Home

Services

About us

Blog

Contacts

GE Predix Platform: Industrial IoT Core for Smart Assets, Edge Logic and Predictive Intelligence

1. GE Predix Platform Architecture: Edge-to-Cloud Continuity for Industrial IoT

2. Predix Analytics and Asset Performance Management: Turning Data into Decisions

3. Build-to-Scale with A-Bots.com: From Industrial Assets to Intuitive IoT Applications

4. Industrial IoT by the Numbers: Why Platforms Like GE Predix Matter

FAQ — GE Predix Platform and Industrial IoT Application Development

1.GE Predix Platform Architecture: Edge-to-Cloud Continuity for Industrial IoT

The GE Predix Platform stands as a cornerstone in the modern industrial Internet of Things ecosystem. Designed by GE Digital to unify operational technology (OT) with information technology (IT), this platform bridges the physical and digital worlds through a robust, modular, and scalable architecture. While many IoT platforms provide telemetry ingestion or visualization, the GE Predix Platform was specifically engineered to handle the unique complexity of industrial environments—where latency, security, and mission-critical uptime requirements reshape the traditional assumptions of software design.

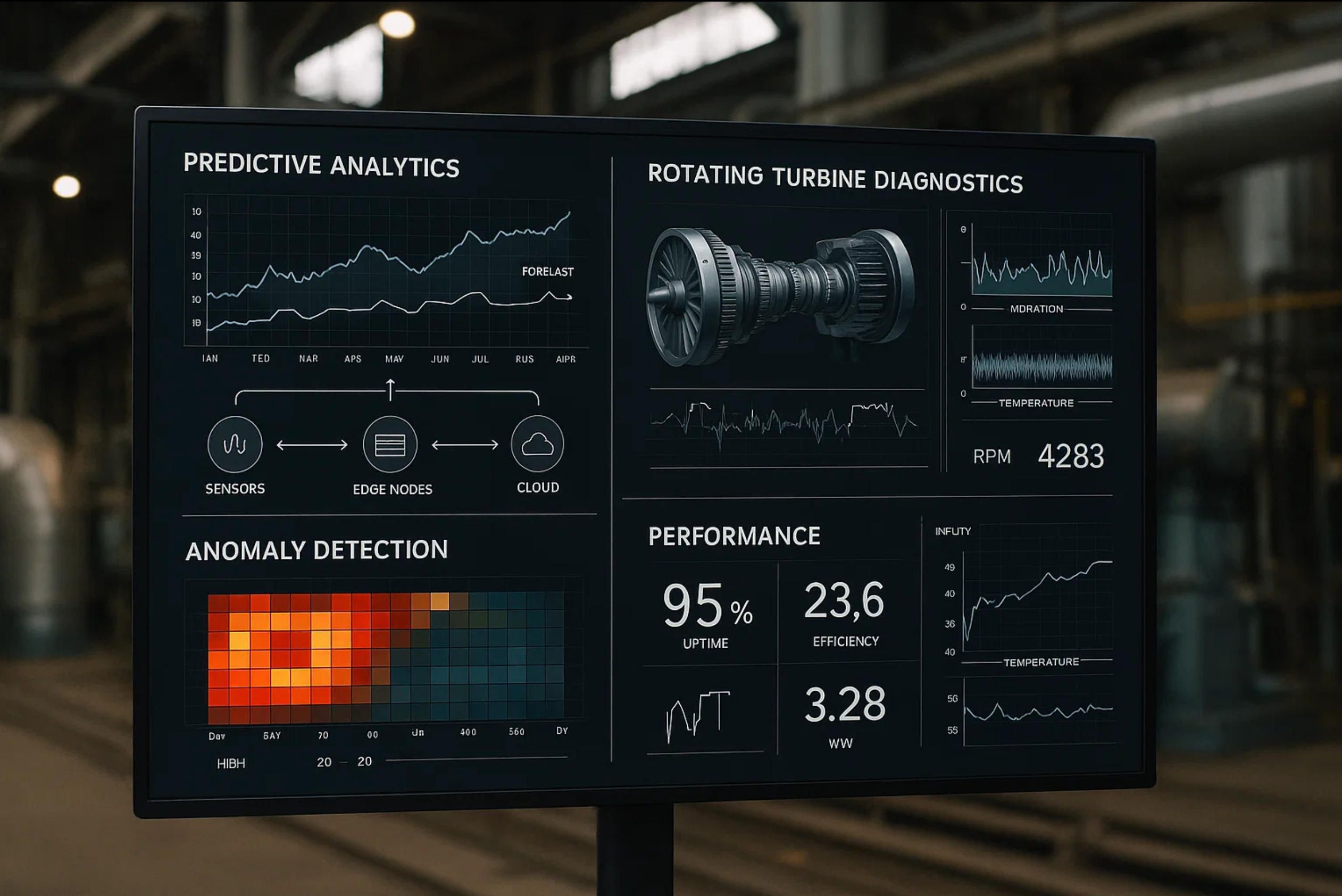

At the heart of the GE Predix Platform lies a deep commitment to edge-to-cloud continuity. This is not simply about collecting sensor data and shipping it off to a cloud server. In industrial contexts—such as power plants, manufacturing facilities, oil rigs, and heavy equipment—data must be acted upon immediately, often within milliseconds. To meet these demands, GE Digital introduced Predix Edge, a local runtime environment capable of hosting containers, performing analytics, enforcing policies, and even supporting machine learning inference directly on-site. This edge tier ensures deterministic response times, even in the event of network latency or cloud outages.

Data originating from field assets flows into the platform through secure data ingestion pipelines, built on a combination of protocols such as OPC UA, MQTT, and Modbus. The Predix Edge agents standardize this data and communicate with Predix Cloud, GE’s hardened PaaS environment hosted on Amazon Web Services, purpose-built to comply with strict industrial-grade security and performance standards. One of the most powerful aspects of the GE Predix Platform is this bi-directional data movement, which not only sends telemetry upstream but also allows instructions, configurations, and software updates to propagate from cloud services down to edge devices. This closed-loop interaction forms the backbone of advanced automation and real-time responsiveness.

Another critical piece of the architecture is the Predix Data Fabric, which unifies disparate data sources across the OT landscape. In traditional industrial setups, different systems generate siloed data: SCADA systems log process events, historians capture time-series signals, while MES and ERP systems manage workflows and production outputs. The GE Predix Platform dissolves these silos by offering a federated, secure model for integrating structured and unstructured data into a central analytical hub. Once harmonized, this data can be consumed by predictive models, dashboards, digital twins, or mobile applications—creating a true single source of truth.

The Digital Twin concept is another hallmark of the platform’s architecture. Within GE Predix, digital twins are dynamic, data-driven software representations of industrial assets. These models do not merely replicate physical form—they simulate operational behavior in real time, evolving as new data is received. By coupling sensor input with engineering design, historical performance, and failure patterns, digital twins enable what-if scenario simulations, fault detection, and maintenance forecasting. For companies operating capital-intensive assets, such as turbines, locomotives, or chemical reactors, these capabilities translate directly into prolonged uptime and reduced operational risk.

Security is a design principle baked into every layer of the GE Predix Platform. From device authentication and TLS encryption to role-based access control (RBAC) and audit logging, the platform aligns with NIST guidelines and critical infrastructure protection protocols. Edge agents are capable of executing policy-based data redaction or obfuscation locally, ensuring that sensitive information never leaves the facility unless explicitly permitted. In the cloud, data residency controls and tenant isolation mechanisms maintain enterprise-grade separation and regulatory compliance across jurisdictions.

Equally important is the modular nature of the GE Predix architecture. Rather than prescribing a rigid technology stack, GE Digital embraced the microservices paradigm. Each core function—data acquisition, storage, analytics, visualization, identity management—exists as a loosely coupled containerized service. This architectural philosophy allows developers and integrators to pick and choose the components relevant to their solution while maintaining interoperability. It also simplifies versioning, rollback, and horizontal scaling—critical for production environments with 24/7 uptime expectations.

One area where the GE Predix Platform demonstrates exceptional value is mobility. While industrial IoT systems are often rooted in control rooms and edge nodes, the mobile dimension is increasingly indispensable. Field operators, reliability engineers, and executives require access to key performance indicators and event alerts from wherever they are. The GE Predix architecture supports RESTful APIs and modern authentication standards (OAuth 2.0, SAML), making it easy to build custom mobile apps on top of the platform. These applications can retrieve telemetry in real time, trigger commands, or visualize anomalies—transforming complex machine behavior into actionable insights on a smartphone or tablet.

This is precisely where a company like A-Bots.com, a trusted Internet of Things application development company, becomes a valuable partner. While the GE Predix Platform provides the foundational backend, organizations often require tailored mobile solutions that align with their operational workflows. A-Bots.com specializes in creating these human-centric interfaces—custom mobile apps that seamlessly connect to Predix APIs, ingest asset performance data, and display it in role-specific dashboards for field users. With experience in industrial-grade UX, offline-first architectures, and secure mobile protocols, A-Bots.com can translate raw telemetry into intuitive decision-making tools.

Moreover, A-Bots.com helps bridge the IT-OT divide, providing end-to-end consulting that encompasses Predix data modeling, edge deployment strategies, mobile DevOps, and long-term maintainability. This means businesses don’t just deploy another software tool—they build a digital nervous system that scales with their industrial assets.

What makes the GE Predix Platform stand out in a crowded IoT marketplace is not just its technical features—it’s the intentionality behind its design. It was not built for connected fridges or smartwatches; it was engineered for steam turbines, jet engines, mining trucks, and gas pipelines. It assumes the harsh realities of the industrial world—electrical noise, extreme temperatures, air-gapped networks—and provides a reliable digital layer that meets those realities with resilience and intelligence.

As Marc Andreessen once noted, “Software is eating the world,” but in the industrial realm, not just any software will do. The GE Predix Platform embodies software that’s capable of listening to 10,000 rotating parts, analyzing vibration patterns in milliseconds, and notifying a field engineer before a failure occurs. And when that notification comes, it might very well appear on a mobile app—built by a company like A-Bots.com—delivered into the hands of a technician who’s 100 kilometers away from the nearest control center.

The modern industrial landscape demands more than dashboards—it requires context-aware intelligence, real-time autonomy, and secure, scalable infrastructure. The GE Predix Platform delivers on all three. And with the right development partner, such as A-Bots.com, that power becomes not only accessible but actionable—reaching the very edge of your operations and placing digital intelligence in the hands of the people who keep industry running.

2.Predix Analytics and Asset Performance Management: Turning Data into Decisions

Industrial data, in its raw form, is inert. Terabytes of vibration signals, pressure readings, thermal images, or RPM logs hold no intrinsic value unless they are transformed into insight—and more importantly, action. The GE Predix Platform was engineered with this precise objective: to turn complex industrial data into smart, contextual, and timely decisions. At the intersection of Predix Analytics and Asset Performance Management (APM) lies a powerful paradigm shift in how industries monitor, maintain, and optimize their most critical assets. This is not simply about dashboards or anomaly alerts—it's about building a cognitive layer over machines, where data continuously informs, predicts, and automates actions throughout the operational lifecycle.

The foundation of this intelligent layer begins with real-time analytics embedded across the GE Predix Platform. Rather than relying solely on cloud-side processing, the architecture supports distributed analytics at the edge, ensuring low-latency computation even in bandwidth-constrained or high-risk environments. Edge nodes equipped with Predix services can run containerized models directly on field gateways or controllers, enabling local decision loops. This allows, for instance, a wind turbine to adjust blade pitch in milliseconds based on predictive load profiles, or a compressor to automatically derate before reaching critical temperature thresholds. It’s not just data visualization; it’s data reflex.

At the cloud level, the Predix Platform unlocks a new dimension of analytical power. GE Digital has integrated a robust suite of tools for data science, including Python-based environments, TensorFlow support, time-series SQL extensions, and native connectors for historical and live streaming data. These tools empower engineers and data scientists to construct predictive models, identify latent failure patterns, and define key operational thresholds across fleets of equipment. Once trained, these models can be deployed both in the cloud and at the edge, forming a synchronized system where machine learning logic travels with the asset.

A cornerstone use case within Predix Analytics is Predictive Maintenance (PdM)—a transformational shift from calendar-based servicing to condition-based intelligence. Through pattern recognition, regression models, and even unsupervised learning, the platform can identify micro-degradations long before alarms are triggered. Take, for example, a gas turbine exhibiting a minor increase in exhaust temperature deviation. Traditional monitoring might flag it only after thresholds are exceeded. Predix, however, correlates this signal with compressor wear history, environmental conditions, and transient load behavior, forecasting a potential efficiency drop weeks in advance. This insight can then be pushed to the enterprise APM dashboard or directly into a mobile app, alerting field technicians with recommendations and replacement part SKUs.

The Asset Performance Management module is where such intelligence becomes operationalized. GE Predix Platform doesn’t stop at analytics—it provides a structured, actionable framework for managing asset reliability, availability, and performance. At its core is the Digital Twin Library, where thousands of industrial asset types—compressors, pumps, transformers, turbines—are digitally represented, complete with metadata, engineering hierarchies, and behavior models. Each twin continuously ingests data, adjusts its parameters, and recalculates risk scores. The APM engine continuously evaluates these twins, flagging potential deviations from baseline and suggesting corrective actions.

But the real power of APM within the GE Predix Platform comes from its integration with decision logic and business rules. Rather than overwhelming users with raw alerts, the system can prioritize based on criticality, operational context, and financial impact. For example, if two pumps show similar early-stage cavitation, but one serves a high-throughput line and the other a backup channel, APM will recommend intervention on the higher-priority asset first. Maintenance windows can be optimized, spare parts pre-positioned, and labor allocated accordingly. This logic is accessible via graphical tools or API endpoints—meaning mobile apps can receive these filtered, intelligent notifications in real-time.

For enterprise clients, especially in sectors like energy, aviation, or heavy manufacturing, the ability to benchmark assets across facilities adds another layer of value. The GE Predix Platform aggregates metrics across geographies, enabling leaders to compare turbine efficiency in different climate zones, or track bearing failures across multiple mining trucks. Such comparative analytics foster a data-driven culture where decisions are rooted not in intuition but in statistically sound, cross-validated insight.

Furthermore, the platform supports anomaly detection at scale. Using unsupervised machine learning, including clustering and PCA techniques, Predix can automatically build behavioral baselines for assets and flag any statistical outliers. Importantly, this doesn’t require labeled failure data, making it especially powerful in rare-event scenarios such as chemical leaks, arc flashes, or rapid thermal runaway. These anomalies are then visualized through intuitive dashboards or embedded into alerting systems—again, all of which can be accessed via mobile interfaces designed for operators in the field.

This is where a development partner like A-Bots.com plays a transformative role. While the backend intelligence of GE Predix is world-class, end users often interact with it through mobile apps—whether it's a maintenance engineer in a substation, a reliability manager walking a factory floor, or an operations supervisor traveling between plants. A-Bots.com specializes in crafting custom mobile apps that extend the power of Predix Analytics and APM into these mobile-first workflows. With native support for real-time telemetry, push notifications, biometric security, and even augmented reality overlays, the applications built by A-Bots.com translate complex data into field-ready decisions.

Consider the scenario of a mobile app for wind farm technicians. Leveraging GE Predix APIs, A-Bots.com can build an application that not only shows turbine-level KPIs but also predicts gearbox failure risk, recommends torque settings for bolt inspections, and geolocates required spare parts in nearby warehouses. All of this is synchronized with the asset’s digital twin and complies with enterprise security policies. The result is a seamless integration of insight and action—right in the technician’s pocket.

What further elevates the GE Predix Platform is its support for closed-loop optimization. It is not enough to predict failures or highlight inefficiencies—the true value lies in enabling systems to adapt. APM can feed recommendations directly into industrial control systems, suggest load adjustments, or reconfigure process parameters in real time. The platform’s extensibility via RESTful APIs and MQTT channels allows third-party apps—like those built by A-Bots.com—to not only read but also write control logic, enabling active optimization from the mobile layer itself.

Trust and transparency are also essential. GE Predix Analytics supports model explainability features, providing detailed logs of model decisions, confidence intervals, and sensitivity analyses. This is critical in regulated industries or when justifying proactive maintenance decisions to stakeholders. These insights can be embedded into custom reporting dashboards or delivered in summarized form through mobile UX elements like heat maps, gauges, or voice summaries—tailored to the user's role and technical fluency.

The importance of role-based access control (RBAC) in this context cannot be overstated. GE Predix Platform allows organizations to define fine-grained data access and control privileges. This means that a plant manager, a shift engineer, and a service vendor may see different slices of the same asset data. A-Bots.com ensures these rules propagate into mobile experiences as well, maintaining security and compliance across devices, networks, and user hierarchies.

Over time, with continuous data ingestion and feedback, the Predix Platform becomes smarter. It refines predictive models, calibrates risk matrices, and sharpens its decision algorithms. This evolutionary intelligence is what differentiates static monitoring systems from truly cognitive industrial platforms. And when combined with human-centric app design and field-deployable mobile UX, it unlocks unparalleled operational agility.

In the industrial IoT space, where downtime costs millions and marginal gains amplify across thousands of assets, decisions must be both precise and fast. The GE Predix Platform provides the precision; A-Bots.com delivers the speed—by putting that insight directly into human hands through tailored applications.

Industrial transformation is no longer about digitizing existing practices—it’s about enabling new behaviors. Thanks to the combined force of Predix Analytics, Asset Performance Management, and expert IoT application development from A-Bots.com, that future is already unfolding.

3.Build-to-Scale with A-Bots.com: From Industrial Assets to Intuitive IoT Applications

Industrial transformation is not merely a shift in hardware, protocols, or cloud adoption—it's a fundamental reimagination of how machines, systems, and humans collaborate in real time. While the GE Predix Platform offers a comprehensive, scalable, and secure backbone for industrial IoT deployments, it is rarely sufficient on its own. The core infrastructure, however powerful, must ultimately meet its users—operators, engineers, supervisors, executives—through a layer of purposeful, responsive, and context-aware applications. This is precisely where A-Bots.com enters the picture: not as another software vendor, but as a strategic IoT application development company that knows how to operationalize Predix data, edge events, and analytical intelligence into scalable mobile and industrial-grade applications that generate real-world results.

To build effectively on top of GE Predix, one must first understand the entire asset-data-action cycle. In a typical industrial setup, field assets—from turbines to compressors to mining equipment—generate continuous streams of telemetry: temperature, vibration, pressure, usage, flow rates, and more. The Predix Edge framework ensures this data is captured locally and either processed on-site or transmitted securely to the Predix Cloud. What comes next is the real challenge: How do you turn this digital exhaust into decisions that are timely, role-specific, and actionable—preferably from a mobile device in the field?

A-Bots.com specializes in designing precisely these types of application flows. Leveraging RESTful APIs, MQTT brokers, GraphQL endpoints, and Predix microservices, the company builds apps that are not simply dashboards but intelligent, interactive tools for real-time decision-making. For instance, an A-Bots.com-developed application might provide shift managers with anomaly detection alerts from a gas turbine while simultaneously allowing them to trigger remote diagnostics workflows, access digital twin records, and assign inspection tasks—right from their smartphones.

But utility is not enough. In the industrial world, resilience, offline operability, and user-centric ergonomics are equally vital. A-Bots.com brings unique expertise in developing offline-first mobile architectures that use local databases and background sync engines to maintain functionality in air-gapped or intermittently connected environments. Whether it's a technician inspecting wind turbines on a mountain ridge or a maintenance crew operating in an underground tunnel, A-Bots apps remain operational even without constant network access, syncing once back online.

Beyond robustness, the focus shifts to scalability—both horizontally (across assets and sites) and vertically (across user roles and organizational hierarchies). GE Predix provides the infrastructure for this through its multi-tenant architecture, but A-Bots.com designs the logic and UX to support thousands of assets, dynamic data contexts, and user segmentation. For example, field engineers may see detailed vibration analytics from a pump motor, while plant supervisors are shown a simplified asset health scorecard derived from aggregated KPIs. Both perspectives are powered by the same data but expressed in ways that align with each user’s responsibility.

Such scalability also depends on A-Bots.com’s ability to orchestrate complex DevOps lifecycles for IoT and mobile apps. The team integrates CI/CD pipelines using GitOps principles, enabling safe, repeatable rollouts of application updates—even in regulated industrial environments. Updates can be scheduled during shift downtimes, versioned per site, and rolled back if anomalies are detected—ensuring business continuity and stakeholder confidence.

In addition, industrial enterprises demand that mobile applications comply with stringent security frameworks. A-Bots.com addresses this by implementing multi-layered security models: biometric authentication, certificate pinning, encrypted local storage, and integration with enterprise identity providers such as Azure AD, Okta, or Keycloak. These safeguards mirror the zero-trust principles that Predix enforces at the platform level, extending them all the way to the device in the operator’s hand.

One of the key enablers of intelligent application workflows is event-driven architecture—something A-Bots.com implements fluently on top of Predix infrastructure. By subscribing to edge or cloud-based event streams, apps can dynamically react to new data, threshold breaches, asset failures, or machine learning inferences. This means an application can proactively notify the nearest available technician, suggest remedial actions, and even reserve inventory stock—before the equipment failure has occurred. With Predictive Maintenance becoming a cornerstone of industrial efficiency, such app behavior transforms how maintenance is coordinated across distributed teams and assets.

The advantage of working with A-Bots.com is that they don’t merely connect APIs—they understand the semantics of industrial operations. Their development process begins not with code, but with stakeholder interviews, field observations, and an in-depth study of standard operating procedures (SOPs). This allows them to translate domain-specific workflows—be it refinery startup protocols or food production line QA audits—into intuitive mobile UX flows, complete with voice input, barcode scanning, checklist validation, or even AI-based visual recognition when applicable.

As clients deploy these solutions across more facilities, the modular design philosophy of A-Bots.com ensures low-friction scale-ups. Components such as asset health monitors, digital inspection forms, or safety alert modules can be reused, extended, or re-skinned to support new lines of business. For example, a smart inspection module for railway equipment can be easily adapted for oil pipelines, thanks to common underlying metadata schemas and API structures.

When industrial clients require integration with legacy systems—SCADA, CMMS, ERP, or custom protocols—A-Bots.com offers middleware development and edge bridging to route data between these systems and the GE Predix Platform. By deploying translation layers and interface modules on the edge, they ensure continuity of operations while progressively modernizing the data architecture. This allows enterprises to digitize incrementally without abandoning mission-critical legacy infrastructure.

Of course, building to scale also means building to last. A-Bots.com employs test-driven development, automated regression testing, and long-term maintainability planning—including training, documentation, and handover workshops. Their post-deployment support includes SLA-backed maintenance, analytics tuning, and feature roadmap evolution based on end-user feedback.

But perhaps the most impactful contribution of A-Bots.com lies in closing the loop between machine data and human insight. By combining Predix’s edge analytics, digital twins, and APM intelligence with intuitive, mobile-first applications, they allow organizations to move from reactive firefighting to proactive optimization. A pump doesn’t just log its status; it informs a person. A failure doesn’t just trigger an alert; it initiates a process. A shift report isn’t just printed; it’s generated automatically, in-app, based on dynamic conditions.

This shift also redefines industrial culture. When frontline workers are empowered with tools that speak their language, reflect their workflows, and respect their time, the result is engagement, ownership, and agility. Through mobile applications developed by A-Bots.com, technicians become data stewards, supervisors become strategic planners, and executives gain live situational awareness—delivered from the field, not just the boardroom.

As organizations look beyond proof-of-concept pilots and toward large-scale rollouts of IoT capabilities, the need for an experienced, agile, and domain-literate development partner becomes paramount. A-Bots.com has proven itself across diverse industries—from heavy equipment and energy grids to smart buildings and manufacturing lines—as a trusted force for turning GE Predix Platform capabilities into custom applications that scale, adapt, and perform.

In an increasingly connected industrial world, where uptime, efficiency, and foresight define competitiveness, the synergy between Predix’s industrial DNA and A-Bots.com’s application development craftsmanship offers a clear path forward. It’s not just about being digital—it’s about being intelligently digital, and doing so at scale.

4.Industrial IoT by the Numbers: Why Platforms Like GE Predix Matter

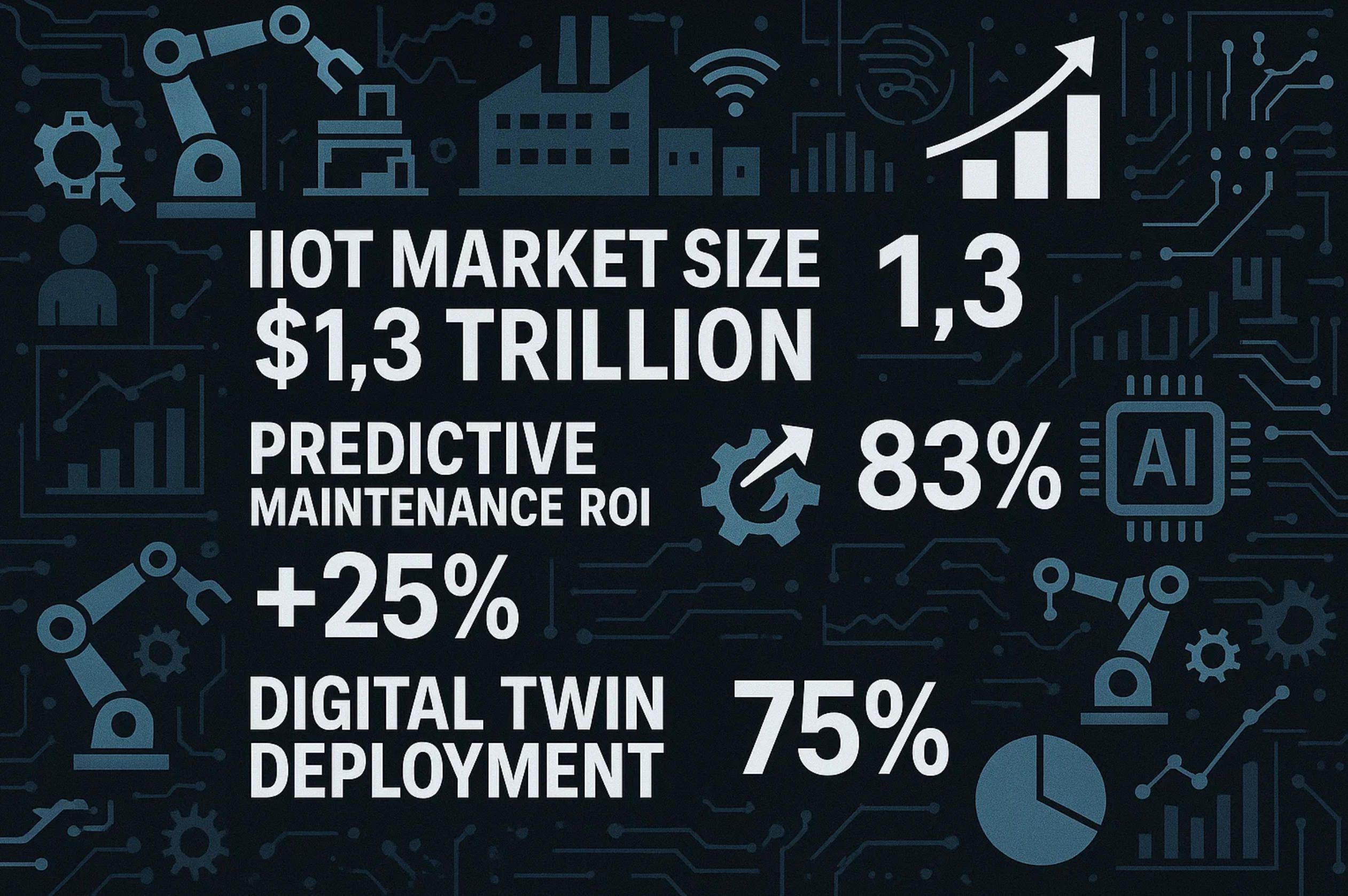

The explosive rise of industrial IoT is more than a technological trend—it’s a measurable transformation sweeping across global industry, redefining asset management, predictive maintenance, and digital decision-making. The GE Predix Platform exists precisely to serve this data-rich, high-stakes environment. To understand its relevance, one must first grasp the scale and urgency behind the IIoT revolution.

According to McKinsey & Company, the industrial IoT market is projected to contribute over $3.7 trillion to global GDP annually by 2030, driven by gains in equipment performance, predictive maintenance, and energy optimization. This includes $200–500 billion in manufacturing efficiency alone—gains that are only realizable when data moves intelligently from machines to human operators and back.

A 2024 report from MarketsandMarkets forecasts that the Industrial IoT market will grow from $110.6 billion in 2020 to $263.4 billion by 2027, a compound annual growth rate (CAGR) of 16.7%. Within this, platforms for asset performance management—like GE Predix—will see one of the fastest adoption curves, as enterprises move away from manual inspections and toward real-time, digital intelligence.

The demand for predictive maintenance—a core application of GE Predix Analytics—is expected to soar. Deloitte estimates that companies deploying predictive maintenance see 25–30% reduction in maintenance costs, 35–45% decrease in unplanned downtime, and 20–25% extension in asset lifetime. These aren't abstract efficiencies—they translate into millions in saved costs and avoided breakdowns in high-capex environments such as energy, chemicals, and transportation.

Meanwhile, edge computing, a key feature of GE Predix Platform’s architecture, is forecasted to become a $274 billion market by 2025, according to IDC. Over 65% of industrial firms have already begun deploying edge capabilities in at least one plant, facility, or site. Edge analytics allows organizations to act on data in less than 50 milliseconds, which is critical in scenarios like real-time fault detection in turbines or latency-sensitive safety systems in autonomous mining operations.

Security, too, remains a top concern. Capgemini’s Smart Factories survey shows that over 48% of manufacturers consider cybersecurity and secure device onboarding their #1 priority when adopting industrial IoT. Platforms like GE Predix, with integrated identity management and secure edge authentication, are central to these rollouts.

Perhaps most telling is the shift in human-machine interaction. A study by Forrester Research revealed that 72% of industrial workers now expect mobile access to asset data, inspection tasks, or APM dashboards. However, only 23% of industrial companies have mature mobile applications in place. This mobility gap is exactly what A-Bots.com aims to close, building scalable, secure, and intuitive mobile applications on top of GE Predix APIs that deliver the right data to the right hands—wherever they are.

Digital twin adoption is another accelerating trend. As of 2025, Gartner reports that over 60% of industrial enterprises are either piloting or deploying digital twins, particularly in energy and discrete manufacturing. These models rely on platforms like Predix to continuously sync real-world data into living software entities that simulate, predict, and optimize complex machinery behavior.

In logistics, UPS reported saving $50 million per year by using IoT-driven route optimization—an insight made possible through real-time telemetry and machine learning. Multiply that logic across thousands of industrial use cases—from predictive failure alerts in offshore oil rigs to automated quality assurance in food processing—and the strategic value of an intelligent platform becomes undeniable.

Ultimately, the numbers tell a unified story: real-time intelligence saves money, time, and assets. But these benefits are only realized when the right application layer exists. That’s why combining the infrastructure strength of GE Predix with the development expertise of A-Bots.com creates an end-to-end capability—from data ingestion at the edge to executive insights in the boardroom. And in the industrial world, where ROI is measured in uptime and avoided disasters, that capability is not just valuable—it’s essential.

FAQ — GE Predix Platform and Industrial IoT Application Development

1. What is the GE Predix Platform?

The GE Predix Platform is an industrial IoT (IIoT) software platform developed by GE Digital. It connects industrial assets, collects real-time data, runs edge analytics, manages digital twins, and enables predictive maintenance across manufacturing, energy, and infrastructure sectors.

2. How is GE Predix different from generic IoT platforms?

Predix is purpose-built for industrial environments. It supports real-time edge analytics, SCADA integration, digital twin modeling, and industrial-grade security protocols that aren’t typical in consumer IoT platforms.

3. What industries use GE Predix?

Industries such as power generation, aviation, oil & gas, manufacturing, transportation, and utilities use the GE Predix Platform to monitor and optimize heavy equipment and complex operations.

4. Is GE Predix a cloud-only platform?

No. Predix supports both cloud and edge computing. It allows processing of critical data on-site with Predix Edge, ensuring ultra-low latency and autonomous decision-making even during network outages.

5. What is Asset Performance Management (APM) in Predix?

APM in GE Predix is a suite of tools for monitoring, analyzing, and optimizing the performance and reliability of industrial assets. It enables predictive maintenance, failure mode analysis, and risk-based inspections using machine data and digital twins.

6. Does GE Predix use digital twins?

Yes. GE Predix provides dynamic digital twins—software models of physical assets that evolve over time with live data. These twins help simulate, predict, and prevent failures.

7. What programming technologies does GE Predix support?

Predix supports microservices, containers, REST APIs, Python, Java, Node.js, and data science tools like TensorFlow and Spark. It’s designed for integration into complex industrial stacks.

8. Can GE Predix be used with mobile apps?

Absolutely. Predix APIs and webhooks allow real-time data to be accessed by custom mobile applications—for monitoring, maintenance scheduling, alerting, and KPI dashboards.

9. Who builds industrial IoT mobile apps for Predix?

Companies like A-Bots.com, an Internet of Things application development company, specialize in building mobile-first applications that integrate seamlessly with GE Predix services, including APM and analytics.

10. Why is mobile access important for GE Predix users?

Mobile access gives field engineers, technicians, and supervisors live insights into asset health, operational alerts, and analytics—without being tied to control rooms or desktop systems.

11. How does A-Bots.com integrate with GE Predix?

A-Bots.com connects to GE Predix through secure APIs, data pipelines, and edge logic, creating custom applications that visualize, analyze, and automate responses based on real-time equipment data.

12. Can A-Bots.com apps work offline?

Yes. A-Bots.com builds offline-first applications for industrial users operating in low-connectivity environments. Apps store and sync data once reconnected to the network.

13. What are the benefits of using Predix for predictive maintenance?

With predictive maintenance, companies can detect anomalies before failures occur. GE Predix enables a 25–30% reduction in maintenance costs and 35–45% less unplanned downtime, according to industry studies.

14. What edge capabilities does GE Predix offer?

Predix Edge allows local data processing, analytics, and machine learning on industrial sites. It ensures safety-critical actions can be performed instantly, even without cloud connectivity.

15. Is GE Predix secure enough for critical infrastructure?

Yes. GE Predix follows NIST cybersecurity standards, offers encrypted communications, RBAC, audit trails, and supports on-premise edge control to meet regulatory compliance for critical industries.

16. How scalable is the GE Predix Platform?

Predix is designed for scale—from a single wind turbine to global fleets of thousands of industrial assets. Its microservices architecture supports multi-tenant deployments and dynamic resource allocation.

17. What kind of apps can be built on top of GE Predix with A-Bots.com?

Examples include mobile inspection tools, APM dashboards, anomaly alerting systems, inventory-aware maintenance apps, and executive portals. All apps are tailored to client workflows and operational goals.

✅ Hashtags

#GEPredix

#IndustrialIoT

#AssetPerformance

#PredictiveMaintenance

#IoTDevelopment

#EdgeComputing

#ABots

#DigitalTwins

#SmartManufacturing

#PredixApps

Other articles

Industrial IoT Solutions at Scale: Secure Edge-to-Cloud with A-Bots.com This expert article reveals A-Bots.com’s proven blueprint for industrial IoT solutions that start small and scale fast. You’ll learn how discovery sprints, modular ARM gateways, Sparkplug-B MQTT backbones and zero-trust security knit together into a resilient edge-to-cloud fabric. From predictive maintenance to real-time energy control, the piece details engagement models, tech-stack decisions and phased roll-outs that turn a single pilot into a multi-site fleet. If your factory, mine or utility aims to boost OEE while passing every compliance audit, A-Bots.com’s industrial IoT solutions deliver the roadmap—secure, future-proof and ready for harsh environments.

IoT Solutions for Retail This article maps the full landscape of IoT solutions for retail, following live data from shelf sensors and BLE beacons through cold-chain logistics to zero-trust edge security. Readers will learn why centimeter-grade positioning, physics-aware spoilage models and autonomous threat response are now baseline expectations, and how A-Bots.com—your custom IoT development company—packages Kubernetes-native edge clusters, multi-path connectivity and GitOps pipelines into a single, scalable platform. By the end, technologists and business leaders alike will grasp how sensor granularity, privacy-centric analytics and build-to-scale workflows fuse into competitive advantage that can be rolled out from flagship pilot to global chain without losing fidelity or compliance.

IBM Watson IoT Platform and Edge AI Development Ready to scale beyond the proof-of-concept? This in-depth guide shows how A-Bots.com fuses the IBM Watson IoT Platform with Kubernetes micro-services, watsonx.ai models, and Flutter dashboards to deliver zero-downtime, edge-aware IoT ecosystems. Explore device onboarding, real-time streaming analytics, predictive maintenance, and enterprise-grade DevSecOps—all without the guesswork of ROI spreadsheets. Whether you manage ten smart valves or a million autonomous assets, A-Bots.com provides the custom firmware, cloud architecture, and mobile experience that convert raw telemetry into actionable insight in under 200 milliseconds.

Telia IoT Platform Telia’s carrier-grade IoT Platform does more than connect SIM cards—it accelerates every stage of a connected-product lifecycle. This article reveals how A-Bots.com, an expert Internet-of-Things app development company, exploits the platform’s native strengths to deliver secure device onboarding in under sixty seconds, build Flink-powered real-time analytics streams, push TensorFlow Lite models to the edge and govern fleets that span thousands of endpoints across multiple regions. From adaptive sampling that slashes airtime costs to GitOps pipelines that keep compliance airtight, you will see practical patterns, formulas and case studies that translate technical muscle into business impact. Whether you manufacture smart lighting, cold-chain monitors or municipal sensor grids, discover why the Telia IoT Platform and A-Bots.com are the fastest route from concept to global-scale, revenue-generating IoT solutions.

IoT Management Platforms Scaling an IoT fleet is impossible without rock-solid management platforms and frictionless mobile UX. This deep-dive explains how A-Bots.com hard-wires security at silicon level, pipes high-velocity telemetry through MQTT-and-Pulsar backbones, automates firmware rollouts under EU Cyber Resilience rules, and delivers Flutter/React-Native dashboards that update as fast as your devices evolve. If you need an IoT mobile app development company that treats scale as a starting point—not an afterthought—start here.

Top stories

Copyright © Alpha Systems LTD All rights reserved.

Made with ❤️ by A-BOTS