Home

Services

About us

Blog

Contacts

John Deere Operations Center, AutoTrac and StarFire GPS: Complete Guide to Precision Agriculture Solutions

Looking to develop, customize, or test precision agriculture solutions? A-Bots.com specializes in creating custom mobile applications and ground control station software for agricultural machinery. Whether you need to build a new control system from scratch, integrate existing John Deere solutions with your fleet management platform, adapt interfaces for specific workflows, or conduct comprehensive testing of precision agriculture systems, our experienced development team delivers enterprise-grade solutions. With expertise in IoT integration, real-time data visualization, and autonomous vehicle communication protocols, we help agricultural technology companies and farming operations optimize their precision farming capabilities.

Understanding John Deere's Precision Agriculture Ecosystem

John Deere has established itself as the market leader in precision agriculture, holding approximately 15-18% of the global agritech market. The company's integrated approach combines hardware, software, and satellite-based positioning to deliver end-to-end farm management capabilities.

The Three Pillars of John Deere Precision Agriculture

1. John Deere Operations Center serves as the cloud-based command hub where farmers manage their entire operation. This platform aggregates data from equipment, fields, and external sources, providing actionable insights for decision-making.

2. John Deere AutoTrac provides automated steering functionality that has transformed field operations. According to research data, AutoTrac usage grew from just 5.3% of planted corn acres in 2001 to 58% by 2016, with adoption rates reaching 72.9% for sorghum and 64.5% for cotton by 2019.

3. John Deere StarFire GPS delivers the positioning accuracy that makes precision farming possible. These receivers utilize multi-constellation GNSS signals with correction services to achieve sub-inch repeatability.

How John Deere AutoTrac Works

John Deere AutoTrac uses satellite positioning combined with automated steering control to guide tractors, combines, and other equipment along predetermined paths. The system eliminates manual steering, allowing operators to focus on implement management and field monitoring.

AutoTrac System Components

The typical AutoTrac installation includes:

- StarFire GNSS receiver - Captures satellite signals and applies corrections

- AutoTrac Universal (ATU) or integrated steering - Physical steering mechanism

- CommandCenter display - In-cab interface for system control

- Activation subscription - Software license enabling AutoTrac functionality

University studies demonstrate that operators typically overlap 5-13% during manual operation, which translates to 60 cm (23 inches) with a 6-meter tillage implement. For a 300-hectare farm, this means farmers actually work and pay for 330 hectares. John Deere AutoTrac reduces this overlap significantly, delivering measurable cost savings.

AutoTrac Configuration Options

AutoTrac Universal (ATU) mounts an electric motor directly to the steering wheel, suitable for retrofit installations on older equipment or non-John Deere machinery. The ATU 200 and ATU 300 models offer different performance levels and compatibility options.

Integrated AutoTrac provides factory-installed steering with components hidden from view, delivering higher accuracy through direct hydraulic integration. This configuration comes standard on newer John Deere tractors in the 6R, 7R, 8R, and 9R series.

John Deere StarFire GPS Technology

John Deere StarFire GPS receivers represent the positioning foundation for all precision agriculture activities. These devices receive signals from multiple satellite constellations (GPS, GLONASS, Galileo, BeiDou) and apply correction algorithms to achieve centimeter-level accuracy.

StarFire Receiver Generations

StarFire 3000 - Earlier generation receiver supporting SF1 and SF2 correction signals, delivering sub-meter to decimeter accuracy.

StarFire 6000 - Mid-generation receiver adding SF3 capability for 3-5 cm pass-to-pass accuracy, suitable for most farming operations.

StarFire 7000 - Latest generation introduced in 2023, offering 73% faster signal acquisition and 17% better accuracy compared to previous models. The StarFire 7000 provides five years of repeatability, enabling year-over-year field operations to follow identical paths.

Correction Signal Options

John Deere offers multiple correction service tiers:

- SF1 - Free basic correction via satellite, 30-50 cm accuracy

- SF2 - Subscription service, sub-meter accuracy

- SF3 - Premium satellite correction, 3-5 cm accuracy

- RTK - Real-time kinematic with base station, 2.5 cm accuracy

Most large-scale farming operations utilize SF3 or RTK correction for activities requiring high precision like planting, spraying, and nutrient application.

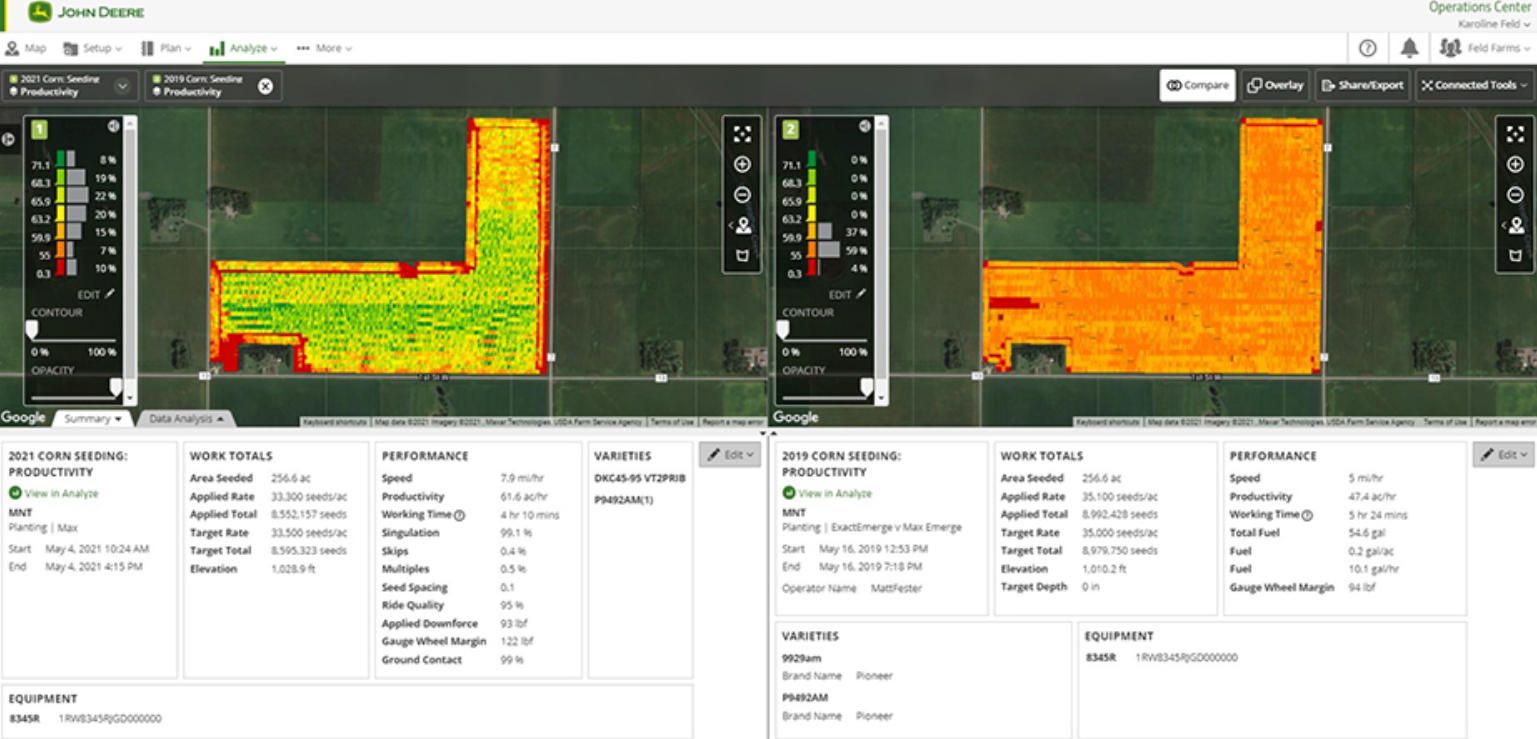

John Deere Operations Center Platform

John Deere Operations Center functions as the digital nerve center for modern farming operations. This cloud-based platform, accessible via web browser or mobile app, centralizes data from all connected equipment and provides tools for planning, analysis, and optimization.

Core Operations Center Capabilities

Equipment Management - Track location, status, and performance metrics for every machine in real-time. John Deere Operations Center displays fuel consumption, hours of operation, idle time, and maintenance alerts across the entire fleet.

Field Documentation - Automatically capture as-applied maps, yield data, and agronomic information without manual data transfer. The system generates coverage maps showing exactly where equipment operated and application rates throughout each field.

Agronomic Analysis - Compare yield performance across fields, identify problem areas, and correlate outcomes with management practices. John Deere Operations Center integrates weather data, soil information, and historical records to support data-driven decisions.

Prescription Management - Create and deploy variable-rate application maps for seeding, fertilizer, and crop protection products. Transfer prescriptions wirelessly to equipment through JDLink connectivity.

JDLink Telematics Integration

JDLink modems installed on equipment provide the two-way communication channel between machines and John Deere Operations Center. These cellular-based devices transmit operating data to the cloud and receive configuration updates, eliminating manual file transfer via USB drives.

The latest JDLink M modems support multi-brand equipment, allowing farmers to monitor competitive machinery within the same Operations Center interface. This capability addresses mixed-fleet operations common on many farms.

Performance Benefits and ROI

Research from Iowa State University Extension documented that John Deere's See & Spray technology, which relies on StarFire positioning and Operations Center integration, achieved 59% average herbicide reduction across 1 million acres in 2024, saving farmers $15.70 per acre.

AutoTrac guidance systems deliver 15-20% efficiency improvements through reduced input costs and overlap elimination, according to university trials. Additional benefits include 10-15% yield increases from improved management practices enabled by yield mapping and data analytics.

Adoption Statistics

Data from the USDA Economic Research Service reveals that guidance system adoption correlates strongly with farm size:

- 73% of largest corn farms (1,725+ acres) use automated guidance

- 82% of largest winter wheat farms (3,140+ acres) have adopted guidance systems

- 68% of largest soybean farms (3,430+ acres) utilize GPS steering

- 67% of largest cotton farms (4,500+ acres) operate with guidance technology

Conversely, smaller operations show lower adoption: only 10% of corn farms under 200 acres use guidance systems, indicating significant market opportunity for accessible precision agriculture solutions.

System Setup and Configuration

Installing John Deere AutoTrac requires several steps and components working together:

Hardware Installation Process

- Mount StarFire receiver - Position antenna on cab roof with clear sky view

- Install steering controller - Integrate ATU on steering column or connect to factory steering harness

- Connect display - Wire CommandCenter or compatible monitor to system

- Configure correction service - Activate SF subscription appropriate for operation

Software Activation and Calibration

John Deere AutoTrac requires activation codes purchased through dealers. Activation costs typically range from $3,500-$5,000 depending on features and display selection. Annual correction subscriptions add $1,000-$3,000 per machine depending on accuracy level selected.

Calibration procedures establish the relationship between antenna position, steering actuation, and vehicle movement. The system guides operators through straight-line and turning maneuvers to characterize the specific machine's behavior. Proper calibration ensures AutoTrac achieves rated accuracy specifications.

Integration with Implement Systems

John Deere extends precision capabilities beyond tractor guidance through implement automation:

iTec Pro automates headland sequences, controlling speed reduction, implement lift, turning, and implement lowering without operator input. This system, released in 2007, coordinates tractor and implement functions for seamless end-of-row operations.

Active Implement Guidance uses a second StarFire receiver mounted on the implement to actively adjust its position independent of tractor guidance. This capability, particularly valuable for planters and tillage equipment, compensates for side-draft and maintains accurate implement tracking even on slopes.

Section Control automatically activates and deactivates implement sections based on previously covered areas, eliminating overlap on point rows and irregular field boundaries. John Deere Operations Center stores coverage maps enabling Section Control to function across multiple field passes and operations.

Comparing John Deere to Alternative Solutions

While John Deere holds market leadership, several competitive systems merit consideration:

Trimble Agriculture offers aftermarket solutions compatible with all equipment brands. Trimble's AutoPilot system provides comparable functionality to John Deere AutoTrac with the advantage of working across mixed fleets. Many farmers operating multiple equipment brands choose Trimble for its universal compatibility.

Case IH AFS provides integrated precision agriculture for CNH Industrial equipment (Case IH and New Holland brands). The AFS AccuGuide system delivers similar capabilities to AutoTrac with tight integration to Case IH machinery.

AGCO/Fendt VarioGuide serves as the factory precision solution for AGCO brands including Fendt, Massey Ferguson, and Valtra. The recent PTx Trimble joint venture enhances AGCO's mixed-fleet capabilities.

Topcon Agriculture targets aftermarket and specialty crop applications with ISOBUS-compliant universal systems. Topcon's Value Line Steering, introduced in 2024, specifically addresses small and medium-sized farms seeking affordable entry into precision agriculture.

Selection between John Deere Operations Center and competitive platforms typically depends on existing equipment brands, desired features, and available support infrastructure.

Advanced Automation Features

John Deere continues evolving beyond basic guidance toward fully autonomous operations:

Autonomy Prep Package available on 8R and 9R series tractors includes hardware provisions for future autonomous capability. This factory option ensures machines have necessary components (transmission type, electrical capacity, communication systems) for autonomous retrofitting.

See & Spray Technology utilizes computer vision to identify plants and selectively apply herbicide only to weeds. This camera-based system, available as a performance upgrade for existing sprayers, reduces herbicide usage while maintaining weed control.

Machine Sync coordinates movement of harvest equipment, automatically adjusting the grain cart tractor's speed and position relative to the combine. This feature reduces operator workload during harvest by automating a traditionally manual task.

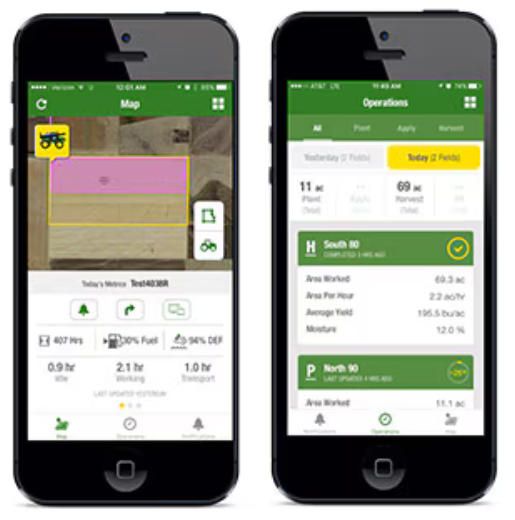

Mobile Access and Remote Management

John Deere Operations Center provides iOS and Android mobile applications enabling field-level access to planning and monitoring tools. The mobile interface allows:

- Real-time equipment tracking and status monitoring

- Field activity documentation and note capture

- Agronomic data viewing (yields, application rates, coverage maps)

- Remote support for operators via shared screen access

Mobile connectivity through JDLink enables farmers to monitor operations from anywhere, receiving alerts about equipment issues, maintenance needs, or operational anomalies requiring attention.

Data Security and Ownership

John Deere implements security measures including encrypted data transmission, role-based access controls, and regular security audits. The company's data agreement specifies that farmers own agronomic data generated by their operations, with John Deere serving as data custodian.

Farmers control sharing permissions, determining which advisors, agronomists, or service providers can access specific data sets. John Deere Operations Center supports data export in standard formats, ensuring farmers can migrate information to alternative platforms if desired.

Cost Considerations and ROI

Typical John Deere AutoTrac system costs:

- New StarFire 7000 receiver: $4,000-$5,500

- AutoTrac activation: $3,500-$5,000

- CommandCenter G5 display: $3,000-$6,000

- ATU 300 steering: $2,000-$2,500

- Annual SF3 correction: $1,800-$2,400 per machine

A complete retrofit installation for one tractor typically ranges $12,000-$18,000 depending on components selected. Factory-equipped new equipment includes AutoTrac capability in the base price or as a modest upcharge.

Payback analysis varies by farm size and operation type, but research indicates typical ROI within 1-2 years for operations over 500 acres. Benefits accrue through reduced overlap (5-10% input savings), decreased fuel consumption (10-15% reduction), and improved productivity (20-30% more acres per day).

Technical Support and Training

John Deere maintains an extensive dealer network providing installation, configuration, and troubleshooting support for precision agriculture systems. Dealers offer:

- Pre-season equipment preparation and software updates

- Operator training on system features and capabilities

- In-season troubleshooting and repair services

- Technology consulting for precision agriculture strategies

John Deere also provides online training resources, video tutorials, and technical documentation through the Operations Center platform and dealer portals.

Future Developments

John Deere has publicly committed to delivering fully autonomous corn and soybean production systems by 2030. This equipment lineup will include autonomous capabilities for tillage, planting, spraying, and harvesting operations.

The company's autonomous tractor, released in 2022 for production use, demonstrates current capabilities. This system uses six stereo camera pairs for 360-degree obstacle detection, GPS guidance for navigation, and neural networks for decision-making. Remote monitoring through John Deere Operations Center allows operators to supervise multiple autonomous machines simultaneously.

Additional development areas include enhanced computer vision for crop health monitoring, AI-driven agronomic recommendations, and expanded data integration with third-party farming software and equipment.

Practical Implementation Recommendations

For farmers considering John Deere AutoTrac adoption:

Start with guidance on primary tillage and spraying equipment where overlap costs are highest and benefits most immediate. These operations typically show fastest payback and build operator confidence with the technology.

Choose correction service appropriate to operation requirements. SF3 satisfies most row crop farming needs, while RTK provides necessary accuracy for specialty crops, controlled traffic systems, and operations requiring year-to-year repeatability.

Invest in operator training to maximize system utilization. Proper setup, calibration, and feature awareness significantly impact achieved benefits and user satisfaction.

Plan for fleet expansion as initial success demonstrates value. Many farms gradually equip additional machines as operators experience precision agriculture advantages.

Leverage John Deere Operations Center for agronomic insights beyond equipment guidance. The platform's analytical capabilities support continuous improvement in farming practices and profitability.

FAQ: John Deere Operations Center, AutoTrac & StarFire GPS

General Questions

What is the difference between John Deere Operations Center, AutoTrac, and StarFire GPS?

John Deere StarFire GPS is the positioning hardware that receives satellite signals and determines equipment location with high accuracy. John Deere AutoTrac is the automated steering system that uses StarFire positioning data to guide tractors and implements along precise paths. John Deere Operations Center is the cloud-based farm management platform that collects data from all connected equipment, provides analytical tools, and enables remote fleet monitoring.

Think of it this way: StarFire tells the system where the equipment is, AutoTrac controls where it goes, and Operations Center manages the entire operation from planning through analysis.

Can I use John Deere AutoTrac on non-John Deere equipment?

Yes, through the AutoTrac Universal (ATU) system. The ATU mounts an electric motor on the steering wheel and works with most tractor brands manufactured after 1990. You'll need a John Deere StarFire receiver, compatible display (such as the 2630 or G5 CommandCenter), and the ATU kit specific to your tractor model.

However, integrated AutoTrac with direct hydraulic steering connection only works on John Deere machinery. The ATU provides slightly lower accuracy (typically 5-8 cm) compared to integrated systems (2-5 cm) but offers excellent performance for most farming operations.

How much does it cost to add John Deere AutoTrac to my existing tractor?

A complete retrofit installation typically costs $12,000-$18,000 and includes:

- StarFire 7000 receiver: $4,000-$5,500

- AutoTrac activation license: $3,500-$5,000

- Display (G5 or 2630): $3,000-$6,000

- AutoTrac Universal steering kit: $2,000-$2,500

- Installation labor: $500-$1,500

- Annual correction subscription (SF3): $1,800-$2,400

Used equipment can reduce costs by 30-50%. Many dealers offer financing options, and some farmers see complete payback within 1-2 seasons on operations over 500 acres through input savings and efficiency gains.

Is John Deere StarFire GPS more accurate than regular GPS?

Yes, significantly. Consumer GPS (like smartphones) provides 3-10 meter accuracy. John Deere StarFire GPS with correction services delivers:

- SF1 (free): 30-50 cm accuracy

- SF2 (subscription): 10-30 cm accuracy

- SF3 (subscription): 3-5 cm pass-to-pass accuracy

- RTK (subscription + base station): 2.5 cm repeatability

This precision enables activities like controlled traffic farming, precise nutrient placement, and year-over-year repeatability where equipment follows identical paths across growing seasons. The StarFire 7000 receiver maintains 2.5 cm accuracy with SF-RTK correction for up to five years of repeatability.

Do I need internet connection to use John Deere AutoTrac in the field?

No, John Deere AutoTrac operates independently without internet connection. The StarFire receiver gets positioning data directly from satellites, and AutoTrac steering functions locally on the equipment.

However, internet connectivity (through JDLink modem) provides additional benefits:

- Automatic data upload to John Deere Operations Center

- Remote monitoring and support

- Wireless prescription map downloads

- Software updates and configuration changes

- Real-time fleet tracking

Most farmers operate AutoTrac successfully in areas without cellular coverage, manually transferring data via USB when returning to the shop.

Technical Questions

What correction signal should I choose: SF1, SF2, SF3, or RTK?

SF1 (free) works for basic guidance on tillage, mowing, and applications where 30-50 cm accuracy suffices. Not recommended for planting or sidedressing.

SF2 ($800-$1,200/year) provides 10-30 cm accuracy suitable for broadcast applications and general field work on larger operations.

SF3 ($1,800-$2,400/year) delivers 3-5 cm accuracy required for planting, row crop cultivation, precision application, and most modern farming practices. This is the most popular choice for serious precision agriculture.

RTK ($2,500-$4,000/year + base station) gives 2.5 cm repeatability needed for controlled traffic farming, specialty crops, transplanting, and operations requiring year-to-year precision. Requires either your own base station or subscription to a local RTK network.

Most row crop farmers choose SF3 as the optimal balance of accuracy and cost. Specialty crop operations often require RTK.

Can I transfer my John Deere AutoTrac system between tractors?

AutoTrac Universal (ATU) systems can transfer between tractors relatively easily. You'll need:

- Compatible mounting bracket for the new tractor

- Wiring harness appropriate to the new machine

- New calibration for the different tractor's steering characteristics

The StarFire receiver and display transfer directly. Budget 2-4 hours for physical transfer and calibration.

Integrated AutoTrac systems with factory hydraulic steering generally cannot transfer between machines as they're engineered specifically for each tractor model. The activation license typically stays with the original machine.

Some farmers purchase portable systems specifically for flexibility across their fleet, while others equip each primary tractor with dedicated systems.

How long does StarFire GPS take to acquire signal and start working?

John Deere StarFire 7000 receivers acquire initial positioning in 2-5 minutes under clear sky conditions. The system needs to receive signals from multiple satellite constellations (GPS, GLONASS, Galileo, BeiDou) and download correction data.

Cold start (receiver off for several days): 3-5 minutes

Warm start (receiver off for a few hours): 1-2 minutes

Hot start (receiver recently on): 30-60 seconds

The StarFire 7000 acquires signals 73% faster than previous generation receivers. Once locked, the system maintains full accuracy as long as it has clear sky view. Driving under trees, near buildings, or in deep valleys may temporarily reduce accuracy until satellite visibility improves.

Plan to turn on displays when starting morning equipment checks, allowing AutoTrac to be ready by the time you reach the field.

What happens if I lose StarFire GPS signal while AutoTrac is active?

John Deere AutoTrac automatically disengages when it loses positioning signal, alerting the operator with visual and audible warnings. The system will not steer blindly without valid position data.

If using RTK correction with a base station, the system can maintain full accuracy for 10-15 minutes after losing radio connection through RTKX technology, which uses the stable StarFire satellite signal as backup.

Most signal losses are brief (passing under trees, near structures) and AutoTrac re-engages automatically once positioning restores. For safety, operators should always remain alert and ready to resume manual steering.

Can I use John Deere AutoTrac at night or in dusty conditions?

Yes, this is one of AutoTrac's major advantages. The system relies on satellite positioning rather than visual references, so it works perfectly in darkness, fog, dust, or any low-visibility conditions.

Many farmers specifically use AutoTrac for night operations during busy seasons, knowing the system maintains identical accuracy regardless of lighting. Some operations run 24-hour harvest campaigns with multiple shifts, leveraging AutoTrac's consistent performance.

The G5 CommandCenter displays include adjustable brightness and night mode settings optimized for dark cab operation.

John Deere Operations Center Questions

Is John Deere Operations Center free to use?

Basic John Deere Operations Center access is free for John Deere equipment owners with JDLink-connected machines. This includes:

- Equipment tracking and monitoring

- Basic field mapping and documentation

- Agronomic data viewing

- Mobile app access

Premium features require subscriptions:

- Advanced analytics and reporting: $500-$1,200/year

- Multi-user access with role management: $300-$800/year

- API access for third-party integrations: $1,000-$2,500/year

- Extended data storage beyond standard retention: Variable pricing

Most farmers find the free tier sufficient for typical operations. Larger operations or those wanting detailed analytics often upgrade to premium tiers.

How do I get data from my equipment into John Deere Operations Center?

Three methods exist:

Automatic upload via JDLink - Equipment with JDLink modems automatically uploads data whenever cellular connection is available. This is the preferred method, providing near-real-time data transfer without operator involvement.

Manual USB transfer - Export data from displays to USB drive, then upload files through Operations Center web interface. This works for older equipment or areas without cellular coverage.

Mobile app documentation - Use Operations Center mobile app to manually document field activities, adding notes, photos, and location data.

The JDLink cellular connection requires modest data usage (typically 50-200 MB per month per machine) and works on most North American carriers.

Can I share my Operations Center data with my agronomist or crop advisor?

Yes, John Deere Operations Center includes granular sharing controls. You can:

- Invite users with specific permission levels (view only, edit, admin)

- Share entire organization or specific fields/equipment

- Set time-limited access for seasonal consultants

- Revoke access at any time

- Export data in standard formats for external analysis

Many farmers share field data with trusted crop advisors, equipment dealers, and agronomists while maintaining control over their information. The platform meets data security standards required by most agricultural lending and insurance organizations.

Does John Deere own my farming data if I use Operations Center?

No. John Deere's data agreement explicitly states that farmers own all agronomic and operational data generated by their equipment. John Deere serves as data custodian, storing and processing information on behalf of farmers.

You control:

- Who can access your data

- How data is used

- Data sharing permissions

- Data export and deletion

John Deere may use anonymized, aggregated data for research and product development, but cannot share your specific farm data with third parties without explicit permission. You can export all data from Operations Center in standard formats and delete your account entirely if desired.

Compatibility and Integration Questions

Will John Deere AutoTrac work with my Case IH/New Holland/AGCO tractor?

Yes, through AutoTrac Universal (ATU). The ATU system mounts on the steering wheel and works with most tractor brands. You'll need:

- John Deere StarFire receiver

- Compatible display (2630, 4640, or G5 CommandCenter)

- AutoTrac Universal steering kit

- Appropriate mounting and wiring harness

The system provides full AutoTrac functionality on competitive equipment. However, some implement control features (section control, variable rate) may have limited compatibility depending on the tractor's electronic architecture.

Many mixed-fleet operations use Trimble or Topcon systems specifically designed for multi-brand compatibility, while John Deere-heavy fleets typically choose AutoTrac for optimal integration.

Can I use my existing Trimble or Topcon system with John Deere Operations Center?

John Deere Operations Center primarily accepts data from John Deere equipment and displays. However, the JDLink Multi-Tool modem can connect to non-John Deere equipment, enabling:

- Location tracking for mixed fleets

- Basic telemetry data (engine hours, fuel level)

- Operations Center visibility of all equipment

Full precision agriculture data (yield maps, application maps, coverage documentation) typically requires John Deere displays or equipment for seamless integration. Some third-party software platforms aggregate data from multiple systems, providing unified views across John Deere, Trimble, and other brands.

Does John Deere AutoTrac integrate with variable rate prescriptions from other software?

Yes, John Deere AutoTrac and displays support industry-standard prescription formats including:

- ISO-XML (ISOBUS Task Data)

- Shapefile with attributes

- GeoTIFF raster maps

- Ag Leader SMS prescriptions

- Climate FieldView prescriptions

You can import prescriptions created in external software (Climate FieldView, Ag Leader SMS, SST Software, etc.) into the John Deere display for execution. The display controls application rates based on position, AutoTrac maintains precise path following, and data logs back to Operations Center.

This interoperability allows farmers to use preferred agronomic software while leveraging John Deere hardware capabilities.

Can I retrofit John Deere AutoTrac to my 20-year-old tractor?

Possibly, depending on the tractor model and condition. Requirements:

Minimum tractor specifications:

- Power steering (hydraulic or electric)

- Electrical system sufficient for added components

- Cab space for display and receiver mounting

- Year approximately 1990 or newer

Older mechanical systems often lack:

- Electronic controls for integration

- Proper shielding for GPS signal interference

- Structural mounting points for components

Consult with a John Deere precision agriculture dealer for compatibility assessment. They can evaluate your specific tractor and recommend appropriate retrofit kits or alternatives. Some very old tractors may be better candidates for competitive systems like Trimble or Topcon that offer more flexible retrofit options.

Troubleshooting and Support Questions

My AutoTrac accuracy seems worse than specified. What should I check?

Common issues affecting AutoTrac accuracy:

StarFire antenna placement - Receiver must have clear sky view without obstruction from cab structures, ROPS, or other equipment. Metal surfaces near the antenna can cause signal reflection.

Calibration quality - Poorly executed calibration produces erratic steering. Re-run calibration procedures on level ground following display instructions carefully.

Correction signal type - Verify you're receiving the expected correction (SF3, RTK, etc.). The display shows current correction status and accuracy estimate.

Tire pressure - Uneven tire pressure causes steering pull that AutoTrac must compensate for, reducing accuracy. Check all tires match manufacturer specifications.

Hydraulic steering issues - Worn steering components or low hydraulic fluid can degrade steering precision. Service underlying mechanical systems.

Speed-related factors - AutoTrac achieves best accuracy at typical field speeds (4-8 mph). Very high speeds or aggressive turns challenge the system.

Contact your dealer if issues persist after checking these factors. They can perform diagnostic tests and recommend solutions.

How often does StarFire GPS need calibration or maintenance?

John Deere StarFire receivers require minimal maintenance:

No regular calibration needed - StarFire receivers self-calibrate continuously using satellite signals. Unlike mechanical systems, electronic positioning needs no periodic adjustment.

Software updates - Dealers can update receiver firmware during annual equipment servicing, typically adding features or improving performance.

Physical inspection - Check antenna mounting annually for corrosion, loose connections, or physical damage. Ensure antenna cables haven't been cut or pinched.

Correction subscriptions - Renew SF3 or RTK correction subscriptions before expiration to maintain accuracy. The system warns when subscriptions approach expiration.

Most StarFire receivers operate reliably for 10+ years with essentially zero maintenance beyond keeping connections clean and subscriptions current.

What training is available for John Deere Operations Center and AutoTrac?

John Deere provides multiple training resources:

Dealer training - Most precision ag dealers offer hands-on training during system installation, covering basic operation, calibration, and troubleshooting. Many dealers schedule pre-season clinics for customers.

Online training - John Deere University offers free online courses covering AutoTrac, Operations Center, and precision agriculture fundamentals. These self-paced courses include videos, quizzes, and certificates.

Mobile app tutorials - Operations Center mobile app includes interactive walkthroughs for key features.

YouTube channel - John Deere maintains official channels with how-to videos, tips, and feature demonstrations.

User manuals - Comprehensive PDF documentation is available through dealer portals and Operations Center.

Phone support - John Deere customer support line provides technical assistance during business hours.

New users should budget 4-8 hours for initial training to become comfortable with system operation. Most farmers achieve proficiency within the first week of regular use.

My JDLink modem isn't uploading data to Operations Center. How do I fix this?

Troubleshooting steps:

Check cellular signal - JDLink requires cellular data connection. Verify adequate signal strength in your typical operating areas. Contact your carrier about coverage if needed.

Confirm subscription status - JDLink requires active subscription. Check subscription status in Operations Center under equipment settings.

Power cycle the modem - Turn equipment off completely for 2-3 minutes, allowing the JDLink modem to reset, then power on and wait 10 minutes for connection.

Verify SIM card - Ensure JDLink modem has properly installed, activated SIM card. Some modems use dual-carrier SIMs that select strongest available network.

Check antenna connection - JDLink cellular antenna must be properly connected and positioned for signal reception.

Review data plan - Verify cellular data plan has sufficient allocation and hasn't reached cap or expired.

Contact dealer - If basic troubleshooting doesn't resolve issues, dealers can diagnose modem hardware problems or assist with carrier activation.

Manual USB data transfer remains available if JDLink connectivity cannot be established.

Comparison Questions

Should I choose John Deere AutoTrac or Trimble AutoPilot?

Choose John Deere AutoTrac if:

- You operate primarily John Deere equipment

- You want seamless integration with implement controls

- Operations Center platform meets your farm management needs

- Local John Deere dealer provides strong precision ag support

Choose Trimble AutoPilot if:

- You operate mixed-brand equipment fleet

- You want universal compatibility across all machinery

- You prefer Trimble's farm management software

- Cost considerations favor aftermarket solutions

Both systems provide excellent accuracy and reliability. The decision typically comes down to equipment brand commitment and desired features. Many large operations run both systems across different equipment types.

Is John Deere AutoTrac worth the investment for a small farm (under 500 acres)?

Economics depend on several factors:

Favorable conditions:

- High-value crops with expensive inputs

- Multiple passes per season (tillage, planting, multiple applications)

- Operator fatigue concerns on long days

- Difficulty hiring qualified operators

- Plans to expand operation

Less favorable conditions:

- Simple cropping systems with few passes

- Very small fields with significant turning time

- Limited annual equipment hours

- Tight budget constraints

The new Value Line offerings from manufacturers like Topcon specifically target smaller operations with reduced-cost systems. Alternatively, used John Deere AutoTrac components can reduce investment by 30-50%.

Most farmers under 500 acres should carefully calculate potential input savings, increased productivity, and improved quality of life before investing. Those uncertain might rent or demo systems during a season before committing.

How does John Deere's autonomous tractor compare to AutoTrac?

John Deere AutoTrac requires an operator in the cab. The system handles steering while the operator monitors equipment, manages headlands, and responds to obstacles or issues.

Autonomous tractor operates without an in-cab operator. The machine uses computer vision, GPS, and AI to navigate fields, detect obstacles, and make decisions independently. A remote supervisor monitors multiple autonomous machines simultaneously.

Current autonomous tractors work for specific repetitive tasks (tillage, some planting operations) on farms with prepared fields and minimal obstacles. The technology is production-ready but adoption remains limited due to cost (premium over conventional equipment) and operational constraints.

AutoTrac will remain the standard for most farming operations for years, with autonomy gradually expanding into specific use cases where economics justify the investment.

Future and Advanced Topics

Will 5G cellular networks improve John Deere Operations Center performance?

5G offers potential benefits but provides limited immediate impact:

Current 4G LTE handles Operations Center adequately - JDLink data uploads (field documentation, telemetry, prescriptions) require modest bandwidth that 4G handles well.

5G benefits for future applications:

- Real-time video streaming from equipment cameras

- Faster large file transfers (high-resolution imagery)

- Lower latency for remote equipment control

- More reliable connectivity in rural areas (if towers deployed)

5G deployment in rural agricultural areas lags urban rollout significantly. Most farming regions will rely on 4G LTE for years. John Deere designs systems to function well on available infrastructure rather than requiring cutting-edge connectivity.

Can I use John Deere StarFire GPS for surveying or construction work?

While John Deere StarFire GPS provides excellent accuracy, it's optimized specifically for agricultural applications. Key considerations:

Appropriate for:

- Farm boundary mapping

- Tile line documentation

- Water management planning

- Field leveling guidance

- Agricultural construction (buildings, grain bins)

Not ideal for:

- Legal surveying (use certified survey equipment)

- Civil engineering projects (specialized construction GPS)

- High-precision applications requiring millimeter accuracy

Professional surveyors and engineers typically use dedicated survey-grade receivers designed for those specific applications. StarFire serves agricultural needs excellently but isn't certified for professional surveying or regulatory construction applications.

What cybersecurity measures protect my John Deere Operations Center account?

John Deere implements multiple security layers:

- Encrypted data transmission - All communication between equipment, mobile devices, and Operations Center uses encryption

- Multi-factor authentication - Optional (recommended) second-factor verification

- Role-based access control - Granular permissions limit what users can view/modify

- Regular security audits - Third-party testing and vulnerability assessment

- Intrusion detection - Monitoring for unauthorized access attempts

- Data redundancy - Multiple backup systems prevent data loss

Best practices for farmers:

- Use strong, unique passwords

- Enable multi-factor authentication

- Review user access permissions regularly

- Don't share account credentials

- Log out from shared devices

- Monitor account activity for anomalies

John Deere takes data security seriously given the competitive sensitivity of farm operations data and the critical nature of equipment control systems.

Conclusion

John Deere Operations Center, AutoTrac, and StarFire GPS represent mature, proven precision agriculture technologies with extensive market adoption and demonstrated performance benefits. The integrated ecosystem addresses farm management from field-level guidance through enterprise-wide analytics, supported by robust hardware, comprehensive software, and global service infrastructure.

While premium-priced compared to some competitive options, John Deere solutions offer seamless integration for John Deere equipment owners and industry-leading accuracy, reliability, and feature breadth. Operations Center serves as a central platform that will continue evolving toward increased automation and intelligence as agriculture progresses toward autonomous systems.

For farms committed to the John Deere equipment platform or seeking best-in-class precision agriculture capabilities, the AutoTrac and Operations Center ecosystem warrants serious consideration despite the investment required.

Ready to enhance your precision agriculture technology? A-Bots.com offers comprehensive development services for agricultural technology companies and farming operations. Our capabilities include:

- Custom Mobile Applications - iOS and Android apps for field operations, equipment monitoring, and data collection

- Ground Control Station Software - Desktop and web-based platforms for fleet management and mission planning

- System Integration - Connect John Deere Operations Center with ERP systems, third-party sensors, and legacy equipment

- API Development - Build bridges between precision ag platforms and custom workflows

- Testing & QA Services - Comprehensive testing of guidance systems, control algorithms, and user interfaces

- UI/UX Customization - Adapt existing platforms to specific operational requirements and user preferences

With expertise spanning IoT protocols, real-time telemetry, autonomous vehicle communication, and agricultural workflows, A-Bots.com delivers production-ready solutions that enhance efficiency and profitability. Contact us to discuss your precision agriculture development needs.

References

- Farm Equipment - "See and Spray Customers See 59% Average Herbicide Savings in 2024" - https://www.farm-equipment.com/

- USDA Economic Research Service - "Most Row Crop Acreage Managed Using Auto-steer and Guidance Systems" - https://www.ers.usda.gov/amber-waves/

- John Deere Operations Center - https://www.deere.com/en/technology-products/precision-ag-technology/

- NASA Spinoff - "GPS Correction Technology Lets Tractors Drive Themselves" - https://spinoff.nasa.gov/

- Mordor Intelligence - "North America Precision Agriculture Market Report 2025-2030" - https://www.mordorintelligence.com/

- Research and Markets - "Global Agritech Market Outlook & Forecast 2025-2030" - https://www.researchandmarkets.com/

✅ Hashtags

#JohnDeereOperationsCenter,

#JohnDeereAutoTrac,

#JohnDeereStarFireGPS,

#PrecisionAgriculture,

#SmartFarming,

#GPSGuidance,

#AutomatedSteering,

#FarmManagement,

#AgTech,

#PrecisionFarming,

#TractorGPS,

#AutonomousFarming,

#FarmAutomation,

#AgriculturalTechnology,

#DigitalFarming,

#FarmProductivity,

#YieldMonitoring,

#VariableRateTechnology,

#RTKCorrection,

#FarmData,

#AgriculturalInnovation,

#SmartAgriculture,

#FarmEfficiency

Other articles

Custom Agriculture App Development for Farmers In 2024, U.S. farmers are more connected than ever — with 82% using smartphones and 85% having internet access. This article explores how mobile applications are transforming everyday operations, from drone-guided field scouting to livestock health tracking and predictive equipment maintenance. It examines why off-the-shelf apps often fail to address specific farm needs and how collaborative, farmer-funded app development is gaining momentum. Through real-world examples and step-by-step guidance, readers will learn how communities of growers can fund, design, and launch custom apps that fit their exact workflows. A-Bots.com offers tailored development services that support both solo farmers and agricultural groups. With offline capabilities, modular design, and support for U.S. and international compliance, these apps grow alongside the farm. Whether you're planting soybeans in Iowa, raising cattle in Texas, or running a greenhouse in California — this article offers the tools and inspiration to build your own farm technology. Discover why more farmers are saying: we don’t wait for the future — we build it.

Custom IoT for Smart Greenhouses and Vertical Farms Modern greenhouses and vertical farms demand more than off-the-shelf solutions. In this article, discover how custom IoT systems — built around your space, your crops, and your team — can unlock new levels of efficiency, automation, and yield. Packed with real-world examples, insights from A-Bots.com engineers, and expert advice, this guide will inspire your next step in smart agriculture. If you're ready to grow smarter — start here.

App Development Companies for Startups: USA, EU and Nordics Guide This guide examines app development companies for startups across USA, European, and Scandinavian markets. American developers excel in rapid scaling and real-time architecture, with projects ranging from $30,000 to $250,000+. European partners specialize in GDPR compliance, fintech solutions, and multi-language applications. Nordic companies lead in impact-driven development, deep tech expertise, and sustainable technology practices. The article analyzes market-specific expectations, development methodologies, and emerging trends including AI integration, low-code platforms, and 5G capabilities. Features expert quotes from industry leaders, authoritative market data, and practical frameworks for evaluating technical expertise, cultural alignment, and post-launch support when selecting development partners.

Logistics and Truck App Development for Self Driving Semi Trucks The logistics industry is entering a new era where automated trucking and self driving semi trucks reshape global supply chains. Success in this transformation depends on advanced logistics and truck app development—apps that manage fleets, integrate IoT, enable predictive maintenance, and provide seamless control of autonomous semi trucks. At A-Bots.com, we specialize in building tailor-made solutions that combine safety, compliance, and innovation. From end-to-end custom development to outsourced testing and QA, our expertise ensures that companies in the U.S., Europe, and China are ready for the future of driverless semi trucks. Explore how mobile platforms are becoming the command centers of modern logistics and discover why A-Bots.com is the trusted logistics app development company for forward-thinking enterprises.

Farmer App Development Company - Smart Farming Apps and Integrations Looking for an app for agriculture that crews will actually open at dawn? A-Bots.com builds lean, offline-first farming applications that slot into what you already run—John Deere Operations Center, Climate FieldView, Trimble—so plans flow into cabs and clean records flow back. As a specialist farmer app development company, we start with a nucleus that pays back quickly: tasks that close the loop, imagery/weather signals that become guided tickets, and auditor/buyer-ready exports. Then we expand through a plugin architecture—labor & QC for orchards and berries, virtual fencing & grazing timelines, or contract-aware traceability/carbon modules—without breaking operator muscle memory. Your smart farming app comes with plain-language data contracts (who sees what, for how long, and why), one-tap export/revocation, and role-based access for advisors, landlords, and buyers. Serving the US, Canada, Scandinavia, and EU, we respect mixed fleets and regional policy, mapping to ADAPT/ISOBUS and EU data expectations by design. Budget tight? We help structure cooperative or buyer-aligned crowdfunding so critical plugins ship sooner—under clear ownership. Build beside the best farmer apps, not against them—and turn season pressure into repeatable wins.

Top stories

Copyright © Alpha Systems LTD All rights reserved.

Made with ❤️ by A-BOTS