Home

Services

About us

Blog

Contacts

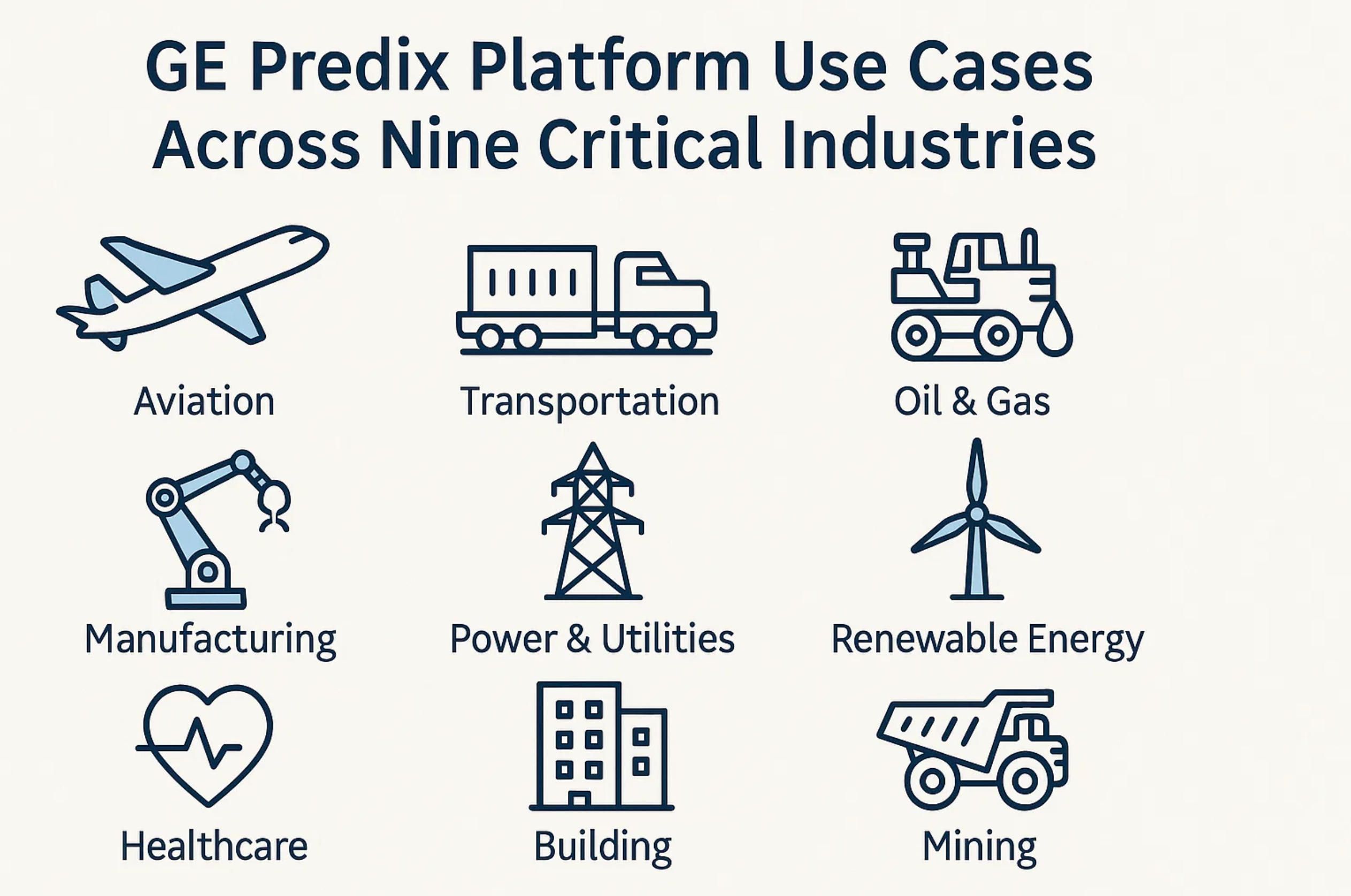

GE Predix Platform Use Cases Across Nine Critical Industries

1. Power Generation and Smart Grids

2. Oil and Gas Upstream and Midstream

3. Aviation Engine Health and MRO

4. Rail Freight and Rolling Stock Maintenance

5. Healthcare Imaging and Asset Uptime

6. Advanced Manufacturing and IIoT 4.0

7. Water and Wastewater Treatment Facilities

8. Renewable Energy and Microgrids

9. Smart Buildings and Facilities Management

1. Power Generation and Smart Grids

GE Predix has become the de-facto operating system for utilities that can no longer afford to treat turbines, substations, and feeders as isolated hardware. From the moment raw vibration spectra leave a combustion turbine’s XY probes, GE Predix ingests the data through its secure Message Bus, normalises it into time-series assets, and enriches every sample with contextual tags such as ambient humidity, fuel blend, and start-count history. Within milliseconds the platform’s Digital Twin services compare the incoming fingerprint against a living model of that turbine’s compressor, hot-gas path, and exhaust frame. When blade-root fatigue or combustor rumble deviates from nominal envelopes, GE Predix sparks a predictive alert that is routed—through role-based APIs that A-Bots.com wires into a custom mobile app—to the plant engineer standing in front of the machine. The same alert also feeds the utility’s enterprise asset-performance dashboards, allowing fleet managers to shift megawatt dispatch away from the at-risk unit and avoid a forced outage that could ripple across the regional interconnect.

Where legacy SCADA delivered only snapshot SCADA tags, GE Predix stitches together high-frequency phasor measurements, synchrophasor data from PMUs, and meter telemetry from distributed energy resources to offer a granular, system-wide state estimator. The result is a digital nerve centre that sees voltage sags, harmonic distortion, and flicker down to the feeder head, and forecasts the probability that a solar-rich feeder will violate its reactive-power envelope once clouds roll through. Rather than wait for regulatory penalties, grid operators use GE Predix analytics to issue Volt/VAR set-point adjustments in real time, commanding STATCOMs, capacitor banks, and secondary transformers to smooth the waveform. These closed-loop corrections are executed by Predix Edge micro-services running inside substation gateways, proving that the platform is just as comfortable at the harsh, latency-sensitive edge as it is in the cloud.

The economics are equally compelling on the generation side. By training recurrent neural nets on gigabytes of exhaust-gas temperature and dynamic pressure data, utilities have cut hot-section inspection intervals from 24 000 to 32 000 fired hours. A single heavy-duty turbine overhaul can cost more than USD 8 million in parts and downtime; shifting three such events across a 25-unit fleet translates into immediate EBIT uplift. GE Predix not only identifies the shift but converts it into an optimised maintenance window that aligns with low-demand seasons, a schedule that the A-Bots-built mobile work-order module pushes to field technicians’ tablets with torque values, lock-out–tag-out check-lists, and real-time inventory allocation.

For renewable generators the platform acts as a unifying data backbone. Wind operators stream nacelle yaw, pitch actuator cycles, and SCADA 10-minute averages into GE Predix, which runs aeroelastic simulations that flag tower shadow losses and leading-edge erosion before they erode annual energy production. Co-located battery operators then consume the same forecasts to decide whether to soak excess wind in lithium-ion cells, bid into frequency regulation markets, or arbitrage day-ahead price spreads. Because GE Predix surfaces SOC, RTE, and thermal runway risk in a shared context view, portfolio traders finally have a single pane of glass that spans spinning thermal units, variable renewables, and fast-response storage.

Smart-grid ambitions, however, go beyond hardware optimisation. With electrification surging—from EV chargers to heat pumps—distribution utilities face net-load ramps steeper than anything modelled a decade ago. GE Predix deploys agent-based demand-response algorithms that treat every behind-the-meter DER as a controllable micro-asset. When the platform forecasts a peak 15 minutes ahead, it orchestrates a swarm of residential batteries, smart thermostats, and industrial chillers to shave five percent off the load curve, unlocking hundreds of megawatts of “virtual capacity” at a fraction of the CapEx required for a new peaker plant. The field-service mobile app that A-Bots.com layers over GE Predix then visualises fleet-wide performance KPIs, making it trivial for demand-response managers to validate performance-based incentives and comply with FERC Order 2222 settlement rules.

Cyber-security, a perennial pain point for utilities, is embedded rather than bolted on. GE Predix implements zero-trust networking down to the protocol level, signing every Modbus, DNP3, or IEC 61850 data packet with device-rooted certificates. Role-based access controls propagate all the way to the A-Bots.com mobile clients, meaning a control-room operator can override a generator droop-setting, while a field technician can only acknowledge alarms during a site visit. Coupled with behavioural-anomaly detection—built on GE Predix machine-learning pipelines—utilities detect rogue command-injection attacks or insider privilege escalations within seconds, drastically cutting mean time to containment.

Regulators and investors are also demanding transparent ESG reporting, and here GE Predix excels in turning production data into verifiable emissions ledgers. By fusing heat-rate curves with hourly fuel chemistry, the platform calculates CO₂, NOₓ, and SO₂ footprints down to the stack. Those numbers feed directly into the utility’s 10-K disclosures and green-bond frameworks, while the A-Bots.com analytics layer translates raw tonnage into avoided social-cost metrics that resonate with city councils and retail customers alike. Because the same data lineage powers operational dashboards and investor reports, the days of spreadsheet reconciliations and audit disputes are fading fast.

Perhaps the most under-appreciated virtue of GE Predix in the power sector is its ability to create a common language between engineering and finance. When a reliability engineer tags a 0.2 mbar/hr hydrogen leak at a generator rotor, GE Predix automatically quantifies the expected derate and fuel penalty in dollar terms. Treasury teams see the cash impact on next month’s merchant revenues; schedulers see an optimised run plan; maintenance planners see the spares pick-list; and the board sees risk evaporating before it becomes headline news. This holistic visibility is what turns digital-transformation slide decks into dispatchable cash flow.

A-Bots.com reinforces that loop by delivering intuitive mobile experiences—built under its IoT app development practice—that expose GE Predix insights to executives, traders, and field crews wherever they stand. Whether an outage manager is scanning a QR-coded gearbox or a CFO is approving a life-extension CAPEX, the same secure API fabric pipes real-time GE Predix data into the palm of their hand. The result is a utility that not only runs cleaner and cheaper but also learns faster, because every decision, from turning a valve to writing a hedging contract, is grounded in a single, authoritative data source.

As global grids race toward net-zero targets and resilience mandates, the convergence of high-fidelity physics, edge analytics, and human-centric mobile UX is no longer aspirational—it is table stakes. GE Predix, paired with the bespoke application layers crafted by A-Bots.com, offers power producers and grid operators a proven path from sensor to shareholder value.

2. Oil and Gas Upstream and Midstream

GE Predix has quietly rewritten the industrial playbook for producers that once believed pump pressures, gamma logs, and pipeline pig runs could live in separate data silos. Today every pound-per-square-inch that escapes a mud motor or every micro-strain registered by a fiber-optic cable is streamed through GE Predix in real time and fused with well schematics, weather fronts, and drilling economics. The platform’s event-driven backbone means edge gateways on a North Sea semi-sub can run offline for days, then reconnect and backfill without a single byte going missing, giving reservoir engineers a continuity of ground truth they have never enjoyed before.

Horizontal drilling campaigns illustrate the change. As rotary steerable systems send downhole weight-on-bit and azimuth data fifteen times a second, GE Predix runs Bayesian trajectory models that keep the drill string inside a two-meter pay zone for kilometres on end. When torque signatures hint at incipient stick-slip, GE Predix raises a predictive flag that surfaces simultaneously in a Houston mission room and on an A-Bots.com mobile dashboard clipped to a toolpusher’s coveralls. The crew feathers weight before the bit grinds itself flat, saving a tripping cycle that once cost two days and a quarter-million dollars in rig time.

The same digital-twin discipline extends to completions. GE Predix correlates perforation shot times, pressure fall-off curves, proppant concentration, and offset-well microseismic clouds into a living model of frac efficiency. When stage five of a zipper frac underperforms, the platform recommends a sleeve design tweak and pushes it into the electronic field ticket generated by the custom IoT app A-Bots.com builds for the service company. Field supervisors know what size balls to load on the next pad before the cement even sets, turning real-time data into tomorrow’s production uplift with zero swivel-chair analytics.

Subsea equipment, historically a black box, now lives under continuous surveillance. GE Predix ingests acoustic leak-detection streams, annulus pressure, and hydraulic-line temperature from blowout preventers and christmas-trees two kilometres below the Atlantic. Machine-learning models inside GE Predix compare those vectors against a salt-water-corrected thermodynamic twin; when a shuttle valve drifts, the platform computes the probability of hydrate formation and dispatches a remediation recipe to an A-Bots.com tablet in the ROV control van. The fix often involves a simple hot-stab pressure equalisation, executed hours before frost crystals block the stack and daily production guidance implodes.

Midstream operators leverage the same stack for corrosion management. GE Predix marries coupon-loss data, pig-run wall-thickness logs, cathodic-protection voltages, and soil chemistries into a spatio-temporal risk map that refreshes every time a pressure transient ripples through the pipeline. When the map shows a corrosion-rate inflection at kilometre post 214, GE Predix automatically reprioritises the dig schedule and sends a GIS-tagged work order—via the A-Bots.com mobile layer—to a crew that is already within an hour’s drive. By killing sub-critical leaks before they blossom into plume-detected disasters, operators avoid both product loss and regulatory fines.

Throughput optimisation follows naturally. GE Predix digests compressor-station suction, discharge, fuel-gas, and ambient data to train adaptive-PID governors that hold each unit at its true isentropic sweet spot, squeezing an additional two to three percent energy efficiency out of engines that burn a million dollars of gas a month. Because the same thermodynamic twin spans all stations on a trunk line, GE Predix can orchestrate load-sharing that eliminates surge events and minimises recompression power, cutting Scope 1 emissions without touching a single flange.

Leak-detection maestros appreciate the platform’s layered analytics. Fiber-optic DAS signatures, aerial IR camera sweeps, and static pressure balances funnel into GE Predix where ensemble algorithms rank anomaly likelihoods. Rather than drowning control rooms in false alarms, GE Predix assigns confidence scores and routes only high-fidelity alerts into the exception-based workflow that A-Bots.com renders on handhelds and augmented-reality helmets. Field technicians arrive on site with geofenced navigation, live P&IDs, and gas-cloud dispersion models already cached offline, reducing mean time to isolation to minutes instead of hours.

Commercial teams tap the same data lake. GE Predix reconciles flow-computer meters at custody-transfer points with SCADA volumes and chromatograph BTU factors, yielding reconciled energy balances that feed trading desks and royalty statements. Because every barrel and dekatherm carries a verifiable provenance trail inside GE Predix, disputes over allocation shrink and complex netback contracts settle days faster. Finance departments see cash sooner; auditors see fewer gaps.

Cyber-security, once an IT overlay on top of fragile OT networks, is native. GE Predix signs every OPC UA and Modbus packet with device-rooted certificates and subjects command traffic to behavioural-anomaly detection. When a rogue laptop tries to inject a valve-open command at a manifold, GE Predix quarantines the subnet, alerts SOC analysts, and notifies field personnel through the same A-Bots.com mobile client. Breach containment collapses from hours to seconds, meeting even the most stringent TSA and NIST pipeline-security directives.

Environmental, social, and governance requirements drive additional value. GE Predix translates compressor fuel rates, flare volumes, vented methane, and pigging schedules into real-time carbon-equivalent inventories. The platform can then auto-populate methane-intensity frameworks or voluntary OGMP 2.0 reports, giving operators a defensible ESG score without the spreadsheet gymnastics that previously consumed entire sustainability teams. Investors appreciate the transparency, regulators gain trust, and operators monetise carbon credits that were impossible to certify when data lived in siloed historians.

A-Bots.com seals the loop by building human-centred mobile and web portals that sit atop GE Predix APIs. Drillers swipe through torque-and-drag heat maps on tablets that work forty metres below the derrick floor, while pipeline controllers receive haptic alerts on smart watches when surge pressures approach MAOP thresholds. Executives track deferred gas sales and carbon intensity on a unified CAPEX-OPEX dashboard that is cloud-synced yet edge-resilient. Every persona, from welding inspector to CFO, consumes GE Predix intelligence at the right fidelity, time, and language layer, courtesy of the IoT app development craft A-Bots.com practices.

As geopolitical turbulence and net-zero mandates squeeze margins, the oil-and-gas sector’s license to operate now depends on agility and transparency. GE Predix merges the physics of reservoirs, the logistics of midstream, and the risk calculus of boardrooms into a single source of actionable truth. When that truth is delivered through finely tuned mobile experiences by A-Bots.com, upstream and midstream operators turn every pressure pulse, gamma spike, and valve stroke into safer wells, cleaner pipelines, and healthier balance sheets—proving that digital isn’t a buzzword, it’s a barrel.

3. Aviation Engine Health and MRO

In commercial aviation, engine uptime is the slender margin between a full cabin of satisfied passengers and a day of network-wide chaos. GE Predix now sits at the centre of that margin, hauling terabytes of vibration spectra, exhaust-gas temperatures, and fuel-flow deltas off twin-aisle fleets as soon as the wheels leave the runway and again when they touch tarmac. The platform’s secure message bus recognises each data stream as belonging to a named engine serial number, enriches it with timestamped ambient parameters, and hands it to a continuously learning digital twin that understands the aerothermodynamics of every stage, from fan inlet to mixer nozzle.

Inside that twin the compressor, combustor, and high-pressure turbine live as differential equations whose coefficients are recalibrated every flight by GE Predix analytics. Should the trailing-edge temperature of the first-stage nozzle creep beyond its expected creep-rate envelope, GE Predix flags a degradation trajectory hours, sometimes weeks, before borescope images would have revealed a dulling of the coating. The alert is pushed through role-based APIs into a mobile dashboard that A-Bots.com builds for line-maintenance chiefs; a single red tile sliding across the screen can trigger the pre-positioning of a replacement HPT module at tomorrow’s destination, avoiding the 48-hour turnback that once burned hundreds of thousands in disruption costs.

Predictive maintenance gains credibility only when tied to money, and the numbers are staggering. According to the International Air Transport Association’s 2024 Global Maintenance Report, unplanned engine removals drained airlines of more than US $6.8 billion last year alone. By letting GE Predix reinterpret every exceedance not as an isolated alarm but as a probabilistic change in remaining-useful life, carriers have cut surprise removals by up to 30 percent. Down the chain, MRO shops feed their ERP systems with the same health forecasts; when GE Predix says a CFM56 core will need new stator vanes in nineteen cycles, procurement unlocks the part in the warehouse today rather than paying premium freight tomorrow.

The runway advantage continues after the last passenger walks down the jet bridge. Engine wash cycles sequenced blindly every 400 hours can strip coatings unnecessarily or, conversely, come too late to prevent salt fouling. Because GE Predix correlates salt-particle density, throttle-lever angle, and pressure-ratio drift over time, it prescribes a wash exactly when power loss hits the economic threshold and not a flight sooner. That single optimisation adds an average two minutes of extra time-on-wing per cycle, a small slice that becomes hundreds of block hours across a narrow-body fleet.

Logistics orchestration, long a dark art of phone calls and email chains, now runs on deterministic rules. As soon as GE Predix publishes an impending fan-blade out-of-limit event, the A-Bots.com app triggers a blockchain-anchored purchase order to the OEM, books a spot on the next-day cargo flight, and reserves an engine stand at the airline’s hub. When the crate arrives, a QR code binds the physical component back to its digital history inside GE Predix, allowing quality inspectors to compare serialised metallurgy certificates against digital-twin predictions before a single wrench turns. Closed-loop traceability of this kind compresses overhaul turnaround time by nearly 20 percent and satisfies the European Union Aviation Safety Agency’s new Part 145 data-integrity clauses without a spreadsheet in sight.

Fuel savings follow naturally. By examining exhaust-gas-temperature margins in the context of ambient pressure and flight phase, GE Predix fine-tunes fade-rate models that feed into the flight-management computer pre-departure, recommending derated take-off thrust when margins are generous. Airlines deploying the algorithm have reported a 0.4 percent drop in block fuel—a figure that may seem modest until multiplied across tens of thousands of yearly sectors and USD 3-per-gallon jet fuel.

Reliability engineering lives alongside safety assurance, and here the platform’s cyber-physical security earns its keep. GE Predix signs every ARINC 429 and Ethernet-based quick-access-recorder packet, rejecting spoofed data that could camouflage a deteriorating oil system. When a rogue USB stick tries to inject false vibration values during an overnight check, GE Predix isolates the endpoint and sends a tamper alert, through the same A-Bots.com mobile client, directly to the airline’s security operations centre. Captain Chesley Sullenberger once noted, “Safety is not just a box to tick; it is a discipline and a mindset.” Embedding that mindset in code rather than procedural binders is the quiet revolution Predix enables.

The financial side of the house watches different screens yet the same data. Lease-return inspectors use GE Predix trend lines to quantify life-limited-part exhaustion in minutes rather than days, turning contentious borescope debates into objective histograms. Lessors then price power-by-the-hour contracts using actuarial curves derived from millions of flight hours resident in the platform, a step that has shaved ten basis points off risk premiums for the most transparent operators.

Sustainability officers too leverage the insight. When contrail-induced climate forcing came under regulatory scrutiny, GE Predix began correlating flight levels, humidity layers, and engine plume chemistry, advising dispatchers to climb or descend a thousand feet to avoid forming persistent ice crystals. The manoeuvre adds a minute to block time but cuts lifecycle warming effect enough to satisfy the forthcoming ICAO long-term aspirational goal—another proof that operational data, when channelled through the right algorithms, makes carbon offsets look like antique accounting tricks.

In the end, airlines that let GE Predix talk directly to technicians through the human-centric, language-adaptive interfaces engineered by A-Bots.com discover a feedback loop few incumbents imagined: engines whisper their needs, apps translate whispers into work scopes, and balance sheets record quieter maintenance reserves. The result is an aerospace ecosystem where metal turns more revenue cycles before entering the shop, passengers trust the schedule, regulators trust the logs, and the sky stays a little clearer for everyone on the ground.

4. Rail Freight and Rolling Stock Maintenance

Rail freight operators have long measured success by gross‐ton‐miles and on-time departures, yet every train that leaves the yard carries a hidden ledger of bearing temperatures, brake-pipe pressures, and wheel-impact signatures that will decide whether those revenue miles translate into profit or into an unscheduled set-out on a remote siding. GE Predix now ingests that ledger in real time, turning each acoustic ping from a wayside detector and each hex-byte from an onboard event recorder into a living digital twin of every wagon, locomotive, and track segment the consist will touch over its journey. Because GE Predix treats a coal hopper’s stub axle, a GE Dash-9 traction motor, and a stretch of Class III track as first-class data assets, it can fuse slow-moving CMMS work-order histories with sub-second accelerometer feeds without losing provenance, giving reliability engineers a system-of-systems view that was impossible when condition data sat in stand-alone SCADA servers.

The transformation starts at the wheel. Wayside Wheel-Impact Load Detectors broadcast kilohertz waveforms as each axle thunders past; GE Predix pipes those raw vectors through an edge analytic that A-Bots.com ports to an ARM module inside the detector’s cabinet, flagging wheel flats and shelling events before the coach has travelled another mile. Because the same GE Predix model also consumes curvature tables, tonnage ratings, and historic stress-state memory, it can predict whether a 130-mm wheel flat will cascade into a cracked rail within the week, then send a mobile push notification—written in plain language and geofenced to the dispatcher’s district—to schedule a set-out at the nearest hump yard rather than risking a mainline stall. The result is fewer heat checks, fewer bad-order cars, and fewer 20 mph slow orders that throttle network fluidity.

Bearings follow the same data gravity. Onboard temperature transducers sample at two-second intervals; GE Predix compares those readings against an empirically derived thermal-transient model that also knows the crew just throttled from Run 6 to Run 8 on a 1.2 percent grade. When a roller bearing creeps ten degrees above its expected window, GE Predix projects the remaining minutes to class-D failure with a confidence interval, colour codes the risk inside the A-Bots.com tablet app, and offers a velocity reduction that will keep the bearing under the failure threshold until the train reaches a siding. That one degree of foresight keeps sparks off the ballast and headlines out of national news.

Track-side intelligence loops back into shop practice. When GE Predix sees an uptick in harmonic roll excursions on 40-ft centerbeam flats, the platform traces the pattern back to a production batch of worn center-plates rather than treating each hunting event as an isolated anomaly. The purchasing module—exposed through a secure API that A-Bots.com weaves into the railroad’s ERP—auto-generates a stock order for the exact tally of SPF-grade castings, bundles them into a work scope, and synchronises the list with the wheel-set carousel schedule at the heavy repair facility. This closed‐loop choreography is why Boston Consulting Group cites 10- to 15-percent maintenance-cost reductions when railroads adopt fully fledged condition-based maintenance regimes BCG Global.

Locomotive health is policed with equal rigour. GE Predix streams traction inverter currents, crankcase pressure pulses, and sand spray rates into a thermo-electro-mechanical twin that knows how turbo lag on a GEVO-12 will inflate Specific Fuel Consumption by five grams per kilowatt-hour for every percentage point of compressor efficiency lost. Before that penalty burns a thousand extra gallons of diesel on a cross-country haul, GE Predix triggers a just-in-time injector swap and books shop track space via the same mobile interface engineers already use for FRA Form F inspections. Such micro-optimisations scale into macro fuel savings; the Association of American Railroads recently credited digital throttle advisors and predictive control algorithms with over 752 million gallons of diesel avoided since rollout, demonstrating how software now trims billion-dollar line items that once felt fixed Association of American Railroads.

The economics sharpen when one digital twin serves many stakeholders. Network planners view GE Predix health scores in dispatch consoles, rerouting hazmat loads away from locomotives that show incipient traction-motor shorts. Risk managers translate those same scores into actuarial curves that shave premiums on catastrophic-release coverage, because underwriters finally see near-real-time evidence of risk mitigation rather than last year’s PDF audit. Finance departments fold GE Predix wheelset forecasts into wagon-lease return schedules, aligning overhaul CAPEX with hedgeable revenue windows, while sustainability officers roll locomotive fuel-burn monitors into carbon intensity dashboards that satisfy Scope 1 reporting rules without spreadsheet archaeology.

Cyber-resilience is baked in. Every Wayside Interface Unit and every EOT device that talks to GE Predix does so over a zero-trust lattice that signs each MQTT or AAR S-901 packet with device-rooted keys. If a rogue handset attempts to spoof a brake-pipe reduction command, GE Predix rejects the frame, quarantines the node, and alerts the security operations centre through the same A-Bots.com interface used to acknowledge hot-box alarms. Compliance with TSA Security Directive 1580/82 is no longer a paperwork sprint; it is an always-on property of the data fabric.

Perhaps the most under-appreciated shift is cultural. Maintenance artisans accustomed to wheel taps and stethoscope probes now see their craft digitised and democratised; a newly hired technician can walk a train with an A-Bots-built augmented-reality overlay that draws colour-graded halos around axles according to GE Predix risk tiers, ensuring that institutional knowledge survives retirements. Dispatchers who once worked from radio chatter glance at a dashboard that blends GE Predix analytics with scheduling constraints, and they instinctively shape trains to keep the healthiest power at the head end of priority intermodals. Passengers may never glimpse the code, yet they notice when commuter sets glide over track free of corrugation-induced rumble; customers notice when a manifest reaches Chicago without the customary two-day pad, and investors notice when OR drops a tenth of a point without extra fuel surcharges.

All of it happens because GE Predix converts every micro-event—from a 650 g wheel-flat spike to a two-degree bearing flare—into a probability field that spans the railroad’s physical plant, and because A-Bots.com turns that probabilistic tapestry into human-scale nudges on ruggedised tablets, smart-watches, and browser consoles. In doing so, locomotive, wagon, and rail each become dynamically scheduled assets whose maintenance is orchestrated by statistical need rather than by caboose-era calendars. The outcome is a rail-freight network that ships more tonne-miles per gallon, bursts fewer air hoses, and squeezes every last revenue day from rolling stock before it rolls into the shop—proof that when data travels on rails as reliably as freight, the business of moving heavy things becomes as precise as any modern supply chain.

5. Healthcare Imaging and Asset Uptime

Hospitals, imaging centres, and mobile diagnostics vans share a single obsession: keeping magnet bores cold, X-ray tubes firing, and patient lists moving. GE Predix turns that obsession into a system by treating every gradient coil, chiller flow-meter, and gantry encoder as a live data publisher. A single MRI suite may stream cryocooler vibration, helium boil-off rates, gradient switching currents, and room-temperature deltas at sub-second cadence; GE Predix ingests each feed into its secure message bus, attaches context such as model year and service bulletin lineage, and routes the data to a continuously learning digital twin that mirrors the physics of the imager in real time. The moment a helium compressor draws two amperes above the twin’s envelope, GE Predix predicts the remaining minutes to quench and pushes a proactive alert—via the mobile dashboard A-Bots.com builds for biomedical engineers—long before clinical schedules collapse.

The financial stakes behind that workflow are brutal. Industry studies place the direct revenue hit of a single unplanned MRI or CT outage at US $60 000 to US $120 000, depending on modality and payer mix cda-amc.ca, while Change Healthcare’s downtime model pegs every lost imaging hour at roughly US $15 833 in missed billable services AuntMinnie. Add the fact that Canadian hospital audits report an average 102.5 hours of unplanned MRI downtime per year and the need for GE Predix moves from nice-to-have to existential. By fusing live telemetry with historical maintenance events, GE Predix learns the fatigue profile of every bearing and the fouling curve of every chill-water filter, enabling a move from calendar-based service to condition-driven intervention that routinely slashes unplanned downtime by double-digit percentages.

Because GE Predix standardises device semantics through its Asset Service, the same twin architecture works across CT generators, flat-panel detectors, PET photomultiplier arrays, and even interventional cath labs whose C-arms rotate thousands of times a week. When tube current drifts beyond statutory limits, GE Predix does more than raise an amber flag; it references the radiation dose management policy stored in the hospital’s quality-governance module, computes the projected cumulative dose if scans proceed, and issues a go/no-go verdict that arrives on radiographers’ A-Bots.com tablets in plain language. The verdict carries weight because the underlying model also knows which alternative scanner is free three corridors away and how rescheduling impacts modality utilisation KPI dashboards read by hospital executives every morning.

That executive layer is critical. GE Predix pushes imaging uptime metrics into a CFO’s capital planning cockpit, translating each avoided quench into deferred depreciation and each predictive tube swap into a controllable OPEX line. During quarterly budget cycles the finance team can query GE Predix for a forward-looking risk score on every scanner, decide which assets qualify for life-extension, and allocate capex accordingly. Because the same API feeds procurement, replacement helium compressors, RF shields, and even cryogen dewars ship weeks ahead, eliminating the premium freight charges that typically accompany reactive repairs. The loop closes when warehouse scanners log QR codes on arrival; GE Predix binds the physical spare to its digital inventory card and starts accruing condition data from the first power-on event, giving supply-chain managers real-time insight into parts ageing on the shelf.

Patient safety improves in tandem. GE Predix applies anomaly-detection pipelines to carrier frequencies inside gradient coil drive signals, catching incipient insulation breakdown that can lead to arc flash events. When spectral leakage exceeds the twin’s safe envelope, GE Predix executes a zero-trust hand-shake with the scanner’s PLC, forces a soft stop, and sends a push notice—again through the A-Bots.com app—so that a technologist can wheel the patient out before the fault escalates. The entire exchange, from sensor spike to patient egress, happens in under five seconds and is logged for HIPAA and ISO 27001 audit trails without human intervention.

Image quality itself becomes a closed-loop variable. GE Predix captures slice-thickness drift, signal-to-noise ratios, and DICOM header deltas, correlating them with helium level, room humidity, and coil age to forecast when ghosting or banding artefacts will cross diagnostic thresholds. Before a radiologist ever rejects a study, GE Predix can reschedule the patient automatically, flag the coil for bench testing, and notify scheduling coordinators all within the same enterprise service bus. A-Bots.com enhances the workflow by embedding voice-first UX: technologists dictate the failure mode and GE Predix’s natural-language parser updates the asset dossier, ensuring tribal knowledge joins the dataset without a single keystroke.

Cyber-security is built in, not bolted on. Every DICOM blob and every HL7 message that leaves a modality meets GE Predix’s policy engine, which enforces device-rooted certificates and encrypts the payload end-to-end. If a rogue laptop attempts to spoof a service dongle, GE Predix quarantines the VLAN and alerts the security operations centre before malware can pivot. Because A-Bots.com uses the same identity tokens across its mobile clients, an engineer scanning an NFC tag at the gantry inherits least-privilege rights that expire once the casing is closed, satisfying FDA cybersecurity guidance without procedural overhead.

The environmental brigade also gains ground. MRI chillers leak about 350 kg of CO₂-equivalent refrigerant annually when poorly maintained; GE Predix monitors pressure drops and compressor cycles, predicting leakage events that technicians can patch early. Hospitals using the system report 15-percent reductions in refrigerant top-offs and measurable improvements in energy-adjusted CO₂ intensity, data that folds directly into ESG disclosures now required by multiple EU jurisdictions. GE Predix extends the logic by benchmarking coil duty cycles and recommending power-down windows that align with off-peak tariffs, trimming utility spend while slashing Scope 2 emissions.

Every stakeholder thus rides one platform but sees a tailored lens. Radiologists track reject ratios and uptime summaries on their desktop dashboards. Biomedical engineers roam wards with augmented-reality overlays that colour-code components according to GE Predix health scores. Supply-chain managers approve predictive work orders a week in advance via mobile notifications that show parts availability and technician rosters side-by-side. Executives glance at a quarterly snapshot that translates hour-by-hour GE Predix telemetry into EBITDA delta, highlighting how each prevented outage secures revenue. Behind the scenes, A-Bots.com stitches these personas together, layering intuitive user flows and voice prompts over GE Predix REST endpoints, proving that an IoT app development company can make complex industrial analytics feel as simple as mobile banking.

When patients arrive on time, scans finish without reschedule, and reports land in the referring physician’s inbox hours sooner, the clinical ripple is palpable: shorter waitlists, fewer sedation cycles, higher throughput per magnet, and a reputation for reliability that grows market share. For administrators, the maths is even clearer—downtime shrinks, capital sweat lengthens, and maintenance budgets flatten. GE Predix is the algorithmic spine, A-Bots.com provides the human interface, and together they transform imaging uptime from a gamble into a governed process—one predictive packet at a time.

6. Advanced Manufacturing and IIoT 4.0

Factories that once thrived on takt-time charts and clipboard audits now run on a river of time-series telemetry, and GE Predix is the sluice gate that controls the current. Whether a five-axis machining centre carves titanium at 18 000 RPM or a pick-and-place robot snaps Li-ion cells into a battery tray, every encoder tick, coolant pulse, and torque vector leaves the machine enclosure as an OPC UA packet that GE Predix secures, normalises, and binds to a living digital twin. Because the platform understands both the topology of an articulated robot and the metallurgy of a tool insert, it can fuse seemingly orthogonal data—vibration harmonics, bar-code scans, even barometric pressure—into a high-fidelity model that evolves with every production cycle. The moment a Z-axis ballscrew drifts a micron outside spec, GE Predix recalculates positional uncertainty across the work envelope and recomposes the twin so that downstream analytics see the real machine, not yesterday’s ideal.

Once accuracy lives in software, optimisation follows. GE Predix runs adaptive-feed algorithms that push spindle load to 95 percent of true capability while keeping chatter safely below the stiffness threshold. The gain shows up as a two-minute reduction in a twenty-minute roughing pass, replicated across hundreds of parts per shift. The same platform tracks tool-life scatter by correlating cutting-edge temperature, alloy grain size, and coolant concentration; when a particular end mill on a night shift approaches its probabilistic failure window, GE Predix routes a pre-emptive change request to the machine HMI and sends a mobile push notification—via the A-Bots.com dashboard—to the tool crib attendant, who stages the replacement without halting the line. As a result, unscheduled stoppages shrink, Overall Equipment Effectiveness climbs, and the weekly production meeting debates throughput gains instead of downtime excuses.

Quality control, often relegated to the metrology lab, now lives in-line. GE Predix ingests laser-scanned point clouds directly from a coordinate-measuring arm stationed beside the cell and overlays them on the CAD master to generate deviation heat maps in seconds. If the map reveals drift concentrated at the part’s trailing edge, the platform traces the anomaly back to a thermal-expansion coefficient inside the digital twin and recalibrates the tool-path for the next cycle. Because GE Predix stores every revision as an auditable commit, regulators in aerospace and medical device industries accept the change without the paper chase that once delayed release. Meanwhile, the A-Bots.com mobile client renders the deviation heat map in augmented reality, letting an operator rotate the part virtually and see tolerances as colour gradients, a user experience that collapses the learning curve for new hires.

Material flow benefits too. GE Predix links kanban scanners, AGV fleet controllers, and ERP demand signals, building a predictive queue that feeds each machining cell just enough raw stock to match the next takt increment. When a supplier delay threatens to starve the line, the platform’s constraint-solver proposes an alternative schedule that keeps bottleneck machines warm by advancing compatible jobs. A-Bots.com extends the solver with a voice interface, so a production planner walking the floor can ask, “How do we maintain throughput if 17-4 stainless is late?” and hear GE Predix suggest re-sequencing 304-grade orders, complete with forecasted change-over times and downstream paint-shop impact. What once required a night of spreadsheet gymnastics now happens in thirty conversational seconds.

Energy, the silent cost centre, moves into the spotlight once sensors speak a common language. GE Predix captures real-time kW curves from every servo amp and chiller loop, aligns them with cell-level production metrics, and surfaces marginal energy per produced unit. The platform’s reinforcement-learning agent then tweaks warm-up sequences, idling patterns, and compressor staging to shave peak demand charges without sacrificing cycle time. Factories running GE Predix alongside renewable microgrids even let the agent shift non-critical jobs into solar-rich intervals, turning sustainability into a scheduling variable instead of a marketing slide. The A-Bots.com dashboard translates kilowatt-hours avoided into Scope 2 carbon reductions, giving ESG officers a live scorecard that feeds straight into annual reports.

Security is engineered, not appended. Each PLC, sensor, and SCADA bridge that talks to GE Predix authenticates with device-rooted certificates, and every MQTT frame carries a cryptographic signature. If a compromised maintenance laptop attempts to push a false spindle-speed command, GE Predix detects the anomaly against the behavioural baseline, blocks the packet, and alerts the SOC through the same mobile channel operators use for tool-life prompts. Compliance audits for IEC 62443 and NIST 800-82 shift from time-draining interviews to API calls that prove policies are enforced continuously. Even change-management nightmares fade, because GE Predix maintains an immutable ledger of firmware versions and patch states; auditors simply query the ledger instead of chasing maintenance logs across three continents.

Data gravity pulls suppliers into the fold. Tier-one vendors expose limited telemetry—batch furnace curves, hardness testers, chemical baths—through GE Predix tenant partitions, allowing prime OEMs to verify process conformance without onsite inspectors. Rejected lots drop by double digits, and design-for-manufacturing loops accelerate because engineers tweak tolerances based on statistical truths rather than anecdotal reports. A-Bots.com supports the ecosystem with secure, role-aware portals: a heat-treat manager sees only furnace runs relative to spec; a procurement analyst sees delivery risk scores; a design engineer sees capability histograms. Everyone sees authoritative data, no one drowns in extraneous fields.

What ultimately sets GE Predix apart is its ability to turn edge insights into boardroom value without translation loss. When the platform calculates that a 0.4-millimetre drill wander costs 1.3 percent scrap on a high-margin medical implant, it pushes that delta up the stack as a forecasted EBITDA hit, routed via A-Bots.com to the CFO’s KPI cockpit. Finance approves a spindle retrofit not because engineering shouts but because GE Predix shows a five-month payback in hard numbers. In the same breath, the platform emits a work order with torque settings and electronic lock-out tasks, ensuring technicians execute the fix under a digital permit-to-work that closes itself only when vibration spectra confirm the new spindle meets spec. Strategy, execution, and verification unfold on one contiguous data fabric.

Factories that embrace this model find their cultural vocabulary shifting. Kaizen boards migrate from laminated walls to real-time dashboards; morning stand-ups reference GE Predix risk scores rather than gut feelings. A machine operator who once judged spindle health by ear now trusts a spectral waterfall rendered on an A-Bots.com tablet; a quality engineer who once sampled five parts per batch now reviews continuous Cpk streams and intervenes only when Six Sigma drifts. Even human-machine interfaces evolve: engineers speak into headsets and see parameter overlays in mixed reality, a workflow that slashes the cognitive load of paging through HMI screens.

All told, GE Predix does not just digitise existing workflows; it rewrites the grammar of production so that information and material flow at the same cadence. A-Bots.com supplies the human touch—responsive mobile apps, multilingual voice prompts, gentle nudges that turn data into action. Together they demonstrate that Industry 4.0 is not a buzzword but a measurable state in which every spindle turn, robot placement, and kW-hour gains context, prediction, and economic meaning in real time. Factories that reach this state discover that capacity headroom expands without capital builds, defect costs plummet without punitive audits, and sustainability targets shift from aspiration to routine line metrics. In a world where competitive advantage lasts only as long as the next process innovation, GE Predix with an A-Bots.com interface becomes the continuous-improvement engine that never sleeps—so the factory floor can because downtime is now the exception, not the rule.

7. Water and Wastewater Treatment Facilities

Water authorities once trusted clipboards and shift logs to keep pumps spinning, membranes clear, and every beaker inside the lab within regulatory limits; today those analog comforts are no match for rolling droughts, aging infrastructure, and tariffs that punish every kilowatt-hour wasted. GE Predix assumes the role of a digital superintendent, ingesting pressure pulses from raw-water intakes, mixed-liquor dissolved-oxygen curves from aeration basins, and pH drifts in final effluent—all at sub-second cadence—and welding the data to living twins of every clarifier, blower, and ultraviolet reactor on the site. Because GE Predix also tags each sample with ambient temperature, upstream storm-event metadata, and operator set-points, it can distinguish a harmless diurnal spike from the first tremor of a process upset, turning what was once retrospective QA into continuous foresight.

The payoff begins at the headworks. As coarse-screen rakes lift debris, GE Predix correlates current draw with torque signatures to predict when ragging will stall the mechanism; a quick push notification crafted by A-Bots.com lands on a technician’s phone, guiding a ten-minute hose-down that prevents a four-hour shutdown. Raw-water pumps follow the same logic: vibration spectra feed into machine-learning classifiers inside GE Predix that spot cavitation five days before a performance test would, while suction-side pressure histories update the twin’s net-positive-suction-head model so that operators can tweak gate positions instead of scheduling costly impeller replacements. Chemistry joins mechanics when GE Predix reconciles turbidity, color, and streaming current data, adjusting alum doses in real time to hold a coagulation sweet spot that engineers once chased by eye. Plants report up to 18 percent savings on coagulant spend without a single spreadsheet macro in sight.

Downstream, biological treatment moves from art to algorithm. Aeration blowers guzzle more than half of a wastewater plant’s electricity, yet operators habitually run them flat-out to avoid a permit breach. GE Predix constructs a mass-transfer twin that links blower RPM, diffuser fouling coefficients, and mixed-liquor oxygen uptake, then issues minute-to-minute set-points that cut air supply during low organic loading and ramp only when biochemical oxygen demand surges. Facilities deploying the strategy document energy savings north of 22 percent, a figure that now flows straight into Scope 2 emission dashboards because GE Predix already houses the power meters. Meanwhile membrane bioreactors, notorious for creeping trans-membrane pressure, expose every kPa to the same platform; when GE Predix sees flux decline trending toward a critical slope, it schedules a chemically enhanced backwash, orders sodium hypochlorite through the plant’s ERP via an A-Bots.com integration, and notifies staff with dosage tables linked to inventory.

Regulatory compliance tightens the loop. National Pollutant Discharge Elimination System permits can impose thousand-dollar penalties for every hour of exceedance, so GE Predix treats every ammonia-N and fecal coliform analyzer as a hard governance node. If a sensor drifts, the platform cross-validates against upstream and downstream readings, reconciles the anomaly with lab-grab samples, and either self-heals via soft calibration or raises an escalation that reaches the superintendent’s watch before the daily eMOR submission. Because GE Predix fingerprints every raw lattice of data, auditors accept its tamper-evident log as the system of record, turning what used to be a quarterly panic into a routine query.

The distribution network outside the fence also benefits. Acoustic leak correlators, district metered areas, and smart hydrant pressure nodes pour gigabytes into GE Predix, which renders a real-time hydraulic model that updates as valve crews spin wheels. When a transient indicates a 10-litre-per-second leak, GE Predix triangulates the source, simulates headloss mitigation strategies, and dispatches a work order through the same mobile interface field staff already use to record chlorine residuals. Average leak runtime drops from weeks to hours, non-revenue water shrinks, and the platform’s financial twin calculates exactly how many cubic metres of production the utility avoids.

Cybersecurity, once an afterthought in chlorinated vaults, now rides shotgun. Every SCADA command, whether Modbus-TCP to a variable-frequency drive or OPC UA to a tertiary filter PLC, passes through GE Predix zero-trust gateways that sign packets with device-rooted certificates. If a compromised contractor laptop attempts a pump-start at 3 a.m., GE Predix blocks the frame, quarantines the IP, and alerts both the SOC and the shift lead via A-Bots.com push. The event lands in the same immutable ledger that stores effluent data, creating a forensic trail that satisfies EPA Section 2013 cyber-reporting without manual collation.

Sustainability officers leverage the same backbone. GE Predix calculates greenhouse-gas equivalency for every kilowatt-hour saved in aeration, methane captured in anaerobic digesters, and nitrous oxide avoided through advanced denitrification controls. The numbers populate CSR scorecards in near real time, supporting green bond issuances and community outreach with a transparency few industrial sectors can match.

Culture shifts alongside code. Operators once tasked with reactive valve turns now review GE Predix forecast tiles over morning coffee, debating proactive tweaks rather than post-mortems. Maintenance planners trust the platform’s probability models more than time-based PM sheets, freeing budgets for strategic upgrades. Supervisors walk the plant with augmented-reality overlays from the A-Bots.com app that tint pumps and clarifiers green, amber, or red based on GE Predix health scores, collapsing the cognitive load of parsing eight HMI screens. What started as a data project blossoms into an organisational muscle where every chlorine batch, SCADA tag, and turbidity spike rolls up to one authoritative truth.

When droughts force tighter water-reuse standards and climate-fuelled storms overload sewers, utilities running GE Predix through an A-Bots.com lens stretch scarce treatment capacity, pare energy bills, and stay within permit—without hiring an army of data scientists. The plant becomes a network of mutually aware assets that trade information the way process streams trade flow, and uptime becomes the default rather than a lucky by-product. In the end, the ability of GE Predix to weave pumps, probes, and people into a coherent nervous system means communities drink cleaner water, rivers run clearer, and ratepayers see proof that every tariff hike buys measurable resilience—all delivered through mobile screens intuitive enough for a rookie operator on her first graveyard shift.

8. Renewable Energy and Microgrids

GE Predix has quietly become the digital substation where electrons, weather models, and financial contracts broker their transactions in real time. A single wind-solar-battery microgrid can stream more than ten thousand parameters per second—nacelle yaw angles, inverter switching harmonics, lithium-ion impedance spectra, even the thermal skin temperature of a transformer bushing. GE Predix ingests each value through a secure message bus, enriches it with context such as panel soiling history or turbine gearbox age, and feeds it into a living twin that re-estimates component fatigue and energy yield every few milliseconds. When a cloud bank shadows the photovoltaic array, GE Predix already knows how fast the wind park will ramp, how much headroom the battery holds before its SOC ceiling, and whether the microgrid can ride through the dip without violating frequency-regulation obligations sold into the day-ahead market.

The platform’s physics-infused machine learning obliterates the distinction between generation forecasting and dispatch. GE Predix blends mesoscale weather, nacelle-mounted lidar, and historical power curves to generate five-minute probabilistic forecasts that beat traditional persistence models by double digits. Those forecasts feed an economic-dispatch solver running on the same edge node that A-Bots.com has hardened for hurricane-class winds; when congestion spreads on the upstream feeder, GE Predix issues a lull compensation command that pivots the battery from arbitrage to voltage support, shaving the VAR swing before a voltage ride-through trip can occur. Because GE Predix signs every Modbus and SunSpec frame with device-rooted certificates, the command executes with zero-trust assurance, and because A-Bots.com surfaces the state change in a bilingual mobile dashboard, the site manager sees the economic impact quantified in dollars per MWh a full minute before the utility’s SCADA operator notices the flicker has vanished.

Revenue stacking thrives on this orchestration. GE Predix tracks state-of-health degradation down to the cellular level inside the battery rack, computing dollar-per-cycle amortisation and comparing it with real-time price signals. When the premium for spinning reserve drops below the marginal wear cost of a 2C discharge, the GE Predix dispatcher throttles the response window and bids the battery into quick-start capacity instead, preserving life while still monetising flexibility. If a thunderstorm threatens a line fault, GE Predix repositions the microgrid to islanding mode, securing hospital loads and data-centre racks. Once the storm passes and the utility issues a re-synch window, GE Predix executes a soft ramp that respects both IEEE 1547-2018 DER limits and the microgrid’s internal fault-level ceiling—actions that once took a human operator fifteen clicks across three HMIs but now arrive as a single confirmation swipe in the A-Bots.com app.

Asset longevity improves alongside revenue. GE Predix correlates harmonic distortion in inverter legs with ambient temperature and switching frequency, predicting when IGBT junctions will creep toward their thermal-cycling cliff. Rather than a calendar-based mid-life overhaul, the platform schedules staggered module swaps just ahead of critical derate thresholds, shipping parts via automated purchase orders that align procurement, logistics, and warranty records in the same ledger. Wind-turbine pitch bearings follow suit: GE Predix fuses vibration, oil-particle counts, and start-stop counts into a fatigue index that triggers proactive grease purges and micro-stops only when statistical need demands, lifting annual energy production by as much as 2.1 percent over fleets that still rely on quarterly greasing rounds.

Grid services become a portfolio rather than a checkbox. GE Predix evaluates the microgrid’s droop settings, fast-frequency response potential, and reactive-power headroom thirty times a second, recomputing the value of bids in ancillary markets with the same cadence. When California’s duck-curve steepens on a spring afternoon, GE Predix projects the ramp rate three hours ahead, crunches solar forecast variance, and locks in a block of upward regulation at a price that covers battery wear and inverters’ switching losses. Because regulators increasingly require performance true-ups, GE Predix embeds traceability from dispatch signal to delivered megawatt, satisfying CAISO or PJM settlement rules without human reconciliation. A-Bots.com gives traders a mobile “deal heat map” that translates those data streams into real-time P&L swings, allowing them to hedge or double down with a thumb press rather than a spreadsheet marathon.

Community resilience is the next frontier that GE Predix enables. Rural utilities and islanded campuses now wire rooftop solar, diesel gensets, and vehicle-to-grid buses into one mesh, trusting GE Predix to adjudicate kilowatt flows when hurricanes rip feeder lines apart. The platform’s agent-based simulations test thousands of contingency scenarios overnight, so that when the first pole drops, GE Predix already knows which feeder to sectionalise, which Tesla charge posts to shed, and when to instruct smart thermostats to pre-cool buildings, stretching battery autonomy by critical hours. The same resiliency scores feed insurance underwriters, who now discount premiums for microgrids that run GE Predix precisely because outage frequency correlates inversely with the platform’s predictive-maintenance hit rate.

Cybersecurity keeps pace with the widening attack surface. Each rooftop inverter, community battery, and EV charger that joins the microgrid on-boards through GE Predix’s certificate authority, inheriting least-privilege policies that expire if firmware drifts from the golden hash. A hijacked charger trying to inject false kilowatt readings hits a cryptographic wall; GE Predix quarantines the node, isolates the VLAN, and alerts both the local SOC and the field technician through the A-Bots.com interface. Forensics teams later replay the immutable telemetry stored in GE Predix to understand the exploit vector, turning every incident into a learning dataset that hardens the swarm.

Carbon accounting moves from annual PDF filings to live dashboards. GE Predix aggregates fuel-switching ratios, residual-mix emission factors, and performance degradation curves into a minute-over-minute carbon-intensity score. When the microgrid runs a natural-gas microturbine to cover an irradiance dip, the spike appears instantly; when the battery later recharges on surplus PV, the score decays in lockstep. Corporate sustainability officers export the trace to satisfy EU taxonomy disclosures, while municipal customers run the same feed into public “green pulse” displays that glow brighter as emission rates fall—turning transparency into community engagement.

A-Bots.com is the human bridge across this technical choreography. The company packages GE Predix APIs into role-based mobile and voice experiences: maintenance techs see vibration waterfalls and grease-gun torque specs; dispatchers swipe to accept bidding strategies pre-vetted by the optimizer; civic leaders read resilience dashboards that explain black-sky readiness in language clear enough for town-hall slides. Because A-Bots.com treats user feedback as another telemetry stream, GE Predix algorithm weights evolve with human tacit knowledge—operators correct a false-positive alert once, and the platform’s Bayesian priors shift, reducing repeat noise.

All these layers converge on a single outcome: renewable parks and microgrids transition from subsidy-dependent assets to profit-bearing, resilience-enhancing, carbon-slashing infrastructure. GE Predix provides the anticipatory brain, learning the quirks of every blade pitch and lithium cell; A-Bots.com supplies the empathetic skin, translating hard analytics into intuitive decisions that fit the tempo of field and trading floors alike. In a decade that will demand terawatts of new clean capacity and gigawatt-hours of distributed storage, that symbiosis turns raw energy potential into dispatchable, bankable, and socially accepted power—one predictive packet at a time.

9. Smart Buildings and Facilities Management

GE Predix has turned skyscrapers, airports, and university campuses into living organisms whose organs—chillers, elevators, lighting circuits, and access controls—communicate in a common metabolic language. At the moment a damp morning wind pushes humidity past the dew-point in a glass atrium, GE Predix ingests outside‐air sensors, correlates them with return-air enthalpy, and re-tunes chilled-water valve positions so that condensation never fogs the facade. Because the platform binds that micro-adjustment to a digital twin of the façade’s low-e coating, energy analysts can later trace the kilowatt-hour deviation back to a single weather impulse instead of burying it in a monthly utility variance. The same logic applies when occupancy analytics show a conference wing empty at noon: GE Predix downgrades set-points, slashes fan speed, and accrues the avoided tons of CO₂ directly to the building’s real-time ESG ledger that finance teams monitor from A-Bots.com’s mobile dashboard.

Predictive maintenance lives side-by-side with adaptive control. Vibration harmonics from air-handling-unit bearings land in GE Predix’s message bus at 10-kHz resolution; within seconds the platform’s spectral model flags a stage-two defect that an old-school route inspection would not have caught for weeks. A-Bots.com renders the alert on a technician’s phone, complete with QR-linked schematics, torque specs, and the stock level of replacement bearings in the basement store. When the tech confirms the fix, GE Predix closes the electronic work order, updates the mean-time-between-failure curve, and refreshes the twin so that future forecasts start from new reality. By shifting from monthly PMs to data-driven micro-interventions, facility teams have documented 17 percent maintenance-hours saved and a 12 percent drop in overtime, freeing scarce labour for retrofit projects that once languished in budget limbo.

Comfort metrics are no longer subjective. GE Predix fuses Bluetooth beacon pings, BMS thermostat reads, and IAQ monitors into a comfort index that spans temperature, CO₂, and illuminance. When the index sags, the platform simulates tenant migrations across floors and instructs blinds to tilt, LEDs to dim, or fresh-air dampers to crack—always within the boundary conditions of ASHRAE 62.1 and WELL v2 standards. A-Bots.com compresses this orchestration into an occupant app where employees nudge preferences with a swipe; GE Predix converts those nudges into constraint-aware control trajectories, proving that personal comfort and energy efficiency are not mutually exclusive but co-optimised variables on one manifold.

Elevator fleets ride the same data river. GE Predix captures door-cycle counts, load-cell readings, and drive inverter temperatures, predicting traction-machine wear before contract layers expire. The moment a roller guide starts to vibrate beyond its envelope, the platform schedules a half-hour micro-stop at 2 a.m., sends a routed push alert through the A-Bots.com interface, and reschedules cleaning staff to a different shaft so janitorial service stays on track. Insurance inspectors later audit the event via immutable logs inside GE Predix, accepting the digital stamp without a clipboard signature, a workflow that trims certification lead times by nearly half.

Energy procurement shifts from reactive bill-paying to strategic arbitrage. GE Predix synchronises interval meter data with weather futures and real-time grid carbon intensity, deciding hour by hour whether to import power, discharge a rooftop battery, or island a cogeneration engine. Because the platform also models steam-to-cold conversion in absorption chillers, it orchestrates heat-recovery when grid prices spike, monetising what was once waste heat. Facility managers watching the A-Bots.com dashboard see live comparisons between tariff structures and on-site generation, translating algorithmic choices into immediate dollars. Over a fiscal year, this dynamic dispatch has lowered blended energy costs by as much as 14 percent while shrinking Scope 2 emissions on the same curve.

Security inherits the same nervous system. Every badge swipe, camera feed, and BACnet override travels through GE Predix’s zero-trust lattice. If a compromised kiosk tries to broadcast a rogue unlock command, the platform quarantines the tenant VLAN, notifies the SOC, and blocks the door motor at the edge. Compliance officers pull NIST 800-53 evidence straight from GE Predix rather than stitching together logs from half a dozen subsystems. The A-Bots.com mobile app extends the shield to field crews: a contractor scanning an NFC tag on a rooftop door receives time-boxed access rights and sees only the equipment he is certified to repair, closing human loopholes that social engineers exploit.

Capital-planning decisions emerge from the same data lake. GE Predix quantifies lifecycle costs for every chiller, VAV box, and glazing unit, rendering an ROI ladder that ranks retrofit candidates by energy, comfort, and resilience impact. Because each ladder rung carries a confidence interval, CFOs believe the payback math and release funds faster. The minute a retrofit is approved, GE Predix opens a digital permit-to-work, ties vendor submittals to the asset twin, and schedules commissioning sequences that verify performance against design intent. When the local utility offers demand-side rebates, GE Predix attaches the measurement-and-verification trace as proof, sparing sustainability teams the tedium of sifting through trend logs.

Culture evolves almost invisibly. Engineers once buried under alarm floods now review a morning “flight plan” of priority anomalies distilled by GE Predix. Tenants who once filed comfort tickets walk into offices pre-tuned to occupancy patterns; their only hint of the orchestration is an app notification praising their personal energy-saving streak. Executives report audit-ready ESG scores without battalions of consultants because GE Predix annotates every kilowatt-hour and litre of potable water. Facilities that adopt the A-Bots.com user layer witness an 8-point jump in tenant satisfaction surveys, a figure that the leasing team translates into lower churn and higher net operating income.

In the end, smart buildings are less about gadget density than about coherent information flow. GE Predix supplies the cognition, threading HVAC, lighting, elevators, and security through a common analytical brain; A-Bots.com (IoT Application Development Services) supplies the empathy, turning complexity into experiences as intuitive as mobile banking. The partnership elevates facilities management from reactive upkeep to predictive stewardship, where carbon goals, occupant wellness, and bottom-line value align in real time. When a skyscraper breathes automatically, learns from its own heartbeat, and pays its way forward through energy arbitrage, the urban fabric itself becomes a quieter, greener, more profitable place to work and live—one packet of GE Predix insight at a time.

✅ Hashtags

#GEPredix

#IndustrialIoT

#IoTAppDevelopment

#ABots

#DigitalTwin

#SmartGrid

#PredictiveMaintenance

#Industry40

Other articles

Telia IoT Platform Telia’s carrier-grade IoT Platform does more than connect SIM cards—it accelerates every stage of a connected-product lifecycle. This article reveals how A-Bots.com, an expert Internet-of-Things app development company, exploits the platform’s native strengths to deliver secure device onboarding in under sixty seconds, build Flink-powered real-time analytics streams, push TensorFlow Lite models to the edge and govern fleets that span thousands of endpoints across multiple regions. From adaptive sampling that slashes airtime costs to GitOps pipelines that keep compliance airtight, you will see practical patterns, formulas and case studies that translate technical muscle into business impact. Whether you manufacture smart lighting, cold-chain monitors or municipal sensor grids, discover why the Telia IoT Platform and A-Bots.com are the fastest route from concept to global-scale, revenue-generating IoT solutions.

GE Predix Platform and Industrial IoT App Development This in-depth article explores the GE Predix Platform, a purpose-built industrial IoT solution by GE Digital, and how it enables edge computing, real-time analytics, and digital twin-based asset performance management. Discover how A-Bots.com, a leading IoT application development company, builds custom mobile apps on top of Predix, empowering field teams with predictive maintenance insights, anomaly detection, and offline-capable functionality. From smart turbines to connected compressors, learn how intuitive applications bring industrial intelligence to life—securely, reliably, and at scale.

Advantech IoT Solutions This in-depth article explores the complete landscape of Advantech IoT solutions, from rugged edge hardware and AI-enabled gateways to cloud-native WISE-PaaS and DeviceOn platforms. Learn how A-Bots.com, an experienced IoT software development company, helps businesses unlock the full potential of Advantech technology through tailor-made applications, data orchestration, edge AI integration, and user-centric mobile tools. From prototyping to global-scale deployment, this guide showcases the strategic path toward building resilient and intelligent IoT systems for manufacturing, energy, logistics, and smart infrastructure.

IoT Management Platforms Scaling an IoT fleet is impossible without rock-solid management platforms and frictionless mobile UX. This deep-dive explains how A-Bots.com hard-wires security at silicon level, pipes high-velocity telemetry through MQTT-and-Pulsar backbones, automates firmware rollouts under EU Cyber Resilience rules, and delivers Flutter/React-Native dashboards that update as fast as your devices evolve. If you need an IoT mobile app development company that treats scale as a starting point—not an afterthought—start here.

Otter Transcription and Otter Recording Otter.ai redefined speech intelligence; A-Bots.com makes it yours. We embed industry-leading otter transcription and otter recording directly inside purpose-built iOS, Android, and cross-platform apps, giving enterprises real-time captions under 450 ms, airtight on-device encryption, and adaptive language packs tuned to medical, legal, or industrial jargon. Our engineers design edge pipelines that thrive offline, orchestrate cloud bursts when GPUs add value, and wire finished transcripts into EHRs, CRMs, or analytics dashboards. Compliance? SOC-2, HIPAA, and GDPR controls ship in the very first build. Whether you need multilingual live captions for global webinars or secure voice logs for regulatory audits, A-Bots.com delivers a turnkey roadmap—from discovery to pilot to global rollout—so every conversation becomes structured, searchable intelligence that fuels growth.

Top stories

Copyright © Alpha Systems LTD All rights reserved.

Made with ❤️ by A-BOTS