Home

Services

About us

Blog

Contacts

Engineering and 3D Modeling Services for Australia: Custom Software Development, Digital Twins, and Advanced Manufacturing Solutions from A-Bots.com

At A-Bots.com, we deliver comprehensive engineering software solutions that address the unique demands of the Australian market. From custom CAD and 3D modeling applications to sophisticated digital twin platforms and Building Information Modeling systems, our development expertise spans the full spectrum of engineering technology requirements. With over 70 completed projects and partnerships extending beyond five years with clients across diverse industries, we understand that Australian businesses require solutions tailored to specific operational challenges rather than generic software packages.

Australia's engineering and manufacturing sectors are undergoing profound digital transformation. The nation's geographic isolation, vast resource extraction operations, ambitious infrastructure programs, and growing advanced manufacturing ambitions create distinct requirements that off-the-shelf software often fails to address adequately. International development teams like A-Bots.com bring fresh perspectives to these challenges, combining global best practices with the flexibility to customize solutions for Australian conditions.

This comprehensive guide examines the Australian engineering software landscape, identifies key market opportunities, explores technical requirements across major industry sectors, and demonstrates how custom development delivers competitive advantages that standardized solutions cannot match.

The Australian Engineering Software Market: Scale, Growth, and Opportunity

CAD and 3D Modeling Software Adoption

The Australia and New Zealand CAD software market reached USD 74.0 million in 2024 and projects growth to USD 153.0 million by 2032, representing a compound annual growth rate of 9.6%. This expansion reflects increasing adoption of high-tech technologies including 3D modeling, digitization, cloud computing, and artificial intelligence across Australian enterprises.

The 3D segment dominates market share and demonstrates the strongest growth trajectory. Enhanced productivity through 3D technology drives demand for 3D-enabled CAD software as organizations recognize the efficiency gains achievable through advanced visualization, simulation, and digital prototyping capabilities. Major players including Autodesk, Dassault Systèmes, Bentley Systems, and PTC maintain significant market presence, yet substantial opportunities exist for specialized solutions addressing industry-specific requirements.

Manufacturing represents a critical growth segment, with Australian manufacturers increasingly integrating CAD software to improve production efficiency, reduce design errors, and accelerate time-to-market. The construction sector similarly demonstrates strong adoption, driven by infrastructure investment programs and government mandates encouraging Building Information Modeling implementation.

Digital Transformation Across Industry Sectors

Australia's economy encompasses diverse sectors requiring sophisticated engineering software solutions. Mining contributes substantially to national GDP and leads global adoption of automation, digital twins, and advanced analytics. Construction investment exceeds AUD 322 billion annually and is projected to reach AUD 523 billion by 2030. Manufacturing accounts for approximately 6% of GDP while employing 870,000 workers and contributing AUD 134.7 billion annually.

Each sector presents distinct engineering software requirements:

Mining operations demand real-time monitoring, predictive maintenance, autonomous equipment integration, and comprehensive digital twin platforms capable of modeling entire mine sites. Construction projects require BIM solutions supporting collaboration across distributed teams, regulatory compliance, and lifecycle management from design through operation. Manufacturing facilities need CAD systems integrated with production planning, quality control, and supply chain management functionalities.

A-Bots.com develops custom solutions addressing these sector-specific requirements, building applications that integrate seamlessly with existing operational systems while providing capabilities unavailable in commercial off-the-shelf packages.

Building Information Modeling: Transforming Australian Construction

Market Dynamics and Growth Projections

The Building Information Modeling market in Australia demonstrates exceptional growth potential, with projections indicating a 16.50% compound annual growth rate through 2034. This pace substantially exceeds global BIM market growth of approximately 13-14%, reflecting Australia's particular combination of infrastructure investment, government policy support, and industry modernization imperatives.

The Australian Construction Industry Forum estimates that a 15% productivity improvement driven by BIM adoption would generate AUD 31 billion in savings across the construction sector. With estimated construction spending exceeding AUD 207 billion annually, even incremental efficiency gains translate to substantial economic value.

Several factors drive accelerated BIM adoption in Australia:

Infrastructure investment programs including METRONET in Western Australia, Sydney Metro, and Melbourne Metro Tunnel require sophisticated digital project management capabilities. Government policy increasingly mandates BIM implementation for public infrastructure projects, following patterns established in the United Kingdom, Singapore, and other developed markets. The construction industry faces severe labor shortages, with Infrastructure Australia projecting a deficit of 131,000 full-time workers in 2024, creating urgency for productivity-enhancing technologies.

Technical Requirements for Australian BIM Solutions

Effective BIM solutions for the Australian market must address several technical and operational requirements:

Compliance with Australian standards and National Construction Code requirements ensures designs meet regulatory expectations. The NCC 2022 changes, including new energy efficiency requirements effective May 2024, add complexity that BIM systems must accommodate. Integration with local council approval processes streamlines permitting workflows.

Collaboration capabilities supporting geographically distributed teams address Australia's vast distances and common project structures involving participants across multiple cities or countries. Cloud-based BIM platforms gain traction by enabling real-time coordination regardless of participant location. However, data sovereignty concerns require careful attention to where project information resides.

Interoperability with common Australian software ecosystems enables BIM solutions to exchange data with accounting systems, project management platforms, and specialized engineering applications already deployed within Australian organizations. Open BIM approaches using Industry Foundation Classes provide flexibility for multi-vendor environments.

Sustainability analysis tools respond to Australia's commitment to net-zero emissions by 2050 and growing ESG reporting requirements. BIM systems incorporating energy modeling, material optimization, and lifecycle assessment capabilities help construction firms demonstrate environmental performance.

A-Bots.com builds BIM solutions incorporating these requirements, developing platforms that address Australian regulatory frameworks, business practices, and operational conditions rather than requiring users to adapt workflows to software designed for other markets.

Integration with Emerging Technologies

Advanced BIM implementations increasingly integrate with complementary technologies enhancing project visualization, analysis, and management:

Digital twin capabilities extend BIM from design and construction phases into ongoing facility operations. By connecting BIM models with Internet of Things sensors installed within completed buildings, organizations create living digital representations supporting predictive maintenance, energy optimization, and space utilization analysis.

Virtual and augmented reality integration enables stakeholders to experience designs before construction begins. Project teams can conduct virtual walkthroughs identifying potential issues, clients can visualize completed spaces, and construction workers can access augmented instructions overlaying digital information onto physical job sites.

Artificial intelligence applications analyze BIM data to identify design conflicts, optimize construction sequences, predict material requirements, and estimate project timelines with increasing accuracy. Machine learning algorithms trained on historical project data improve prediction capabilities over time.

A-Bots.com develops BIM solutions incorporating these advanced capabilities, building platforms that position Australian construction firms at the forefront of industry innovation.

Digital Twins for Mining: Australia's Global Leadership Position

The Mining Technology Landscape

Australia maintains global leadership in mining technology adoption, with the world's largest fleet of autonomous trucks numbering 927 vehicles as of July 2024, far exceeding China with 562 and Canada with 289. This technological sophistication extends to digital twin implementations that create virtual replicas of mining operations enabling simulation, optimization, and predictive analysis.

The nation's mining sector has established an extensive research and development network encompassing 65 programs with Australian universities, supported by initiatives including the Trailblazer Universities Programme with AUD 370.3 million in federal government funding for new research capabilities and commercialization outcomes.

Major mining companies including BHP, Rio Tinto, and Newcrest actively deploy digital twin technology. Newcrest has worked for several years on digitally replicating its flagship Cadia mine in New South Wales, demonstrating the industry's commitment to comprehensive digital transformation.

Digital Twin Technical Architecture

Mining digital twins require sophisticated technical architectures integrating multiple data sources, analytical capabilities, and visualization systems:

Data acquisition layers collect information from diverse sources including geological surveys, equipment sensors, production systems, environmental monitoring, and satellite imagery. Integration challenges arise from legacy systems using varied protocols and data formats, requiring middleware solutions that normalize and contextualize incoming data streams.

Spatial modeling components create three-dimensional representations of mine geometry, ore bodies, infrastructure, and equipment. These models incorporate geological uncertainty, updating dynamically as exploration and production activities reveal new information about subsurface conditions.

Simulation engines enable testing of alternative operational scenarios without disrupting actual production. Engineers can evaluate different extraction sequences, equipment deployments, and processing configurations, identifying optimal approaches before implementation.

Predictive analytics applications apply machine learning algorithms to historical data, forecasting equipment failures, production rates, and resource recovery outcomes. These predictions enable proactive maintenance scheduling, inventory optimization, and more accurate production planning.

Visualization interfaces present complex operational data in intuitive formats supporting decision-making by personnel ranging from equipment operators to executive leadership. Mobile applications extend access to remote locations common in Australian mining operations.

A-Bots.com develops custom digital twin platforms incorporating these capabilities, building solutions tailored to specific mining operations rather than generic systems requiring extensive customization.

Applications Across Mining Operations

Digital twin technology supports optimization throughout the mining value chain:

Exploration and planning applications model ore body characteristics, simulating alternative mine designs to maximize resource recovery while minimizing environmental impact and operational costs. Engineers can test different pit geometries, underground configurations, and development sequences, evaluating economic outcomes before committing capital.

Production optimization applications analyze real-time equipment performance, identifying bottlenecks and inefficiencies. Integration with autonomous equipment systems enables coordinated fleet management, optimizing haul routes and loading sequences to maximize throughput.

Processing optimization applications model mineral processing circuits, simulating crushing, grinding, and flotation operations to maximize recovery rates while minimizing energy consumption. Digital twins can identify optimal operating parameters for varying ore characteristics, adjusting setpoints as feed material changes.

Maintenance optimization applications predict equipment failures before they occur, enabling scheduled repairs that minimize unplanned downtime. By analyzing sensor data patterns preceding historical failures, machine learning algorithms identify early warning indicators for developing problems.

Environmental management applications monitor emissions, water usage, and land disturbance, supporting regulatory compliance and sustainability reporting. Digital twins can simulate environmental impacts of planned activities, identifying potential issues before they materialize.

Development Considerations for Mining Applications

Building effective digital twin solutions for Australian mining operations requires understanding industry-specific challenges:

Connectivity constraints arise from remote locations where mining operations typically occur. Solutions must function effectively with intermittent or bandwidth-limited network connections, caching data locally and synchronizing when connectivity permits.

Integration with existing systems including mine planning software, fleet management systems, and enterprise resource planning platforms requires careful interface design. Mining operations have substantial investments in current technology stacks, and digital twin solutions must complement rather than replace these systems.

Security requirements reflect the critical nature of mining infrastructure and the sensitive commercial information contained within digital twin platforms. Cybersecurity architectures must protect against both external threats and insider risks.

Scalability needs accommodate growth from pilot implementations to enterprise-wide deployment. Solutions architected for single-site trials may require significant rearchitecting to support multi-site operations generating substantially larger data volumes.

Change management support helps mining organizations realize value from digital twin investments. Technology implementation alone rarely delivers expected benefits without accompanying organizational changes in decision-making processes, skill development, and performance management.

A-Bots.com addresses these considerations throughout the development process, delivering digital twin solutions that integrate successfully within complex mining operational environments.

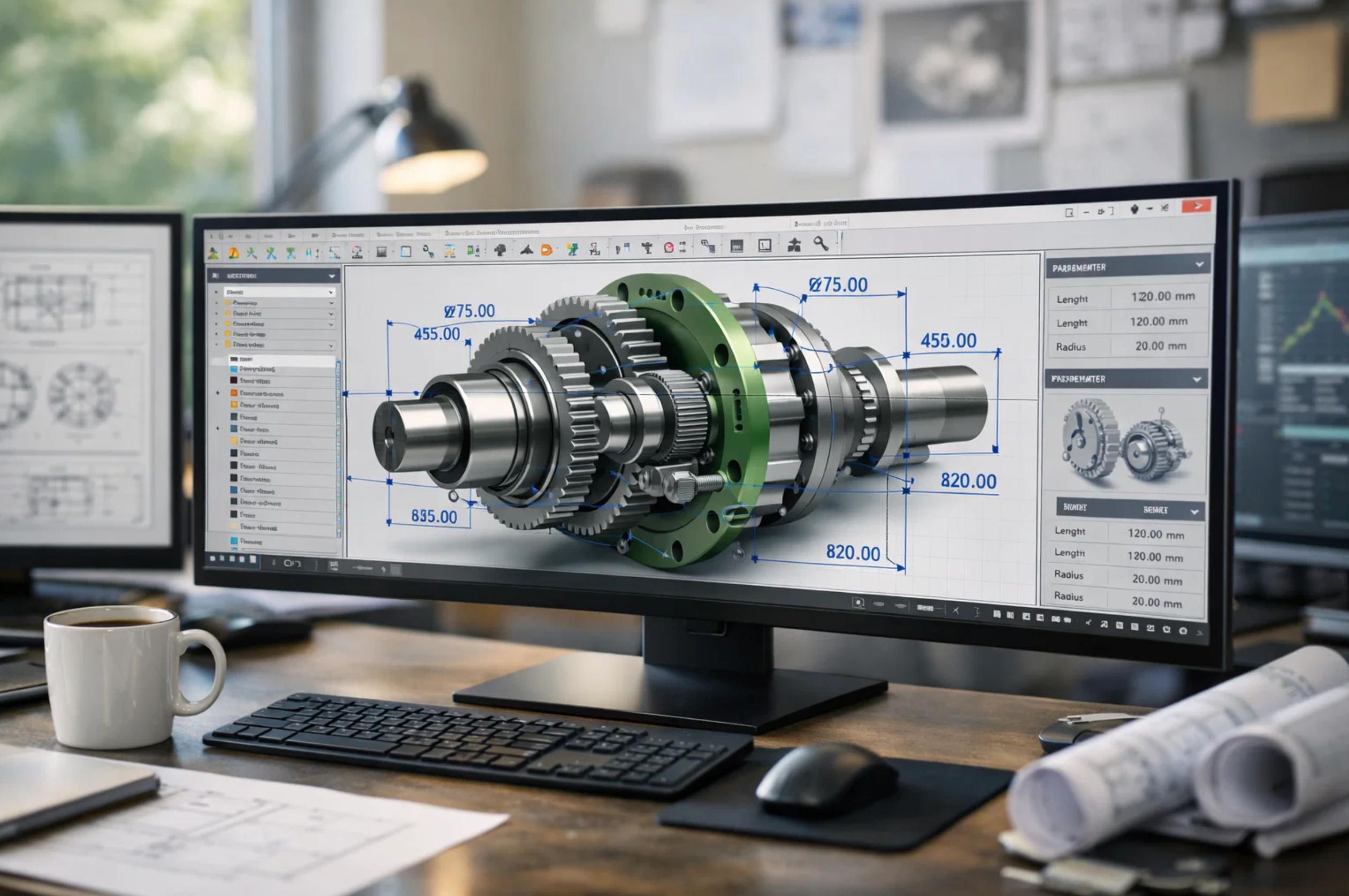

3D Modeling and CAD Development: Technical Capabilities

Core Development Competencies

A-Bots.com maintains comprehensive capabilities for developing custom CAD and 3D modeling applications:

Geometric modeling engines enable creation and manipulation of three-dimensional objects using various representation schemes including boundary representation, constructive solid geometry, and subdivision surfaces. Selection of appropriate geometric kernel technologies depends on application requirements including precision, performance, and interoperability objectives.

Parametric design capabilities allow users to define relationships between model elements, automatically updating dependent features when parameters change. This approach accelerates design iteration and ensures consistency across related components.

Assembly modeling functionality manages relationships between multiple parts within complex products or structures. Constraint systems maintain proper positioning as designs evolve, while interference checking identifies potential conflicts.

Drawing generation automates creation of two-dimensional documentation from three-dimensional models, producing engineering drawings compliant with Australian drafting standards and organizational conventions.

Data exchange implementations support import and export of standard file formats including STEP, IGES, DXF, and DWG, enabling interoperability with external systems and collaboration partners using different software platforms.

Visualization capabilities render photorealistic images and animations from model data, supporting design review, client presentations, and marketing applications.

Integration with Analysis and Simulation Tools

Modern engineering workflows require tight integration between CAD systems and analysis tools:

Finite element analysis integration enables structural, thermal, and fluid dynamics simulations directly from CAD geometry. Meshing algorithms convert continuous geometric representations into discrete element models suitable for numerical analysis.

Computational fluid dynamics capabilities simulate air and fluid flow around and through designed objects, supporting aerodynamic optimization, heat exchanger design, and similar applications.

Kinematic and dynamic simulation evaluates mechanical system behavior, analyzing motion, forces, and energy throughout operating cycles.

Manufacturing simulation validates that designed parts can be produced using intended processes, identifying potential tooling interferences, accessibility issues, and process parameter requirements.

A-Bots.com develops integrated solutions combining design and analysis capabilities, streamlining engineering workflows that traditionally required manual data transfer between disconnected applications.

Cloud Architecture and Collaboration Features

Contemporary CAD development increasingly emphasizes cloud deployment and collaborative capabilities:

Cloud-native architectures leverage scalable computing resources for demanding operations including rendering, simulation, and optimization. Pay-per-use models reduce capital requirements while providing access to computational capacity exceeding practical on-premises infrastructure.

Real-time collaboration enables multiple users to work simultaneously on shared models, seeing each other's changes as they occur. Version control systems track modification history, enabling review of evolution and recovery of previous states.

Web-based interfaces expand access beyond traditional engineering workstations, enabling design review from tablets, smartphones, and standard computers without specialized graphics hardware.

API architectures support integration with enterprise systems and custom workflow automation, enabling organizations to embed CAD capabilities within broader business processes.

A-Bots.com builds cloud-ready CAD solutions incorporating these capabilities while addressing data sovereignty requirements relevant to Australian organizations managing sensitive intellectual property.

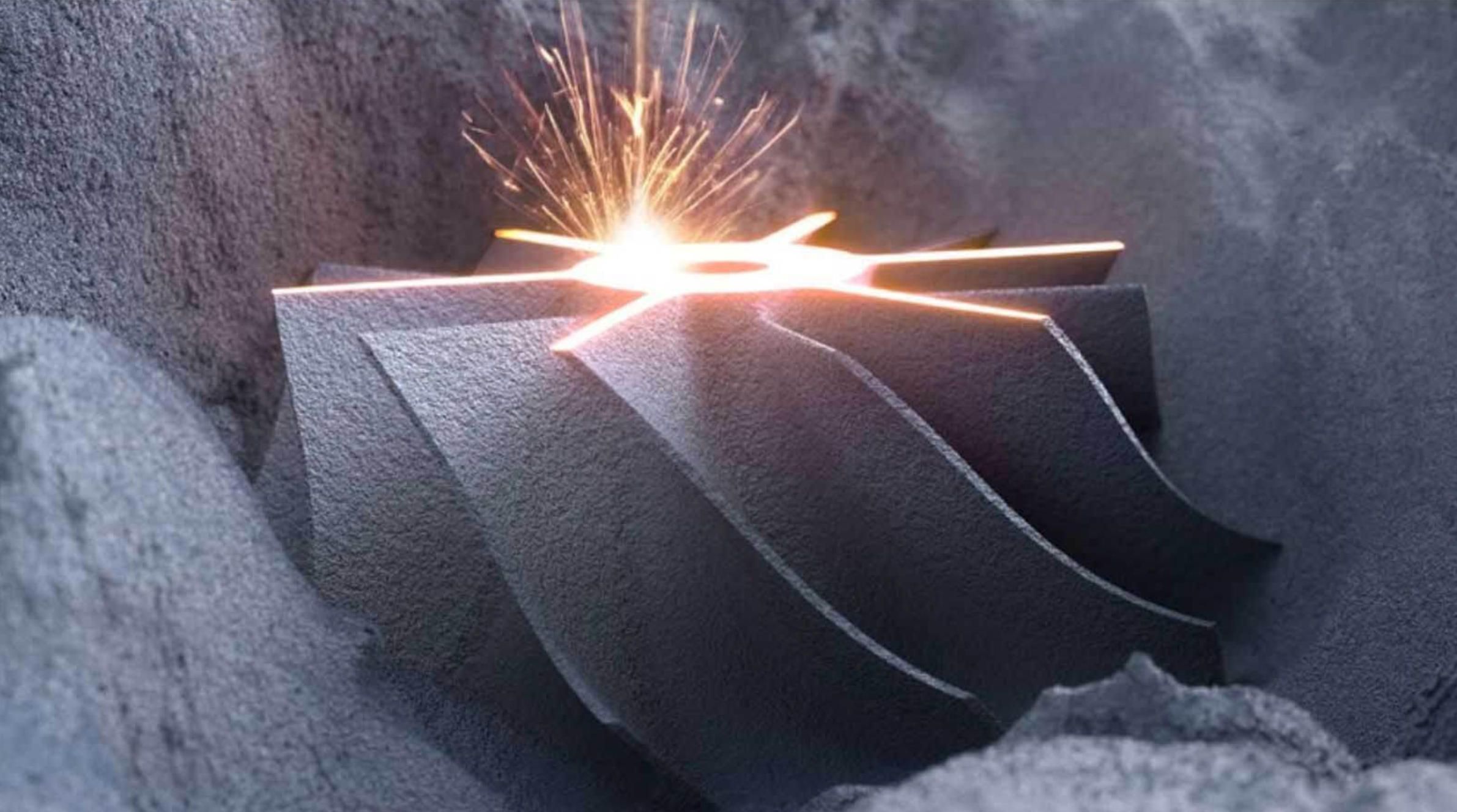

Advanced Manufacturing and 3D Printing Solutions

The Australian Additive Manufacturing Market

Australia's 3D printing market demonstrates exceptional growth potential, valued at AUD 821.94 million in 2025 with projections reaching AUD 4.56 billion by 2035, representing a compound annual growth rate of 18.7%. Alternative estimates place the 2024 market at USD 570 million, growing to USD 2.52 billion by 2033 at 17.95% CAGR.

Several factors drive this expansion:

Industrial manufacturing modernization creates demand for rapid prototyping and low-volume production capabilities that additive manufacturing delivers more cost-effectively than traditional approaches for appropriate applications.

Supply chain resilience concerns, heightened by pandemic disruptions and geopolitical uncertainties, motivate localized production capabilities reducing dependence on international suppliers. Australia's geographic isolation amplifies these considerations.

Healthcare innovation requires patient-specific devices including surgical guides, implants, and anatomical models that 3D printing enables economically at quantities of one.

Defense requirements for rapid deployment capabilities and maintenance of aging equipment drive adoption of field-deployable additive manufacturing systems.

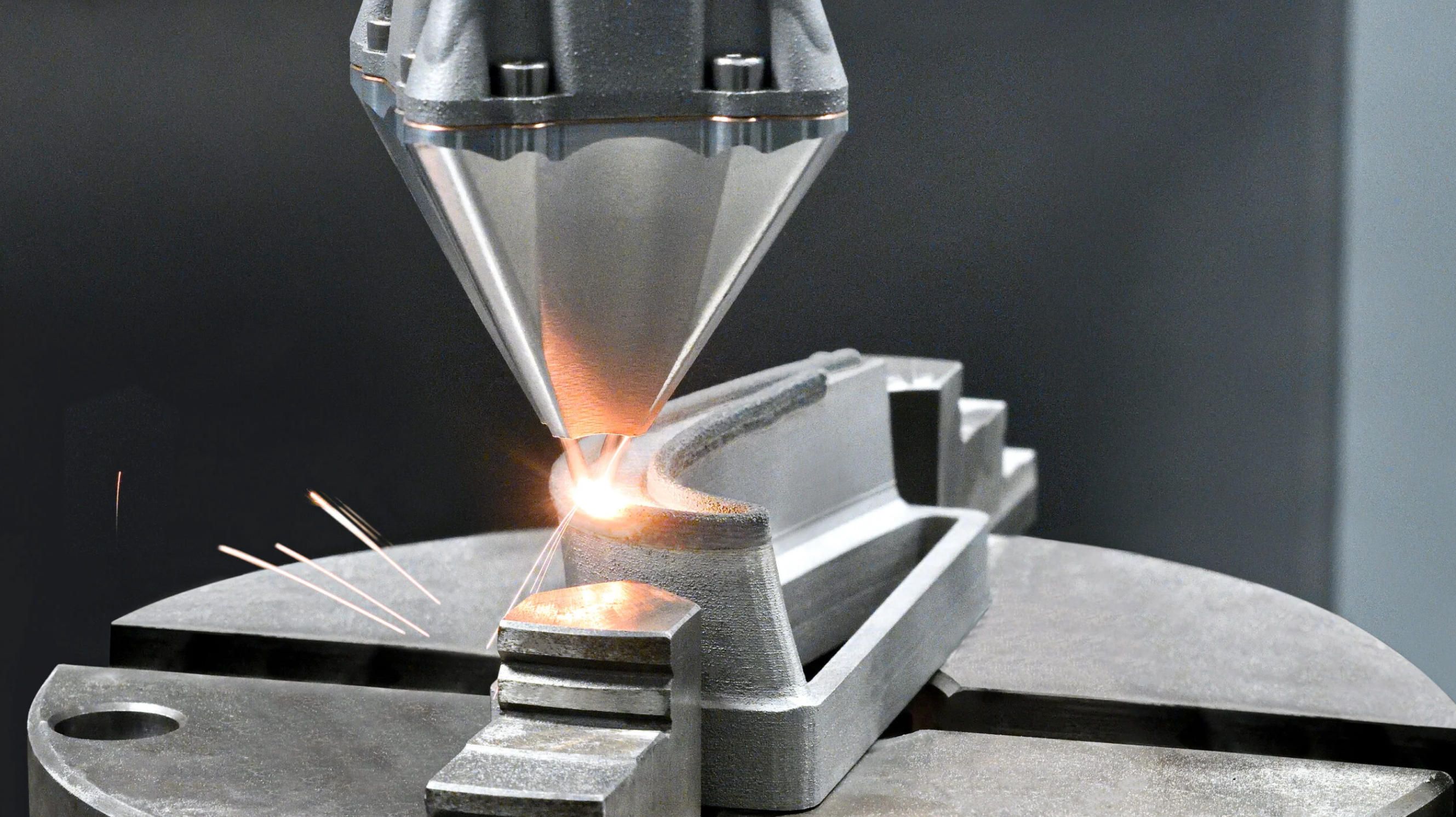

Australian 3D Printing Industry Leaders

Australia has developed notable capabilities in metal additive manufacturing, particularly cold spray technologies:

SPEE3D, based near Melbourne, manufactures cold spray additive manufacturing systems capable of producing metal parts without melting material. The company's systems have been adopted by military organizations in the United States, Japan, United Kingdom, and other nations for field maintenance and rapid manufacturing applications.

Titomic similarly specializes in cold spray technology, with applications in aerospace and defense sectors including a joint venture with Repkon in Turkey for barrel manufacturing. The company maintains contracts with major aerospace firms including Boeing.

AML3D, of Adelaide, has pivoted from contract manufacturing to original equipment manufacturing, with its Wire-Arc Additive Manufacturing technology gaining traction particularly in US military applications. The company reported revenue growth exceeding 1,000% in fiscal 2024, driven primarily by US Navy submarine program contracts.

These companies demonstrate Australia's capacity for innovation in additive manufacturing, creating opportunities for software development supporting their platforms and broader industry adoption.

Software Requirements for Additive Manufacturing

Effective utilization of 3D printing technology requires sophisticated software capabilities:

Design for additive manufacturing tools optimize geometries for layer-by-layer production, incorporating support structure generation, orientation optimization, and feature design suitable for selected processes.

Build preparation software slices three-dimensional models into individual layers, generating tool paths controlling material deposition or energy source movement during production.

Process simulation predicts thermal behavior, residual stresses, and potential distortion during manufacturing, enabling proactive design modifications avoiding costly trial-and-error approaches.

Quality assurance systems monitor production processes in real-time, detecting anomalies potentially indicating defects. Machine learning algorithms trained on historical data improve detection accuracy over time.

Post-processing workflow management coordinates secondary operations including heat treatment, machining, and inspection required to complete manufactured parts.

Materials database management tracks properties of available materials, qualification status, and usage history supporting traceability requirements in regulated industries.

A-Bots.com develops software solutions addressing these requirements, building applications that integrate with specific additive manufacturing equipment or provide platform-independent capabilities supporting multi-vendor environments.

Engineering Services Outsourcing: Market Dynamics and Opportunities

The Australian Outsourcing Landscape

Australia's engineering services outsourcing market demonstrates substantial scale and growth potential. The broader outsourcing services market generated USD 62 billion in 2024 revenue and projects growth to USD 122.6 billion by 2030, representing a 12.3% compound annual growth rate. Engineering services outsourcing constitutes the largest segment at 86.75% market share.

Several factors drive outsourcing adoption:

Cost efficiency motivations seek to leverage lower labor costs available in offshore locations while maintaining quality standards. Australian wages and salaries increased 5.7% in the year to March 2025, intensifying cost pressures on engineering-intensive industries.

Skills access addresses shortages in specialized engineering disciplines. Australia's manufacturing sector faces documented labor shortages, and specialized expertise in areas including automation, digital engineering, and advanced simulation may be more readily available through global talent pools.

Scalability requirements enable organizations to adjust engineering capacity as project demands fluctuate without maintaining permanent staff for peak periods.

Focus on core competencies allows organizations to concentrate internal resources on activities providing competitive differentiation while outsourcing commoditized engineering tasks.

Engineering Disciplines and Services

Outsourced engineering services span diverse disciplines:

Mechanical engineering services include product design, CAD modeling, finite element analysis, and manufacturing engineering support.

Electrical engineering services encompass circuit design, PCB layout, embedded systems development, and power systems engineering.

Civil and structural engineering services include structural analysis, infrastructure design, and construction documentation.

Software engineering services address embedded systems, industrial control software, and engineering application development.

Process engineering services support chemical processing, manufacturing workflow optimization, and automation system design.

Testing and validation services provide independent verification of designs through analysis, simulation, and physical testing.

Quality and Communication Considerations

Successful engineering outsourcing requires attention to quality management and communication:

Quality management systems ensure outsourced deliverables meet required standards. ISO certification provides baseline assurance, while project-specific quality plans address unique requirements.

Communication protocols establish expectations for responsiveness, meeting schedules, and documentation practices. Time zone differences between Australia and common outsourcing destinations require explicit agreement on availability and turnaround expectations.

Intellectual property protection addresses concerns about confidential design information shared with external parties. Contractual provisions, access controls, and security practices should reflect sensitivity of shared information.

Technical alignment ensures outsourcing partners possess appropriate skills, tools, and experience for assigned work. Capability assessments and trial projects help verify alignment before committing to major engagements.

A-Bots.com provides engineering services addressing these considerations, combining technical expertise with project management practices supporting successful distributed collaboration.

Custom Software Development for Engineering Applications

Development Methodology for Engineering Software

Building effective engineering software requires methodologies accommodating technical complexity and domain expertise:

Requirements engineering for engineering applications demands deep understanding of target workflows, user needs, and technical constraints. Domain experts must participate actively in requirements definition, ensuring developed solutions address actual operational challenges.

Architecture design considers performance requirements for computationally intensive operations, scalability needs for growing data volumes, and integration requirements for connecting with existing systems. Engineering applications often require careful attention to numerical precision and computational efficiency.

Iterative development enables progressive refinement based on user feedback. Engineering software users typically have strong opinions about workflow design and feature priorities; iterative approaches allow adjustments based on actual experience rather than abstract requirements.

Testing strategies for engineering software include validation against analytical solutions, comparison with established software, and evaluation by domain experts. Verification of computational correctness requires particular attention given potential consequences of calculation errors in engineering applications.

Technology Selection Considerations

Engineering software development involves numerous technology selection decisions:

Programming languages selection balances factors including computational performance, developer productivity, and ecosystem maturity. C++ remains common for performance-critical computational components, while Python often serves for scripting, automation, and data analysis tasks. Web technologies enable browser-based interfaces expanding accessibility.

Geometric kernel selection provides foundation for 3D modeling capabilities. Options include commercial kernels such as Parasolid and ACIS, open source alternatives such as Open CASCADE, and custom implementations for specialized requirements.

Database technologies accommodate diverse data types and access patterns characteristic of engineering applications. Relational databases support structured transactional data, while document databases and spatial databases address less structured and geometric data respectively.

Cloud platform selection considers factors including geographic availability, service offerings, pricing, and compliance capabilities. Major platforms including AWS, Azure, and Google Cloud each maintain Australian regions addressing data sovereignty requirements.

Visualization technologies render complex engineering models for user interaction. Options range from established desktop graphics libraries to web-based approaches using WebGL and related technologies.

Integration Architecture Patterns

Engineering applications typically require integration with multiple external systems:

Enterprise system integration connects engineering applications with ERP, PLM, and other business systems, enabling data sharing that reduces manual entry and ensures consistency.

Engineering tool integration enables data exchange with CAD systems, analysis tools, and other specialized applications. Standard formats including STEP, IFC, and neutral file formats facilitate interoperability, though custom integrations may provide richer functionality.

Equipment integration connects software systems with physical equipment including manufacturing systems, monitoring infrastructure, and laboratory instruments.

Cloud service integration leverages external capabilities including AI/ML services, rendering farms, and specialized computational resources.

A-Bots.com architects integration approaches appropriate for specific client environments, addressing technical requirements while managing complexity and ongoing maintenance considerations.

Industry-Specific Solutions

Aerospace and Defense Engineering

Australia's aerospace and defense sector presents significant engineering software opportunities:

Defense investment programs including those associated with the AUKUS alliance drive demand for engineering capabilities supporting advanced technology development. Australia's commitment to building nuclear-powered submarines creates unprecedented requirements for specialized engineering software.

Aerospace manufacturing growth reflects both defense requirements and civil aviation sector development. Engineering software supports design, analysis, and manufacturing of aircraft components, drone systems, and space technology.

Certification requirements in aerospace demand rigorous documentation and traceability capabilities that engineering software must support. Regulatory compliance adds complexity but also creates differentiation opportunities for solutions specifically addressing certification workflows.

Healthcare and Medical Devices

Healthcare engineering software requirements reflect unique industry characteristics:

Regulatory compliance with Therapeutic Goods Administration requirements shapes software development for medical device applications. Quality management system integration, design history file documentation, and validation procedures must be incorporated from project inception.

Patient-specific device development enabled by 3D printing requires software supporting medical image processing, design customization, and manufacturing preparation.

Hospital innovation programs, including Western Australia's RPH Innovation Hub launched in 2024, create demand for accessible design tools supporting clinical staff participation in device development.

Resources and Energy

Australia's resources and energy sector presents diverse engineering software requirements:

Mining engineering software supports activities from exploration through extraction, processing, and closure. Digital twin platforms, mine planning systems, and autonomous equipment integration represent major development areas.

Oil and gas engineering applications address facility design, pipeline engineering, and production optimization. Digital twin technology increasingly supports lifecycle management of offshore and onshore infrastructure.

Renewable energy engineering software supports design and optimization of solar, wind, and storage installations. Australia's renewable energy expansion creates growing demand for engineering tools supporting these technologies.

Testing and Quality Assurance Services

Engineering Software Testing Requirements

Engineering software presents particular testing challenges requiring specialized approaches:

Numerical accuracy verification ensures calculations produce correct results within acceptable tolerances. Testing against analytical solutions, benchmark problems, and alternative software implementations helps verify computational correctness.

Performance testing evaluates response times, throughput, and resource utilization under realistic workloads. Engineering applications often involve computationally intensive operations where performance significantly impacts user productivity.

Usability testing with domain experts ensures interfaces support efficient workflows and match user expectations. Engineering software users typically have substantial experience with existing tools, and new solutions must demonstrate clear advantages to justify switching costs.

Integration testing verifies correct operation within broader system environments, including data exchange with external applications and appropriate behavior across organizational boundaries.

Security testing addresses vulnerabilities potentially exposing sensitive engineering data or enabling unauthorized system access.

A-Bots.com Testing Capabilities

A-Bots.com provides comprehensive testing services for engineering applications:

Existing application testing helps organizations identify deficiencies in current software, providing actionable recommendations for improvement or replacement decisions.

Development testing integrated throughout the development lifecycle catches issues early when correction costs remain low.

Independent verification and validation provides external assessment supporting regulatory submissions or organizational governance requirements.

Performance optimization identifies bottlenecks and implements improvements enhancing application responsiveness and scalability.

Partnership Engagement Models

Project-Based Development

Project-based engagements address defined requirements within established scope, schedule, and budget parameters:

Fixed-price projects provide cost certainty for well-defined requirements, with A-Bots.com assuming delivery risk in exchange for agreed pricing.

Time-and-materials projects accommodate evolving requirements or exploratory development where scope cannot be fully defined initially.

Milestone-based projects structure work into discrete phases with defined deliverables and payment triggers.

Dedicated Development Teams

Dedicated team arrangements provide sustained development capacity:

Team augmentation integrates A-Bots.com developers within client organizations, working under client direction alongside existing staff.

Managed teams operate semi-autonomously under A-Bots.com management, with client involvement primarily at requirements and review stages.

Center of excellence arrangements establish specialized capabilities serving multiple internal client teams or business units.

Ongoing Support and Maintenance

Post-deployment support ensures continued application effectiveness:

Corrective maintenance addresses defects discovered during production operation.

Adaptive maintenance accommodates changes in operating environments, integrated systems, or regulatory requirements.

Perfective maintenance implements enhancements responding to evolving user needs or competitive pressures.

Preventive maintenance proactively addresses technical debt, security vulnerabilities, and platform currency.

Simulation and Finite Element Analysis Solutions

The Growing Demand for Simulation Software

Australian industries increasingly recognize simulation as essential for competitive product development and operational optimization. Rather than relying exclusively on physical prototyping and testing, organizations employ computational simulation to evaluate designs virtually, reducing development cycles and costs while enabling exploration of more design alternatives.

The global simulation software market demonstrates robust growth, with finite element analysis, computational fluid dynamics, and multiphysics simulation platforms becoming standard tools across engineering disciplines. Australian adoption follows global trends while reflecting particular emphasis on applications relevant to dominant local industries including mining equipment, resources processing, construction, and defense.

Key drivers of simulation adoption include:

Product complexity increases as customers demand more sophisticated capabilities within constrained size, weight, and cost parameters. Simulation enables engineers to optimize designs against multiple competing objectives simultaneously.

Time-to-market pressures intensify as competitive cycles accelerate across industries. Simulation reduces physical testing iterations, enabling faster progression from concept to production.

Quality expectations rise as customers become less tolerant of product failures. Simulation identifies potential failure modes before physical manifestation, enabling proactive design improvements.

Regulatory requirements in industries including medical devices, aerospace, and construction mandate demonstration of safety and performance through analysis, making simulation capability essential for market access.

Sustainability considerations motivate optimization of material usage, energy consumption, and product lifecycle impacts that simulation enables.

Technical Capabilities in Simulation Development

A-Bots.com develops custom simulation solutions addressing requirements unmet by commercial packages:

Specialized physics implementations address phenomena outside standard commercial software scope. Industries with unique physical processes may require custom simulation capabilities unavailable in general-purpose tools.

Workflow integration embeds simulation within broader engineering processes, automating data transfer between CAD systems, simulation tools, and downstream applications. Integrated workflows reduce manual intervention while ensuring consistency.

Optimization algorithms automatically explore design spaces seeking configurations satisfying specified objectives and constraints. Automated optimization delivers solutions human designers might never discover through manual iteration.

Uncertainty quantification assesses sensitivity of simulation results to input parameter variations, characterizing confidence in predictions and identifying critical parameters requiring precise specification.

High-performance computing deployment leverages cluster and cloud computing resources for computationally demanding simulations. Efficient parallelization enables analysis of problems exceeding single-workstation capability.

Results visualization transforms numerical simulation outputs into intuitive visual representations supporting interpretation and communication. Effective visualization helps non-specialists understand simulation findings.

Industry Applications of Simulation Technology

Simulation technology applies across industries represented in the Australian economy:

Mining equipment simulation evaluates structural integrity, fatigue life, and dynamic behavior of equipment operating in demanding conditions. Simulation identifies potential failures before field occurrence, improving equipment reliability and safety.

Resources processing simulation models material flows, thermal processes, and chemical reactions within processing facilities. Optimization of processing parameters improves recovery rates while reducing energy consumption and environmental impact.

Construction simulation evaluates structural performance under various loading conditions including seismic events, wind loading, and thermal effects. Australian construction codes require demonstration of structural adequacy through analysis.

Defense applications employ simulation for vehicle survivability analysis, weapon effects modeling, and system performance evaluation. Simulation supports procurement decisions and operational planning.

Medical device simulation demonstrates safety and efficacy supporting regulatory submissions. Finite element analysis of implants, computational fluid dynamics of delivery devices, and biomechanical modeling of device-tissue interactions address regulatory requirements.

IoT Integration and Smart Engineering Systems

Connected Engineering Infrastructure

The Internet of Things transforms engineering from discrete design activities into continuous feedback loops connecting design, production, operation, and improvement. Sensors embedded in products and production equipment generate data streams enabling real-time performance monitoring, predictive maintenance, and design optimization based on actual operating experience.

Australian industries adopt IoT technologies across diverse applications:

Mining operations deploy extensive sensor networks monitoring equipment condition, environmental parameters, and production metrics. Connected systems enable remote operation of equipment in hazardous or remote locations.

Building systems incorporate sensors monitoring occupancy, environmental conditions, and equipment status. Smart building platforms optimize energy consumption while maintaining occupant comfort.

Manufacturing facilities connect production equipment through industrial IoT platforms, enabling real-time visibility into production status and equipment health.

Infrastructure systems including bridges, pipelines, and electrical networks employ structural health monitoring identifying degradation before failure occurs.

Software Requirements for IoT Engineering Applications

IoT engineering applications require sophisticated software capabilities:

Data acquisition systems collect information from diverse sensor types using varied communication protocols. Edge computing capabilities filter and preprocess data, reducing bandwidth requirements while enabling rapid local response.

Time-series databases efficiently store and query the continuous data streams characteristic of IoT applications. Specialized database technologies address the unique performance requirements of high-volume time-series data.

Analytics platforms process sensor data to extract actionable insights. Rule-based alerting identifies threshold exceedances, while machine learning algorithms detect subtle patterns indicating developing problems.

Visualization dashboards present current status and historical trends in intuitive formats. Geographic information system integration provides spatial context for distributed sensor networks.

Integration with engineering systems connects IoT data with CAD models, digital twins, and enterprise systems, enabling sensor data to inform design decisions and operational planning.

Security architectures protect IoT systems against cyberattacks potentially compromising operational safety or exposing sensitive data. Industrial IoT security requires particular attention given potential physical consequences of successful attacks.

A-Bots.com develops IoT engineering solutions incorporating these capabilities, building platforms that transform sensor data into engineering value.

Case Study: Predictive Maintenance Systems

Predictive maintenance represents a high-value IoT application where A-Bots.com capabilities directly translate to client benefit:

Condition monitoring systems collect vibration, temperature, current, and other parameters from operating equipment. Sensor selection and placement based on engineering understanding of failure modes ensures relevant data capture.

Feature extraction algorithms transform raw sensor signals into condition indicators meaningful for maintenance decisions. Engineering knowledge informs feature selection, ensuring extracted characteristics correlate with equipment health.

Machine learning models trained on historical data predict remaining useful life and probability of failure. Model accuracy improves over time as additional failure examples augment training datasets.

Maintenance optimization algorithms schedule maintenance activities balancing failure risk against intervention costs. Optimization considers spare parts availability, workforce capacity, and production scheduling constraints.

Integration with enterprise asset management systems ensures maintenance recommendations flow into work order systems, and maintenance history feeds back into predictive models.

Augmented and Virtual Reality for Engineering

Immersive Visualization Technologies

Augmented and virtual reality technologies offer powerful capabilities for engineering visualization, training, and collaboration:

Virtual reality creates fully immersive digital environments where users can experience designs at full scale before physical construction. Design reviews conducted in VR identify issues invisible in traditional representations, while client presentations build understanding and confidence.

Augmented reality overlays digital information onto physical environments, enabling field workers to access relevant data without diverting attention from tasks. Maintenance technicians can view equipment schematics, work instructions, and sensor readings while hands remain free for work.

Mixed reality blends physical and digital elements, enabling interaction with virtual objects as though physically present. Collaborative design sessions can include participants examining shared virtual models from different physical locations.

Engineering Applications of Immersive Technologies

Immersive technologies address diverse engineering requirements:

Design review sessions benefit from ability to experience designs at actual scale rather than viewing scaled representations on screens. Stakeholders unfamiliar with engineering drawings can understand and provide meaningful feedback on designs presented in VR.

Construction visualization shows clients completed facilities before ground is broken, building confidence and identifying desired changes while modifications remain inexpensive.

Training applications prepare personnel for complex procedures using realistic simulations. Equipment operators, maintenance technicians, and emergency responders can develop skills without risking personnel or equipment.

Remote assistance connects field workers with experts who can see what workers see and provide guidance overlaid on their view. Expertise can be delivered regardless of physical location.

Sales and marketing applications showcase products and facilities to prospects who cannot visit physical locations. Immersive experiences create engagement exceeding traditional presentations.

Development Considerations for Immersive Applications

Building effective immersive applications requires attention to unique technical considerations:

Performance optimization ensures comfortable user experiences. Frame rates below critical thresholds cause motion sickness, requiring careful optimization of rendering pipelines.

3D asset creation produces models suitable for real-time rendering. Assets must balance visual fidelity against performance impact, with level-of-detail systems adjusting complexity based on viewing distance.

Interaction design enables intuitive manipulation of virtual objects. Natural interaction patterns reduce training requirements while improving user satisfaction.

Hardware selection balances capability, cost, and deployment practicality. Head-mounted displays range from smartphone-based systems through tethered high-end devices to standalone all-in-one units.

Integration with engineering data sources ensures immersive experiences reflect current design states. Connection with CAD and BIM systems enables visualization of latest design versions without manual export processes.

A-Bots.com develops immersive visualization applications addressing specific client requirements, from design review tools to field support applications and training simulations.

Artificial Intelligence and Machine Learning in Engineering

AI Transformation of Engineering Practice

Artificial intelligence and machine learning increasingly augment engineering capabilities:

Generative design algorithms explore vast design spaces, producing solutions meeting specified objectives and constraints that human designers might never conceive. AI-generated designs often exhibit unconventional geometries optimized for performance rather than manufacturing convenience.

Topology optimization determines optimal material distribution within defined volumes, identifying structures achieving required strength with minimum mass. Resulting designs frequently appear organic, reflecting optimization for load paths rather than manufacturing simplicity.

Design automation captures engineering knowledge in rule-based systems generating designs automatically for routine applications. Automation frees engineers for challenging problems while ensuring consistent quality for standard solutions.

Defect detection applies computer vision to inspection images, identifying quality issues with consistency exceeding human inspectors. Machine learning models trained on defect examples generalize to detect previously unseen defect instances.

Predictive modeling forecasts outcomes based on historical data patterns. Applications range from equipment failure prediction through project schedule estimation to market demand forecasting.

Natural language processing extracts information from unstructured text including specifications, reports, and correspondence. Automated document analysis accelerates information retrieval while reducing risk of overlooking relevant content.

Implementation Considerations

Successful AI implementation in engineering contexts requires attention to particular considerations:

Data quality fundamentally determines achievable model performance. Engineering organizations must assess available data, address quality gaps, and establish processes ensuring ongoing data integrity.

Explainability requirements in engineering applications often exceed typical machine learning practice. Engineers and regulators may require understanding of why models produce specific outputs, not merely what outputs result.

Validation approaches must demonstrate model performance on problems representative of intended applications. Standard machine learning metrics may inadequately characterize suitability for engineering decisions.

Integration with engineering workflows ensures AI capabilities become practical tools rather than isolated curiosities. Seamless incorporation within existing processes encourages adoption and enables value realization.

Change management addresses human factors in AI adoption. Engineers may resist perceived threats to professional judgment, requiring careful attention to positioning AI as augmentation rather than replacement.

A-Bots.com develops AI solutions for engineering applications, combining machine learning expertise with engineering domain understanding to deliver systems that earn user trust through demonstrated value.

Reverse Engineering and 3D Scanning Solutions

Digital Capture of Physical Objects

Reverse engineering transforms physical objects into digital models enabling analysis, modification, and reproduction. 3D scanning technologies capture geometric data from existing objects, creating point clouds or mesh representations serving as foundations for CAD model reconstruction.

Applications driving reverse engineering adoption include:

Legacy equipment maintenance requires documentation for components where original drawings no longer exist or never existed. Scanning captures current geometry enabling spare part fabrication and modification design.

Competitor analysis examines rival products to understand design approaches and identify improvement opportunities. Dimensional analysis reveals manufacturing tolerances and material usage.

Quality inspection compares manufactured parts against design intent, identifying deviations requiring correction. Scan-to-CAD comparison automates dimensional verification.

Custom fitting creates products matched to individual anatomy or existing installations. Prosthetics, orthotics, and retrofit components benefit from capture of mating surfaces.

Cultural heritage preservation documents artifacts and structures in digital form, protecting against loss and enabling remote study.

3D Scanning Technology Landscape

Multiple scanning technologies address different application requirements:

Structured light scanning projects patterns onto surfaces, analyzing distortion to calculate surface geometry. Desktop structured light scanners offer high accuracy for appropriately sized objects.

Laser scanning measures distance through time-of-flight or phase-shift techniques, building point clouds through systematic surface coverage. Terrestrial laser scanning captures building-scale subjects.

Photogrammetry reconstructs geometry from multiple photographs, calculating surface points through image correlation. Photogrammetry offers flexibility and low equipment cost but requires appropriate subject characteristics.

Computed tomography penetrates solid objects using X-rays, revealing internal geometry invisible to surface scanning. CT scanning addresses objects with complex internal features.

Contact measurement uses physical probes to record point locations with high accuracy. Coordinate measuring machines offer precision exceeding optical methods for appropriate applications.

Software Development for Reverse Engineering Workflows

Effective reverse engineering requires sophisticated software capabilities:

Point cloud processing filters noise, registers multiple scans, and reduces data volumes to manageable sizes. Processing algorithms significantly impact downstream model quality.

Surface reconstruction converts point data into continuous surface representations suitable for engineering use. Algorithmic choices trade accuracy against smoothness and file size.

Feature recognition identifies geometric primitives including planes, cylinders, and spheres within scanned data. Recognized features enable parametric model construction.

CAD model reconstruction creates solid models from scan data, producing geometry suitable for modification and manufacturing. Reconstruction approaches range from automatic algorithms through interactive tools.

Deviation analysis compares scanned geometry against reference models, quantifying and visualizing differences. Analysis results inform quality decisions and process improvement.

A-Bots.com develops software supporting reverse engineering workflows, creating applications that transform physical objects into actionable digital assets.

Product Lifecycle Management Integration

Engineering Data Management Challenges

Engineering organizations generate massive data volumes including CAD models, drawings, specifications, analysis reports, and correspondence. Managing this information throughout product lifecycles presents substantial challenges:

Version control ensures engineers work with current information and can access historical versions when needed. Without systematic version management, teams risk incorporating obsolete information into current work.

Access control restricts sensitive information to authorized personnel while enabling appropriate collaboration. Engineering data often includes proprietary intellectual property requiring protection.

Search and retrieval capabilities help engineers find relevant information among massive repositories. Effective search saves time and reduces risk of overlooking existing solutions.

Workflow automation routes information through review and approval processes, ensuring appropriate oversight while minimizing delays. Automated workflows maintain audit trails supporting regulatory compliance.

Integration with authoring tools enables seamless access to managed data from within CAD and other applications engineers use daily. Integrated access encourages adoption and reduces friction.

PLM System Capabilities

Product Lifecycle Management systems address engineering data management requirements:

Document management provides version-controlled storage for engineering documents with metadata enabling search and organization.

Bill of materials management maintains structured product definitions linking components into assemblies and assemblies into products.

Change management tracks proposed modifications through evaluation and approval processes, maintaining records of decisions and rationale.

Configuration management identifies specific combinations of components comprising delivered products, supporting maintenance and regulatory compliance.

Project management coordinates engineering activities, tracking schedules, resources, and deliverables.

Integration capabilities connect PLM systems with CAD tools, ERP systems, and other enterprise applications.

Custom Development for PLM Environments

While commercial PLM platforms provide extensive baseline capabilities, organizations frequently require customization:

Industry-specific workflows adapt generic processes to particular regulatory requirements or business practices.

Legacy system integration connects PLM platforms with existing applications organizations cannot or choose not to replace.

Custom reporting extracts information in formats supporting specific decision-making needs.

User interface optimization simplifies common tasks and reduces training requirements for specific user populations.

Mobile access extends PLM capabilities to field personnel without access to traditional workstations.

A-Bots.com develops customizations and integrations for PLM platforms, extending commercial capabilities to address specific organizational requirements.

Compliance and Regulatory Considerations

Australian Regulatory Framework

Engineering software serving Australian industries must accommodate relevant regulatory requirements:

National Construction Code establishes minimum requirements for safety, health, amenity, and sustainability of buildings. Engineering software supporting construction must facilitate NCC compliance demonstration.

Work Health and Safety legislation requires elimination or minimization of risks associated with plant and structures. Engineering analysis supporting safety demonstrations must satisfy evidentiary standards.

Therapeutic Goods Administration regulates medical devices, requiring design controls and risk management processes that engineering software must support.

Defence industry security requirements apply to organizations participating in defence supply chains. Engineering systems handling classified information must satisfy accreditation requirements.

Environmental regulations require assessment and management of development impacts. Engineering software supporting environmental analysis must produce results suitable for regulatory submission.

International Standards Compliance

Engineering software frequently must comply with international standards:

ISO 9001 quality management systems require documented processes and records that engineering software must support creating and maintaining.

AS9100 aerospace quality management adds requirements beyond ISO 9001 that aerospace engineering software must accommodate.

ISO 13485 medical device quality management establishes requirements specific to medical device development that healthcare engineering software must address.

ISO 27001 information security management requires controls over engineering data that system architectures must implement.

Industry-specific standards including API, ASME, and AS/NZS standards establish technical requirements that engineering software must help users satisfy.

Building Compliance Into Software Design

A-Bots.com approaches compliance as fundamental design consideration rather than afterthought:

Requirements traceability maintains connections between requirements, designs, implementations, and tests, supporting demonstration that delivered systems satisfy specified needs.

Audit trail capabilities record actions taken within systems, enabling reconstruction of decision histories.

Electronic signature support provides legally valid approval records for regulated environments.

Validation documentation demonstrates that software performs as intended through systematic testing against requirements.

Change control processes ensure modifications undergo appropriate review before deployment to production systems.

A-Bots.com develops software satisfying Australian and international regulatory requirements, building compliance capabilities that reduce regulatory risk while supporting efficient operations.

Conclusion: Partnering for Engineering Software Excellence

Australia's engineering software market presents substantial opportunities across mining, construction, manufacturing, and specialized sectors including aerospace, healthcare, and energy. Market growth driven by digital transformation, productivity imperatives, and regulatory requirements creates sustained demand for sophisticated solutions.

A-Bots.com brings international perspective and proven development capabilities to Australian engineering software challenges. Our experience spanning diverse industries and technology domains enables us to deliver solutions addressing specific operational requirements rather than generic applications requiring extensive customization.

Whether your organization requires custom CAD and 3D modeling applications, digital twin platforms for complex operations, BIM solutions supporting construction projects, or software supporting advanced manufacturing including 3D printing, A-Bots.com delivers production-ready solutions optimized for Australian conditions.

Contact A-Bots.com to discuss your engineering software requirements. Our team is prepared to explore opportunities ranging from comprehensive platform development to focused applications addressing specific operational challenges, testing and quality assurance services for existing systems, and ongoing support ensuring continued effectiveness of deployed solutions.

The Australian engineering software landscape continues evolving rapidly. Organizations that invest in modern digital capabilities position themselves for competitive success in an increasingly technology-intensive global economy. A-Bots.com stands ready to partner in realizing that potential.

✅ Hashtags

#EngineeringSoftware

#CADDevelopment

#3DModeling

#DigitalTwins

#BIMSoftware

#AdvancedManufacturing

#MiningTech

#ConstructionTech

#ABots

Other articles

Food Social Network App Development | A-Bots.com This comprehensive business plan explores the development of a food social network mobile application designed to answer the daily question: "What should I cook today?" The platform combines personal food journaling with social discovery, enabling users to document meals, share recipes, and explore what people eat in different cities worldwide. With the social networking app market projected to reach $1 trillion by 2035 and recipe apps growing at 9.57% annually, this concept addresses a significant market gap. The document covers market analysis, core features including the unique geographic food explorer, monetization strategies, development timeline, and investment requirements ranging from $50,000 for MVP to $350,000 for full-scale launch.

Mobile App Developers Melbourne This comprehensive guide examines three leading mobile app developers Melbourne businesses rely on for digital transformation. Wave Digital brings 25+ years of experience with exclusive local development teams. Appetiser offers global scale with offices across four countries and partnerships with F1 and Daikin. DreamWalk emphasizes ethical development with 89 #1 iTunes rankings. The article explores Melbourne's $2.6 billion mobile app market, analyzes technical approaches including native versus cross-platform development, and discusses advantages of international development partnerships. A-Bots.com provides alternative solutions for businesses seeking cost-effective custom development or comprehensive testing services for existing applications.

App Developers Sydney | Custom Mobile App Development 2026 Sydney has emerged as a global technology hub with IT spending projected to reach A$146.85 billion in 2025. The city's tech ecosystem, centered around Tech Central, hosts 81 ASX-listed digital companies worth $52 billion and attracted 65% of Australia's startup funding in 2024. From unicorn success stories like Canva and Atlassian to government initiatives supporting innovation, Sydney offers exceptional opportunities for mobile app development. This comprehensive guide covers development costs, key industries, technology trends, and how to choose the right development partner for your project. A-Bots.com provides custom mobile development and professional testing services across iOS, Android, and cross-platform frameworks.

App Developers Brisbane: Custom Taxi App Development for Urban Mobility Solutions Brisbane's transportation sector demands sophisticated mobile applications capable of serving 2.5 million residents and nearly 9.5 million annual visitors. This comprehensive guide examines the local app development landscape, profiling leading companies including Code Heroes and App Gurus alongside their technical capabilities and notable projects. The article analyzes existing Brisbane taxi app platforms such as 13cabs, Black & White Cabs, and Rydo, identifying market gaps where custom development delivers competitive advantage. Technical considerations spanning Flutter frameworks, real-time GPS integration, and payment gateway implementation provide actionable insights for transportation businesses. International development perspectives from A-Bots.com demonstrate how cross-border partnerships can introduce approaches that differentiate Brisbane taxi applications in an increasingly competitive market.

Perth Parking App and Uber App Perth: Custom Development Guide Perth stands as the world's most isolated major city, stretching 150 kilometers along the Western Australian coastline with a population exceeding 2.38 million. This unique geography creates distinct challenges for parking and rideshare services that standard applications fail to address effectively. The article examines current Perth parking app solutions including City of Perth Parking and EasyPark integration, analyzes the Uber app Perth market where Uber dominates with 80% share following Ola's 2024 exit, and explores opportunities for custom mobility development. With the global smart parking market projected to reach USD 33.82 billion by 2033 and Australian ride-hailing growing at 13.9% CAGR, Perth presents substantial opportunities for innovative transportation applications.

Top stories

Copyright © Alpha Systems LTD All rights reserved.

Made with ❤️ by A-BOTS