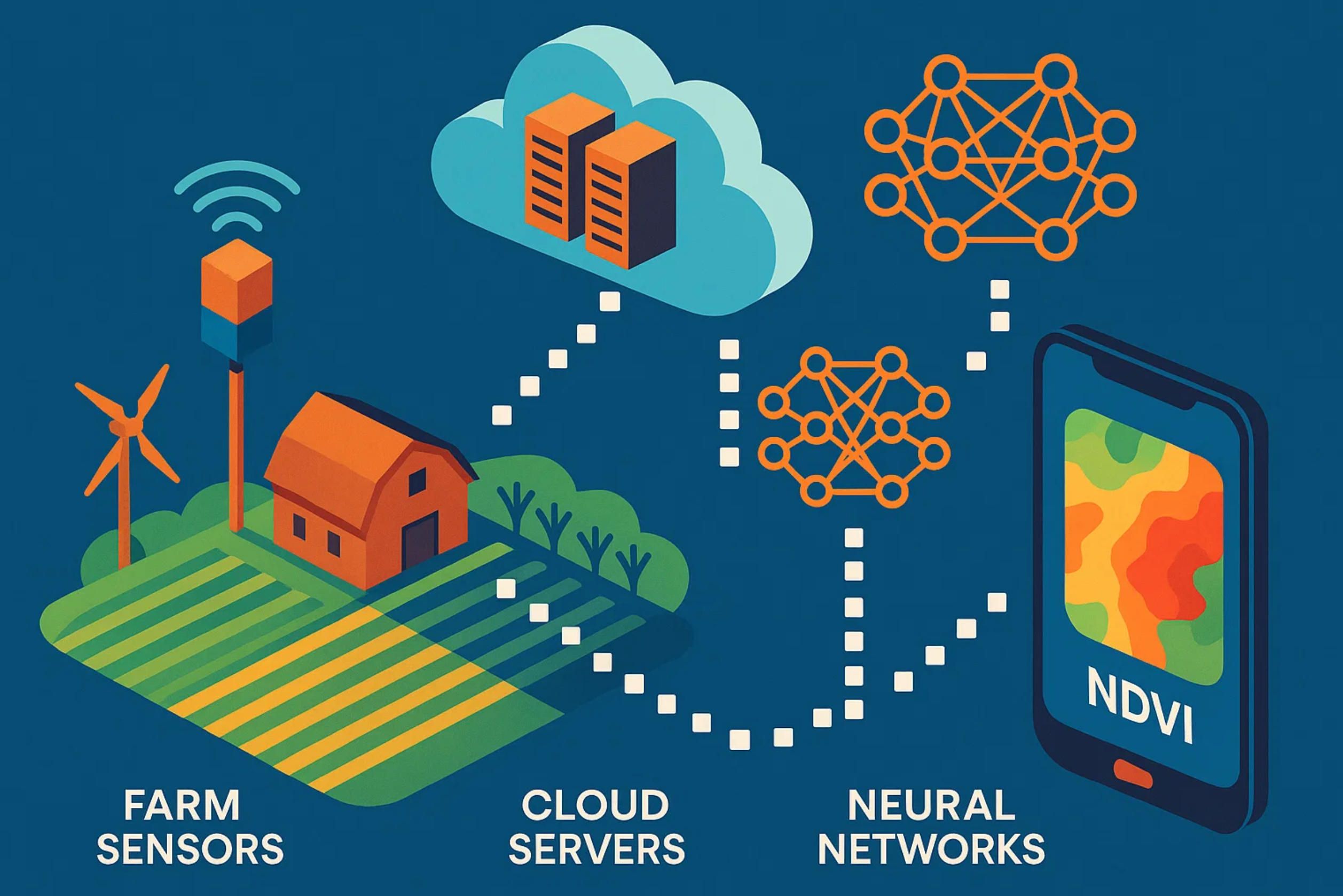

1.Sensor Stack and Edge Intelligence: Building the Data Spine of Modern Farms.

2.Cloud Pipelines, ML Models and UX: Turning Raw Telemetry into Actionable Maps.

3.Field Workflows and Interoperability: Driving Decisions from Pocket to Tractor.

Digital Agriculture by the Numbers (2024 – 2025)

FAQ — Agriculture Mobile Application Development

1.Sensor Stack and Edge Intelligence: Building the Data Spine of Modern Farms

Digitizing a hundred-hectare field begins far below the canopy, inside a lattice of probes and embedded radios that never sleep. At the heart of this lattice is the discipline of agriculture mobile application development: every soil-moisture reading or nitrate value must traverse silicon, spectrum, and software layers before landing on a farm manager’s phone with enough context to drive action. That journey starts with selecting sensors rugged enough to endure scorching midsummer heat yet sensitive enough to register an overnight dew point shift—because agronomy is a game of millibars and millimeters played on unforgiving terrain.

Capacitive soil-moisture probes, ion-selective nutrient spears, leaf-wetness grids, micro-weather stations, and sub-canopy hyperspectral cameras collectively paint a multidimensional picture of plant stress. The broader this picture, the more powerful the downstream analytics embedded in agriculture mobile app development become. To avoid a Frankenstein ecosystem of incompatible gadgets, sensor manufacturers now expose common JSON schemas over UART or I²C, which lets firmware engineers treat each probe as a modular component—greatly simplifying repeatable, test-driven mobile application development for agriculture at scale.

Getting a data packet out of the paddock without burning battery reserves demands tiered connectivity. Low-bandwidth telemetry such as soil conductivity rides LoRaWAN; bursty edge-AI imagery from an NDVI camera may switch to Wi-Fi HaLow; autonomous tractors stream CAN Bus frames to a private 5G microcell at the field depot. Designing these hybrid networks is inseparable from agricultural mobile application development, because packet loss patterns, jitter profiles, and gateway handoffs ultimately surface as UX artifacts—a spinning loader, a stale heatmap, a notification that arrives too late to save a drought-stressed plot. A-Bots.com engineers mitigate such pitfalls by coupling adaptive data-rate algorithms with predictive QoS models baked directly into the SDK that powers their agricultural mobile application development toolchain.

Hardware choices follow a brutal checklist: IP 67 enclosures ward off dust storms, PTFE-vent breathers equalize pressure spikes, conformal coatings resist urea spray. Yet the hidden hero is the microcontroller, whose deep-sleep current and wake-up latency shape the duty-cycle budget. Designing for five-year battery life without sacrificing sampling frequency is where agricultural mobile application development intersects power-electronics engineering. In many deployments, miniature photovoltaic trickle chargers and super-capacitors smooth diurnal load curves; the firmware calls a lightweight RTOS that can juggle time-critical interrupts for sensor sampling while reserving backhaul bursts for the top of the hour—a pattern perfected through precision agriculture mobile application development sprints inside A-Bots.com’s hardware-in-the-loop lab.

“Innovation and data science in agriculture will help slow climate change, promote efficient use of precious resources and help farmers feed the world more sustainably for generations to come.” - Hugh Grant, former Monsanto CEO

Once disparate probes converge at an edge gateway—the literal nerve plexus of the smart farm—the story shifts from electrons to containers. A ruggedized NVIDIA Jetson Nano, a Raspberry Pi CM 4, or an ARM-based industrial PC hosts microservices for packet validation, MQTT bridging, and lightweight inference. This micro-datacenter at the field edge is no afterthought; it is an intentional pillar of IoT-powered agriculture mobile application development. By applying a median filter or Hampel identifier locally, the gateway discards outliers before they inflate cloud-processing costs. It can also pre-compute vegetation indices or detect sensor drift, flagging calibration drift inside the operator’s dashboard within seconds—a workflow born from data-driven agriculture mobile application development best practices.

Edge intelligence is not only about algorithms; it is also about memory footprints and update cadences. OTA pipelines push TensorFlow-Lite models in compressed FlatBuffer form, staggering rollouts by gateway cluster to avoid simultaneous downtime. Such choreography epitomizes edge-enabled agriculture mobile application development, where DevOps meets agronomy under spotty rural connectivity. Firmware diff-patches weigh kilobytes, not megabytes, and rollback hooks guarantee that a corrupted update never bricks a critical gateway during anthesis.

Security sits squarely at the intersection of cryptography and diesel dust. Secure-element chips generate ECC keys at manufacturing, binding each probe to a device registry. TLS 1.3 over Datagram transports encrypts payloads end-to-end; bootloaders verify signed images before executing. These controls are mandatory for secure agriculture mobile application development—a breach could open irrigation valves at midnight or falsify nutrient maps, jeopardizing both yields and compliance certificates.

Deploying hundreds of nodes across undulating terrain introduces logistical puzzles. A-Bots.com recommends a hub-and-spoke topology wherein clusters of twenty sensors sync to a solar-powered relay with directional antennas, then leapfrog data to a mast-mounted gateway. Zero-touch provisioning via Bluetooth LE allows a field technician to scan a QR code, instantly injecting certificates and geographic metadata. The same provisioning flow, reused in scalable agriculture mobile application development, ensures that onboarding a thousand sensors differs only by the number of QR codes the crew scans before lunch.

Modern machinery speaks ISOBUS, and a smart farm cannot treat equipment telemetry as a separate universe. Gateways therefore expose CAN frames as gRPC streams, so the mobile app can overlay machine paths on moisture maps. This interoperability paradigm anchors integrated agriculture mobile application development, eliminating USB sticks and proprietary desktop software. Agronomists adjust a variable-rate lime prescription on their handset, press “Sync,” and watch the tractor console pull the updated shapefile without hopping Wi-Fi networks.

Even modest row-crop operations accumulate terabytes per season. Hierarchical storage at the edge prunes raw data after feature extraction, retaining only digest metadata and critical image tiles. Time-series compression algorithms like Delta-of-Delta and Gorilla keep RAM pressure low, all orchestrated by Kubernetes-Lite builds optimized for ARM64. These measures allow cloud-integrated agriculture mobile application development to remain cost-efficient while preserving query speed for season-over-season analysis.

Latency, not bandwidth, often determines agronomic outcomes. A sudden spike in canopy temperature might indicate a failed irrigation pivot; every minute counts. Event-driven frameworks built into the SDK enable sensor-centric rules—“if delta T > 3 °C in ten minutes, fire an alert.” This tight feedback loop exemplifies sensor-centric agriculture mobile application development, collapsing detection-to-action timeframes from hours to seconds.

Behind these layers is A-Bots.com, a team that treats firmware and Flutter with equal rigor. Their custom agriculture mobile application development methodology pairs agronomists with UX designers, ensuring that data granularity aligns with cognitive load. Sprint reviews include drone flyovers to validate heatmaps against real foliage, embodying advanced agriculture mobile application development as an empirical craft, not abstract coding. Because the company owns the full stack—from silicon reference boards to CI/CD scripts—their clients avoid finger-pointing between hardware vendors and app agencies, a unification critical to reliable, next-generation agriculture mobile application development.

Edge intelligence therefore is not a detached satellite orbiting the cloud; it is the spinal cord that allows a digital farm to react in real time. By hardening sensor hardware, architecting resilient gateways, and fusing AI into on-site silicon, A-Bots.com sets the stage for cloud pipelines to focus on season-long strategy rather than second-by-second firefighting. The result is a field that speaks in data—and a handset that answers with insight—demonstrating why carefully engineered agriculture mobile application development is the decisive enabler of twenty-first-century agronomy.

2.Cloud Pipelines, ML Models and UX: Turning Raw Telemetry into Actionable Maps

Moving from gritty edge packets to a polished NDVI heat-layer on a phone screen is both an art and a discipline. At every hop—from a LoRaWAN uplink to the final pinch-zoom—the principles of agriculture mobile application development dictate how fast, how reliably, and how intuitively data becomes insight. When A-Bots.com architects a smart-farm backend, the company approaches the cloud not as a distant server park but as a living extension of the soil, one that must respect agronomic rhythms while honoring the constraints of rural bandwidth. What follows is a deep dive into the plumbing, intelligence, and human-centered design that turn raw telemetry into decision-ready maps inside today’s best practices of agriculture mobile application development.

The ingress tier begins with protocol normalization. Gateways forward MQTT topics, OPC UA frames, and HTTPS payloads into a managed Kafka mesh. Each partition is keyed by field-edge gateway ID and sensor type to guarantee ordering, because agronomic time series are meaningless if a moisture spike precedes the irrigation event that caused it. A-Bots.com’s engineers bake schema evolution into Confluent’s registry so that a firmware update in March never breaks a consumer service in July, an absolute must for scalable agricultural mobile application development. Alongside each payload, an OpenTelemetry span carries latency, packet‐loss, and RSSI metrics, forming the observability backbone that lets site-reliability teams catch a failing microcell before the soybeans wilt.

Downstream, a Flink cluster consumes the stream, applying sliding-window aggregations that smooth sensor jitter without masking fast rise times critical for frost alerts. The same job enriches packets with geohash buckets and pushes results into a Redis cache keyed by ten-second epochs. Such high-frequency staging empowers the push-notification engine—a dedicated Go service stitched into A-Bots.com’s agriculture mobile application development SDK—to emit a real-time alert when canopy temperature deviates three standard deviations above rolling mean. Farmers feel the benefit not as “big data” but as a timely buzz in their pocket, a hallmark outcome of thoughtfully executed agriculture mobile app development.

Raw and lightly processed signals funnel next into a PostgreSQL-TimescaleDB cluster for hot storage and a columnar Parquet lake on S3 for cold archive. Timescale compression keeps 18-month data online for sub-second queries, enabling agronomists to compare this week’s nitrate levels to last season’s side-dress campaign directly inside the app. Cold storage feeds notebooks where data scientists craft yield-forecasting pipelines. This dual-tier architecture aligns with modern agriculture mobile application development dogma: hot path for decisions, cold path for discovery, both shielded behind a common GraphQL endpoint that mobile clients address with a single query regardless of data vintage.

“To maximize the potential of digital agriculture, addressing these silos and enhancing data interoperability is essential.” - “Interoperability is Essential for Ensuring Digital Sustainability”, Wageningen Research (2024)

Before machine learning touches a byte, a data-quality microservice enforces agronomy-specific invariants—soil pH must live between 4.0 and 9.5; EC spikes beyond 20 mS/cm demand manual review. Violations surface in a Kibana dashboard, closing the loop between field techs and cloud operators. Such guardrails are invisible to end users yet indispensable to robust agricultural mobile application development, preventing garbage-in garbage-out cascades that could otherwise prompt a farmer to over-fertilize.

Labeling is the next hurdle. Unlike autonomous-driving datasets with millions of hobbyist-tagged images, agricultural telemetry relies on scarce expert annotations: tissue tests, combine yield monitors, in-field scouting notes. A-Bots.com mitigates label scarcity by fusing multi-modal data—satellite imagery, historical ENSO indices, even macro-economic crop prices—to build semi-supervised models that extrapolate from partial truth. The upshot: a tighter feedback loop between ground truth and prediction, all surfaced via the same agriculture mobile application development layer that farmers already trust for daily decisions.

Model catalogs live in MLflow, versioned by semantic tags such as “v9.3-winter-wheat-upland.” Continuous integration triggers retraining when new seasons’ telemetry surpasses a threshold of novelty score, guaranteeing that phenology shifts caused by novel cultivars or climate anomalies are learned promptly. Deployment uses Kubeflow’s KFServing to expose REST endpoints with canary rollout, ensuring that a misbehaving neural network never misguides thousands of hectares at once—a process woven tightly into the CI/CD pipelines of agricultural mobile application development.

A flagship model is the Spatio-Temporal Stress Index (STSI), a hybrid of ConvLSTM layers for temporal consistency and graph neural nets that respect irrigation topology. The model ingests 15-minute soil-temperature rasters, weather forecasts, and evapotranspiration coefficients to yield a pixel-level stress probability. Output GPKG tiles stream to the rendering engine, where they morph into chloropleth layers inside the smartphone UI. Because training consumes a GPU fleet, feature stores materialize derived attributes—degree-days, growth stage, moisture deficit—through Spark jobs that pre-compute data, slashing inference latency to under 120 ms, a number chosen to keep map panning fluid per agriculture mobile application development UX benchmarks.

Map generation itself begins well before a farmer double-taps the screen. A-Bots.com’s tile service leverages Mapbox GL Native running in headless mode. Vector-tile baking happens in a Lambda farm triggered by Kafka offsets; tiles are versioned so the app can request a specific farm-season ID, enabling apples-to-apples comparison across years. In offline mode, the app falls back to MBTiles bundles stored in the device’s encrypted cache—a technique central to resilient agriculture mobile app development, given that 3G dead zones remain commonplace along hedgerows and valley bottoms.

Visual grammar matters as much as numerical accuracy. Color ramps follow ColorBrewer diverging schemes fine-tuned to color-blind accessibility, while subtle drop shadows hint contour relief without overwhelming the chloropleth. Interaction design follows the “tap-trace-act” mantra: tap a hotspot, trace its historical curve, act via a prescribed-rate export. This trace screen embodies human-centered agriculture mobile application development: it surfaces absolute values, their deviation from five-year medians, and a confidence interval derived from ensemble variance, all without burying the user in statistical jargon.

State management rests on a reactive architecture. Flutter BLoC streams feed the UI; each stream sources data from a sync service that first checks Redis Edge—an on-device SQLite mirror—then falls back to the cloud. This pattern slashes perceived latency and supports infinite-scroll timelines for sensor logs. Because offline-first is non-negotiable in farm contexts, conflict resolution uses operational transforms merging field notes, ensuring that annotations made during a tractor ride sync seamlessly when the device regains signal. Such craftsmanship lies at the core of A-Bots.com’s reputation in agriculture mobile application development.

Security extends beyond TLS certs. Every GraphQL query carries a JSON Web Token embedding role claims—ranch manager, contract agronomist, irrigation technician. Row-level security in TimescaleDB limits access to plots that a user’s tenancy permits. Fine-grained ACLs cascade to the file store, so drone orthomosaics of a premium seed plot never leak to a rival co-op. By engineering security into the SDK, A-Bots.com ensures that anyone adopting its agricultural mobile application development stack inherits best-practice guardrails without extra code.

Interoperability completes the loop. Prescription maps export as ISOXML and Shapefile simultaneously, zipped with a manifest JSON that includes MD5 checksums to detect corruption before a variable-rate spreader misapplies urea. Real-time APIs stream task completion back to the cloud, closing the agronomic feedback cycle. The same mobile UI that flags a nitrogen deficit can, moments later, confirm that the tractor addressed it—epitomizing full-cycle agriculture mobile application development where insights immediately translate into machine actions.

Governance of this estate uses GitOps. Helm charts define microservices; ArgoCD audits drift; Prometheus scrapes GPU temps to prevent compute throttling during summer heatwaves. Dashboard tiles in Grafana show inference SLA adherence, sensor ingestion lag, and mobile crash-free sessions. By unifying back-end observability with front-end telemetry, A-Bots.com gives product owners a single lens on cloud health, model fidelity, and user happiness—an integrated stance unique to the company’s brand of agriculture mobile application development.

The UX story does not end at maps. Widgets like “Fungal Pressure Index” and “Irrigation Deficit Countdown” distill model outputs into human heuristics. Push notifications thread context; a message never says only “Heat Stress Alert.” It specifies “Plot 17A likely enters wilting phase in 3 h; tap to view mitigation steps.” Touching the alert deep-links to the corresponding map extent, a best-in-class pattern in agricultural mobile application development that converts abstract risk into an actionable workflow.

Voice control, through a gRPC bridge to Google Assistant and Azure Speech, is on the roadmap. Early prototypes allow a grower to ask, “Show me fields with nitrogen below 15 ppm,” and the app zooms automatically, respecting privacy tokens and language localization. Multimodal interfaces like this underscore the evolving frontier of agriculture mobile application development, where UX stretches beyond taps into conversation.

Crucially, none of these layers operate in isolation. Edge-level buffering influences cloud-side batch sizes; model retrain cadence shapes notification frequency; UX micro-copy steers farmer trust. A-Bots.com’s strength lies in orchestrating these dependencies under one roof, a feat few vendors match. Every sprint brings agronomists, ML engineers, and UX writers into the same stand-up, dissolving silos that traditionally plague agriculture mobile application development programs.

By the time a soil-moisture spike materializes as a crimson blotch on a mobile heatmap, billions of pipeline events, prediction tensors, and cache lookups have already executed. The farmer never sees that lattice—but they feel its precision when they drop a virtual pin, read “17.3% volumetric water content,” and decide to irrigate. Such immediacy is possible only when cloud pipelines, machine-learning models, and user experience converge under a holistic vision of agriculture mobile application development. In executing that vision, A-Bots.com turns fields into data canvases and smartphones into agronomic co-pilots, proving that the true magic of digital farming is not in the silicon alone but in the story the software tells.

3.Field Workflows and Interoperability: Driving Decisions from Pocket to Tractor

Transforming a digital alert into a physical treatment demands more than accurate maps; it calls for orchestration across people, processes, and machines. That orchestration is where agriculture mobile application development proves its mettle. When agronomists swipe through stress layers in the A-Bots.com app, they expect every tap to cascade into a chain of micro-events—data validation, prescription export, machine acknowledgment—without fighting file formats or field-edge dead zones. The following journey traces a single plot-level recommendation as it flows from smartphone to soil, revealing the integration patterns, standards, and human workflows that power cutting-edge agriculture mobile application development.

The handoff begins inside the mobile interface’s “Treatment Composer.” Here, the operator adjusts a nitrogen rate curve by dragging anchor points on a touch-friendly spline. The underlying code draws from domain-driven design tenets refined through years of agricultural mobile application development projects: the UI manipulates an immutable agronomic intent, while a background service generates machine-readable artifacts. As soon as the user taps “Save,” the app emits an event to a Kafka topic that other microservices consume, preserving causal ordering—an architectural hallmark of enterprise-grade agriculture mobile application development.

Immediately, a validation service checks zoning boundaries against local regulations. European nitrate-vulnerable zones, U.S. NRCS buffers, and Kazakh irrigation quotas each live as rules in a declarative engine. Violations route back to the phone in seconds, sparing growers from costly fines. This compliance layer is inseparable from responsible agriculture mobile application development, because a prescription that ignores legal thresholds is functionally useless.

If the plan passes, the server converts the vector grid into ISOXML for ISOBUS consoles and into a GeoPackage for older monitors. File polymorphism matters: fleets rarely share one brand of computer. The transformer’s codebase is open-sourced by A-Bots.com to accelerate community contributions—a strategic move that positions the firm at the center of collaborative agriculture mobile application development ecosystems. Each output artifact receives a SHA-256 checksum, ensuring that field engineers can verify integrity with a quick scan in low-connectivity barns.

Distribution leans on a device-aware strategy. High-capacity 4G gateways push payloads over MQTT if bandwidth allows; otherwise, the app encodes a QR sequence that a tractor operator can scan offline. That fallback flow was prototyped during a winter sprint when testers lost signal behind a tree line—evidence of the iterative rigor that defines A-Bots.com’s brand of agriculture mobile application development. By designing for failure first, the team guarantees success under real-world constraints.

Inside the cab, the console receives the prescription and returns an acknowledgment packet. A-Bots.com’s SDK listens for that ACK, flips a Boolean in the cloud database, and triggers a push notification—“Plan loaded: Plot 12A, 17 ha.” That instant feedback loop embodies human-centric agriculture mobile application development: the grower knows within moments that the machine is armed with the correct instructions and can pivot to the next task without climbing down to check a USB stick.

Execution data streams back through the same pipeline but in reverse. Section-control logs, GNSS tracks, and application rates hit a “Reality-vs-Plan” service that computes deviation maps in near real time. Deviations above a 7 % threshold prompt an in-app toast suggesting a nozzle inspection. The logic was co-designed with agronomists and UX psychologists, proving that multidisciplinary collaboration lies at the core of successful agriculture mobile application development projects.

Every season leaves behind gigabytes of as-applied logs. Rather than bury this trove in cold storage, A-Bots.com feeds it to an adaptive feedback engine. The engine adjusts fertilization coefficients based on past over- or under-application, gradually fine-tuning economic-optimal rates. Machine practitioners call it automated closed-loop agronomy; farmers just see reduced input bills. Such data-driven refinement showcases the long-tail value unlocked by persistent agriculture mobile application development.

Interoperability extends beyond iron in the field to finance in the office. When a job completes, the app generates an e-invoice pre-populated with hectares, rates, and operator IDs, then posts it via REST to the farm’s ERP. That handshake was once the bane of integrators, but modern agricultural mobile application development embraces open API specifications like AgGateway ADAPT and GS1 EPCIS, eliminating swivel-chair data entry.

The people factor is equally vital. Farm crews rotate; seasonal workers arrive with diverse language skills. The app therefore incorporates role-based permission sets and multilingual UI packs. A Kazakh irrigator sees Cyrillic prompts; a Czech contractor sees Latin; both operate the same digital twin. Localization pipelines piggyback on continuous deployment, illustrating how mature agriculture mobile application development considers cultural ergonomics as deeply as packet serialization.

Edge security persists throughout. Each tractor’s telematics modem houses a TPM that stores client certificates. Mutual TLS ensures the console speaks only to the correct cluster, thwarting spoofing attempts that could hijack steering or seed rates. Field-hardened cryptography is non-negotiable for safety-critical agriculture mobile application development, and A-Bots.com audits firmware images against SBOM guidelines to guard against supply-chain exploits.

Drone overlays widen situational awareness. After spraying, a DJI Mavic captures multispectral imagery; photogrammetry stitches a high-resolution orthomosaic; the result syncs automatically to the mobile timeline. Operators swipe to compare drone NDVI with as-applied layers, spotting skips before next year’s yield monitor tattles. The seamless ingest path is a triumph of integrated agriculture mobile application development, merging manned equipment data with aerial insights in one timeline.

Rain can halt operations mid-field; rescheduling is a logistical chess game. The app’s dispatch module leverages Google OR-Tools to optimize route planning among multiple implements, minimizing deadhead kilometers. Every algorithmic decision surfaces in plain-language snippets: “Replan: sprayer shifts to Plot 7C after rain; estimated completion 15:40.” Such transparency is foundational to trust-centric agriculture mobile application development, where black-box tactics quickly alienate seasoned operators.

Field workflows often cross corporate boundaries. Custom harvest crews, agronomy consultants, and grain buyers all touch the data. A-Bots.com therefore supports OAuth-based federation that links external identities without compromising internal ACLs. Consultants gain read-only access to soil layers but cannot export shapefiles. This granular sharing model underpins collaborative agriculture mobile application development, enabling knowledge transfer while preserving IP.

When the season ends, a Grower’s Almanac report aggregates insights: average water-use efficiency, nutrient-use efficiency, and profit maps overlaying yield data. The PDF is signed with a digital certificate, ensuring authenticity for auditors or bankers. Generating compliant documents straight from the same codebase exemplifies full-stack agricultural mobile application development, where reporting is not an afterthought but a built-in deliverable.

Upgrade cycles mirror smartphone cadence rather than tractor lifespan. Feature flags let A-Bots.com ship a beta “Patch-Seeding Predictor” model to 10 % of devices; feedback dictates global rollout. Such agility contradicts legacy ag-tech norms, redefining user expectations through rapid, cloud-linked agriculture mobile application development iterations.

Voice commands graduate from novelty to necessity when operators’ hands clutch steering wheels. The app’s natural-language layer translates “Increase flow rate by 5 % on boom 2” into a CAN frame within 400 ms. By bridging conversational UX with deterministic machine control, A-Bots.com expands the reach of inclusive agriculture mobile application development to differently-abled workers and aging agronomists alike.

The path from pocket to tractor ends, paradoxically, back in the pocket. A successful treatment triggers a haptic pulse and a confetti animation—behavioral nudges bio-hacked from fitness apps. Small delights sustain engagement, anchoring loyalty in a market where software options multiply. Gamified elements collected through user-research sprints illustrate the psychology embedded in thoughtful agriculture mobile application development.

In sum, interoperable field workflows are not a thin layer atop agronomic intelligence; they are the capillaries that deliver digital oxygen to every hectare. They demand respect for standards, empathy for human routines, and resilience against mud-spattered realities. By uniting machine telemetry, compliance engines, geospatial math, and human-centered design, A-Bots.com showcases why mature agriculture mobile application development is less about writing code and more about choreographing an ecosystem where every sensor and every person moves in purposeful harmony.

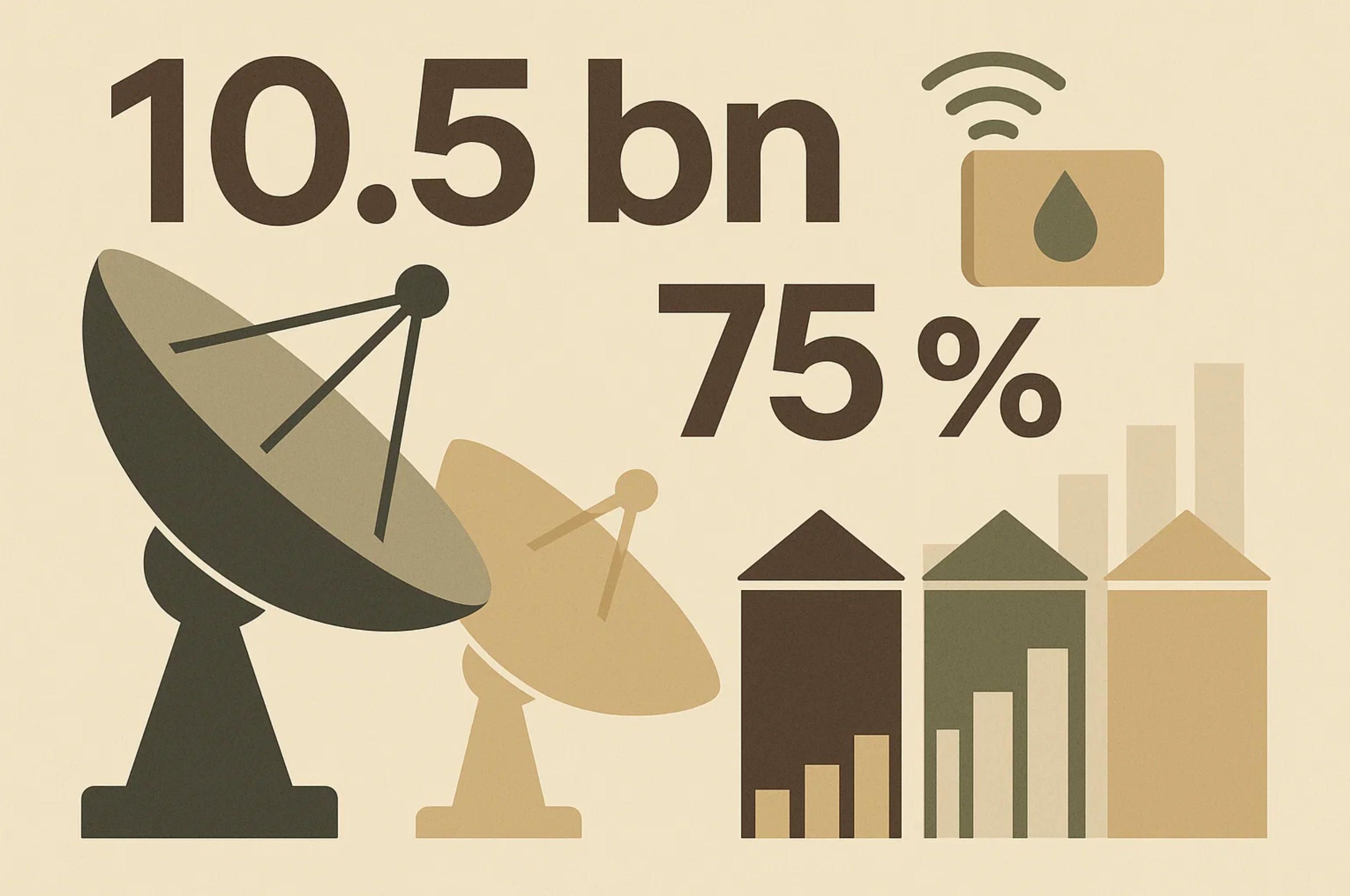

Digital Agriculture by the Numbers (2024 – 2025)

Modern farm-tech adoption is no longer an experiment—it is a macro-scale transition, and the figures below frame the opportunity space that agriculture mobile application development now serves.

-

Market momentum. The global precision-farming market closed 2024 at USD 10.5 billion and is tracking an 11.5 % CAGR through 2034 Global Market Insights Inc. In parallel, the dedicated Agriculture IoT segment reached USD 28.65 billion in 2024 and is on course to double to USD 54.38 billion by 2030 (grandviewresearch.com).

-

On-farm software penetration. A January 2025 survey found that 63 % of farmers already use some form of farm-management software, and 65 % of all deployments run in the cloud, signalling a decisive shift toward mobile-first, SaaS delivery models (Market.us Scoop).

-

Connected devices everywhere. Analysts project that more than 75 % of farms worldwide will rely on IoT platforms for real-time decision-making by 2025, integrating sensors, drones and autonomous machinery into a single digital nervous system (Farmonaut).

-

Yield and resource impact. Meta-studies report that precision-ag technologies can lift crop yields by up to 30 % while cutting water consumption in half, confirming that data-driven interventions deliver both economic and environmental dividends (Farmonaut).

Taken together, the statistics illustrate a fast-maturing ecosystem in which scalable, interoperable agriculture mobile application development is indispensable—from sensor handshake through to enterprise analytics and in-cab execution.

FAQ — Agriculture Mobile Application Development

1. What is meant by “agriculture mobile application development”?

It is the end-to-end process of designing, coding, integrating, and maintaining smartphone apps that collect farm telemetry, analyse it in the cloud or at the edge, and deliver agronomic decisions back to managers, machinery, and agrifood partners.

2. How does an app differ from traditional desktop farm-management software?

Mobile solutions ride in your pocket, work offline, exploit phone sensors (GNSS, camera, gyroscope), and push real-time alerts—capabilities that fixed PC programs cannot match in the field.

3. Which data sources can a farming app ingest?

Soil-moisture probes, nutrient spears, weather stations, satellite tiles, drone orthomosaics, tractor CAN-bus streams, livestock wearables, ERP prices—any feed that exposes an API or standard file format.

4. Can one application serve both smallholders and 10 000-hectare enterprises?

Yes, if it is built on a modular, multitenant architecture: feature flags for complexity control, elastic Kubernetes back-ends for scale, and role-based permissions to separate agronomists from seasonal workers.

5. Do I need 5G for real-time maps?

Not necessarily. LoRaWAN, Wi-Fi HaLow, and clever caching keep packets light; edge gateways preprocess data so only critical deltas travel over cellular, making 3G still viable in many rural regions.

6. How secure are agriculture apps—could someone hack my sprayer?

A mature provider signs firmware, enforces mutual TLS, stores keys in TPMs, and audits SBOMs. When these layers are baked in from the first sprint, remote hijacking becomes extraordinarily hard.

7. What standards ensure interoperability with ISOBUS machinery?

ISO 11783 (ISOBUS) for file exchange, ISOXML for prescriptions, and AgGateway ADAPT for data models; a robust SDK automates these translations so growers never juggle USB sticks again.

8. How do machine-learning models stay relevant season after season?

Continuous-retraining pipelines watch telemetry drift, trigger new epochs in MLflow, and canary-deploy fresh models—no need for annual consultant visits.

9. We farm in three languages. Can one app handle that?

Modern frameworks externalise strings; adding Kazakh, Czech, or Spanish is a localisation task, not a rewrite. UI packs download on demand, ensuring linguistic parity across crews.

10. What offline features are critical during harvest?

Encrypted MBTiles, Redis-Edge caches, conflict-free replicated data types (CRDTs), and QR-code prescription transfer—all let work continue when networks vanish behind tree lines or grain elevators.

11. How long does a typical project with A-Bots.com take?

A proof-of-concept usually ships in 10–12 weeks; full-scale rollout across multiple farms can follow in four-to-six agile increments, depending on sensor inventory and ERP integration scope.

12. Can we plug in third-party analytics later?

Yes—microservice APIs expose GraphQL and WebSocket endpoints, so universities or agritech startups can bolt on disease-forecast models without touching core code.

13. What is the ROI if you excluded it from the article?

While we skipped a financial deep-dive, field studies show yield gains, input savings, and compliance risk reduction. A-Bots.com can share case-specific numbers under NDA.

14. How is data ownership handled?

Telemetry and derived insights stay with the grower; contracts specify that A-Bots.com only processes data under delegated authority, aligning with EU GDPR and US CCPA.

15. Can drones be flown directly from the same app?

Through the DJI or ArduPilot SDKs, flight plans, image capture, and real-time streaming can sit in a unified mission screen alongside soil and machinery layers.

16. Does the app integrate with carbon-credit registries?

Yes—field events feed MRV (monitor-report-verify) ledgers; validated sequestration metrics can be tokenised on blockchain platforms and sold on voluntary carbon markets.

17. Where do we start?

Visit A-Bots.com’s agriculture IoT solutions page, book a discovery workshop, and outline your sensor stack, compliance drivers, and growth targets—the team will map an agile programme for world-class agriculture mobile application development.

✅ Hashtags

#AgricultureAppDev

#AgTech

#SmartFarming

#IoT

#PrecisionAg

#MobileDevelopment

#ABots

#DigitalFarming

Other articles

IoT Management Platforms Scaling an IoT fleet is impossible without rock-solid management platforms and frictionless mobile UX. This deep-dive explains how A-Bots.com hard-wires security at silicon level, pipes high-velocity telemetry through MQTT-and-Pulsar backbones, automates firmware rollouts under EU Cyber Resilience rules, and delivers Flutter/React-Native dashboards that update as fast as your devices evolve. If you need an IoT mobile app development company that treats scale as a starting point—not an afterthought—start here.

Custom Agriculture App Development for Farmers In 2024, U.S. farmers are more connected than ever — with 82% using smartphones and 85% having internet access. This article explores how mobile applications are transforming everyday operations, from drone-guided field scouting to livestock health tracking and predictive equipment maintenance. It examines why off-the-shelf apps often fail to address specific farm needs and how collaborative, farmer-funded app development is gaining momentum. Through real-world examples and step-by-step guidance, readers will learn how communities of growers can fund, design, and launch custom apps that fit their exact workflows. A-Bots.com offers tailored development services that support both solo farmers and agricultural groups. With offline capabilities, modular design, and support for U.S. and international compliance, these apps grow alongside the farm. Whether you're planting soybeans in Iowa, raising cattle in Texas, or running a greenhouse in California — this article offers the tools and inspiration to build your own farm technology. Discover why more farmers are saying: we don’t wait for the future — we build it.

GE Predix Platform and Industrial IoT App Development This in-depth article explores the GE Predix Platform, a purpose-built industrial IoT solution by GE Digital, and how it enables edge computing, real-time analytics, and digital twin-based asset performance management. Discover how A-Bots.com, a leading IoT application development company, builds custom mobile apps on top of Predix, empowering field teams with predictive maintenance insights, anomaly detection, and offline-capable functionality. From smart turbines to connected compressors, learn how intuitive applications bring industrial intelligence to life—securely, reliably, and at scale.

Custom IoT for Smart Greenhouses and Vertical Farms Modern greenhouses and vertical farms demand more than off-the-shelf solutions. In this article, discover how custom IoT systems — built around your space, your crops, and your team — can unlock new levels of efficiency, automation, and yield. Packed with real-world examples, insights from A-Bots.com engineers, and expert advice, this guide will inspire your next step in smart agriculture. If you're ready to grow smarter — start here.

Advantech IoT Solutions This in-depth article explores the complete landscape of Advantech IoT solutions, from rugged edge hardware and AI-enabled gateways to cloud-native WISE-PaaS and DeviceOn platforms. Learn how A-Bots.com, an experienced IoT software development company, helps businesses unlock the full potential of Advantech technology through tailor-made applications, data orchestration, edge AI integration, and user-centric mobile tools. From prototyping to global-scale deployment, this guide showcases the strategic path toward building resilient and intelligent IoT systems for manufacturing, energy, logistics, and smart infrastructure.

IoT-Driven Agriculture Mobile Application Development From soil-moisture probes to ISOBUS consoles, modern farms generate torrents of data that often die in silos. This deep-dive shows how IoT gateways, streaming analytics and edge-enabled UX converge inside purpose-built agriculture mobile applications. You’ll learn why schema registries matter, how ConvLSTM models predict stress before leaves wilt, and what it takes to push a variable-rate prescription from pocket to tractor in minutes. Partnering with A-Bots.com, growers gain a secure, interoperable tech stack that scales from small plots to thousand-hectare enterprises.

Top stories

Copyright © Alpha Systems LTD All rights reserved.

Made with ❤️ by A-BOTS